Choosing Vinyl (uPVC) or Aluminum Windows

PVC windows are budget-friendly and great for insulation,

while aluminum windows excel in durability, aestheticset extreme conditions.

—Read on to find the perfect fit for your needs!

When renovating or replacing windows, PVC (uPVC) windows and aluminum windows are two of the most common options available. Each offers its unique advantages—PVC windows are budget-friendly with excellent soundproofing, while aluminum windows excel in durability and aesthetics. But which option best suits your home?

When renovating or replacing windows, PVC (uPVC) windows and aluminum windows are two of the most common options available. Each offers its unique advantages—PVC windows are budget-friendly with excellent soundproofing, while aluminum windows excel in durability and aesthetics. But which option best suits your home?

This article provides a comprehensive comparison across multiple factors such as thermal insulation, soundproofing, security, cost, and aesthetics to guide you toward the smartest decision. Whether you’re a practical buyer working within a budget or a design-savvy homeowner seeking premium quality, you’ll discover the ideal solution tailored to your needs.

Material and Structure Comparison

| Aspect | PVC Windows (uPVC Windows) | Aluminum Windows (Aluminum Alloy Windows) |

|---|---|---|

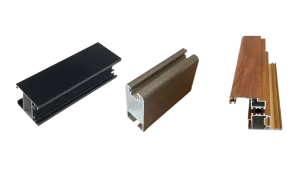

| Core Material | Polyvinyl chloride (PVC) profile with steel reinforcement for stability. | Aluminum alloy profile (available in standard or thermal break designs). |

| Structural Features | Multi-chambered design with inner steel for added strength and durability. | Metallic frame; thermal break technology available for insulation. |

| Poids | Lightweight, easy to handle. | Moderate weight, with thermal break aluminum being slightly heavier. |

PVC is a polymer material with a density of approximately 1.4 g/cm³, while aluminum is a metal with a density of about 2.7 g/cm³, making PVC nearly half as dense as aluminum. PVC offers superior performance in soundproofing and thermal insulation compared to standard aluminum; however, aluminum’s thermal performance can be significantly enhanced with thermal break technology. Both materials are resistant to corrosion, but PVC, like other plastics, is susceptible to aging over time. Additionally, PVC is more cost-effective than aluminum, making it an economical choice for many applications.

PVC is a polymer material with a density of approximately 1.4 g/cm³, while aluminum is a metal with a density of about 2.7 g/cm³, making PVC nearly half as dense as aluminum. PVC offers superior performance in soundproofing and thermal insulation compared to standard aluminum; however, aluminum’s thermal performance can be significantly enhanced with thermal break technology. Both materials are resistant to corrosion, but PVC, like other plastics, is susceptible to aging over time. Additionally, PVC is more cost-effective than aluminum, making it an economical choice for many applications.

Performance Comparison

| Performance | PVC Windows (uPVC Windows) | Aluminum Windows (Aluminum Alloy Windows) |

|---|---|---|

| Isolation thermique | ★★★★★ Excellent insulation due to multi-chamber design (low U-value). |

★★★☆☆ Standard aluminum conducts heat quickly; thermal break aluminum achieves ★★★★★. |

| Isolation phonique | ★★★★★ Effective noise reduction (30-35dB) with chambered and sealed design. | ★★★★☆ Depends on glass configuration (double-glazed glass can achieve up to 30dB). |

| Durabilité | ★★★☆☆ Prone to aging and yellowing (lifespan: 10-15 years). | ★★★★★ Highly resistant to corrosion and deformation (lifespan: 20-30 years). |

| Security | ★★★☆☆ Relies on the thickness of steel reinforcement. | ★★★★★ Strong metal frame with excellent impact resistance. |

| Wind Resistance | ★★★☆☆ Suitable for low wind pressure areas. | ★★★★★ High rigidity, ideal for typhoon-prone regions (resistant to winds up to 12 levels). |

The differences in thermal and sound insulation between PVC and aluminum windows are largely determined by the inherent properties of the materials. Plastics, such as PVC, naturally provide better insulation and soundproofing than metals. Additionally, PVC profiles are assembled using welding techniques, creating better airtightness compared to aluminum profiles, which are connected with fasteners. While thermal break technology can significantly improve aluminum’s insulation and soundproofing performance, it still relies on additional enhancements.

As a polymer, PVC is prone to aging over time due to the breakdown of its molecular long chains, typically occurring after 10-15 years. Aluminum, on the other hand, does not face this issue. When exposed to air, aluminum forms a dense oxide layer that prevents further oxidation, making it highly corrosion-resistant. Aluminum window frames can last 40-50 years without structural failure, though their surface treatments may not endure as long.

As a polymer, PVC is prone to aging over time due to the breakdown of its molecular long chains, typically occurring after 10-15 years. Aluminum, on the other hand, does not face this issue. When exposed to air, aluminum forms a dense oxide layer that prevents further oxidation, making it highly corrosion-resistant. Aluminum window frames can last 40-50 years without structural failure, though their surface treatments may not endure as long.

In terms of strength, pure aluminum is soft, but aluminum alloys, such as 6060, 6061et 6063, are commonly used for windows due to their high strength. PVC windows, reinforced with internal steel structures, achieve improved strength but still fall short of aluminum alloys. This makes aluminum the preferred choice for applications requiring greater durability and structural integrity.

Aesthetic Comparison

| Aspect | PVC Windows (uPVC Windows) | Aluminum Windows (Aluminum Alloy Windows) |

|---|---|---|

| Design Style | Suited for traditional or minimalist styles, with wider frames (60-80mm). Available in white or woodgrain finishes (wood-like effect). | Strong modern appeal, ultra-slim frames (30-40mm). Ideal for floor-to-ceiling or panoramic windows. Wide color options, including metallics and matte black. |

| Visual Transparency | Thick frames limit glass area, making it suitable for small or divided window designs. | Slim frames maximize glass size, offering better views, ample natural light, and suitability for large or open spaces. |

| Finition de la surface | Noticeable plastic appearance, which can feel less premium (unless using high-end woodgrain options). | Sleek metallic or matte finishes exude sophistication, blending seamlessly with glass for a high-end look. |

| Customization Flexibility | Limited options in color and style, challenging to fit distinctive architectural designs. | Highly customizable, including curved or unusual shapes, perfect for modern or industrial architectural styles. |

In terms of aesthetics, aluminum window frames offer a more modern and refined appearance compared to PVC. Aluminum frames can be made significantly slimmer, with ultra-narrow dark-colored frames becoming a popular trend in contemporary design. While PVC can be produced in various colors or wood grain finishes, its visual appeal is generally inferior to that of aluminum. Aluminum allows for a variety of traitements de surface, including brushed, matte, or textured finishes, which provide a sophisticated and premium look far beyond what PVC can achieve.

In terms of aesthetics, aluminum window frames offer a more modern and refined appearance compared to PVC. Aluminum frames can be made significantly slimmer, with ultra-narrow dark-colored frames becoming a popular trend in contemporary design. While PVC can be produced in various colors or wood grain finishes, its visual appeal is generally inferior to that of aluminum. Aluminum allows for a variety of traitements de surface, including brushed, matte, or textured finishes, which provide a sophisticated and premium look far beyond what PVC can achieve.

When coated with PVDF fluorocarbon paint, aluminum frames can maintain their color for up to 20 years without fading. In contrast, PVC tends to age over time, becoming discolored or yellowed, which can appear unattractive. Additionally, aluminum frames can be repainted after fading, offering extended usability, a feature PVC lacks. Structurally, aluminum also allows for more complex and versatile designs, making it a superior choice for both aesthetic and architectural flexibility.

Cost and Maintenance Comparison

| Aspect | PVC Windows (uPVC Windows) | Aluminum Windows (Aluminum Alloy Windows) |

|---|---|---|

| Price | Lower cost (budget-friendly). | Higher cost; thermal break aluminum is significantly more expensive. |

| Maintenance Cost | Requires periodic checks on sealing strips; prone to aging and may need replacement. | Minimal maintenance; highly weather-resistant surface. |

| Energy Savings | High energy efficiency saves on electricity costs due to excellent insulation. | Thermal break aluminum provides significant energy savings with enhanced insulation. |

From a cost perspective, both PVC and aluminum are subject to market fluctuations as bulk commodities. However, aluminum is generally much more expensive, usually priced at three times that of PVC by weight. The processus d'extrusion for aluminum is also more complex and costly compared to PVC extrusion. Additionally, the adoption of thermal break technology in aluminum windows to improve insulation and soundproofing further increases its production cost. As a result, PVC windows are a more cost-effective option in most cases, while aluminum windows, particularly with thermal break features, cater to premium markets due to their higher manufacturing expenses and superior performance.

Buying Recommendations

1. Economic and Practical: Choose PVC Windows

1. Economic and Practical: Choose PVC Windows

Best for budget-conscious buyers and spaces with high soundproofing requirements, such as bedrooms or traditional homes.

2. Long-Term Quality: Choose Aluminum Windows

Ideal for long-term investments, self-owned homes, or locations exposed to harsh weather conditions. Opt for thermal break aluminum for superior insulation and durability.

3. Hybrid Solution: Mix and Match

- Use aluminum windows for exposed areas like balconies, where wind and rain resistance are critical.

- Use PVC windows for quieter spaces like bedrooms, where insulation and noise reduction are key.

4. Value and Practicality:

Go with PVC windows if you prioritize cost efficiency and live in a traditional home or area with mild weather conditions.

5. Aesthetics and Modern Design:

Optez pour aluminum windows if you value sleek, modern designs, slim frames, and the large glass areas that enhance the overall appearance and lighting of your space.