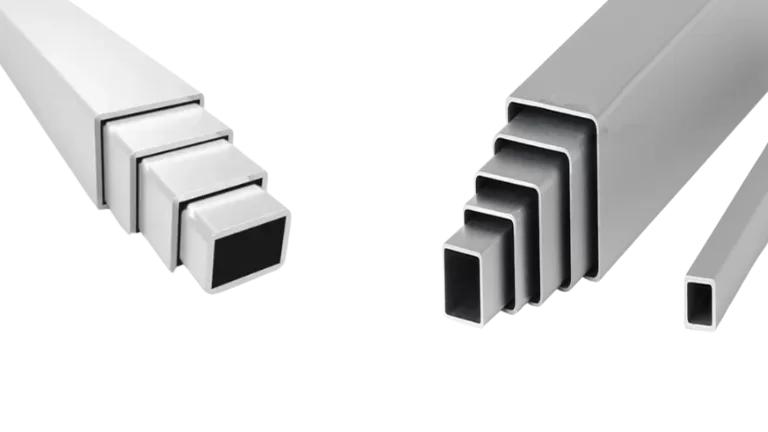

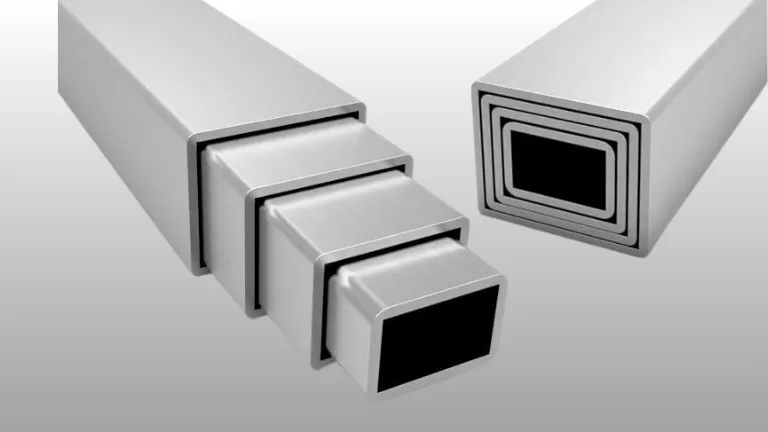

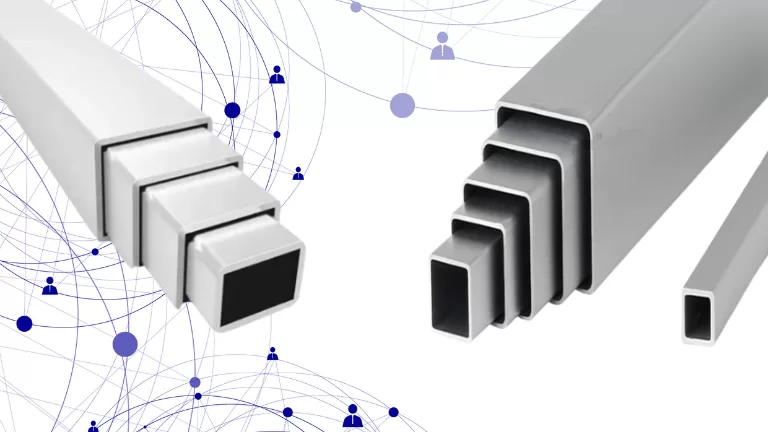

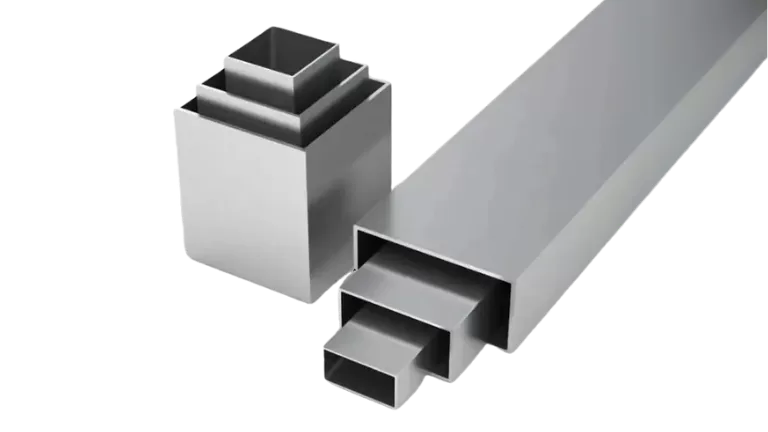

Tube rectangulaire télescopique en aluminium personnalisable

HTS offers telescoping aluminum rectangular tubings with high precision and versatile design, along with flexible customization services. With 40 advanced extrusion lines, we ensure fast delivery for all orders.

- High Precision Dimensions: Advanced technology ensures that each aluminum square tube precisely matches your specifications.

- Multi-functional Design: The telescopic structure is suitable for various applications, offering versatile solutions and greater project flexibility.

- Flexible Customization: Available in different sizes, wall thicknesses, and locking mechanisms to meet the needs of special projects.

- Fast Delivery: With 40 efficient extrusion lines, we guarantee timely fulfillment even for large-volume orders.

Telescoping Aluminum Rectangular Tubing

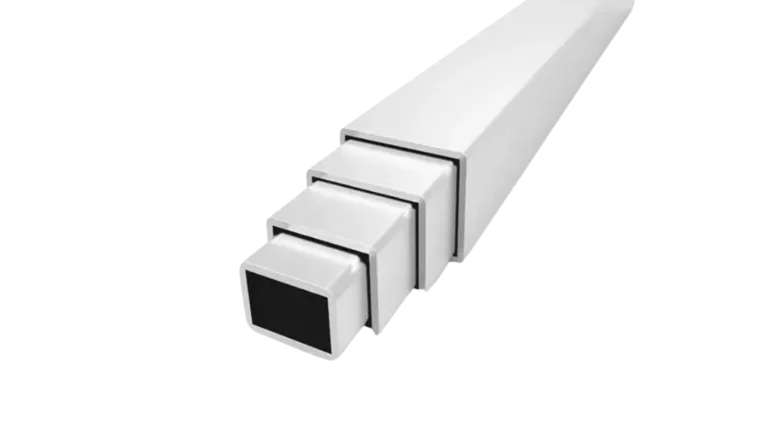

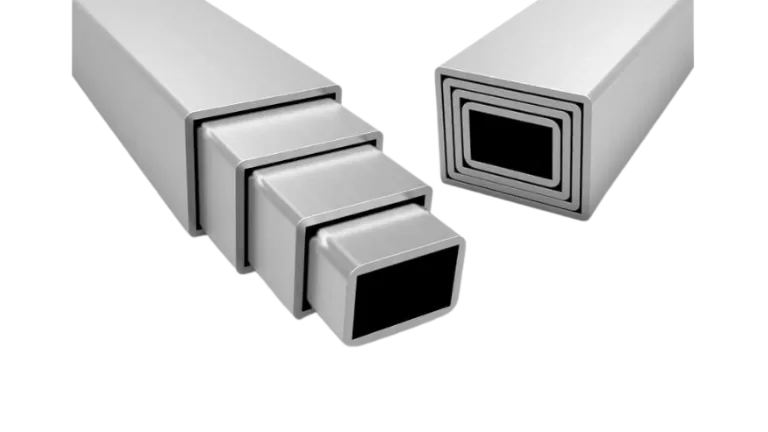

We specialize in providing custom telescoping aluminum rectangular tubings, manufactured using our advanced processus d'extrusion de l'aluminium. These aluminum tubes are designed with different-sized sections that slide smoothly into one another, allowing for adjustable length as needed. The sturdy square shape offers enhanced strength and stability, making them ideal for applications such as adjustable frames, supports, and extension poles. Made from high-quality, corrosion-resistant aluminum, our tubes can be customized in size, wall thickness, or locking mechanism to meet your specific requirements. With precise engineering, flexible options, and efficient extrusion production, we deliver reliable, tailored solutions for your projects.

Telescoping Rectangular Tubing Specifications

| Paramètres | Gamme de spécifications | Notes |

|---|---|---|

| Outer Size | 10 × 10 ~ 100 × 100 mm | Customizable on request |

| Épaisseur de la paroi | 0.8 ~ 5.0 mm | Select as needed for strength |

| Standard Length | 6.0 m | Any length can be cut |

| Telescoping Stages | 2 to 5+ stages | Multi-stage nesting available |

| Matériau | 6061/6063/custom aluminum alloy | Anodized, powder coated optional |

| Tolérance | ±0.05 ~ ±0.1 mm | High precision CNC machining |

Telescoping Rectangular Tubing Raw Material

1. The 6061 aluminum  alloy is a popular choice for telescoping aluminum rectangular tubings due to its well-balanced combination of good mechanical properties, excellent corrosion resistance, and ease of welding and machining. With a density of approximately 2.70 g/cm³, 6061 alloy provides both strength and lightweight performance, making it suitable for a wide range of structural and engineering applications where durability and versatility are important.

alloy is a popular choice for telescoping aluminum rectangular tubings due to its well-balanced combination of good mechanical properties, excellent corrosion resistance, and ease of welding and machining. With a density of approximately 2.70 g/cm³, 6061 alloy provides both strength and lightweight performance, making it suitable for a wide range of structural and engineering applications where durability and versatility are important.

2. The 6063 aluminum alloy is especially favored for extrusion processes, thanks to its ability to produce a smooth, attractive surface finish and its reliable strength. It also delivers high corrosion resistance, which is particularly important for products used outdoors or in challenging environments. With a similar density of around 2.70 g/cm³, 6063 alloy is widely used in architectural and structural applications where both appearance and performance are essential.

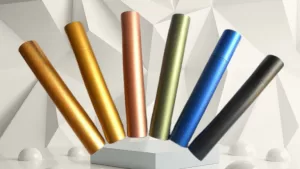

Telescoping Rectangular Tubing Surface Treatment

Common surface treatments  for aluminum telescopic rectangular tubings include anodizing, powder coating, and electrophoretic coating. Among these, anodizing not only greatly enhances the corrosion resistance of the tubes but also provides a refined and attractive surface appearance. Our anodized telescoping rectangular tubings are available in a variety of popular colors such as silver, black, champagne, and bronze to meet different aesthetic and application needs. Additionally, powder coating and electrophoretic coating can offer a uniform finish and an extra protective layer, significantly extending the service life of the tubes and improving their decorative appeal.

for aluminum telescopic rectangular tubings include anodizing, powder coating, and electrophoretic coating. Among these, anodizing not only greatly enhances the corrosion resistance of the tubes but also provides a refined and attractive surface appearance. Our anodized telescoping rectangular tubings are available in a variety of popular colors such as silver, black, champagne, and bronze to meet different aesthetic and application needs. Additionally, powder coating and electrophoretic coating can offer a uniform finish and an extra protective layer, significantly extending the service life of the tubes and improving their decorative appeal.

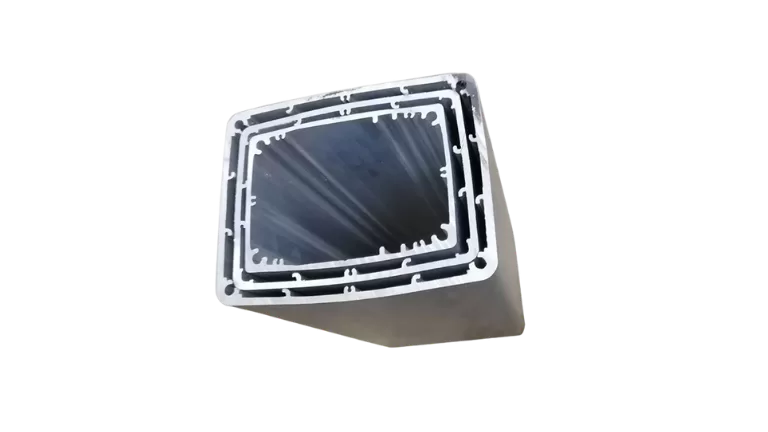

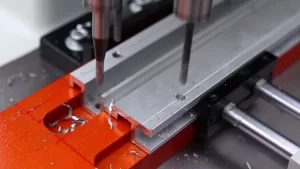

Usinage et fabrication

To provide complete  solutions for telescoping aluminum rectangular tubings, we offer extensive further processing capabilities. Our services include CNC machining, milling, threading, drilling, precision cutting, punching, welding, and assembly. With this full range of fabrication options, we can deliver ready-to-use telescoping aluminum square tubes that are precisely tailored to your project requirements, offering unmatched flexibility and reliability for your applications. Whether you need custom lengths, specific hole patterns, or complex assemblies, our experienced team is equipped to handle various design and production needs. This enables you to save time and reduce costs by receiving high-quality, finished products that are ready for immediate use in your project.

solutions for telescoping aluminum rectangular tubings, we offer extensive further processing capabilities. Our services include CNC machining, milling, threading, drilling, precision cutting, punching, welding, and assembly. With this full range of fabrication options, we can deliver ready-to-use telescoping aluminum square tubes that are precisely tailored to your project requirements, offering unmatched flexibility and reliability for your applications. Whether you need custom lengths, specific hole patterns, or complex assemblies, our experienced team is equipped to handle various design and production needs. This enables you to save time and reduce costs by receiving high-quality, finished products that are ready for immediate use in your project.

Applications of Telescoping Rectangular Tubing

Telescoping aluminum rectangular tubings are widely used in various fields due to their lightweight, high strength, corrosion resistance, and excellent machinability. Common applications include:

1. Outdoor and sports equipment: Such as tent frames, camera tripods, trekking poles, bicycle accessories, and fishing rod handles. The telescoping structure allows for portability and adjustable length.

2. Industrial equipment: Used for machine guards, adjustable stands and frames, tool handles, lifting platforms, and instrument arms. These applications benefit from flexible adjustment of height or length and efficient space utilization.

3. Building and construction: Utilized in movable partitions, retractable doors and windows, curtain wall structures, and other components to enhance flexibility and ease of installation.

4. Furniture and household products: For example, telescoping tables and chairs, clothes racks, drying racks, and curtain rods. The telescoping feature makes storage and adjustment convenient.

Features of Telescoping Rectangular Tubing

The telescoping aluminum rectangular tubing has the following notable features:

1. Léger : Aluminum has a low density, making the structure easy to handle and install.

2. High strength: With proper design, it can withstand considerable force and pressure, meeting various application requirements.

3. Excellent corrosion resistance: After surface treatments such as anodizing and powder coating, it offers outstanding resistance to corrosion and is suitable for different environments.

4. Good machinability: It is easy to cut, drill, punch, weld, and perform other secondary processing, making it ideal for custom specifications.

5. Convenient telescopic adjustment: The length can be freely adjusted as needed, improving flexibility and space utilization.

6. Attractive appearance: The surface is smooth and can be finished in various colors and textures, offering excellent decorative effects.

7. Environmentally friendly and recyclable: Aluminum is recyclable and environmentally friendly.

Telescoping Aluminum Rectangular Tubing vs Telescoping Steel Rectangular Tubing

| Objet | Telescoping Aluminum Rectangular Tubing | Telescoping Steel Rectangular Tubing |

|---|---|---|

| Poids | Very light, easy to handle and install | Heavier, more difficult to handle and install |

| La force | High, suitable for most applications | Very high, suitable for heavy-duty applications |

| Résistance à la corrosion | Excellent, resists rust and corrosion | Average, requires coating for rust protection |

| Usinabilité | Easy to cut, drill, and machine | More difficult to machine |

| Adjustability | Easy length adjustment | Adjustable, but heavy weight makes it harder |

| Respect de l'environnement | Recyclable, environmentally friendly | Recyclable, but higher energy consumption during processing |

Salon de l'usine

Our facility features 40 advanced extrusion lines dedicated to the efficient production of aluminum profiles. For surface finishing, we offer a complete range of options with one anodizing and electrophoresis line, two vertical powder coating systems, and two horizontal powder coating systems. Additionally, we are equipped with two sandblasting units and six wood grain transfer printing lines to deliver a wide variety of decorative finishes. Supporting our manufacturing process, we have casting furnaces for aluminum billet production, as well as aging, annealing, and water cooling equipment, and comprehensive machining capabilities. This robust setup enables us to consistently deliver high-quality products across diverse applications.