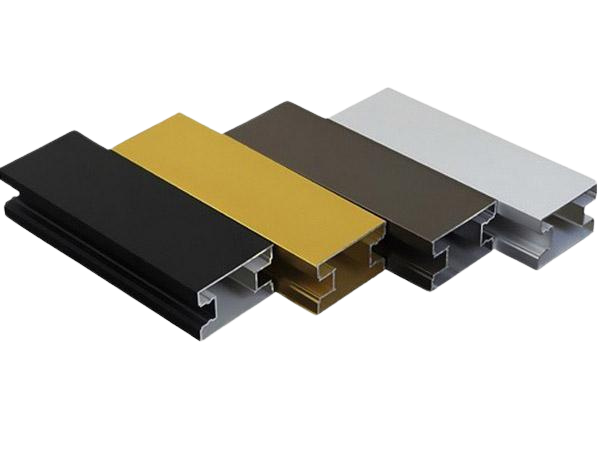

PVDF Coated Aluminum Profiles

Overview

Fluorocarbon (PVDF) spray coating is a widely used surface treatment method for aluminum alloy profiles. It involves applying a fluorocarbon-based coating onto the surface of the profiles, providing numerous benefits. This coating offers exceptional durability, protecting the profiles from corrosion, chemicals, and UV radiation. It also provides excellent weather resistance, safeguarding against rain, sunlight, extreme temperatures, and pollutants. Additionally, fluorocarbon spray coatings come in a variety of colors and finishes, enhancing the aesthetics of the aluminum profiles. The coating is known for its longevity, low maintenance requirements, and cost-effectiveness. It can be applied to various applications such as windows, doors, curtain walls, and decorative elements, offering design flexibility. Moreover, fluorocarbon spray coatings are environmentally friendly, complying with regulations and promoting sustainable practices.

Advantages

1. Enhanced durability

The fluorocarbon coating significantly improves the durability of aluminum profiles. It provides a protective layer that is highly resistant to corrosion, chemicals, and UV radiation. This ensures that the profiles can withstand harsh environments and maintain their structural integrity over an extended period.

2. Weather resistance

Aluminum profiles with fluorocarbon spray coating exhibit exceptional weather resistance. They are highly resistant to damage caused by rain, sunlight, extreme temperatures, and atmospheric pollutants. This makes them suitable for outdoor applications where exposure to harsh weather conditions is a concern.

3. Low maintenance

Fluorocarbon spray-coated aluminum profiles require minimal maintenance. The coating’s smooth and non-stick surface repels dirt, stains, and fingerprints, making it easier to clean and maintain the profiles. This reduces the time and effort required for regular upkeep, resulting in cost savings and convenience.

4. Color and finish options

Fluorocarbon spray coatings provide a wide range of color and finish options for aluminum profiles. This allows for customization and the ability to match the profiles with specific design requirements. The coatings also maintain their color and gloss for an extended period, ensuring that the profiles retain their aesthetic appeal over time.

5. Longevity and cost-effectiveness

The durability and weather resistance offered by fluorocarbon spray coatings contribute to the longevity of aluminum profiles. They can withstand the test of time without significant degradation or the need for frequent replacements. This translates into cost savings in the long run, as there is reduced expenditure on repairs, replacements, and maintenance.

Factory

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer based in China. We specialize in various stages of aluminum profile production, from mold design and melting to extrusion, oxidation, electrophoresis, coating, and polishing, providing a comprehensive range of services.

Our product range encompasses aluminum profiles suitable for windows and doors (including thermal break section), industrial applications (T-slot, channel, tubing), and photovoltaic systems. Situated in Jiangxi, our spacious production facility covers 30,000 square meters and employs over 200 skilled professionals, enabling us to produce more than 10,000 metric tons of aluminum profiles annually.

At HTS NEW MATERIALS, we also offer various surface treatments, including anodizing, electrophoretic coating, powder coating, PVDF coating, and wood grain transfer printing, to enhance both functionality and appearance. Whether it’s for construction, industry, or renewable energy, our high-quality aluminum profiles are ready to meet your specific needs.