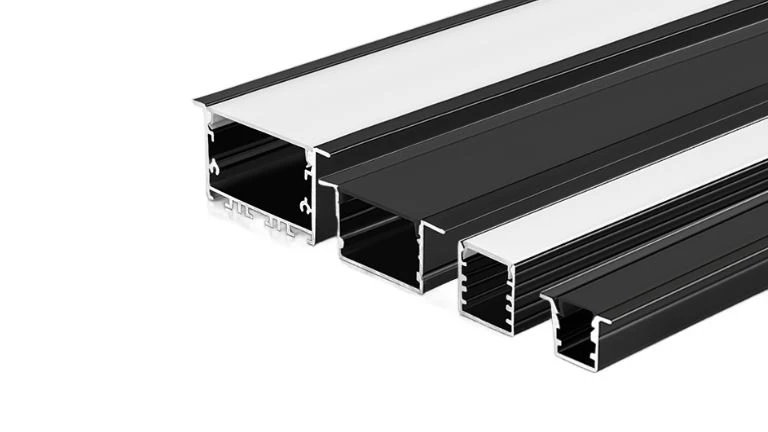

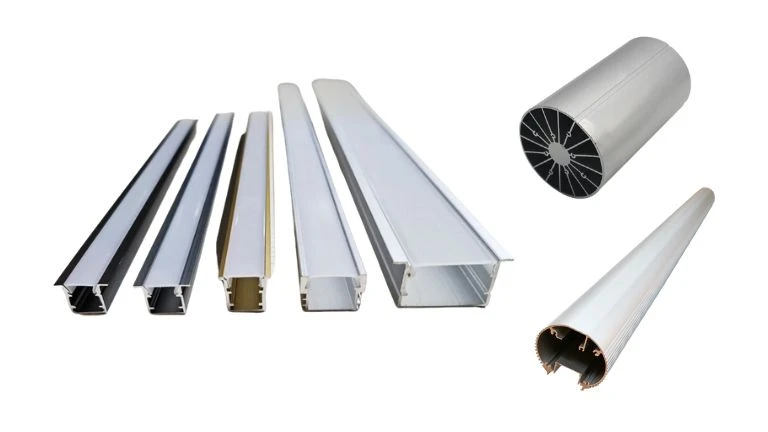

Custom LED Aluminum Profile

Aluminum profiles are widely used in LED lighting applications due to their excellent thermal management properties, lightweight nature, and versatility in design. These profiles serve as effective heat sinks, dispersing heat generated by LEDs and thereby prolonging the lifespan of the lighting system. The robust structure of aluminum profiles provides durability and protection for the LED components. Additionally, they offer aesthetic value by allowing sleek and modern designs, accommodating various shapes and sizes of LED strips. Aluminum profiles also enhance the diffusion of light, creating a more uniform illumination and reducing glare. This makes them essential in both residential and commercial lighting solutions, where efficiency, durability, and design flexibility are key considerations.

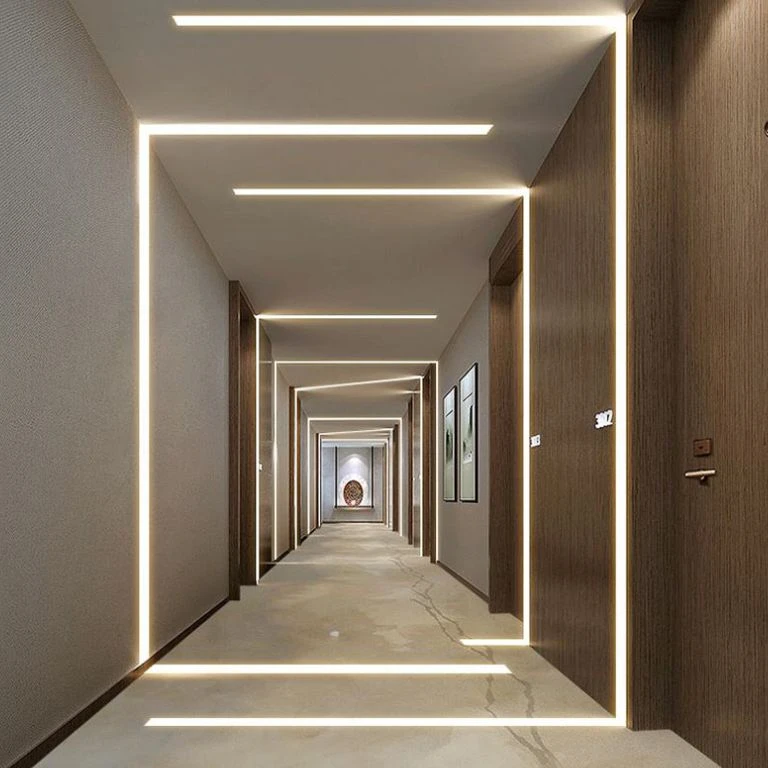

LED Strip Aluminum Channel Install

Aluminum channels are used in LED strip installations to provide structural support and effective thermal management, ensuring the longevity of the LEDs. They also offer a sleek, professional appearance and help diffuse light for even illumination, reducing glare. These features make aluminum channels an ideal choice for both aesthetic and functional lighting applications.

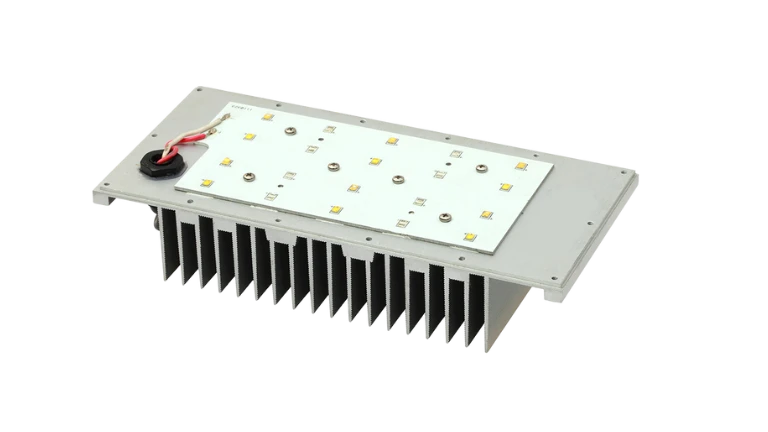

Aluminum LED Heatsink Profile Extrusion

Aluminum profiles serve as excellent heat sinks in LED lighting systems, efficiently dissipating the heat generated by the LEDs to extend their lifespan and maintain optimal performance. Their high thermal conductivity ensures rapid heat transfer away from the LED components, preventing overheating. This efficient thermal management is crucial in sustaining the brightness and efficacy of LED lights over time.

Reliable Aluminium Profiles Extrusion Supplier

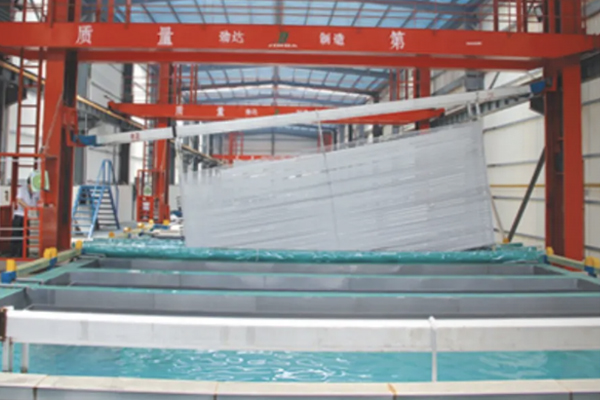

Factory

Raw Material

6061 Aluminum Alloy: This is one of the most commonly used aluminum alloys, known for its excellent mechanical properties and corrosion resistance. It is suitable for a wide range of applications, including structural frameworks, conveyor systems, and mechanical components.

6063 Aluminum Alloy: This aluminum alloy offers good machinability and surface appearance, making it suitable for applications that require a higher surface quality, such as display racks, door and window frames, etc.

Custom Aluminum Extrusion Process

At HTS Aluminum Profiles, we specialize in delivering custom aluminum extrusion solutions tailored to your specific needs. Here’s a step-by-step guide to our customization process:

Step 1: Initial Consultation

Your journey begins with an initial consultation where we discuss your project requirements. We encourage you to share your design concepts, application needs, and any critical parameters that the aluminum profile must meet. This collaborative approach ensures that we fully understand your vision and objectives.

Step 2: Design and Engineering

Leveraging our extensive experience in aluminum extrusion, our skilled engineers work closely with you to refine your design. We consider factors such as the aluminum alloy grade, temper, and mechanical properties required for your application. Our team uses advanced CAD software to create precise technical drawings and 3D models of the proposed profile.

Step 3: Die Fabrication

Once the design is finalized, we proceed to manufacture the custom extrusion dies. Our precision die-making process ensures that the final profile will match your specifications with high accuracy. We employ state-of-the-art CNC machines to craft dies that can withstand the rigors of extrusion while maintaining tight tolerances.

Step 4: Aluminum Extrusion

With the dies ready, the actual extrusion process begins. We select the appropriate aluminum alloy and heat it to the precise extrusion temperature. The heated billet is then pressed through the die to create the custom profile. Our extrusion presses, ranging from 600 to 3600 tons, are capable of producing a wide range of profile sizes and shapes.

Step 5: Surface Treatment and Finishing

Following extrusion, the profiles undergo various surface treatments as per your requirements. Options include anodizing, electroplating, sandblasting, powder coating, fluorocarbon painting, and wood grain transfer printing. These processes enhance the profiles’ durability, corrosion resistance, and aesthetic appeal.

Step 6: Quality Assurance

Quality is at the heart of everything we do. Each custom aluminum profile is subjected to rigorous quality checks to ensure it meets ISO standards and our European quality certifications. We perform dimensional inspections, mechanical testing, and surface finish evaluations to guarantee that your profiles are delivered without defects.

Step 7: Packing and Delivery

After passing all quality inspections, the aluminum profiles are carefully packed to prevent any damage during transit. We use robust packaging materials and methods tailored to the profiles’ dimensions and your delivery preferences. Our logistics team then manages the safe and timely delivery of your custom aluminum profiles to your specified location.

Step 8: After-Sales Support

Our commitment to your satisfaction extends beyond delivery. We offer comprehensive after-sales support to address any concerns or additional requirements you may have. Our customer service team is always ready to assist you with any questions or feedback.