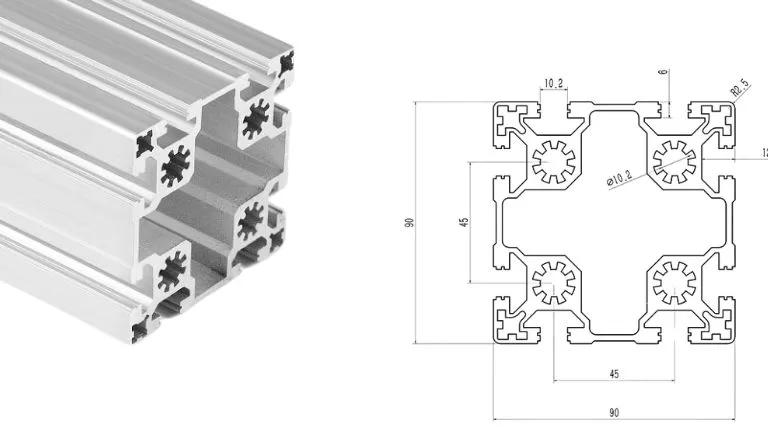

Carcasa de aluminio extruido a medida

Las carcasas de aluminio extruido son estructuras duraderas, ligeras y versátiles diseñadas para proteger componentes electrónicos, sensores, módulos de alimentación y otros dispositivos. Fabricadas con precisión procesos de extrusiónEstas carcasas combinan solidez, resistencia a la corrosión y una excelente disipación del calorpor lo que son ideales para sectores como la electrónica, las telecomunicaciones, la automoción y la automatización industrial.

Como altamente personalizable recintos, las carcasas de aluminio extruido ofrecen una protección superior contra daños mecánicos, factores ambientales e interferencias electromagnéticas (EMI) en comparación con las alternativas de plástico o chapa metálica. Su aspecto profesional y su adaptabilidad las hacen adecuadas tanto para aplicaciones de consumo como industriales.

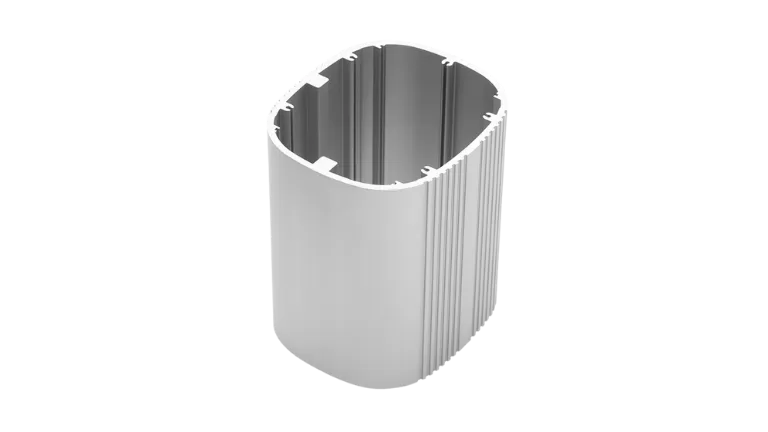

Carcasas redondas

Las carcasas redondas de aluminio extruido se utilizan ampliamente en productos electromecánicos debido a su diseño elegante y compacto y a su excelente integridad estructural. Estas carcasas proporcionan una protección sin fisuras para motores, sensores y otros componentes cilíndricos, ofreciendo una durabilidad superior y un peso ligero. Su forma redonda también garantiza un montaje eficaz y facilita la integración en sistemas rotativos o mecánicos.

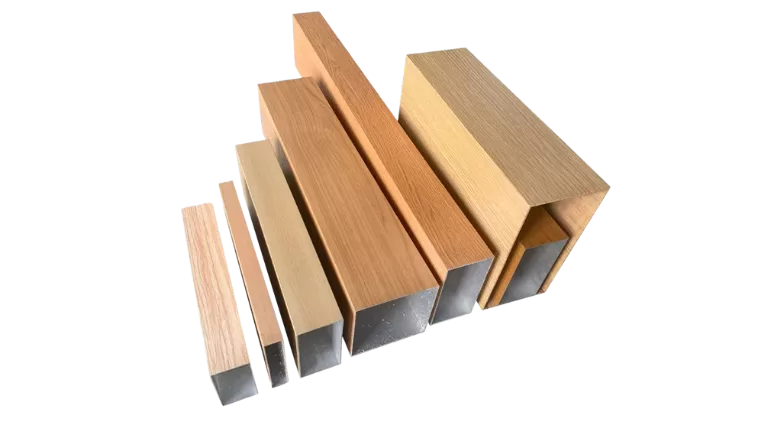

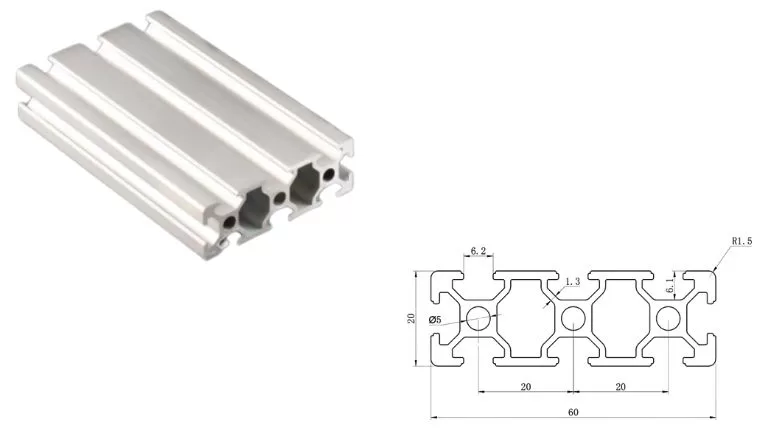

Las carcasas de aluminio extruido rectangulares o en forma de caja son ideales para productos electrónicos como comunicadores, módulos y sistemas de control. Con dimensiones precisas y compartimentos personalizables, estas carcasas ofrecen una excelente protección contra los factores ambientales y las interferencias electromagnéticas (EMI). Su diseño versátil permite montar fácilmente placas de circuitos y componentes, lo que las convierte en una opción popular en electrónica de consumo y dispositivos de control industrial.

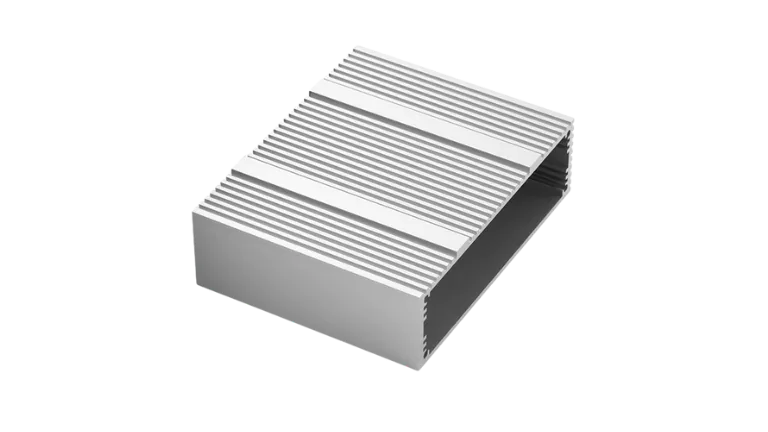

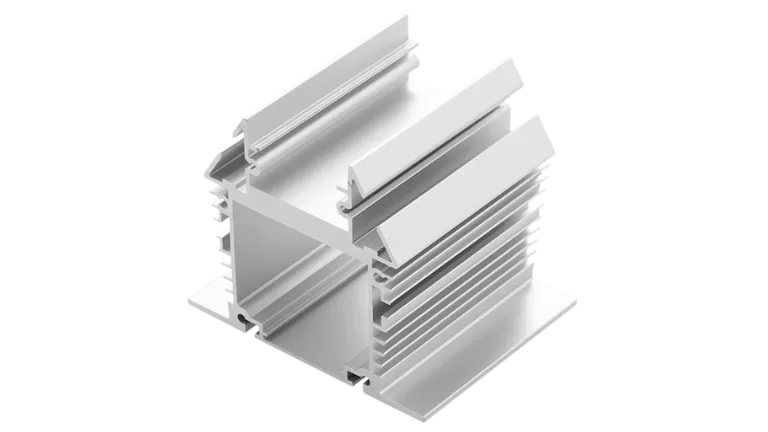

Las carcasas de aluminio extruido con aletas de refrigeración integradas están diseñadas para aplicaciones que requieren una excelente disipación del calor. Estas carcasas son perfectas para módulos de potencia, controladores LED y componentes electrónicos de alta temperatura en los que la gestión térmica es fundamental. Las aletas extendidas aumentan significativamente el área de superficie para una transferencia de calor eficiente, garantizando un rendimiento fiable incluso en entornos de alta temperatura.

Capacidad de procesamiento de carcasas de aluminio extruido

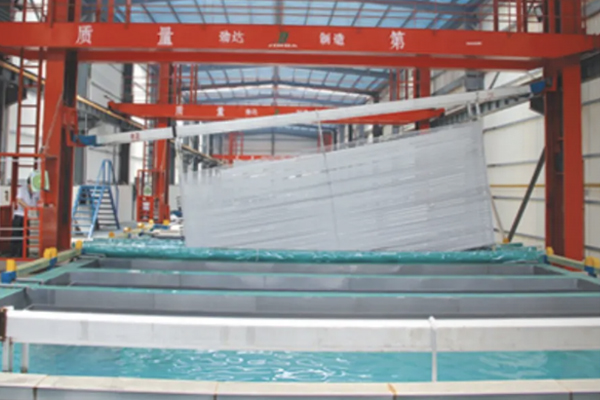

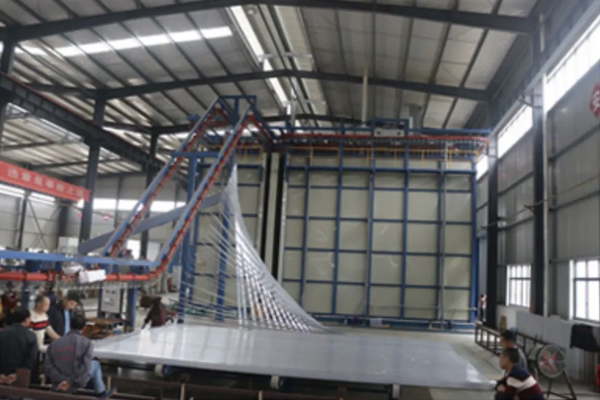

Como fabricante líder de extrusión de aluminio con sede en China, estamos especializados en la producción de carcasas de aluminio extruido de alta calidad para una amplia gama de aplicaciones. Nuestras capacidades comienzan con el diseño y desarrollo de moldes personalizados, garantizando formas precisas que cumplen los requisitos únicos de cada proyecto. Desde la extrusión en bruto hasta el acabado de superficies y el mecanizado avanzado, nuestros procesos de fabricación totalmente integrados nos permiten ofrecer carcasas de aluminio con un rendimiento y una durabilidad excepcionales.

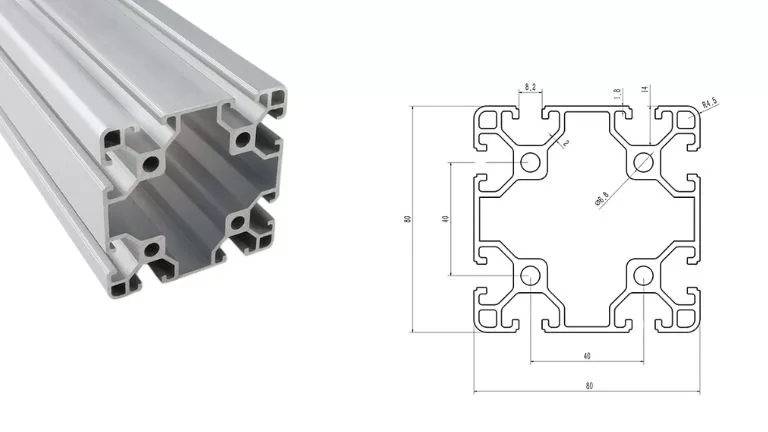

Nuestras instalaciones de producción están equipadas con más de 40 líneas de extrusión avanzadas, incluidas potentes prensas de extrusión de 6000 toneladas. Esto nos permite crear carcasas de aluminio extruido de distintas formas y tamaños, como cuerpos cilíndricos, carcasas rectangulares y diseños de disipación térmica con aletas. Si necesita carcasas para componentes electrónicos, módulos de potencia o sistemas industriales, le ofrecemos soluciones a medida que se ajustan exactamente a sus especificaciones.

Contamos con la experiencia necesaria para diseñar y producir moldes de extrusión en nuestras instalaciones, lo que garantiza la precisión y la eficacia en la fabricación de perfiles de aluminio. Nuestro experimentado equipo trabaja en estrecha colaboración con los clientes para desarrollar moldes personalizados a partir de planos o muestras, garantizando un rendimiento óptimo para sus requisitos específicos. Normalmente, el proceso de producción de moldes dura unos 7 días, tras los cuales proporcionamos muestras para que el cliente las confirme antes de iniciar la producción a gran escala.

Contamos con la experiencia necesaria para diseñar y producir moldes de extrusión en nuestras instalaciones, lo que garantiza la precisión y la eficacia en la fabricación de perfiles de aluminio. Nuestro experimentado equipo trabaja en estrecha colaboración con los clientes para desarrollar moldes personalizados a partir de planos o muestras, garantizando un rendimiento óptimo para sus requisitos específicos. Normalmente, el proceso de producción de moldes dura unos 7 días, tras los cuales proporcionamos muestras para que el cliente las confirme antes de iniciar la producción a gran escala.

Ofrecemos diversas opciones de tratamiento de superficies, como anodizado, revestimiento en polvo y chorro de arena, para mejorar el aspecto, la durabilidad y la resistencia a la corrosión de nuestras carcasas de aluminio extruido. Estos tratamientos garantizan un excelente rendimiento en entornos difíciles, al tiempo que proporcionan un acabado elegante y profesional. Además, podemos aplicar colores y texturas personalizados que se adapten a requisitos de diseño específicos, garantizando que las carcasas satisfagan tanto las necesidades funcionales como las estéticas. Nuestros tratamientos superficiales se someten a rigurosas pruebas para garantizar una protección duradera y la calidad en una gran variedad de aplicaciones.

Para cumplir las normas más exigentes, nuestros avanzados procesos de mecanizado y fabricación garantizan la precisión en cada detalle, desde el roscado y el taladrado hasta el mecanizado CNC. También ofrecemos soluciones listas para el montaje, con carcasas preparadas para una integración perfecta en sus dispositivos y sistemas. Gracias a nuestras capacidades de precisión mejoradas, nos adaptamos a diseños complejos y tolerancias ajustadas, garantizando un rendimiento fiable para componentes electrónicos e industriales sensibles. Además, nuestros procesos de inspección internos garantizan que todas las carcasas cumplan estrictas normas de calidad antes de la entrega.

Opciones de personalización

Ofrecemos una amplia gama de opciones de personalización de carcasas de aluminio extruido para satisfacer sus requisitos exclusivos. Desde los materiales hasta los toques finales, cada detalle puede adaptarse para ofrecer la solución perfecta para su proyecto.

Opciones de material

Elija entre aleaciones de aluminio de alta calidad como 6063, 6061 o 6005 para satisfacer las demandas específicas de rendimiento de su aplicación. Cada aleación ofrece una excelente solidez, resistencia a la corrosión y conductividad térmica, lo que las hace ideales para aplicaciones electrónicas, industriales o de automoción. Además, ofrecemos opciones de tratamiento térmico, como el revenido T5 y T6, para mejorar aún más las propiedades mecánicas, la dureza y la durabilidad del material, garantizando que cumpla los rigurosos requisitos de su proyecto.

Desarrollo de moldes personalizados

Ofrecemos servicios de diseño y desarrollo de moldes personalizados para crear perfiles de carcasas de aluminio extruido de cualquier forma o configuración. Tanto si necesita diseños personalizados cilíndricos, rectangulares o complejos, podemos desarrollar moldes a partir de los planos o muestras físicas que nos proporcione. Con un proceso racionalizado y equipos avanzados, normalmente completamos la producción de moldes en aproximadamente 7 días, garantizando una fabricación rápida y precisa para cumplir los plazos de su proyecto.

Opciones de tratamiento de superficies

Mejore la durabilidad, el aspecto y la resistencia a la corrosión de sus carcasas de aluminio extruido con una amplia gama de tratamientos superficiales. Estos tratamientos no sólo mejoran el rendimiento en entornos difíciles, sino que también permiten la personalización para adaptarse a las necesidades estéticas o funcionales. Nuestras opciones incluyen:

Anodizado (transparente, negro, de color, etc.)

Proporciona una resistencia superior a la corrosión al tiempo que crea una capa de óxido decorativa y protectora. El anodizado también puede personalizarse en varios colores para adaptarse a los requisitos de su marca o diseño, con un acabado duradero que resiste los arañazos y el desgaste.

Recubrimiento en polvo

Ofrece un acabado duradero y decorativo que es respetuoso con el medio ambiente y resistente al desconchado, la decoloración y la abrasión. Disponible en una gran variedad de colores y texturas, el revestimiento en polvo mejora el atractivo visual al tiempo que garantiza que la carcasa resista las duras condiciones ambientales.

Chorro de arena

Crea una textura uniforme y mate en la superficie, mejorando el atractivo estético y preparando la carcasa para tratamientos posteriores como el anodizado o la pintura. El proceso elimina las imperfecciones de la superficie, lo que da como resultado un acabado limpio y liso que añade sofisticación al diseño.

Cepillado y pulido

Produce un aspecto elegante y profesional al crear una textura fina o un acabado de espejo en la superficie. El cepillado acentúa un aspecto moderno e industrial, mientras que el pulido da como resultado un aspecto altamente reflectante y de primera calidad, adecuado para aplicaciones de gama alta.

Grabado químico

Permite patrones de superficie más profundos, texturas únicas o diseños intrincados, perfectos para marcas o acabados personalizados. Este método realza el atractivo estético de la carcasa al tiempo que mantiene una excelente funcionalidad y durabilidad.

Opciones de servicios de mecanizado de superficies

Ofrecemos mecanizado de precisión para crear diseños de carcasas con geometrías complejas y tolerancias ajustadas. Esto incluye servicios como:

Roscado y taladrado

Mecanizado CNC

Ranurado, roscado y grabado

Estos procesos garantizan que las carcasas estén listas para el montaje y cumplan los requisitos específicos de los componentes.

Personalización del logotipo

Personalice sus carcasas de aluminio extruido con logotipos o marcas a medida. Las opciones incluyen grabado por láser, serigrafía o perfiles en relieve/grabados, lo que le permite realzar la identidad de su producto.

Opciones de envasado

Adapte su embalaje a sus necesidades con opciones como cajas personalizadas, inserciones de espuma, retractilado o películas protectoras. También ofrecemos soluciones de embalaje ecológicas para apoyar iniciativas sostenibles al tiempo que garantizamos un transporte seguro.

Nuestra fábrica

Extrusión a medida

En HTS NUEVOS MATERIALESEstamos especializados en el suministro de extrusiones de aluminio personalizadas diseñadas para satisfacer sus necesidades específicas. Con instalaciones de producción avanzadas y más de 40 líneas de extrusión, suministramos perfiles de primera calidad diseñados con precisión para una amplia gama de sectores, como el aeroespacial, la automoción y la construcción, entre otros.

Nuestros servicios de extrusión a medida incluyen:

- Secciones transversales a medida: Cree perfiles de aluminio únicos con nuestras capacidades de troquelado experto, personalizados para adaptarse a las necesidades específicas de su proyecto.

- Diversos acabados superficiales: Mejore tanto el aspecto como la durabilidad de sus perfiles con opciones como anodizado, recubrimiento en polvo, pulido y mucho más.

- Mecanizado de precisión: Garantice una precisión dimensional exacta con servicios de corte, taladrado, fresado y mecanizado avanzado.

- Temperaturas flexibles: Seleccione entre una variedad de tratamientos térmicos, incluidos T5, T6 y otros, para conseguir las propiedades mecánicas ideales para su aplicación.

Asociarse con HTS NUEVOS MATERIALES para soluciones de extrusión de aluminio a medida innovadoras, rentables y fiables que impulsen el éxito de su proyecto.

RFQ de perfil de aluminio extruido

A la hora de elegir entre carcasas de aluminio extruido y fundido a presión, es importante comprender en qué se diferencian en cuanto a propiedades del material, métodos de fabricación, flexibilidad de diseño y aplicaciones. A continuación se desglosan las principales diferencias:

1. Proceso de fabricación

- Carcasa de aluminio extruido:

El proceso de extrusión consiste en forzar tochos de aluminio calentados a través de una matriz personalizada para crear perfiles largos con una sección transversal uniforme. A continuación, estos perfiles se cortan, mecanizan o moldean en una variedad de diseños de carcasas. - Carcasa de aluminio fundido a presión:

La fundición a presión consiste en inyectar aluminio fundido a alta presión en un molde de acero (matriz) para darle una forma específica. El proceso produce piezas totalmente formadas en un solo paso, por lo que suele requerir menos mecanizado secundario.

2. Uso y propiedades del material

- Aluminio extruido:

Utiliza aleaciones de aluminio como 6063, 6061 y 6005, conocidas por su excelente resistencia a la corrosión, alta relación resistencia-peso y conductividad térmica superior. Ideal para carcasas que requieren ligereza y un alto rendimiento térmico, como carcasas de LED y cajas electrónicas. - Aluminio fundido a presión:

Utiliza aleaciones como ADC12 y A380, que suelen tener mayor densidad y una resistencia a la corrosión ligeramente reducida, pero ofrecen excelentes propiedades de fundición. Son ideales para crear formas complejas e integradas con una buena estabilidad dimensional.

3. Complejidad del diseño

- Aluminio extruido:

El más adecuado para diseños sencillos y lineales con una sección transversal consistente, como carcasas cilíndricas o rectangulares. Aunque el mecanizado adicional puede añadir complejidad, los diseños se limitan principalmente al perfil de extrusión. - Aluminio fundido a presión:

Ofrece una libertad de diseño significativamente mayor, permitiendo geometrías muy detalladas y complejas, como curvas, paredes finas y patrones intrincados. Perfecto para piezas que requieren características integradas, como orificios de montaje o paredes finas.

4. Precisión dimensional y acabado superficial

- Aluminio extruido:

Requiere un procesamiento posterior, como el mecanizado CNC, para conseguir tolerancias dimensionales ajustadas y diseños específicos. Normalmente, el acabado superficial es uniforme, pero un acabado adicional (como el anodizado o el recubrimiento en polvo) mejora su aspecto final. - Aluminio fundido a presión:

Consigue tolerancias estrechas y formas detalladas directamente del molde. Presenta una superficie más lisa al salir de la matriz, pero pueden añadirse opciones de acabado como el recubrimiento o el pulido por motivos estéticos.

5. Coste y volumen de producción

- Aluminio extruido:

Adecuado para volúmenes de producción medios y altos en los que se necesitan perfiles largos y consistentes. El coste inicial de las matrices es inferior al de la fundición a presión, por lo que resulta más económico para determinados diseños. - Aluminio fundido a presión:

Implica mayores costes de molde y es más adecuado para la producción de grandes volúmenes. El coste por pieza disminuye significativamente con lotes de mayor tamaño debido a la eficiencia del proceso de un solo paso.

6. Aplicaciones

- Aluminio extruido:

Se utiliza comúnmente para carcasas que requieren una excelente disipación del calor, como disipadores de calor de LED, carcasas electrónicas y carcasas industriales. - Aluminio fundido a presión:

Se utiliza en carcasas con formas complejas o diseños muy integrados, como piezas de automóviles, carcasas de motores y cajas complejas para maquinaria o electrodomésticos.

Conclusión

- Carcasa de aluminio extruido es ideal para aplicaciones en las que la sencillez, la ligereza y una excelente conductividad térmica son esenciales.

- Carcasa de aluminio fundido a presión es más adecuado para diseños complejos y detallados que requieren una gran precisión dimensional y características integradas.

La elección entre una y otra depende de sus requisitos específicos, como el diseño, el rendimiento, el volumen de producción y el presupuesto.

A la hora de seleccionar un material para aplicaciones de carcasa, es fundamental tener en cuenta factores como el peso, la resistencia, la disipación del calor, el aspecto y la flexibilidad de procesamiento. A continuación se ofrece una comparación detallada de carcasas de aluminio extruido, carcasas de plásticoy carcasas de acero.

| Característica | Carcasa de aluminio extruido | Carcasa de plástico | Carcasa de acero |

|---|---|---|---|

| Peso | Ligero, fácil de manejar e instalar. | El más ligero, pero de menor resistencia. | Pesado, lo que dificulta el transporte y la instalación. |

| Resistencia y durabilidad | Alta resistencia y excelente resistencia a la deformación, ofreciendo durabilidad a largo plazo. | Baja resistencia, propensa a agrietarse o romperse bajo tensión. | Excelente solidez, muy resistente a las fuerzas externas. |

| Disipación del calor | Conductividad térmica superior, ideal para aplicaciones que requieren una disipación eficaz del calor. | Mala disipación del calor, especialmente en entornos cerrados. | Disipación térmica moderada, conductividad térmica lenta. |

| Resistencia a la corrosión | Excelente resistencia a la corrosión, mejorada con tratamientos de anodizado. | Escasa resistencia a la corrosión, propensa a degradarse con el tiempo. | Requiere revestimiento o galvanizado para resistir la corrosión. |

| Aspecto Premium | Diseño moderno y personalizable con un aspecto elegante y de gama alta. | Simple, con un aspecto visual sencillo, menos premium. | Adecuado para diseños de estilo industrial, pero carece de estética moderna. |

| Flexibilidad de procesamiento | Altamente personalizable, permite formas complejas y diseños precisos mediante técnicas avanzadas de mecanizado y extrusión. | Personalización moderada, con algunas limitaciones en el tratamiento de determinadas características o geometrías. | Poca flexibilidad, con costes de procesamiento más elevados para los diseños personalizados. |

| Blindaje electromagnético | Excelente apantallamiento contra interferencias, adecuado para componentes electrónicos. | Carece de capacidad de blindaje electromagnético. | Rendimiento de apantallamiento superior, incluso superior al de las carcasas de aluminio en algunas aplicaciones. |

| Aplicaciones | Versátil para uso en interiores y exteriores, aplicable en electrónica, entornos industriales, etc. | Comúnmente utilizado en aplicaciones de interior debido a su limitada durabilidad y resistencia. | Ideal para carcasas de equipos industriales pesados y entornos que requieran una gran resistencia mecánica. |

1. Productos industriales

- Cajas de control industrial: Se utiliza para controladores PLC, relés o sensores industriales, ofreciendo una protección robusta en entornos exigentes.

- Carcasas de equipos eléctricos: Proporcionan una protección fiable para paneles, pantallas y terminales de entrada.

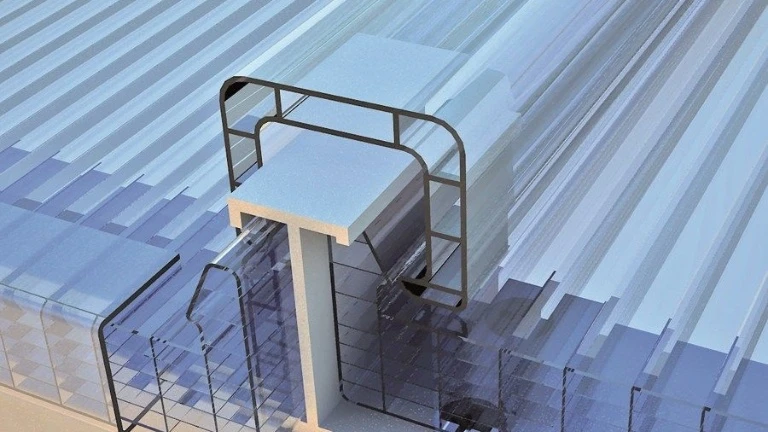

- Productos de automatización industrial: Sirven como envolventes de protección para dispositivos de control de automatización y sistemas modulares, garantizando la seguridad de funcionamiento y la durabilidad.

2. Equipos de comunicación

- Dispositivos de red inalámbricos y por cable: Carcasas para amplificadores de señal, routers y otros equipos de red.

- Módulos de estaciones base de telecomunicaciones: Diseñado para resistir las duras condiciones exteriores y proteger al mismo tiempo los módulos de comunicación internos.

- Transceptores de fibra y dispositivos de radio: Carcasas duraderas para equipos como módulos ópticos y pequeños dispositivos de comunicación inalámbrica.

3. Electrónica de consumo

- Amplificadores de audio: Carcasas selladas que mejoran tanto la disipación del calor como el rendimiento de protección.

- Dispositivos portátiles de alimentación: Carcasas protectoras para power banks, dispositivos portátiles y adaptadores.

- Dispositivos domésticos inteligentes: Carcasas para sistemas como concentradores inteligentes, productos inalámbricos y módulos de control.

4. Automoción y transporte

- Electrónica del automóvil: Carcasas para módulos electrónicos como sistemas de gestión de baterías (BMS) o controladores de motores eléctricos.

- Carcasas de protección del controlador del motor y de la pantalla: Proporciona un blindaje robusto para los sistemas de a bordo.

- Equipos de tránsito ferroviario: Armarios para dispositivos de comunicación, amplificadores de señal u otros componentes ferroviarios críticos.

5. Dispositivos médicos

- Equipos de diagnóstico y pruebas: Carcasas compactas para dispositivos médicos como herramientas de diagnóstico portátiles.

- Bombas de infusión y dispositivos de monitorización: Carcasas de protección para equipos de monitorización médica, incluidas las máquinas de ECG.

- Módulos de instrumental médico: Soportes modulares de aluminio para instrumental médico sensible.

6. Energía y energías renovables

- Carcasas de sistemas de almacenamiento de energía: Carcasas de protección para baterías y sistemas de inversores.

- Carcasas para controladores LED: Carcasas fiables para controladores LED que garantizan la regulación térmica y la durabilidad.

- Equipos de control de energía solar: Carcasas para inversores solares, sistemas de gestión de baterías y pilas de carga.

7. Dispositivos e instrumentos de exterior

- Cámaras de vigilancia y seguridad: Carcasas robustas y resistentes a la intemperie para equipos de vigilancia en exteriores.

- Carcasas de sensores resistentes a la lluvia y al polvo: Protección para sensores de exterior utilizados en condiciones climáticas adversas o en emplazamientos industriales.

- Instrumentos de vigilancia meteorológica y medioambiental: Cajas para dispositivos utilizados para controlar el clima o la contaminación.

Para los proyectos de extrusión de aluminio a medida, aceptamos una gran variedad de formatos de dibujo, entre los que se incluyen Archivos CAD, Ficheros STEPy Archivos PDF. Sin embargo, para extrusiones que requieren procesos de mecanizado adicionales, se recomienda proporcionar Ficheros STEPya que garantizan un modelado 3D preciso para la exactitud del mecanizado.

En Archivos PDF son aceptables, convertirlos en dibujos CAD puede provocar la pérdida de ciertos detalles, lo que nos obligaría a redibujar manualmente el diseño, con el consiguiente aumento del plazo de entrega. Para obtener un presupuesto más rápido y preciso, le recomendamos que nos facilite Archivos CAD (por ejemplo, DWG/DXF) y Ficheros STEP para garantizar la eficacia de la evaluación del diseño y la fijación de precios.

Los honorarios de los moldes son una parte esencial del proceso de extrusión de aluminio a medida. Dado que cada pedido requiere un molde de diseño exclusivo adaptado a requisitos específicos, estos moldes no pueden utilizarse para otros productos. Por lo tanto, la tarifa del molde es necesaria y no negociable.

Necesitamos 100% pago por adelantado de la tasa del molde antes de que comience el desarrollo del molde para garantizar una producción puntual. Sin embargo, como muestra de agradecimiento por su apoyo, ofrecemos la devolución del importe del molde o descuentos equivalentes una vez que el pedido alcance un determinado volumen de producción. Las políticas específicas pueden discutirse en función del volumen de su pedido y los detalles de colaboración.

Nuestra cantidad mínima de pedido (MOQ) varía en función del tamaño del producto. Para productos de menor tamaño, la MOQ suele ser 500 kgmientras que para los productos de mayor tamaño 2 toneladas.

Le especificaremos los requisitos exactos de MOQ durante el proceso de cotización. Si la cantidad de su pedido no se ajusta al MOQ, podemos organizar la producción, pero se aplicará una tarifa adicional para cubrir el precalentamiento del molde y el tiempo de preparación de la producción. Puede estar seguro de que este coste adicional será razonable y nuestro objetivo es que sea el mínimo posible para garantizar una cooperación fluida.

La producción de moldes suele llevar 7 días. Una vez confirmada la muestra, la producción de un contenedor lleno de 26 toneladas generalmente requiere 14 días sólo para extrusión. Si se requiere un tratamiento de superficie, se requiere un 3 días será necesario. Para el mecanizado, se necesitará tiempo adicional en función de la complejidad y el volumen del trabajo de mecanizado. El tiempo adicional exacto para el mecanizado se determinará en función de los requisitos específicos de procesamiento.

Los perfiles de aluminio son resistentes a la corrosión por naturaleza debido a la formación de una fina capa protectora de óxido cuando se exponen al aire o al agua. Esta capa de óxido es estable y autorreparable, lo que significa que incluso si la superficie se raya o se corta (como en los extremos expuestos o durante el procesamiento), el aluminio no se oxidará ni corroerá como el hierro o el acero. En su lugar, las zonas expuestas formarán rápidamente una nueva capa de óxido, proporcionando una protección continua contra la oxidación posterior.

Con un diseño, una instalación y un mantenimiento adecuados, los perfiles de aluminio pueden durar décadasincluso en entornos difíciles. Por ejemplo, el aluminio sin tratar puede resistir fácilmente entre 20 y 30 años en aplicaciones al aire libre, mientras que los perfiles con tratamientos superficiales como el anodizado o el recubrimiento en polvo pueden durar incluso más, superando a menudo los 20 años. 50 años. Esto convierte al aluminio en una opción excelente para aplicaciones en las que la durabilidad y el rendimiento a largo plazo son esenciales.

El precio de los perfiles de aluminio consta de varios componentes: costes de la materia prima, tasas de procesamiento de extrusión, tasas de tratamiento de superficies, costes de mecanizado y tasas adicionales de embalaje. Entre ellos, el coste del aluminio como materia prima tiende a fluctuar con frecuencia, mientras que los demás honorarios permanecen relativamente estables. Debido a estas fluctuaciones, nuestros presupuestos suelen ser válidos para 7 días.

La fijación de precios puede estructurarse de distintas maneras en función del producto y los requisitos. Puede calcularse por peso (por ejemplo, coste por tonelada), por longitud (por ejemplo, coste por metro), o por pieza (por ejemplo, coste por unidad). En el caso de los productos que requieren un gran mecanizado, como disipadores de calorEl precio se calcula generalmente por pieza para reflejar con exactitud los costes adicionales de procesamiento. Este enfoque de precios flexible garantiza que el presupuesto se adapte a las necesidades específicas del cliente.

Podemos fabricar perfiles de aluminio conforme a requisitos técnicos que cumplen Normas europeas (EN), normas americanas (ASTM/AA)u otras normas especificadas por el cliente. La producción a medida se adapta para garantizar que los perfiles cumplen los requisitos estándar específicos solicitados.

Nuestros equipos de producción están diseñados sistema métrico. Si los dibujos facilitados están en el sistema imperialPara garantizar la precisión, los convertiremos en unidades métricas para la producción.

Es importante tener en cuenta que, aunque podemos mecanizar orificios con rosca imperial para elementos de fijación, si necesita que le suministremos los correspondientes tornillería imperialno siempre están disponibles en stock. Los pedidos personalizados de fijaciones imperiales suelen requerir un gran volumen para la producción. Tenga esto en cuenta a la hora de planificar su proyecto.