Materiales para marcos de aluminio extruido

La carpintería de aluminio extruido es un sistema de carpintería modular compuesto por Perfiles de aluminio con ranura en T fabricado mediante el proceso de extrusión de aluminio, junto con un surtido de accesorios compatibles. Conocido por su flexibilidad, alta resistencia, diseño ligero y facilidad de montaje, este sistema se ha convertido en la piedra angular de los modernos armazones de equipos industriales, sistemas de automatización, proyectos de investigación y soluciones de visualización comercial. Debido a su naturaleza reutilizable y reconfigurable, se le suele llamar el "Lego de las industrias".

Este sistema de entramado se utiliza ampliamente en aplicaciones como soportes de equipos industriales, bancos de trabajo, estructuras de laboratorio y entramados de pequeños dispositivos modulares. En comparación con estructuras tradicionales como el acero o la madera, la carpintería de aluminio extruido ofrece ventajas significativas en términos de personalización, comodidad y resistencia a la corrosión. Su adaptabilidad y sus cualidades ecológicas lo convierten en la solución ideal para las industrias que buscan eficiencia, durabilidad y prácticas sostenibles.

Ventajas de las estructuras de aluminio extruido

Diseño modular

El marco de aluminio extruido presenta un diseño de ranura en T que permite un montaje rápido con componentes estándar como pernos y deslizadores. La ausencia de soldaduras facilita la reutilización, reconfiguración y personalización, garantizando una flexibilidad excepcional para diversas aplicaciones.

Ligero y resistente

El aluminio extruido, que pesa sólo un tercio que el acero, ofrece una gran resistencia y rigidez. Su ligereza lo hace ideal para aplicaciones que van desde cargas ligeras a semipesadas, a la vez que simplifica el transporte y la instalación.

Excelente resistencia a la corrosión

Naturalmente resistente a la oxidación, el aluminio funciona bien en entornos húmedos o químicamente agresivos. El anodizado puede mejorar aún más la durabilidad de la superficie, garantizando un rendimiento duradero en condiciones exigentes.

Estética elegante y moderna

Con superficies lisas, líneas limpias y un aspecto industrial moderno, la carpintería de aluminio extruido ofrece una sensación de calidad superior. Además, puede personalizarse con distintos acabados superficiales, texturas y colores para satisfacer necesidades de diseño específicas.

Amplia compatibilidad de accesorios

Una amplia gama de accesorios, como conectores, ruedas, pies de apoyo y ranuras para paneles, hacen que las estructuras de aluminio sean muy versátiles. Permiten realizar ampliaciones rápidas y configuraciones personalizadas en estructuras complejas o sistemas especializados.

Respetuoso con el medio ambiente y sostenible

El aluminio es 100% reciclable, lo que lo convierte en una solución ecológica alineada con los principios de la economía circular. Su reutilización favorece las prácticas sostenibles, reduciendo los residuos de material y el impacto medioambiental.

Aplicaciones de las estructuras de aluminio extruido

Las estructuras de aluminio extruido, en particular los perfiles de aluminio con ranura en T, se utilizan ampliamente en todos los sectores debido a su versatilidad, resistencia y facilidad de montaje. Estas son algunas aplicaciones comunes:

1. Automatización industrial y construcción de maquinaria

- Bastidores de máquinas

- Sistemas de transporte

- Armarios para equipos

- Brazos robóticos y estaciones de trabajo

- Bancos de pruebas y automatización

2. Puestos de trabajo y mobiliario modular

- Bancos de trabajo regulables

- Puestos de trabajo ergonómicos

- Mesas de inspección y estanterías

- Mobiliario modular de oficina e industrial

3. Cerramientos de seguridad y sistemas de protección

- Vallas de seguridad y sistemas de protección de máquinas

- Barreras de protección para equipos peligrosos

- Cerramientos personalizados para cumplir las normas de seguridad en el lugar de trabajo

4. Sistemas de transporte y logística

- Estaciones de embalaje y clasificación

- Carros y carretillas a medida

- Estanterías de almacenamiento y estanterías industriales

5. Construcción y diseño arquitectónico

- Estructuras ligeras

- Paredes divisorias y expositores

- Stands y expositores personalizados para ferias comerciales

- Sistemas de montaje de paneles solares

6. Proyectos de bricolaje y hobby

- Estanterías y muebles a medida

- Proyectos de domótica

- Espacio Maker y creación de prototipos

7. Salas blancas y laboratorios

- Recintos sin contaminación

- Bastidores modulares para salas blancas

- Montajes de mobiliario y equipos de laboratorio

8. Otras aplicaciones personalizadas

- Plantillas de montaje aeroespacial y de automoción

- Estructuras para vehículos recreativos (RV) o embarcaciones

- Marcos agrícolas y de invernaderos

Ranura en T para marco de aluminio extruido

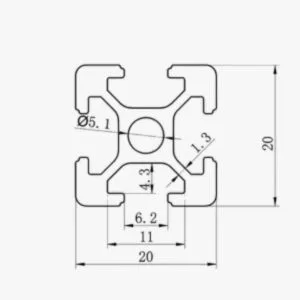

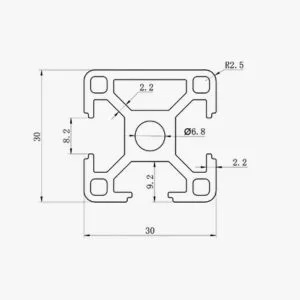

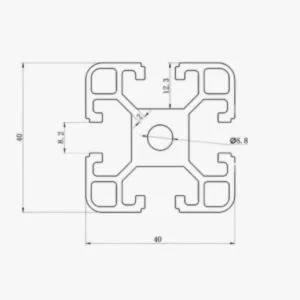

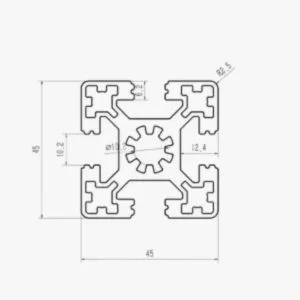

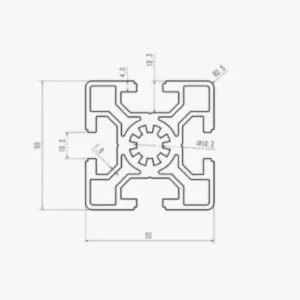

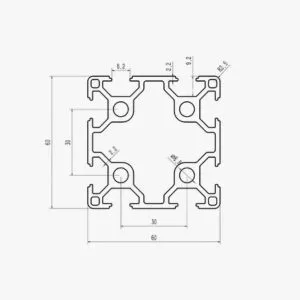

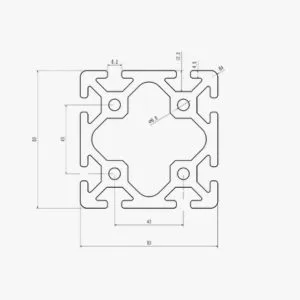

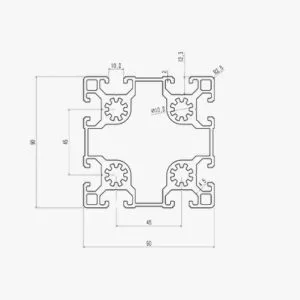

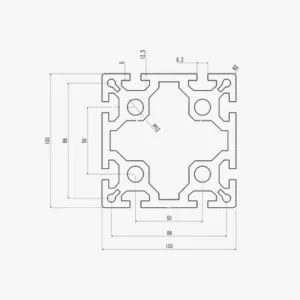

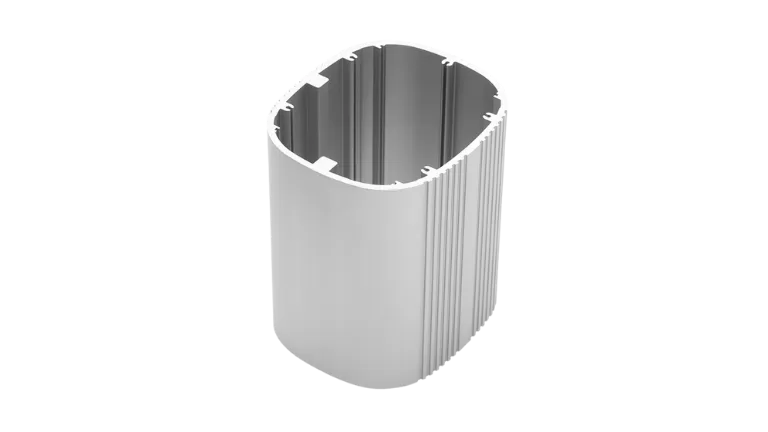

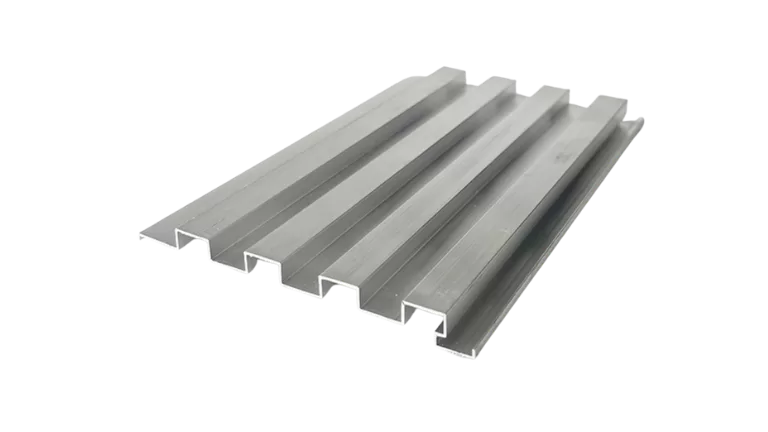

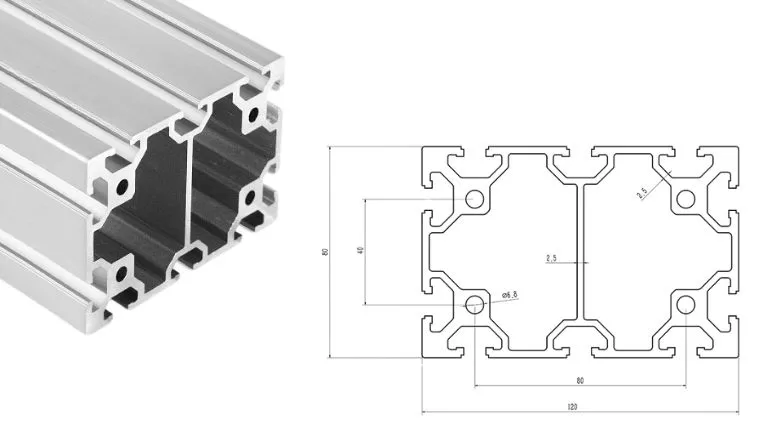

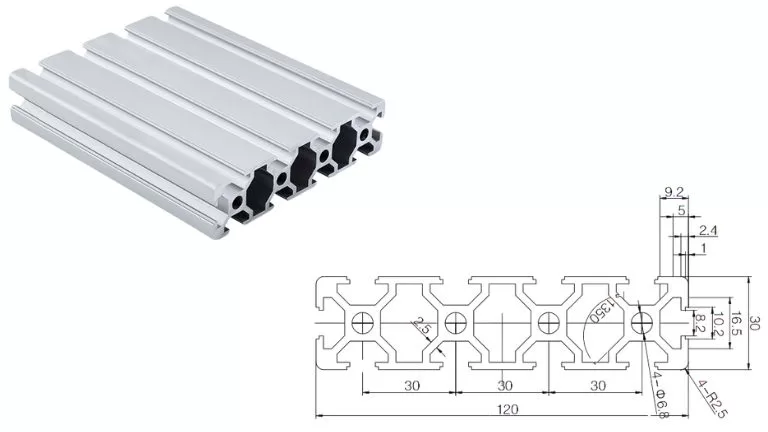

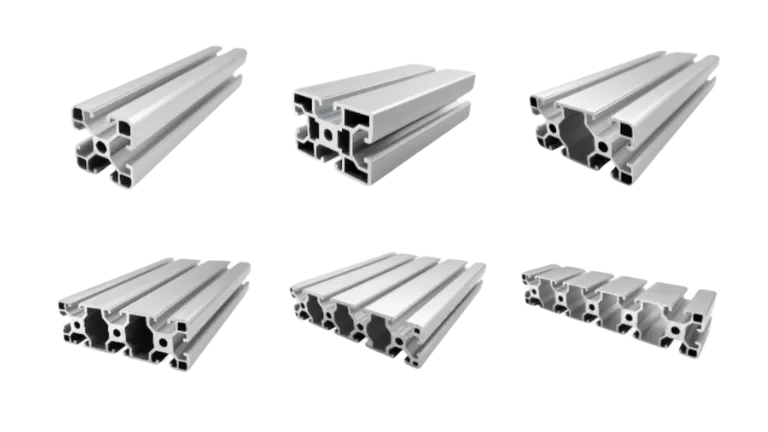

Los perfiles de aluminio con ranura en T se presentan en series de diferentes tamaños, como las series 20, 30 y 40, que responden a diversos requisitos de resistencia y aplicación en todos los sectores. Estos versátiles perfiles pueden personalizarse aún más con modelos derivados, incluidos perfiles sellados por uno o dos lados, que mejoran la estética y potencian la funcionalidad estructural. Los perfiles de ranura en T para esquinas están diseñados específicamente para transiciones redondeadas en las esquinas exteriores, creando curvas suaves y un aspecto más limpio a la vez que preservan la modularidad y conectividad del sistema.

Los perfiles de ranura en V, por el contrario, presentan un diseño de ranura biselada que funciona como canal estructural y como pista de movimiento lineal. Se utilizan habitualmente en impresoras 3D, máquinas CNC y otros sistemas basados en movimiento.

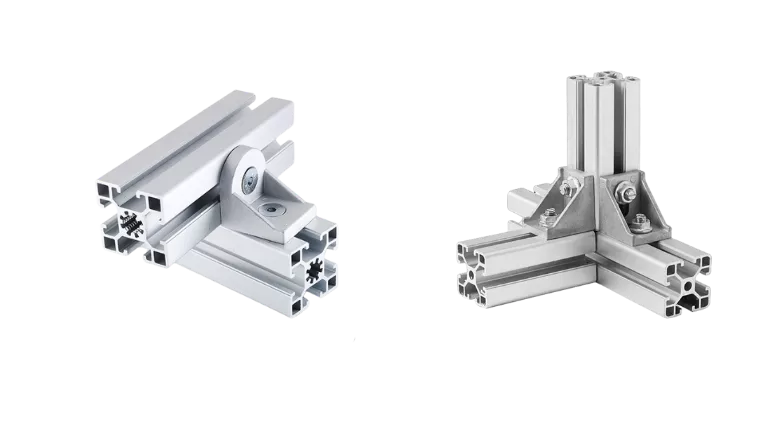

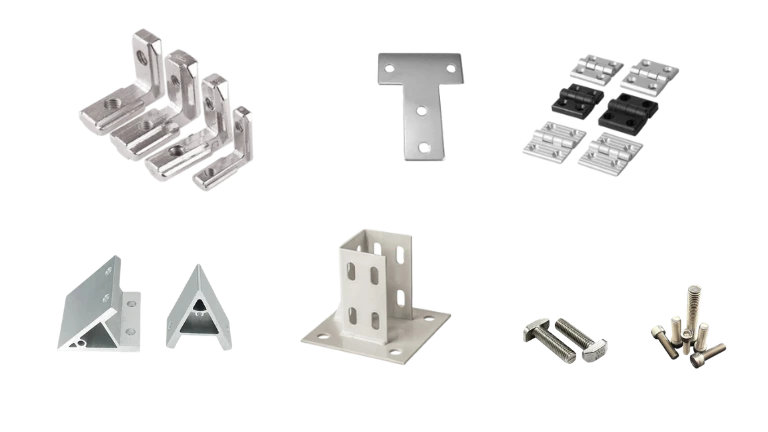

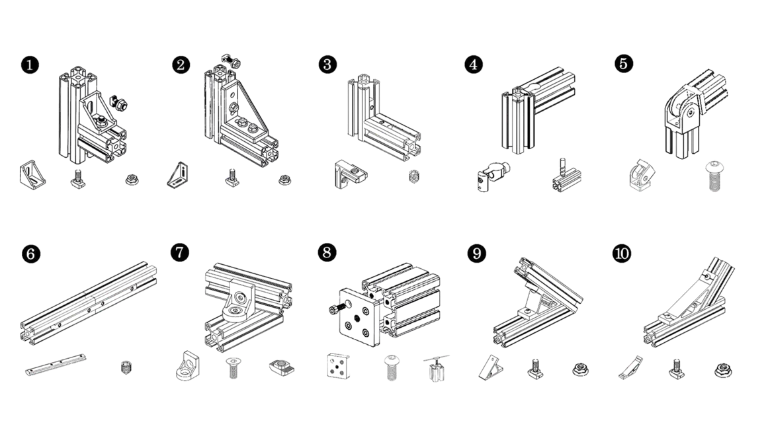

Los sistemas de entramado de aluminio extruido se basan en una variedad de tipos de conectores para ensamblar estructuras de forma eficaz y segura. Estos conectores están diseñados para funcionar a la perfección con perfiles de aluminio de ranura en T y proporcionan flexibilidad para diversos diseños estructurales. Los tipos más comunes de conectores incluyen:

Escuadras: Se utiliza para unir perfiles en ángulos de 90 grados, ofreciendo conexiones fuertes y estables para marcos y cerramientos.

Conectores internos: Conectores ocultos que encajan en el interior de la ranura en T para crear un exterior limpio y enrasado, adecuado para aplicaciones que requieren un aspecto aerodinámico.

Soportes angulares: Soportes ajustables o fijos para crear uniones en ángulo o multidireccionales.

Placas de unión: Placas planas utilizadas para unir dos o más perfiles, a menudo utilizadas para reforzar o ampliar la longitud de la estructura.

Fijaciones de anclaje: Herraje especializado que permite unir perfiles perpendicularmente anclándolos en el canal de la ranura en T.

Tuercas en T: Imprescindibles para montar o modificar estructuras, se deslizan en las ranuras en T y funcionan como base para pernos o tornillos.

Bisagras: Permiten conexiones dinámicas o pivotantes, ideales para crear puertas, tapas o secciones móviles dentro del marco.

Tapas: Se utilizan para rematar los extremos de los perfiles, protegiendo la estructura y proporcionando un aspecto acabado, a la vez que a veces sirven de conectores para juntas de extremo a extremo.

Métodos de conexión para marcos de aluminio extruido

Los sistemas de entramado de aluminio extruido están diseñados para un montaje modular y flexible, basándose en una variedad de métodos de conexión para adaptarse a las diferentes necesidades estructurales. Los principales métodos de conexión incluyen:

Conexiones con tuercas en T y pernos

Es el método de conexión más común y versátil. Las tuercas en T se deslizan en la ranura en T del perfil de aluminio y proporcionan una base roscada para los pernos, que fijan los perfiles o accesorios entre sí. Este método es sencillo, resistente y fácil de ajustar o desmontar cuando sea necesario.

Conectores internos (ocultos)

Los conectores internos encajan dentro de la ranura en T, ofreciendo una conexión segura y oculta. Este método se utiliza a menudo cuando se prefiere un exterior limpio y enrasado. Los conectores internos incluyen fijaciones de anclaje o barras de unión rectas para conectar dos perfiles en ángulo recto o en línea.

Escuadras

Las escuadras de esquina son conectores externos que permiten unir perfiles en ángulos de 90 grados. Estas escuadras se atornillan a los perfiles y son ideales para construir marcos fuertes y rígidos. Se suelen utilizar en aplicaciones que requieren conexiones visibles y fácilmente ajustables.

Placas de unión

Las placas de unión planas se utilizan para unir dos o más perfiles uno al lado del otro o en ángulos complejos. Se montan externamente y se fijan con pernos, proporcionando un refuerzo adicional en aplicaciones de alta carga o para ampliar la longitud de los perfiles.

Conexiones de extremo a extremo

Los conectores de extremo a extremo, como las varillas roscadas o los conectores a tope, se utilizan para unir dos perfiles linealmente. Garantizan la alineación y la estabilidad, al tiempo que permiten alargar los perfiles de forma flexible y compacta.

Conexiones pivotantes y deslizantes

Para aplicaciones que requieren movimiento, como brazos ajustables o puertas, se utilizan uniones pivotantes y mecanismos lineales de deslizamiento. Se suelen emplear bisagras, uniones pivotantes o sistemas de ranura en V (para el movimiento deslizante).

Soldadura o uniones fijas (menos comunes)

Aunque no se utilizan con frecuencia en los sistemas modulares estándar, las cartelas soldadas o fijas pueden emplearse cuando se requieren conexiones extremadamente rígidas o permanentes.

Solución de entramado de aluminio extruido

HTS-ALU es un fabricante líder de perfiles de aluminio en China, equipado con 40 avanzadas líneas de producción de extrusión y capacidades completas de tratamiento de superficies y mecanizado, incluyendo anodizado, recubrimiento en polvo, chorro de arena, taladrado, roscado y procesamiento CNC.

Ofrecemos versátiles perfiles de aluminio extruido con ranura en T y accesorios ampliamente utilizados en automatización industrial, armarios de máquinas, estaciones de trabajo y proyectos de bricolaje. Nuestro amplio inventario permite el envío inmediato, con perfiles cortados a medida según sus especificaciones y emparejados con los conectores necesarios para facilitar el montaje.

Tanto si se trata de grandes proyectos industriales como de pequeños pedidos personalizados, estamos preparados para satisfacer sus necesidades. Ofrecemos envíos a todo el mundo, incluso para pedidos pequeños, siempre que los clientes cubran los gastos de envío, lo que garantiza un servicio fiable y soluciones de alta calidad, esté donde esté.

Capacidad de procesamiento de perfiles de aluminio

Como líder fabricante de extrusión de aluminio con sede en China, estamos comprometidos con el suministro de perfiles de aluminio de alta calidad para una amplia gama de industrias. Nuestras capacidades comienzan con el diseño y la fabricación de moldes personalizados, garantizando formas de extrusión precisas que satisfagan las necesidades específicas de nuestros clientes. Desde la extrusión en bruto hasta el acabado de superficies y el mecanizado avanzado, nuestros procesos de fabricación totalmente integrados nos permiten suministrar perfiles de aluminio que cumplen las normas más exigentes y satisfacen los requisitos exclusivos de cada proyecto.

Nuestras instalaciones de producción albergan más de 40 líneas de extrusión avanzadas, con equipos de vanguardia como una potente prensa de extrusión de 6000 toneladas. Esto permite crear perfiles de aluminio de diversos tamaños y formas, desde aplicaciones industriales estándar hasta productos especializados como perfiles de rotura de puente térmico para puertas y ventanas de alta gama. La flexibilidad de nuestra capacidad de extrusión nos permite atender a un amplio espectro de sectores, como la construcción y la ingeniería de precisión.

Nuestras instalaciones de producción albergan más de 40 líneas de extrusión avanzadas, con equipos de vanguardia como una potente prensa de extrusión de 6000 toneladas. Esto permite crear perfiles de aluminio de diversos tamaños y formas, desde aplicaciones industriales estándar hasta productos especializados como perfiles de rotura de puente térmico para puertas y ventanas de alta gama. La flexibilidad de nuestra capacidad de extrusión nos permite atender a un amplio espectro de sectores, como la construcción y la ingeniería de precisión.

Contamos con la experiencia necesaria para diseñar y producir moldes de extrusión en nuestras instalaciones, lo que garantiza la precisión y la eficacia en la fabricación de perfiles de aluminio. Nuestro experimentado equipo trabaja en estrecha colaboración con los clientes para desarrollar moldes personalizados a partir de planos o muestras, garantizando un rendimiento óptimo para sus requisitos específicos. Normalmente, el proceso de producción de moldes dura unos 7 días, tras los cuales proporcionamos muestras para que el cliente las confirme antes de iniciar la producción a gran escala.

Contamos con la experiencia necesaria para diseñar y producir moldes de extrusión en nuestras instalaciones, lo que garantiza la precisión y la eficacia en la fabricación de perfiles de aluminio. Nuestro experimentado equipo trabaja en estrecha colaboración con los clientes para desarrollar moldes personalizados a partir de planos o muestras, garantizando un rendimiento óptimo para sus requisitos específicos. Normalmente, el proceso de producción de moldes dura unos 7 días, tras los cuales proporcionamos muestras para que el cliente las confirme antes de iniciar la producción a gran escala.

Para una mayor durabilidad y atractivo visual, ofrecemos varias soluciones de tratamiento de superficies. Entre ellas se incluyen el anodizado para una mayor resistencia a la corrosión, el recubrimiento en polvo para acabados vibrantes, el recubrimiento de fluorocarbono para una mayor resistencia a la intemperie y la tecnología de transferencia de vetas de madera para diseños elegantes y de aspecto natural. Estos tratamientos se pueden personalizar para adaptarse a necesidades estéticas y funcionales específicas, garantizando que los perfiles no sólo funcionen bien, sino que también tengan un aspecto excepcional.

Para proporcionar soluciones completas de perfiles de aluminio, ofrecemos amplias capacidades de procesamiento posterior. Nuestros servicios incluyen mecanizado CNC, fresado, roscado, taladrado, corte de precisión, punzonado, soldadura y montaje. Esta gama de opciones de fabricación nos permite suministrar perfiles listos para usar y adaptados a las especificaciones exactas del proyecto, ofreciendo una flexibilidad y fiabilidad inigualables a nuestros clientes.

RFQ de perfil de aluminio extruido

Nuestros perfiles de aluminio con ranura en T estándar en stock están fabricados con la aleación 6063-T5, un material conocido por su excelente solidez, resistencia a la corrosión y acabado superficial. Es muy versátil y resulta ideal para la mayoría de aplicaciones industriales, como carcasas de máquinas, estaciones de trabajo, sistemas de transporte y proyectos de bricolaje.

Para requisitos especializados, ofrecemos personalización en otros grados y materiales de aluminio:

- 6061-T6: Ofrece mayor resistencia y mejor resistencia a la fatiga en comparación con 6063-T5, por lo que es ideal para aplicaciones pesadas o marcos estructurales.

- 6082: Conocido por sus propiedades mecánicas mejoradas y su resistencia a la corrosión, es adecuado para aplicaciones sometidas a cargas dinámicas o en entornos difíciles.

- 6005: Perfecta para proyectos que requieren una gran resistencia y un excelente acabado, utilizada habitualmente en aplicaciones estructurales a medida.

- Otras aleaciones a petición: Si tiene requisitos de material específicos, como aleaciones con propiedades específicas de conductividad térmica o dureza, podemos trabajar con usted para satisfacer sus necesidades.

- Otros materiales: Para proyectos que necesitan materiales distintos del aluminio, podemos explorar soluciones que impliquen diferentes metales o compuestos para satisfacer sus necesidades técnicas.

Gracias a nuestras completas capacidades de producción, que incluyen 40 líneas de extrusión e instalaciones completas de tratamiento de superficies y mecanizado, podemos desarrollar perfiles de ranura en T en el material que mejor se adapte a los requisitos de su proyecto. Tanto si lo que busca es una alta resistencia, una resistencia superior a la corrosión o la capacidad de mecanizado, nos comprometemos a ofrecerle soluciones adaptadas a su aplicación exclusiva.

Nuestros perfiles de aluminio con ranura en T suelen acabarse con dos tratamientos superficiales estándar:

- Anodizado plata (acabado natural): Proporciona una superficie limpia y resistente a la corrosión con un elegante aspecto plateado, ideal para la mayoría de las aplicaciones industriales y estéticas.

- Negro mate anodizado: Proporciona un moderno acabado negro no reflectante, que ofrece una excelente durabilidad y resistencia a los arañazos para un aspecto refinado y profesional.

Además de estas opciones estándar, también ofrecemos tratamientos de superficie personalizados para satisfacer los requisitos específicos de cada proyecto. Los acabados personalizados disponibles incluyen:

- Anodizado de color: Varios colores como el oro, el bronce o el azul para fines decorativos o de marca.

- Recubrimiento en polvo: Para una mayor protección, resistencia a la intemperie y opciones de color adicionales con un acabado liso o texturizado.

- Chorro de arena: Proporciona una textura uniforme y mate para un aspecto de primera calidad.

- Electroforesis: Ofrece un acabado brillante con una resistencia superior a la corrosión, adecuado para aplicaciones en exteriores.

- Pulido o cepillado: Para una estética de alto brillo o satinado, comúnmente utilizado en productos de cara al consumidor.

Podemos adaptar el tratamiento superficial a sus requisitos de diseño y rendimiento, garantizando que sus perfiles no sólo funcionen a la perfección, sino que también tengan un aspecto magnífico en su aplicación prevista.

Ofrecemos servicios integrales de mecanizado de perfiles de aluminio con ranura en T para garantizar que estén listos para el montaje y se adapten perfectamente a las especificaciones de su proyecto. Nuestros avanzados equipos y nuestro cualificado equipo pueden ofrecer las siguientes opciones de personalización:

- Corte a medida: Los perfiles pueden cortarse a la longitud exacta que necesite, garantizando un ajuste preciso para su aplicación.

- Corte en ángulo: Se pueden realizar cortes angulares especiales según sus especificaciones, ideales para crear marcos o estructuras con diseños no estándar.

- Taladrado y roscado: Se pueden añadir orificios pretaladrados y roscados para simplificar el proceso de montaje y ahorrar tiempo in situ.

- Ranurado y fresado: Podemos mecanizar ranuras especiales en perfiles para aplicaciones únicas o para alojar componentes adicionales.

- Avellanado y biselado: Para acabados lisos y enrasados, perfectos para crear montajes de aspecto profesional y limpio.

Nuestros servicios de mecanizado están diseñados para facilitar la preparación de perfiles de ranura en T para el montaje. Tanto si necesita un único perfil cortado a medida como grandes lotes con mecanizado complejo, tenemos la capacidad de ofrecer resultados de alta calidad de forma eficiente. Combinados con nuestra amplia gama de accesorios, garantizamos una solución profesional y sin fisuras de principio a fin.

Mantenemos un amplio inventario de perfiles de aluminio con ranura en T y accesorios, como se indica en nuestro sitio web HTS-ALU. Nuestro stock incluye principalmente perfiles anodizados en plata, que son los más populares, junto con una selección más reducida de perfiles anodizados en negro.

Una de nuestras principales ventajas es la flexibilidad.no hay cantidad mínima de pedido (MOQ). Tanto si necesita unos pocos perfiles para un pequeño proyecto como un gran lote para uso industrial, estamos aquí para satisfacer sus demandas.

Nuestro inventario se encuentra en China, y podemos realizar envíos a todo el mundo. Para pedidos pequeños, los gastos de envío pueden ser más elevados en relación con el tamaño del pedido, por lo que recomendamos a los clientes que confirmen sus preferencias de transporte. Siempre que esté dispuesto a cubrir los gastos de transporte, estaremos encantados de atender pedidos de cualquier tamaño y entregarlos de forma eficiente.

Gracias a nuestras existencias y a nuestras flexibles opciones de pedido, le garantizamos que dispondrá de los materiales que necesite cuando los necesite.

Para los proyectos de extrusión de aluminio a medida, aceptamos una gran variedad de formatos de dibujo, entre los que se incluyen Archivos CAD, Ficheros STEPy Archivos PDF. Sin embargo, para extrusiones que requieren procesos de mecanizado adicionales, se recomienda proporcionar Ficheros STEPya que garantizan un modelado 3D preciso para la exactitud del mecanizado.

En Archivos PDF son aceptables, convertirlos en dibujos CAD puede provocar la pérdida de ciertos detalles, lo que nos obligaría a redibujar manualmente el diseño, con el consiguiente aumento del plazo de entrega. Para obtener un presupuesto más rápido y preciso, le recomendamos que nos facilite Archivos CAD (por ejemplo, DWG/DXF) y Ficheros STEP para garantizar la eficacia de la evaluación del diseño y la fijación de precios.

Los honorarios de los moldes son una parte esencial del proceso de extrusión de aluminio a medida. Dado que cada pedido requiere un molde de diseño exclusivo adaptado a requisitos específicos, estos moldes no pueden utilizarse para otros productos. Por lo tanto, la tarifa del molde es necesaria y no negociable.

Necesitamos 100% pago por adelantado de la tasa del molde antes de que comience el desarrollo del molde para garantizar una producción puntual. Sin embargo, como muestra de agradecimiento por su apoyo, ofrecemos la devolución del importe del molde o descuentos equivalentes una vez que el pedido alcance un determinado volumen de producción. Las políticas específicas pueden discutirse en función del volumen de su pedido y los detalles de colaboración.

El embalaje puede personalizarse según sus necesidades. Las opciones incluyen el uso de film protector o papel para separar y proteger la superficie, o film de espuma para una protección adicional de la superficie. Los productos pueden paletizarse o embalarse en cajas de cartón, y el cliente puede especificar la cantidad por palé o caja.

El embalaje estándar consiste en agrupar varias piezas con envoltorio de plástico y fijarlas en palés. Cualquier requisito de embalaje que exceda del estándar se tendrá en cuenta, y los costes asociados se comunicarán claramente al cliente.

Los perfiles de aluminio son resistentes a la corrosión por naturaleza debido a la formación de una fina capa protectora de óxido cuando se exponen al aire o al agua. Esta capa de óxido es estable y autorreparable, lo que significa que incluso si la superficie se raya o se corta (como en los extremos expuestos o durante el procesamiento), el aluminio no se oxidará ni corroerá como el hierro o el acero. En su lugar, las zonas expuestas formarán rápidamente una nueva capa de óxido, proporcionando una protección continua contra la oxidación posterior.

Con un diseño, una instalación y un mantenimiento adecuados, los perfiles de aluminio pueden durar décadasincluso en entornos difíciles. Por ejemplo, el aluminio sin tratar puede resistir fácilmente entre 20 y 30 años en aplicaciones al aire libre, mientras que los perfiles con tratamientos superficiales como el anodizado o el recubrimiento en polvo pueden durar incluso más, superando a menudo los 20 años. 50 años. Esto convierte al aluminio en una opción excelente para aplicaciones en las que la durabilidad y el rendimiento a largo plazo son esenciales.

El precio de los perfiles de aluminio consta de varios componentes: costes de la materia prima, tasas de procesamiento de extrusión, tasas de tratamiento de superficies, costes de mecanizado y tasas adicionales de embalaje. Entre ellos, el coste del aluminio como materia prima tiende a fluctuar con frecuencia, mientras que los demás honorarios permanecen relativamente estables. Debido a estas fluctuaciones, nuestros presupuestos suelen ser válidos para 7 días.

La fijación de precios puede estructurarse de distintas maneras en función del producto y los requisitos. Puede calcularse por peso (por ejemplo, coste por tonelada), por longitud (por ejemplo, coste por metro), o por pieza (por ejemplo, coste por unidad). En el caso de los productos que requieren un gran mecanizado, como disipadores de calorEl precio se calcula generalmente por pieza para reflejar con exactitud los costes adicionales de procesamiento. Este enfoque de precios flexible garantiza que el presupuesto se adapte a las necesidades específicas del cliente.

Podemos fabricar perfiles de aluminio conforme a requisitos técnicos que cumplen Normas europeas (EN), normas americanas (ASTM/AA)u otras normas especificadas por el cliente. La producción a medida se adapta para garantizar que los perfiles cumplen los requisitos estándar específicos solicitados.

Nuestros equipos de producción están diseñados sistema métrico. Si los dibujos facilitados están en el sistema imperialPara garantizar la precisión, los convertiremos en unidades métricas para la producción.

Es importante tener en cuenta que, aunque podemos mecanizar orificios con rosca imperial para elementos de fijación, si necesita que le suministremos los correspondientes tornillería imperialno siempre están disponibles en stock. Los pedidos personalizados de fijaciones imperiales suelen requerir un gran volumen para la producción. Tenga esto en cuenta a la hora de planificar su proyecto.