Conductividad del aluminio en la industria eléctrica

Según el Instituto Internacional del Aluminio (IAI), se espera que la demanda mundial de aluminio para la industria electrónica aumente de 8 a 12 millones de toneladas en los próximos años. Al mismo tiempo, también se prevé que la demanda de cobre alcance un nivel similar, en torno a los 13 millones de toneladas. Esto plantea una cuestión importante: ¿cómo funciona realmente el aluminio como material conductor? Para los diseñadores, desarrolladores de productos y empresas que desean aprovechar la rentabilidad y las propiedades de ligereza del aluminio, es esencial conocer su conductividad eléctrica. En este artículo, exploraremos los conductores de aluminio, las características eléctricas del aluminio y su potencial como alternativa al cobre y otros metales conductores.

Propiedades metálicas del aluminio

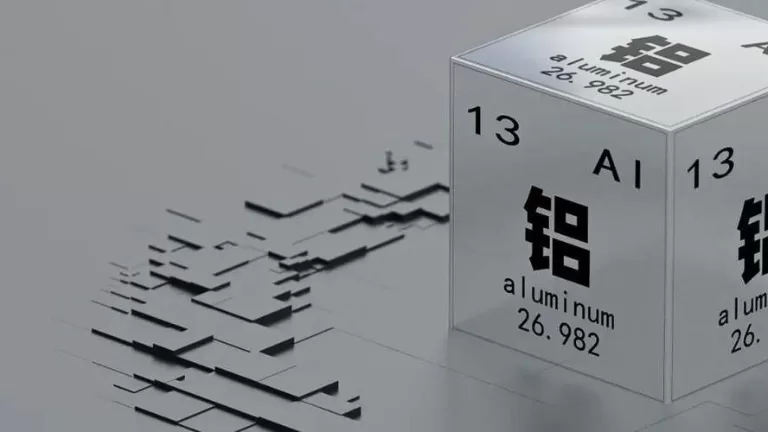

¿Sabía que el aluminio es el metal más abundante de la Tierra y ocupa el número 13 de la tabla periódica? Aunque está en todas partes, el aluminio puro no se encuentra en la naturaleza: hay que extraerlo del mineral de bauxita mediante procesos industriales.

Cuando se trata de conducir la electricidad, el aluminio ocupa el cuarto lugar después de la plata, el cobre y el oro. No todas las aleaciones de aluminio conducen la electricidad por igual, pero las propiedades naturales del metal lo convierten en una excelente opción para aplicaciones eléctricas. El aluminio es ligero, fácil de trabajar y muy resistente a la corrosión. Esto significa que es fácil de moldear y soldar, lo que facilita la instalación y el mantenimiento.

Dato curioso: el número 13 no es sólo un símbolo, sino que representa el número de electrones que orbitan alrededor del átomo de aluminio. La disposición de estos electrones es lo que confiere al aluminio su impresionante conductividad eléctrica.

Conductividad eléctrica del aluminio frente a otros metales

Comprobar la conductividad eléctrica del aluminio no sólo ayuda a identificar su grado de aleación, sino que también determina si ha sido tratado térmicamente, ya que el tratamiento térmico cambia los niveles de conductividad. Cada aleación y método de tratamiento tiene su propia clasificación IACS (International Annealed Copper Standard).

Existen diferencias en la conductividad eléctrica tanto entre las aleaciones de aluminio como entre el aluminio y otros metales. Esta tabla de ResearchGate compara la conductividad del aluminio con la de varios metales conocidos.

| Rango | Metal | Conductividad eléctrica (S * m-1) |

|---|---|---|

| 1 | Plata | 66.7 * 106 |

| 2 | Cobre | 64.1 * 106 |

| 3 | Oro | 49.0 * 106 |

| 4 | Aluminio | 40.8 * 106 |

| 5 | Rodio | 23.3 * 106 |

| 6 | Zinc | 18.2 * 106 |

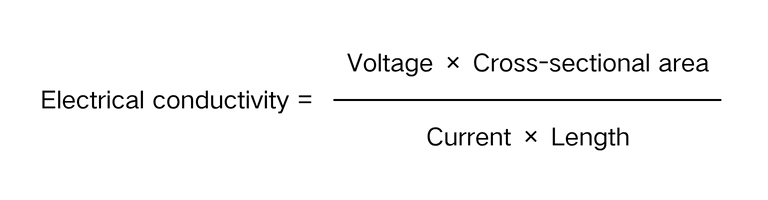

Cómo medir la conductividad eléctrica

La conductividad eléctrica nos dice lo bien que un metal puede conducir la electricidad, y se mide en Siemens por metro (S/m). Para comprobar la conductividad del aluminio, haga lo siguiente: En primer lugar, se hace pasar una cantidad conocida de corriente a través de la muestra de aluminio. A continuación, se mide la caída de tensión entre dos puntos de la muestra mediante sondas. Con estos valores, puede calcular fácilmente la conductividad eléctrica utilizando la fórmula estándar. Es un proceso sencillo y te da una idea clara de la eficacia con la que el aluminio transporta la corriente eléctrica.

Conductividad eléctrica del aluminio

El aluminio es uno de los mejores metales conductores de electricidad, sólo superado por el cobre puro. Los conductores de aluminio puro tienen una conductividad eléctrica de 33,3×10⁷ S/m. Para facilitar las comparaciones, solemos considerar la conductividad del aluminio en relación con la del cobre puro, que se utiliza como norma industrial denominada Norma Internacional del Cobre Recocido (IACS). La conductividad del aluminio es aproximadamente 61% IACS, lo que significa que el aluminio conduce la electricidad con una eficacia 61% superior a la del cobre.

Gracias a su rentabilidad y a su baja resistencia eléctrica, el aluminio se utiliza mucho en equipos eléctricos. También hay que tener en cuenta que el aluminio es ligero (aproximadamente 30% la densidad del cobre), lo que lo convierte en una opción ideal para los cables eléctricos aéreos. De hecho, la mayoría de las líneas de transmisión de energía utilizan conductores de aluminio, e incluso la electricidad doméstica se suministra habitualmente a través de cableado de aluminio.

¿Cómo conduce la electricidad el aluminio?

La capacidad del aluminio para conducir la electricidad se debe a su estructura atómica y a la forma en que se enlazan sus átomos. Básicamente, la electricidad es el flujo de carga -a menudo electrones- a través de un material. En un átomo de aluminio, el centro (el núcleo) está repleto de protones y neutrones, pero los electrones exteriores no están muy unidos. Estos electrones exteriores pueden moverse libremente.

Cuando un átomo de aluminio pierde uno de sus electrones exteriores, se convierte en un ion de aluminio cargado positivamente. En un trozo de aluminio, los átomos están muy juntos y sus electrones exteriores forman lo que se llama un "mar de electrones libres". Cuando hay tensión en un trozo de aluminio, estos electrones libres fluyen hacia el extremo positivo. Este movimiento de electrones es lo que crea una corriente eléctrica, que es la razón básica por la que el aluminio conduce tan bien la electricidad.

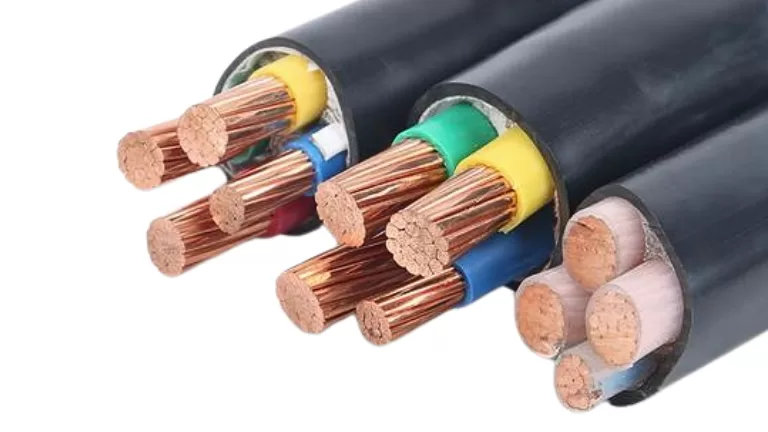

¿Por qué el cobre es mejor conductor que el aluminio?

Aunque el aluminio es un gran conductor eléctrico, el cobre sigue siendo la mejor opción para la mayoría del cableado. Esto se debe a varias razones: el cobre es más dúctil, tiene un aspecto característico y es más resistente y duro que el aluminio. Pero lo más importante, desde el punto de vista eléctrico, es que el cobre tiene una menor resistividad eléctrica, por lo que, a igualdad de longitud y tamaño, un cable de cobre transporta mejor la electricidad que uno de aluminio.

Todo depende de cómo se mueven los electrones en cada metal. En el cobre, los electrones libres tienen menos "colisiones fonónicas", pequeñas interrupciones causadas por las vibraciones de los átomos que pueden dispersar los electrones y ralentizar la corriente. Aunque el aluminio tiene en realidad más electrones libres, sus electrones tienen más probabilidades de ser dispersados por estas vibraciones, lo que aumenta la resistencia. Por eso el cobre sigue siendo la mejor opción cuando se necesita la máxima conductividad.

Grados de aleación de aluminio y conductividad eléctrica

Aunque el aluminio puro es un excelente conductor, la mayoría de las aplicaciones del mundo real utilizan aluminio procesado, aleado o con impurezas añadidas. Las aleaciones de aluminio se clasifican por grados, desde la serie 1000 hasta la serie 8000. La serie 1000 es la de mayor pureza y, por tanto, la de mejor conductividad. Por ejemplo, el aluminio de grado EC (como el 1350 Al), que forma parte de la serie 1000, ofrece una gran conductividad eléctrica y térmica, con una conductividad de aproximadamente 61% IACS. Otros grados, como el AA-8006 y el AA-8011, también son buenos conductores y se utilizan habitualmente en alambres de aluminio y aplicaciones de construcción. La serie 2000 incluye principalmente aleaciones de cobre, mientras que la serie 6000 combina magnesio y silicio con aluminio.

Cómo afectan los tratamientos superficiales a la conductividad del aluminio

El tratamiento superficial del aluminio puede modificar su comportamiento eléctrico. Naturalmente, el aluminio forma una capa de óxido muy fina que no es conductora. Para aumentar su durabilidad, el aluminio suele anodizarse, lo que engrosa la capa de óxido y aumenta la resistencia a la corrosión, pero también crea una capa aislante que no conduce la electricidad. Otros tratamientos, como el recubrimiento en polvo, el tratamiento térmico, la pintura o los revestimientos plásticos, también pueden influir en la conductividad. A veces, analizar la relación entre la conductividad medida de un conductor y su valor IACS ayuda a identificar el tipo de tratamiento térmico al que ha sido sometido.

Dónde se utiliza el aluminio en productos eléctricos y electrónicos

Alambres y cables

El alambre de aluminio es muy popular en las líneas eléctricas aéreas porque es mucho más ligero que el cobre (pesa aproximadamente un tercio), lo que ayuda a minimizar el pandeo del cable. Aunque el cobre sigue siendo el material preferido en hogares y obras, el aluminio se utiliza mucho en entornos industriales y centrales eléctricas. En algunos casos, los cables de aluminio de alto rendimiento de la serie 8000 se utilizan incluso para el cableado doméstico.

Componentes eléctricos

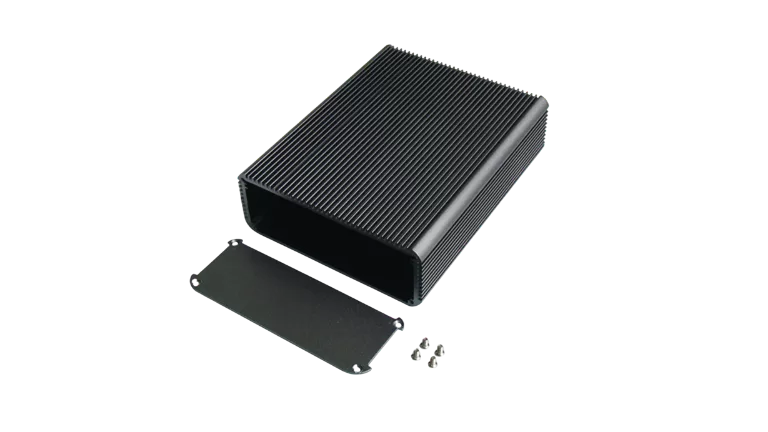

Desde pequeños conectores hasta grandes dispositivos electrónicos, la buena conductividad y ligereza del aluminio lo convierten en el material favorito para muchos componentes eléctricos. También se utiliza mucho en vehículos eléctricos, donde las carcasas de aluminio de los motores y otras piezas ayudan a compensar el gran peso de las baterías.

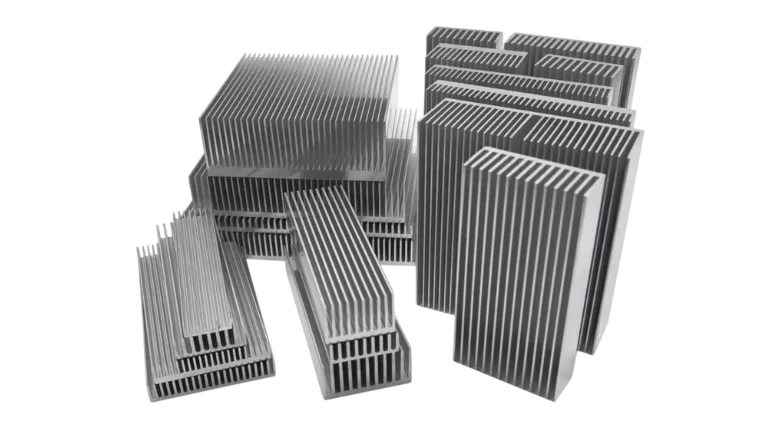

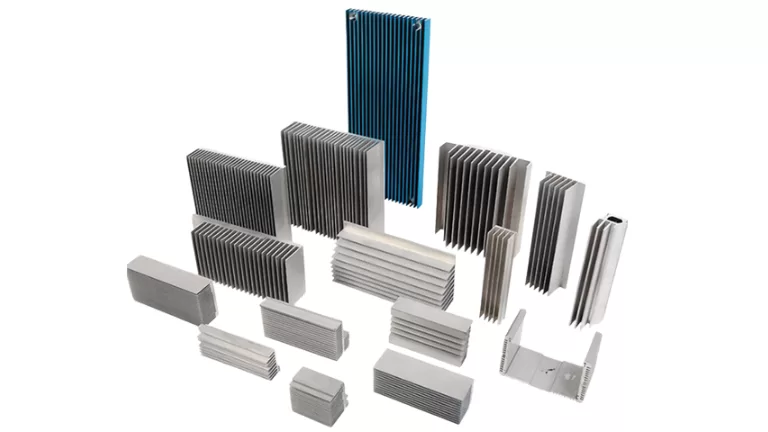

Disipadores de calor

La excelente conductividad térmica del aluminio lo hace ideal para disipadores de calor, que ayudan a refrigerar aparatos electrónicos como ordenadores, procesadores, dispositivos de iluminación y amplificadores. Al maximizar la disipación del calor, los disipadores de calor de aluminio mantienen los dispositivos funcionando sin problemas y con eficiencia.

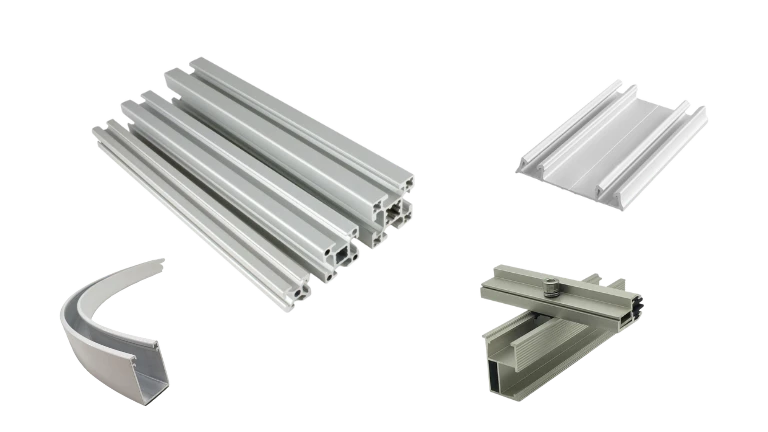

Capacidad de procesamiento de perfiles de aluminio

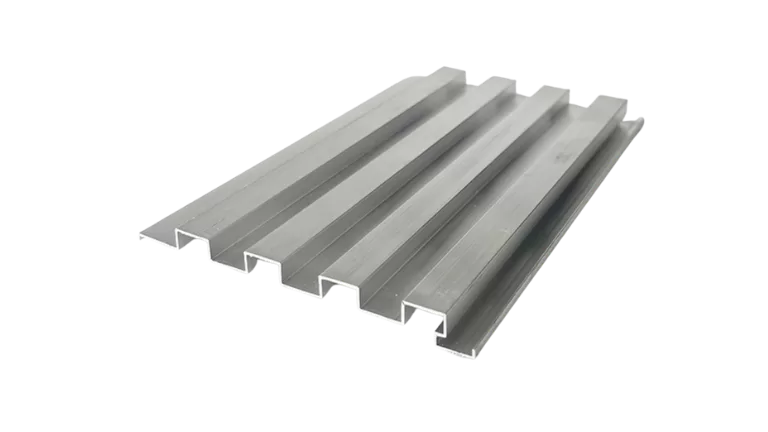

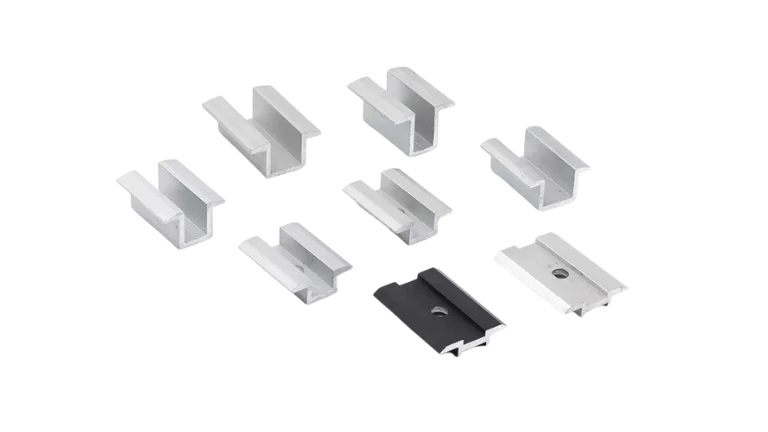

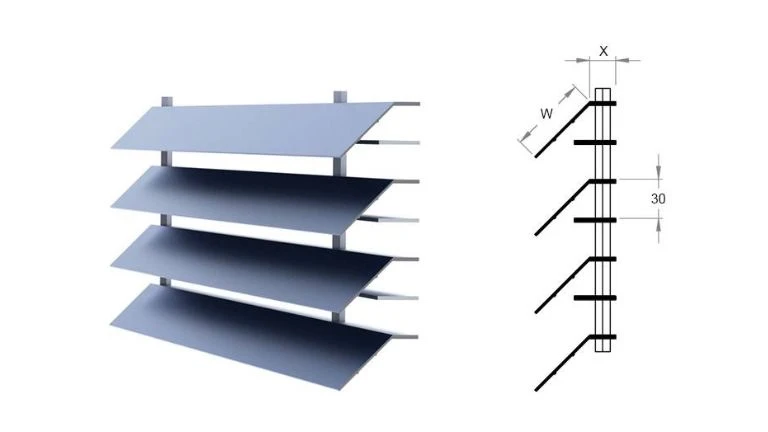

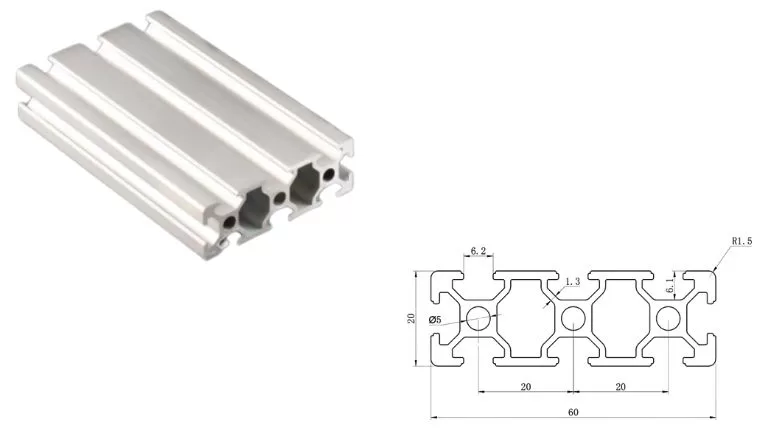

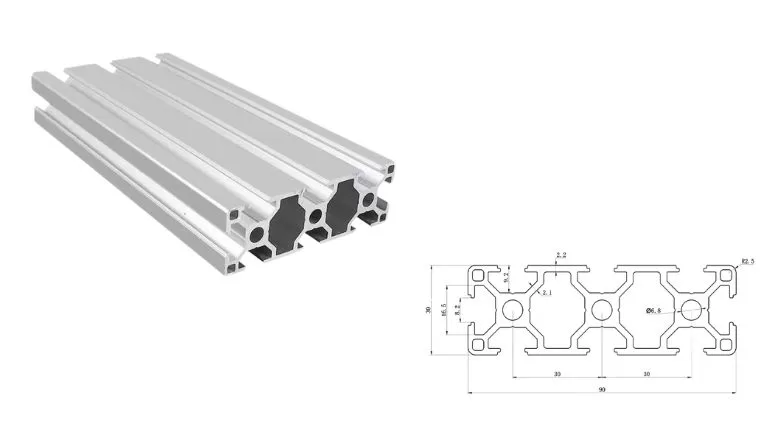

Como líder fabricante de extrusión de aluminio con sede en China, estamos comprometidos con el suministro de perfiles de aluminio de alta calidad para una amplia gama de industrias. Nuestras capacidades comienzan con el diseño y la fabricación de moldes personalizados, garantizando formas de extrusión precisas que satisfagan las necesidades específicas de nuestros clientes. Desde la extrusión en bruto hasta el acabado de superficies y el mecanizado avanzado, nuestros procesos de fabricación totalmente integrados nos permiten suministrar perfiles de aluminio que cumplen las normas más exigentes y satisfacen los requisitos exclusivos de cada proyecto.

Nuestras instalaciones de producción albergan más de 40 líneas de extrusión avanzadas, con equipos de vanguardia como una potente prensa de extrusión de 6000 toneladas. Esto permite crear perfiles de aluminio de diversos tamaños y formas, desde aplicaciones industriales estándar hasta productos especializados como perfiles de rotura de puente térmico para puertas y ventanas de alta gama. La flexibilidad de nuestra capacidad de extrusión nos permite atender a un amplio espectro de sectores, como la construcción y la ingeniería de precisión.

Nuestras instalaciones de producción albergan más de 40 líneas de extrusión avanzadas, con equipos de vanguardia como una potente prensa de extrusión de 6000 toneladas. Esto permite crear perfiles de aluminio de diversos tamaños y formas, desde aplicaciones industriales estándar hasta productos especializados como perfiles de rotura de puente térmico para puertas y ventanas de alta gama. La flexibilidad de nuestra capacidad de extrusión nos permite atender a un amplio espectro de sectores, como la construcción y la ingeniería de precisión.

Contamos con la experiencia necesaria para diseñar y producir moldes de extrusión en nuestras instalaciones, lo que garantiza la precisión y la eficacia en la fabricación de perfiles de aluminio. Nuestro experimentado equipo trabaja en estrecha colaboración con los clientes para desarrollar moldes personalizados a partir de planos o muestras, garantizando un rendimiento óptimo para sus requisitos específicos. Normalmente, el proceso de producción de moldes dura unos 7 días, tras los cuales proporcionamos muestras para que el cliente las confirme antes de iniciar la producción a gran escala.

Contamos con la experiencia necesaria para diseñar y producir moldes de extrusión en nuestras instalaciones, lo que garantiza la precisión y la eficacia en la fabricación de perfiles de aluminio. Nuestro experimentado equipo trabaja en estrecha colaboración con los clientes para desarrollar moldes personalizados a partir de planos o muestras, garantizando un rendimiento óptimo para sus requisitos específicos. Normalmente, el proceso de producción de moldes dura unos 7 días, tras los cuales proporcionamos muestras para que el cliente las confirme antes de iniciar la producción a gran escala.

Para una mayor durabilidad y atractivo visual, ofrecemos varias soluciones de tratamiento de superficies. Entre ellas se incluyen el anodizado para una mayor resistencia a la corrosión, el recubrimiento en polvo para acabados vibrantes, el recubrimiento de fluorocarbono para una mayor resistencia a la intemperie y la tecnología de transferencia de vetas de madera para diseños elegantes y de aspecto natural. Estos tratamientos se pueden personalizar para adaptarse a necesidades estéticas y funcionales específicas, garantizando que los perfiles no sólo funcionen bien, sino que también tengan un aspecto excepcional.

Para proporcionar soluciones completas de perfiles de aluminio, ofrecemos amplias capacidades de procesamiento posterior. Nuestros servicios incluyen mecanizado CNC, fresado, roscado, taladrado, corte de precisión, punzonado, soldadura y montaje. Esta gama de opciones de fabricación nos permite suministrar perfiles listos para usar y adaptados a las especificaciones exactas del proyecto, ofreciendo una flexibilidad y fiabilidad inigualables a nuestros clientes.

Extrusión de aluminio a medida

En HTS NUEVOS MATERIALESEstamos especializados en el suministro de extrusiones de aluminio personalizadas diseñadas para satisfacer sus necesidades específicas. Con instalaciones de producción avanzadas y más de 40 líneas de extrusión, suministramos perfiles de primera calidad diseñados con precisión para una amplia gama de sectores, como el aeroespacial, la automoción y la construcción, entre otros.

Nuestros servicios de extrusión a medida incluyen:

- Secciones transversales a medida: Cree perfiles de aluminio únicos con nuestras capacidades de troquelado experto, personalizados para adaptarse a las necesidades específicas de su proyecto.

- Diversos acabados superficiales: Mejore tanto el aspecto como la durabilidad de sus perfiles con opciones como anodizado, recubrimiento en polvo, pulido y mucho más.

- Mecanizado de precisión: Garantice una precisión dimensional exacta con servicios de corte, taladrado, fresado y mecanizado avanzado.

- Temperaturas flexibles: Seleccione entre una variedad de tratamientos térmicos, incluidos T5, T6 y otros, para conseguir las propiedades mecánicas ideales para su aplicación.

Asociarse con HTS NUEVOS MATERIALES para soluciones de extrusión de aluminio a medida innovadoras, rentables y fiables que impulsen el éxito de su proyecto.