Custom Industry Aluminum Profile Extrusion

Industrial aluminum profiles are engineered extrusions used across various sectors due to their strength, lightness, and adaptability. These profiles are shaped by forcing aluminum through a die, resulting in precise cross-sections for diverse applications. Commonly found in construction, transportation, and manufacturing, they provide critical support and structure while offering the flexibility to be customized for specific needs.

Our company, situated in a key industrial hub, excels in producing custom aluminum profiles tailored to client specifications. We leverage the material’s natural durability and our advanced manufacturing techniques to deliver profiles that offer both performance and longevity. Whether for intricate machinery components or robust architectural frameworks, our factory is dedicated to providing bespoke solutions that drive industry innovation.

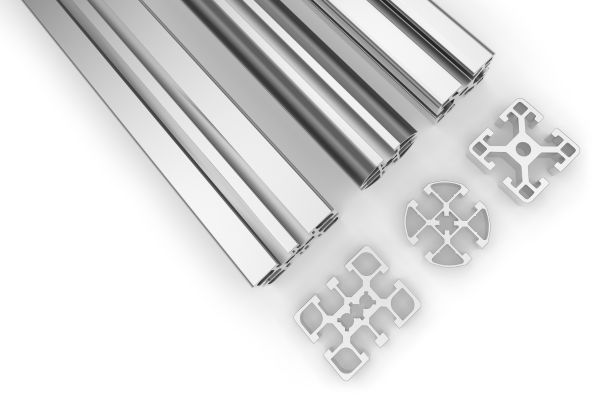

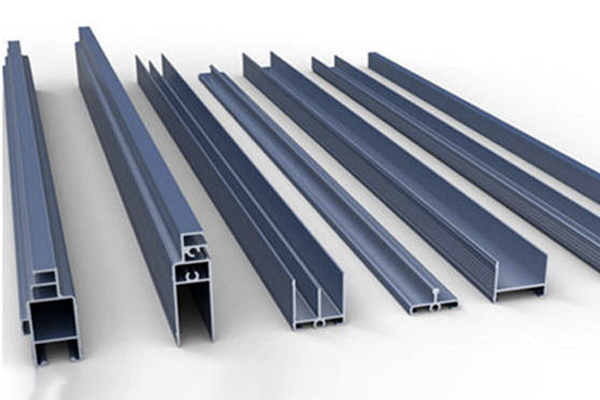

T-Slot Aluminum Profiles

T-Slot aluminum profiles are known for their versatility and ease of assembly, making them a popular choice for building modular structures such as workbenches, machine guards, and custom enclosures. The T-shaped slots allow for the attachment of various components and accessories without the need for drilling or welding, facilitating quick and flexible construction.

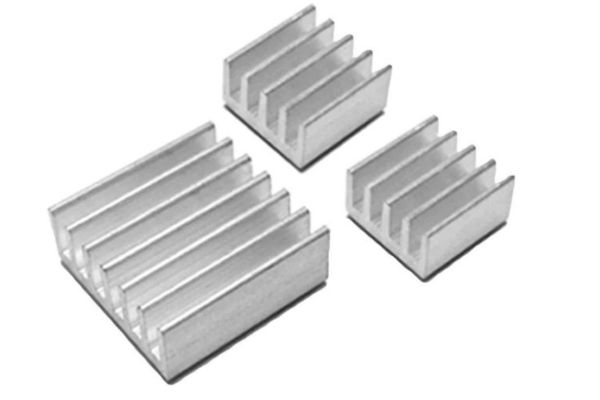

Aluminum Heatsink Profiles

Aluminum heatsink profiles are designed to dissipate heat in electronic devices and LED lighting systems. Their high thermal conductivity and surface area efficiently manage heat, which is critical for maintaining the performance and longevity of heat-generating components. These profiles come in various shapes and sizes to cater to different cooling requirements.

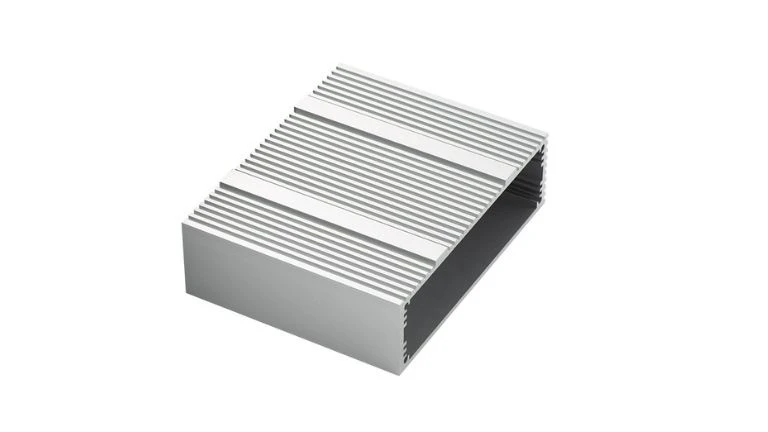

Aluminum Enclouse Profiles

Aluminum enclosures are designed to protect electronic components, industrial equipment, and other sensitive systems from environmental factors such as dust, moisture, and impact. Their lightweight, durable, and corrosion-resistant properties make them ideal for a wide range of applications. These enclosures are available in various sizes and configurations to meet diverse industry needs, ensuring both functionality and aesthetic appeal.

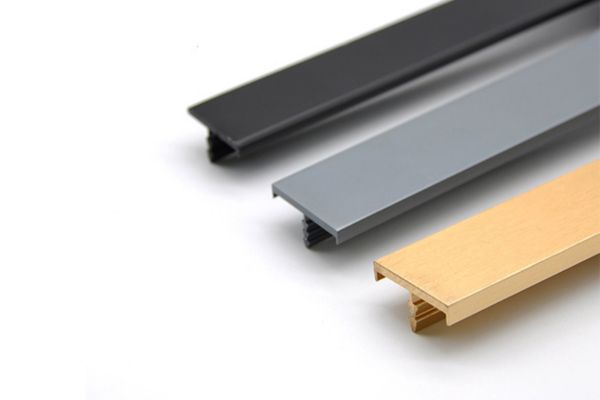

Aluminum Profiles for LED Strips

Aluminum profiles for LED strips are designed to house and protect LED lighting strips while also acting as a heat sink to extend the life of the LEDs. They come in various shapes that can be recessed into surfaces or mounted externally, providing a sleek and modern look to lighting installations.

Aluminum Profiles for Solar Panels

Aluminum profiles for solar panels are used to create durable and lightweight mounting systems for photovoltaic installations. These profiles are engineered to withstand environmental stresses while providing a secure foundation for solar modules, contributing to the overall efficiency and sustainability of solar energy systems.

Aluminum Profiles for Trim

In the realm of decorative applications, aluminum profiles offer a sleek and contemporary look. They are used for creating decorative trims, ceiling accents, and custom furniture. The malleability of aluminum allows for intricate designs, while its durability ensures that the aesthetic appeal lasts for years.

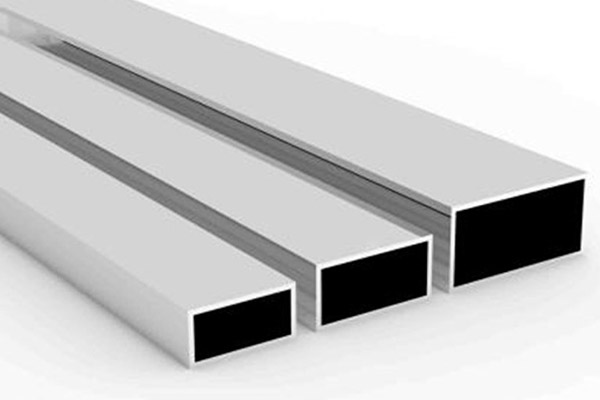

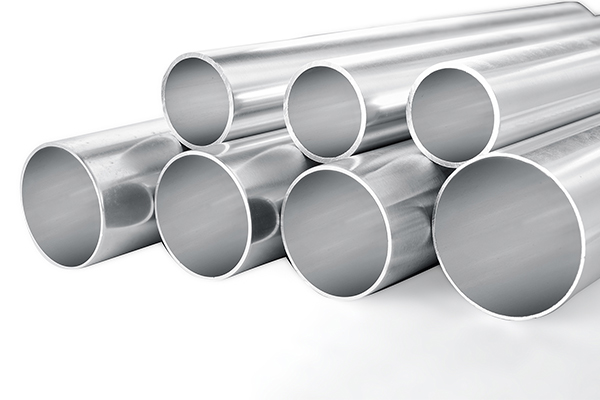

Aluminum Section Shapes

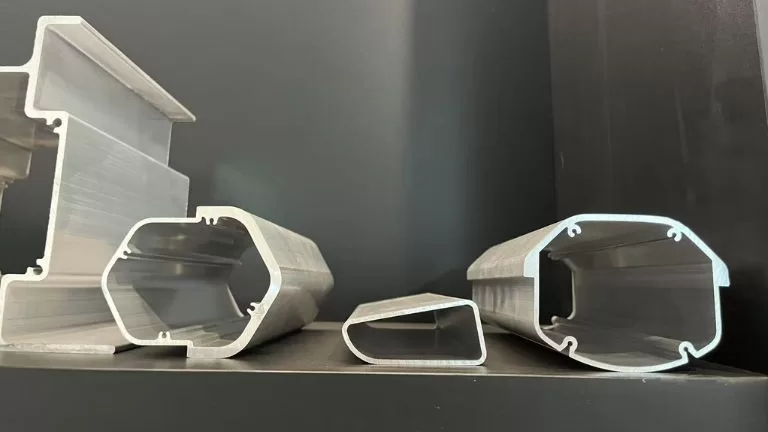

Customize Your Aluminum Profile

As a factory with advanced industry aluminum extrusion capabilities, we take pride in our ability to customize profiles to any degree of complexity. Our state-of-the-art machinery and skilled workforce enable us to produce profiles with intricate designs, precise tolerances, and superior finishes. Whether it’s a small batch of specialized components or a large-scale production run, our factory is equipped to handle orders of all sizes with the same level of precision and efficiency.

Common Aluminum Profile Alloy Grades

Choosing the right alloy and heat treatment for industrial aluminum profiles is crucial for ensuring optimal performance in various applications. Our team of experts advises on the best material grade that provides the necessary tensile strength, corrosion resistance, and workability. We consider factors such as environmental exposure, mechanical loads, and manufacturing processes to recommend the most suitable aluminum alloy.

6061: This is a precipitation-hardened aluminum alloy, containing magnesium and silicon as its major alloying elements.

6063: This alloy is often used for extrusion applications. It contains silicon and magnesium as the major alloying elements.

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

|---|---|---|---|---|---|---|---|---|

| 6061 | 0.4~0.8 | 0.7 | 0.15~0.40 | 0.15 | 0.8~1.2 | 0.04~0.35 | 0.25 | 0.15 |

| 6063 | 0.2~0.6 | 0.35 | 0.10 | 0.10 | 0.45~0.9 | 0.10 | 0.10 | 0.10 |

Surface Treatments for Industrial Aluminum Profiles

Surface treatment for aluminum window profiles serves two important purposes: protection and customization. There are several straightforward methods for this. Anodizing involves creating a protective oxide layer through an electrochemical process, providing corrosion resistance. Electrophoretic coating (e-coating) ensures even coverage and enhanced durability. Powder coating uses dry powder for a tough, colorful finish. PVDF coating offers excellent weather resistance. Wood grain transfer printing replicates a wood texture for a natural look. Each of these methods caters to different needs, from safeguarding against the elements to achieving a desired aesthetic for aluminum window profiles.

How does custom window aluminum extrusion work

Step 1: Our engineer will review your detailed size or drawing and provide a cross-sectional drawing for your confirmation.

Step 2: We open dies for your custom extrusion, create a sample, and send it to you for approval.

Step 3: If modifications are needed, we adjust the die size until you are satisfied with the sample.

Step 4: We inspect the raw material using a spectrum analyzer and proceed with extrusion production, providing weekly progress updates.

Step 5: Depending on your desired surface finish, we offer anodizing, electrophoresis, powder coating, or PVDF options.

Step 6: To ensure safe transportation, we carefully pack your products to avoid any damage.

Our Factory

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer based in China. We specialize in various stages of aluminum profile production, from mold design and melting to extrusion, oxidation, electrophoresis, coating, and polishing, providing a comprehensive range of services.

Our product range encompasses aluminum profiles suitable for windows and doors (including thermal break section), industrial applications (T-slot, channel, tubing), and photovoltaic systems. Situated in Jiangxi, our spacious production facility covers 30,000 square meters and employs over 200 skilled professionals, enabling us to produce more than 10,000 metric tons of aluminum profiles annually.

At HTS NEW MATERIALS, we also offer various surface treatments, including anodizing, electrophoretic coating, powder coating, PVDF coating, and wood grain transfer printing, to enhance both functionality and appearance. Whether it’s for construction, industry, or renewable energy, our high-quality aluminum profiles are ready to meet your specific needs.