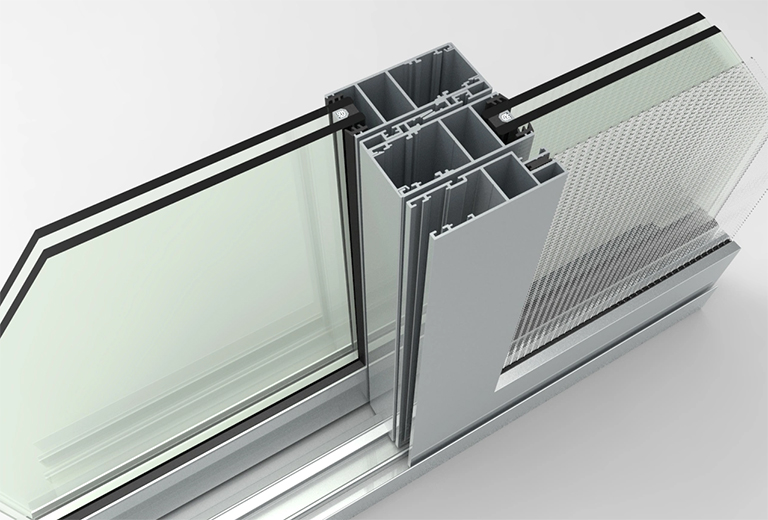

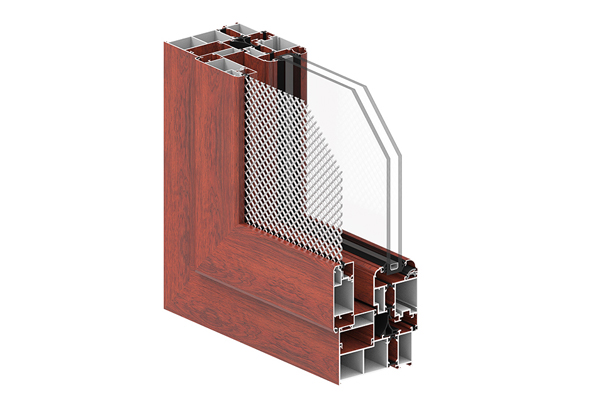

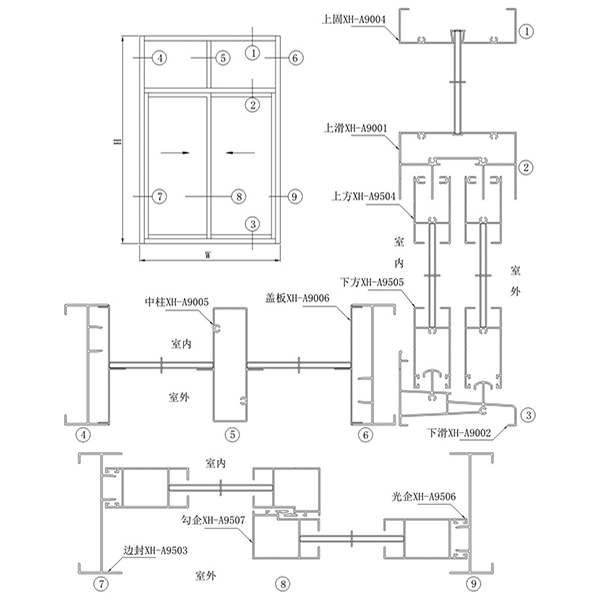

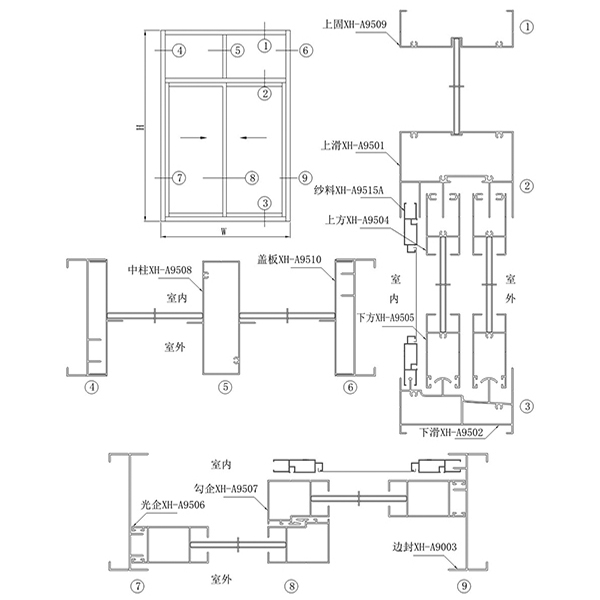

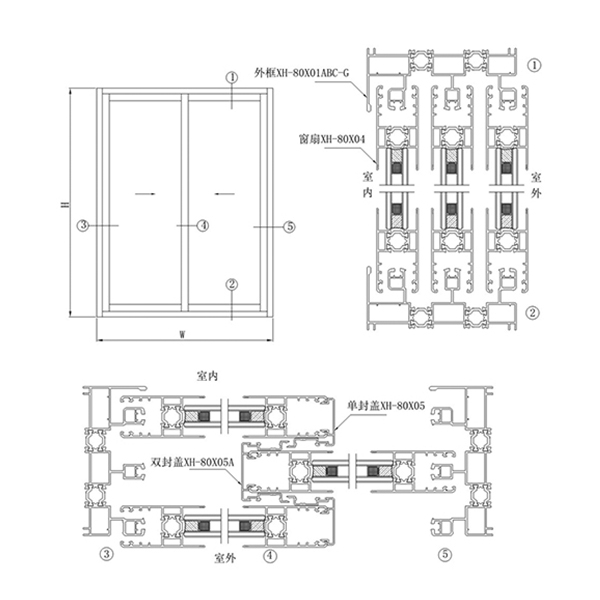

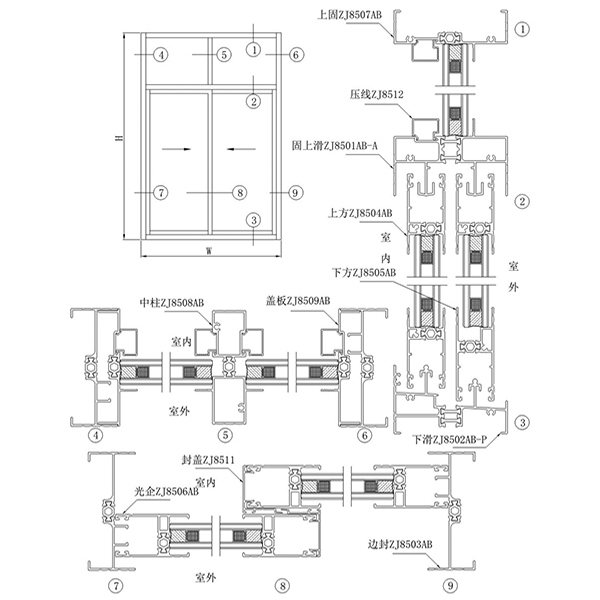

Sliding Window Aluminium Section

Sliding windows are a popular choice for many homeowners and businesses due to their functionality, aesthetics, and energy efficiency. Among the various materials used for sliding windows, aluminium is widely favored for its durability, strength, and low maintenance requirements. This overview will provide a comprehensive understanding of sliding window aluminium sections, highlighting their key features, benefits, and applications.

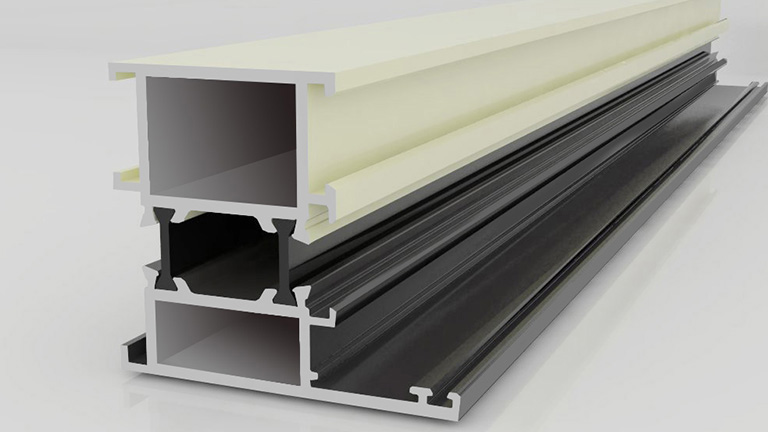

Aluminium sliding window sections refer to the profiles or frames made from aluminium alloy that are used to construct sliding windows. These sections are engineered to provide structural integrity while allowing the smooth movement of the window panels horizontally along a track or rail system. The aluminum material offers excellent strength-to-weight ratio, corrosion resistance, and weatherproofing properties, making it an ideal choice for window frame material.

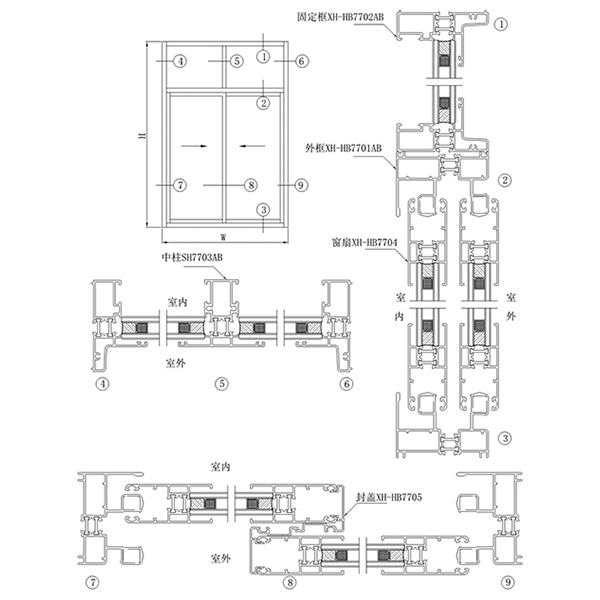

Sliding Window Aluminium Frame

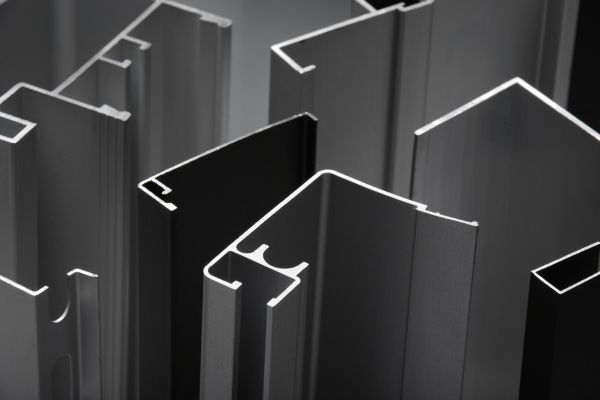

Customize Your Aluminum Profile

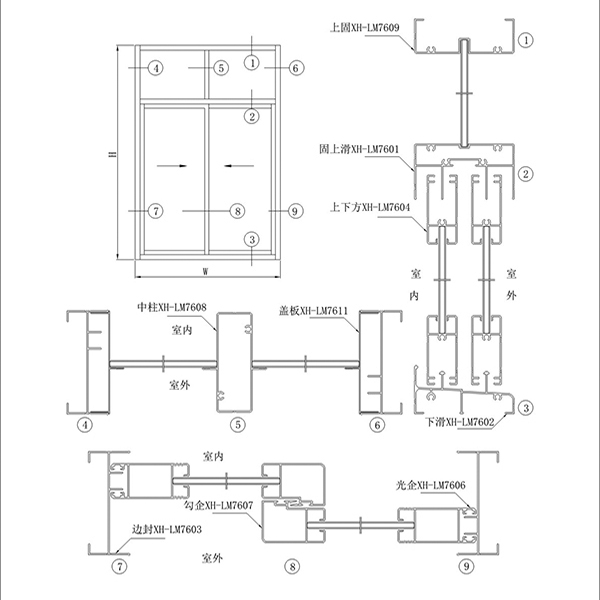

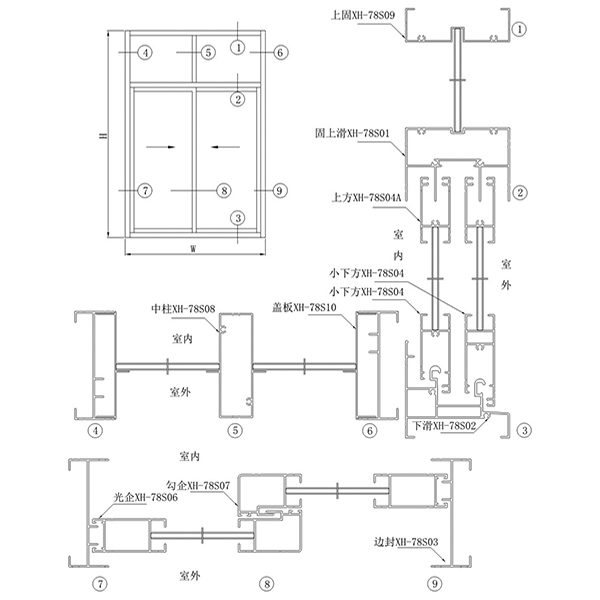

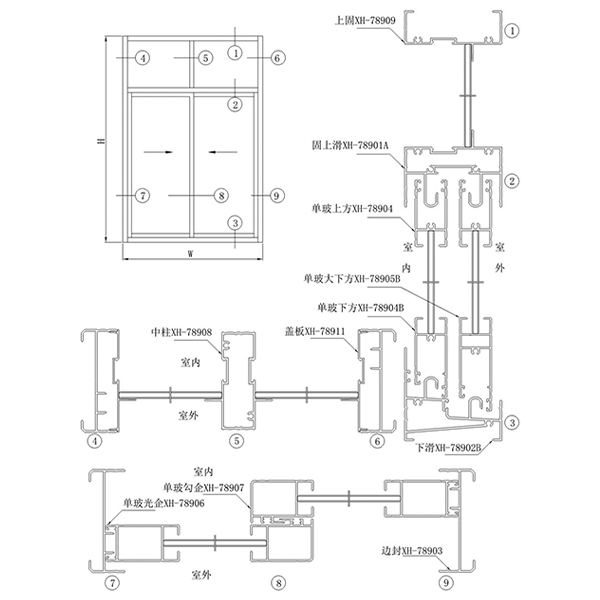

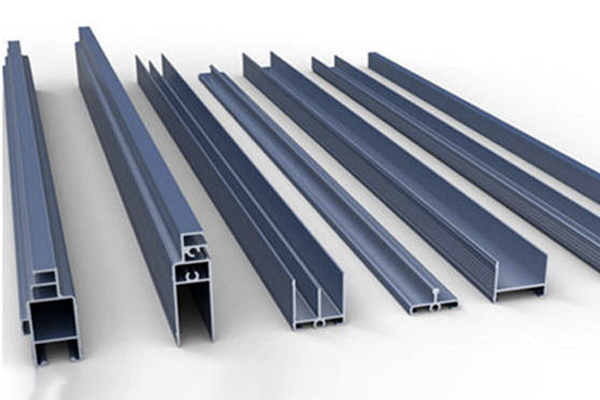

Specification

| Material | 6000 Series aluminum alloy |

| Temper | T3-T8 |

| Thickness |

General profiles thickness: 0.8mm—1.4mm; Anodizing protection thickness: 8-12 micron; Normal powder coated thickness: 60-100 micron |

| Surface treatment | Anodizing, Electroplating, Polishing, Sandblasted, Powder coating, Brushed, PVDF, etc. |

| Color | Customized Color |

| MOQ | 500KG |

| Delivery time | 15-20 days after sample confirmed & down payment, or negotiated |

| Port | Guangzhou,Ningbo, Shanghai |

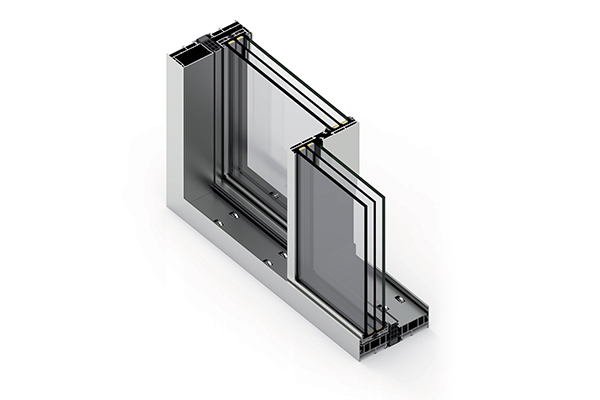

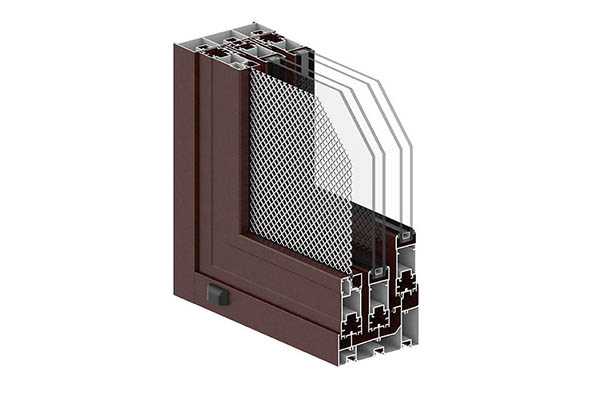

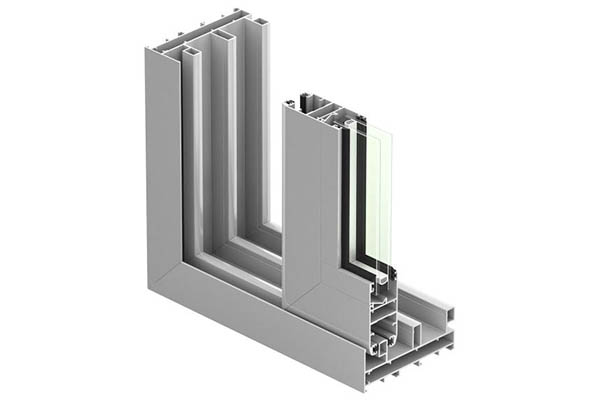

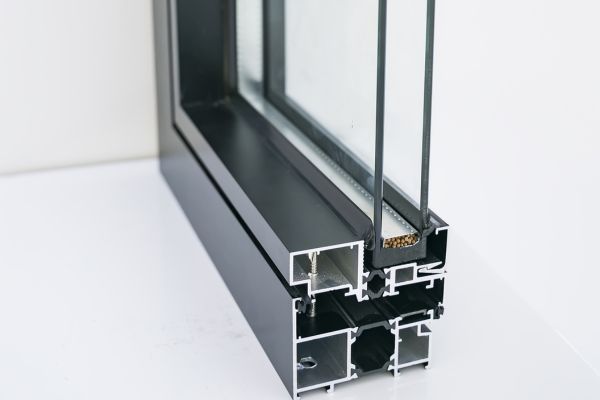

Finished Windows

Reliable Windows Aluminium Profiles Supplier

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer from China. With expertise in mold design, melting, extrusion, oxidation, electrophoresis, coating, and polishing, we offer a comprehensive range of services.

Our product portfolio includes aluminum profiles for windows and doors, industrial applications, and photovoltaic systems. Located in Jiangxi, our production facility spans 30,000 square meters and employs over 200 skilled professionals, allowing us to produce over 10,000 metric tons of aluminum profiles annually.

Sliding Window Frame

The Sliding Window redefines convenience and modern design. Operating horizontally, it effortlessly glides to open, maximizing space utilization. Its sleek profile and smooth functionality make it an excellent choice for contemporary homes and offices, offering unobstructed views and efficient ventilation. Ideal for those who value both aesthetics and practicality in their windows.

Casement Window Frame

The Casement Window epitomizes timeless sophistication. Its hinged design, swinging open like a door, adds a touch of classic charm while enabling excellent ventilation control. This window style suits various architectural themes, offering versatility and energy efficiency. With options for top-hung, side-hung, or bottom-hung sashes, it caters to diverse preferences, making it a quintessential choice for those seeking elegance and functionality in their windows.

Awning Window Frame

The Awning Window stands as a testament to functional elegance. Through its innovative top-hinged design, it opens outward, inviting in breezes while providing a shield against rain. This proves particularly advantageous for spaces like kitchens and bathrooms, where ventilation remains paramount even during light showers. Beyond its practicality, the Awning Window contributes a touch of contemporary aesthetics to various settings, making it a versatile and sought-after choice for both residential and commercial spaces.

Tilt & Turn Window Frame

The Tilt & Turn Window stands at the forefront of modern innovation. This versatile window type allows for two distinct opening modes: tilting inward at the top for gentle ventilation and turning inward from the side for easy cleaning and enhanced airflow. Its practicality is matched by its contemporary aesthetics, making it a popular choice for spaces where functionality and style converge. Whether it's about improving indoor air quality or embracing sleek design, the Tilt & Turn Window offers a seamless blend of form and function for today's discerning homeowners.

Folding Window Frame

The Folding Window introduces a new dimension to space and design. With its innovative folding mechanism, it smoothly transforms from a solid barrier to an open expanse, seamlessly connecting indoors and outdoors. This window style is a testament to versatility, offering panoramic views and ample ventilation when fully opened, while conserving space when closed. Its contemporary aesthetic and ability to merge convenience with aesthetics make it an ideal choice for those who seek a harmonious integration of architecture and nature in their living or work spaces.

Single Hung Window Frame

The Single Hung Window is a blend of simplicity and functionality. The bottom sash is movable, allowing controlled airflow, while the top sash remains fixed. This classic design offers a timeless appeal, making it a popular choice for traditional and modern homes alike. Its straightforward operation and clean lines add a touch of elegance to any space, while its energy efficiency ensures comfort and savings. The Single Hung Window embodies a balance of style and practicality, perfect for those who appreciate understated beauty and reliable performance.

Double Hung Window Frame

The Double Hung Window marries tradition with adaptability. Both upper and lower sashes are operable, facilitating efficient airflow and easy cleaning. Its timeless design suits various architectural styles, providing a classic look while incorporating modern functionalities. This window type offers versatility for controlling ventilation, making it ideal for bedrooms, living spaces, and more. With its harmonious blend of aesthetics and practicality, the Double Hung Window continues to be a favored choice, offering a seamless connection between the past and the present in any home or building.

Fixed Window Frame

The Fixed Window captures the essence of architectural refinement. It remains immobile, serving as a visual frame to panoramic views and a source of abundant natural light. This design choice embodies a sleek, modern aesthetic, enhancing the visual appeal of interiors while providing a sense of spaciousness. The Fixed Window, with its seamless blend of form and function, is a testament to the power of simplicity in elevating both residential and commercial spaces.

Surface

Surface treatment for aluminum window profiles serves two important purposes: protection and customization. There are several straightforward methods for this. Anodizing involves creating a protective oxide layer through an electrochemical process, providing corrosion resistance. Electrophoretic coating (e-coating) ensures even coverage and enhanced durability. Powder coating uses dry powder for a tough, colorful finish. PVDF coating offers excellent weather resistance. Wood grain transfer printing replicates a wood texture for a natural look. Each of these methods caters to different needs, from safeguarding against the elements to achieving a desired aesthetic for aluminum window profiles.

Anodizing

The aluminum profiles are immersed in an acidic solution and undergo electrolytic oxidation to form an oxide film. Anodizing enhances the corrosion resistance, hardness, and surface smoothness of the aluminum profiles. It can also be used with dyeing agents to achieve different colors.

Class of oxide film: AA10; AA15; AA20

Surface type: Matte; flat

Color: Silver white; bronze; champagne

Fetures: Corrosion resistant; durable; shining and decorative

Electrophoretic Coating

The charged aluminum profiles are immersed in a coating solution in an electrolytic tank. Through electrophoresis, the coating evenly adheres to the aluminum surface. Electrophoretic coating provides good weather resistance, color stability, and a smooth and uniform coating.

Corrosion resistance of composite film: ≥9.5 level

Paint film cohesive: Zero lever

Paint film hardness: ≥3H

Surface: Matte; flat; high brightness

Color: Silver white; bronze; champagne

Features: Corrosion resistant; durable; smooth and shining

Powder Coating

Powdered coating material is sprayed onto the aluminum profiles, and then melted and cured at high temperatures. Powder coating offers durability, corrosion resistance, and a pleasing appearance. It is also environmentally friendly.

Coat thickness:40-120um

Coat shock resistance: No cracking or fall off after shock test

Coat cohesion: Zero lever

Surface type: Highly glossy; semi glossy; matte

Color: Ral color

Features: Variety of colors

PVDF Coating

PVDF coating, a type of spray coating, utilizes a PVDF resin-based paint that provides exceptional resistance to weathering, UV radiation, and chemicals, making it suitable for demanding outdoor applications.

Coat thickness:30-65um

Coat shock resistance: No cracking or fall off after shock test

Coat cohesion: Zero lever

Glossiness: 60°

Features: With metallic luster, bright color, high weather resistance

Wood Grain Transfer

This process involves transferring wood grain patterns or textures onto the aluminum profiles using a transfer method. It gives the aluminum profiles the appearance of wood while retaining the advantages of aluminum, such as weather resistance and corrosion resistance.

Surface texture: Wooden; marble

features: Wood-like visual experience

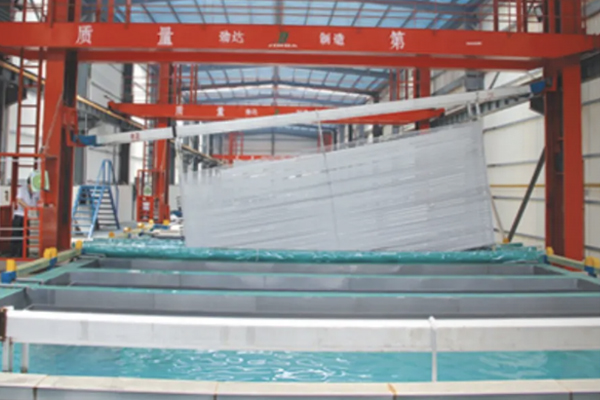

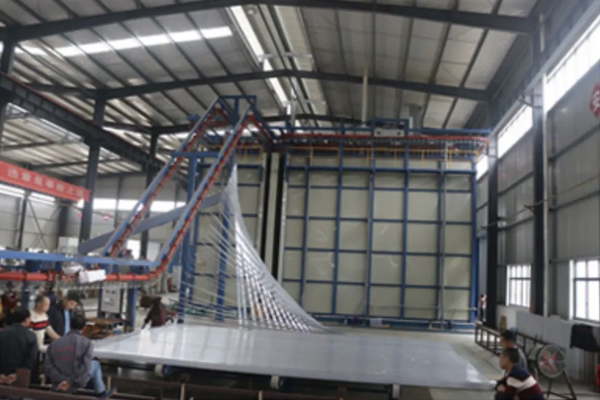

Factory

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer based in China. We specialize in various stages of aluminum profile production, from mold design and melting to extrusion, oxidation, electrophoresis, coating, and polishing, providing a comprehensive range of services.

Our product range encompasses aluminum profiles suitable for windows and doors (including thermal break section), industrial applications (T-slot, channel, tubing), and photovoltaic systems. Situated in Jiangxi, our spacious production facility covers 30,000 square meters and employs over 200 skilled professionals, enabling us to produce more than 10,000 metric tons of aluminum profiles annually.

At HTS NEW MATERIALS, we also offer various surface treatments, including anodizing, electrophoretic coating, powder coating, PVDF coating, and wood grain transfer printing, to enhance both functionality and appearance. Whether it’s for construction, industry, or renewable energy, our high-quality aluminum profiles are ready to meet your specific needs.

Raw Material

The aluminum profiles for doors and windows typically use common aluminum alloy grades, including 6061, 6063, and 6082. These aluminum alloy grades offer excellent mechanical properties, processability, and corrosion resistance, making them well-suited for manufacturing door and window profiles.

6061 Aluminum Alloy: It has high strength, excellent corrosion resistance, and weldability. It is suitable for manufacturing door and window profiles that require high strength and compressive capabilities.

6063 Aluminum Alloy: It is commonly used in the production of door and window profiles, offering good formability and corrosion resistance. It is suitable for creating profiles of various shapes and contours.

6082 Aluminum Alloy: It has high strength, good corrosion resistance, and mechanical properties. It is suitable for manufacturing door and window profiles that need to withstand high pressure and heavy loads.

Advantages of Using Aluminum Alloy Window

Lightweight: Aluminum is a lightweight material, making it easier to handle, transport, and install. This is especially beneficial for larger windows and doors, reducing the overall weight and strain on the structure.

Strength and Durability: Despite its lightweight nature, aluminum alloy is inherently strong and durable. It can withstand various weather conditions, including extreme temperatures, humidity, and UV radiation, without warping, cracking, or corroding. This ensures a longer lifespan for the doors and windows.

Low Maintenance: Aluminum alloy doors and windows require minimal maintenance. Unlike other materials, such as wood, aluminum does not require regular painting, sealing, or extensive upkeep. Occasional cleaning with mild soap and water is usually sufficient to keep them looking new.

Design Flexibility: Aluminum alloy can be easily extruded into various shapes, sizes, and profiles, allowing for versatile design options. This flexibility enables the creation of sleek, modern, and aesthetically pleasing doors and windows, while also accommodating different architectural styles.

Energy Efficiency: Aluminum profiles can be designed to incorporate thermal breaks and insulation materials, improving energy efficiency. This helps to reduce heat transfer and enhance insulation, resulting in lower energy consumption for heating and cooling, and potentially reducing energy costs.

Recyclability: Aluminum is a highly recyclable material, meaning that it can be recycled and reused without compromising its quality. Choosing aluminum alloy doors and windows contributes to sustainable practices and reduces environmental impact.

Sound Insulation: Aluminum profiles can be engineered to provide effective sound insulation, reducing external noise pollution and creating a more peaceful indoor environment.

Fire Resistance: Aluminum alloy is inherently fire-resistant, offering an added safety feature in case of a fire.

Excellent Thermal Insulation: Thermal break aluminum profiles utilize a combination of inner and outer frames with flexible connections. The frames are sealed with double seals, including one rubber strip and two wool strips, ensuring excellent air and water tightness. The window sashes are equipped with insulated glass, effectively improving sound insulation, heat insulation, and energy efficiency. The low U-value of the profiles demonstrates significant energy-saving effects, leading to long-term cost savings in heating and cooling expenses.

Waterproof Performance: The structural drainage system of thermal break aluminum windows and doors is designed based on the principle of pressure balance. The downward sloping design with step-like features and strategically placed drainage outlets ensures effective water drainage and excellent water tightness.

Frost and Condensation Prevention: The three-layer sealing structure of thermal break aluminum profiles effectively separates water vapor chambers, achieving a balance of air and water pressure. This significantly improves the water tightness and air tightness of doors and windows, preventing frost and condensation build-up.

Noise Insulation: The carefully designed structure of thermal break aluminum profiles ensures tight joints and optimal performance in noise insulation. Test results show that the air sound insulation rating reaches 30-40 dB, effectively reducing external noise disturbances. Residents living within 50 meters of a highway or in busy urban areas can enjoy a quiet and peaceful indoor environment.

How to Produce Aluminum Profile

Aluminum profiles for doors and windows are manufactured using high-quality aluminum alloys, specifically designed for their structural integrity, durability, and corrosion resistance. The primary raw material used in the production of these profiles is aluminum extrusion billets.

Aluminum extrusion billets are cylindrical logs or ingots made from a blend of aluminum and various alloying elements. These alloying elements, such as silicon, magnesium, manganese, and copper, are added in precise proportions to enhance the strength, ductility, and other desired properties of the final aluminum profiles.

The billets undergo a series of processes to convert them into the desired profiles for doors and windows. The first step is heating the billets to a specific temperature, making them soft and malleable. Then, they are forced through a specially designed die under high pressure, using an extrusion press. The die imparts the desired shape and cross-sectional profile to the aluminum, resulting in the extruded profiles.

After extrusion, the profiles undergo various finishing processes, such as cutting, machining, surface treatment, and powder coating. These processes further enhance the aesthetics, functionality, and durability of the profiles, making them suitable for use in doors and windows.

How to Select Aluminum Profiles

Define Your Requirements: Determine your specific requirements for the aluminum profiles. Consider factors such as the intended application, load-bearing capacity, thermal insulation needs, aesthetic preferences, and any specific industry standards or certifications that may be required.

Assess Material Quality: Check the material grade of the aluminum profiles. High-quality profiles often use standardized aluminum alloy grades such as 6061, 6063, or 6082. Verify if the profiles are made from pure aluminum or if they are alloyed with other elements to enhance their properties.

Physical Inspection: Physically inspect the profiles to evaluate their quality. Look for smooth and uniform surfaces, free from visible defects like scratches, dents, or irregularities. Check the dimensions and tolerances to ensure they meet your specifications.

Surface Treatment and Coating: Examine any surface treatments or coatings applied to the profiles. Anodized or powder-coated finishes are common for enhanced protection and aesthetics. Assess the quality and durability of the coating, ensuring it is uniform and resistant to corrosion, fading, and scratching.

Structural Integrity: Assess the strength and structural integrity of the profiles. Consider their load-bearing capacity, rigidity, and resistance to deformation. Profiles with proper heat treatment and extrusion techniques tend to exhibit better structural properties.

Certification and Compliance: Check if the aluminum profiles meet relevant industry standards and certifications. Look for certifications like ISO 9001 for quality management systems or specific industry certifications that demonstrate adherence to recognized quality standards.

How does custom window aluminum extrusion work

Step 1: Our engineer will review your detailed size or drawing and provide a cross-sectional drawing for your confirmation.

Step 2: We open dies for your custom extrusion, create a sample, and send it to you for approval.

Step 3: If modifications are needed, we adjust the die size until you are satisfied with the sample.

Step 4: We inspect the raw material using a spectrum analyzer and proceed with extrusion production, providing weekly progress updates.

Step 5: Depending on your desired surface finish, we offer anodizing, electrophoresis, powder coating, or PVDF options.

Step 6: To ensure safe transportation, we carefully pack your products to avoid any damage.