Custom Extrusion Aluminum Alloy Profile for Glass Railing

Overview

Aluminum railing profiles are integral components in the construction of railings for various settings, including residential balconies, commercial complexes, and public spaces. These profiles provide the structural framework for glass railings, contributing to the safety and aesthetic appeal of buildings. Their market application is vast due to their versatility and the value they add to properties.

Advantages of Extruded of Aluminum Railing

In the realm of modern construction, extruded aluminum railing profiles are highly regarded for their robustness, low maintenance requirements, and elegant aesthetics. These profiles, often crafted from aluminum alloys for superior strength, eclipse traditional materials like wood or steel by offering greater durability with less upkeep, even under harsh environmental conditions. Their resistance to corrosion and ability to withstand extreme weather while retaining their appearance makes them a preferred choice. The lightweight yet strong nature of extruded aluminum facilitates a more straightforward and economical installation process, ultimately yielding a durable railing system that embodies both functional excellence and modern design.

Aluminum Railing Section Solutions

Our factory’s capability to offer bespoke extruded aluminium profiles for glass railing systems is where our expertise truly shines. We embrace the following aspects to serve our clients.

Precision Aluminum Extrusion Process

The aluminum extrusion process exemplifies precision engineering, enabling us to mold aluminum alloy into intricate cross-sections that conform to exacting specifications. This precision is pivotal, as it guarantees that each extruded profile is meticulously customized to fulfill the specific structural and aesthetic demands of diverse projects with unwavering accuracy.

Material for Aluminium Profiles Railings

We meticulously select from a diverse array of aluminum alloys for our railings, choosing the optimal composition that not only balances weight and strength but also meets rigorous safety standards. This careful selection ensures enhanced corrosion resistance and provides a product that is not only enduring and elegant but also aligns with the highest safety benchmarks in the industry.

Aluminum Railing Structures and Installations

Our aluminum railing profiles are designed to cater to a multitude of structural forms and mounting methods. We produce profiles precisely according to the client’s specifications, whether they provide us with detailed drawings or physical samples. If required, we are also equipped to assist in the design process, tailoring our profiles to meet the unique demands and preferences of our clients, ensuring every aspect from the method of glass attachment to the shape of the handrail is meticulously crafted for an impeccable integration.

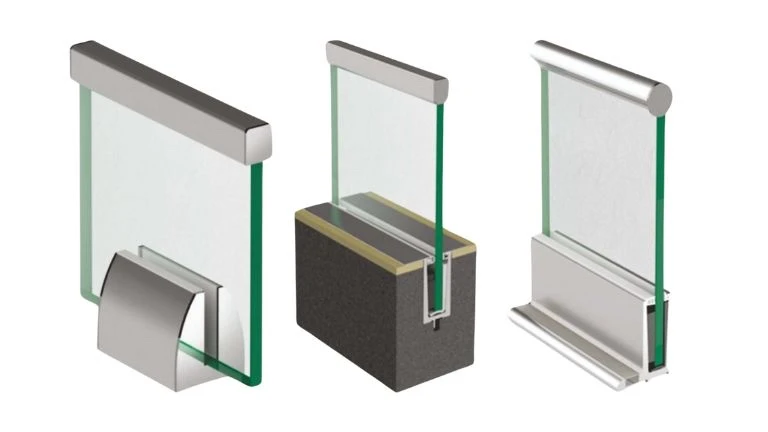

Aluminum profiles glass railings can be mounted using various methods, depending on the design requirements, structural considerations, and aesthetic preferences. Here are three common ground installation methods for aluminum profiles in glass railing systems:

Base Plate Mounting: This method involves attaching a base plate or flange to the bottom of the aluminum profile. The base plate is then anchored to the ground or floor surface using bolts. This is a popular method for installations where the surface is solid and can handle drilling, such as concrete or steel substrates. It provides a strong and stable foundation for the railing system.

Fascia or Side Mounting: In situations where top mounting is not possible or desired, the aluminum profile can be installed on the side of the floor or balcony edge. This method, also known as a fascia mount, involves securing the profile to the side rather than the top of the installation surface. It’s an excellent choice for preserving floor space and for achieving a clean, floating appearance of the glass railing.

Core Drill or In-Ground Mounting: Core drilling involves creating a cylindrical hole in the ground into which the aluminum profile is inserted and then secured with grout or another bonding agent. This method is often used for installations in solid surfaces where a seamless look is desired. It’s common in outdoor applications or where the railing needs to appear as if it’s growing out of the floor.

Aluminum Railing Profile Surface Treatment

The final touch to any aluminum railing profile is its surface treatment. From anodizing to powder coating, we provide a spectrum of finishes that protect and enhance the metal, adding to its visual appeal and longevity. Additionally, we offer the option to create wood grain finishes, allowing the railing to resemble the appearance of wood for a more natural aesthetic.

In addition to enhancing aesthetics, surface treatment of aluminum profiles can also improve their corrosion resistance, wear resistance, and weather resistance, thereby extending the product’s lifespan. Furthermore, surface treatment can provide special functions such as fire resistance, antistatic properties, and antibacterial properties, making aluminum profiles more practical and versatile in different environments and applications.

Custom Your Aluminum Profile

Let our expertise in custom aluminum profiles take your projects to the next level.

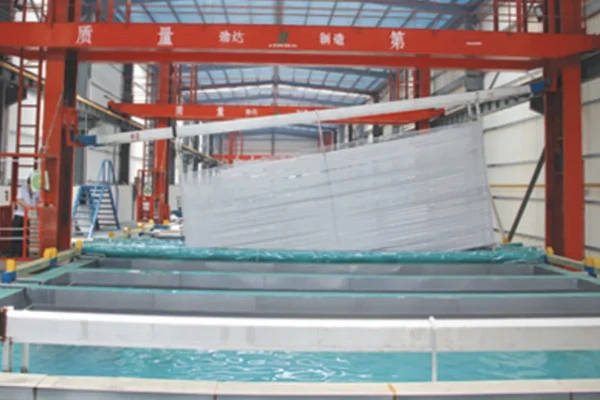

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer based in China. We specialize in various stages of aluminum profile production, from mold design and melting to extrusion, oxidation, electrophoresis, coating, and polishing, providing a comprehensive range of services.

Our product range encompasses aluminum profiles suitable for windows and doors (including thermal break section), industrial applications (T-slot, channel, tubing), and photovoltaic systems. Situated in Jiangxi, our spacious production facility covers 30,000 square meters and employs over 200 skilled professionals, enabling us to produce more than 10,000 metric tons of aluminum profiles annually.

At HTS NEW MATERIALS, we also offer various surface treatments, including anodizing, electrophoretic coating, powder coating, PVDF coating, and wood grain transfer printing, to enhance both functionality and appearance. Whether it’s for construction, industry, or renewable energy, our high-quality aluminum profiles are ready to meet your specific needs.