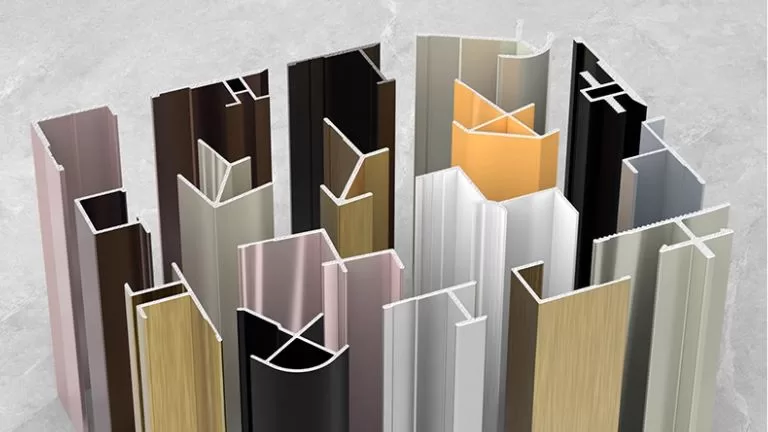

Aluminum Tile Trim for Edge and Corner Finishing

Aluminum Tile Edge Trim is a finishing profile designed to protect and enhance the edges of tiled surfaces. Serving as a decorative and protective transition piece, it covers sharp or unfinished tile edges, prevents chipping, and delivers a sleek, professional appearance. These trims are widely used for wall and floor tiles, ensuring clean and durable edges in various applications.

Available in multiple profiles, finishes, and colors, aluminum tile edge trims are perfect for creating visually appealing transitions between tiles and other materials. They provide both aesthetic enhancement and long-lasting protection, making them a versatile choice for residential, commercial, and industrial spaces.

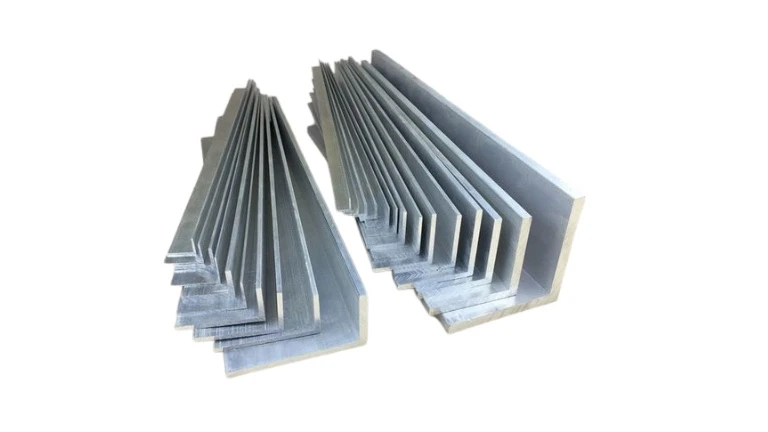

L Aluminum Tile Trim

L-Shaped Tile Trim provides a clean and polished edge for tiles, offering excellent protection for external corners and exposed areas. This trim is ideal for finishing edges smoothly while enhancing the overall appearance.

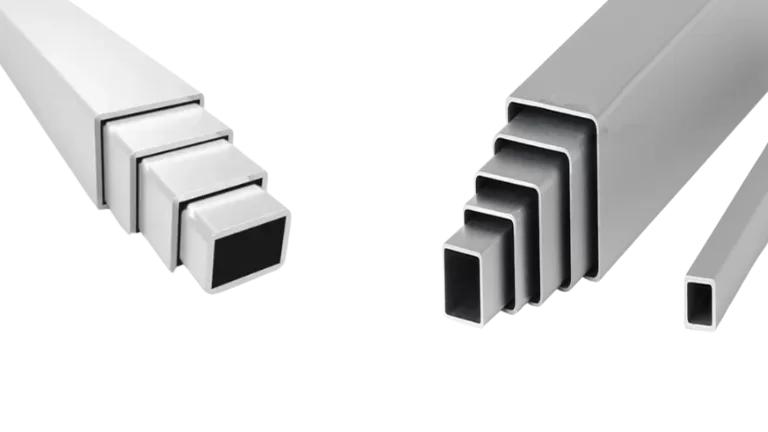

Box | Square Tile Trim

Box or Square Tile Trim features a squared design that enhances the stylish and modern appeal of tiled surfaces. Its sharp lines make it an ideal choice for contemporary interiors without over-complicating the finish.

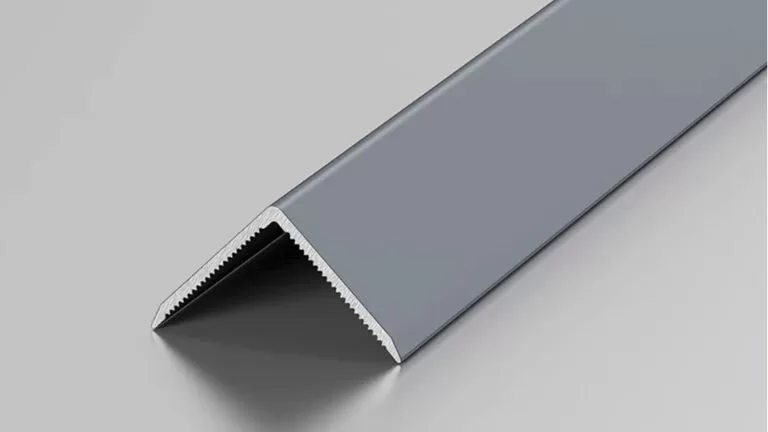

Triangular Aluminum Trim

Triangular or Beveled Tile Trim is designed with a slanted or triangular shape to ensure smooth and seamless transitions between tiled surfaces. Its unique profile adds elegance while maintaining functionality.

T-Shaped Tile Edging Trim

T-Shaped Tile Trim serves as a practical connector between two tiled surfaces of the same height. This trim simplifies the transition process while delivering a uniform and cohesive finish.

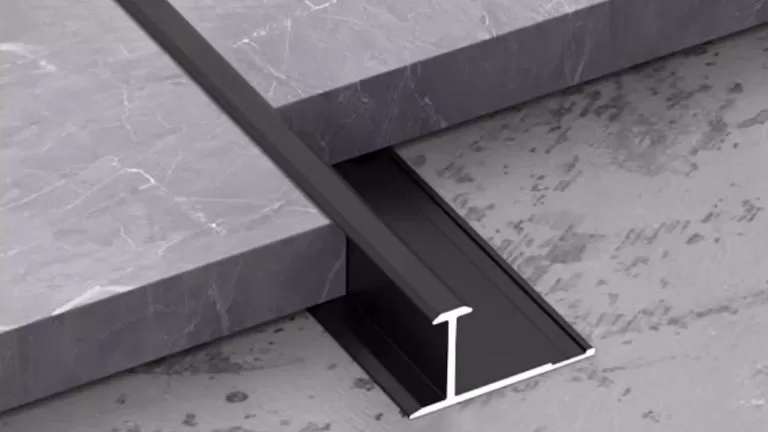

I-Shaped Tile Edging Trim

I-Shaped Tile Trim is perfect for filling and bridging gaps between separate tiles, offering additional strength where needed. Its simple profile ensures a clean and understated final look.

U-Shaped Aluminium Trim

U-Shaped Tile Trim provides complete edge protection, making it ideal for countertops, wall edges, or similar areas where durability matters. Its design enhances functionality without detracting from visual appeal.

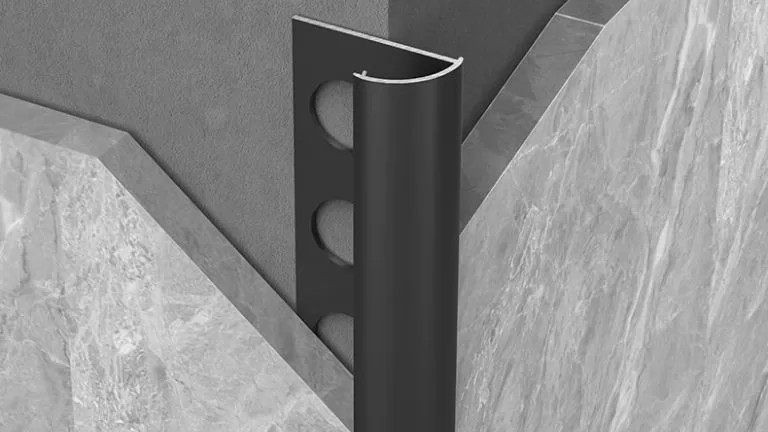

Round Aluminum Tile Trim

Round Tile Trim provides a curved and smooth edge for tiles, offering a soft and elegant appearance. It ensures seamless transitions between surfaces while enhancing safety by eliminating sharp edges, making it both stylish and practical.

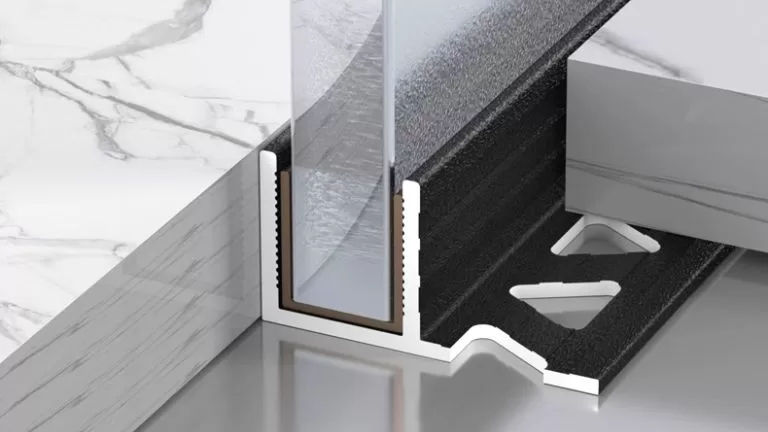

F Shaped Shower Profiles

F-Shaped Shower Profile is designed for waterproof and seamless transitions in shower areas. It connects tiled walls with glass or other surfaces while adding a sleek, minimalist look to modern bathrooms.

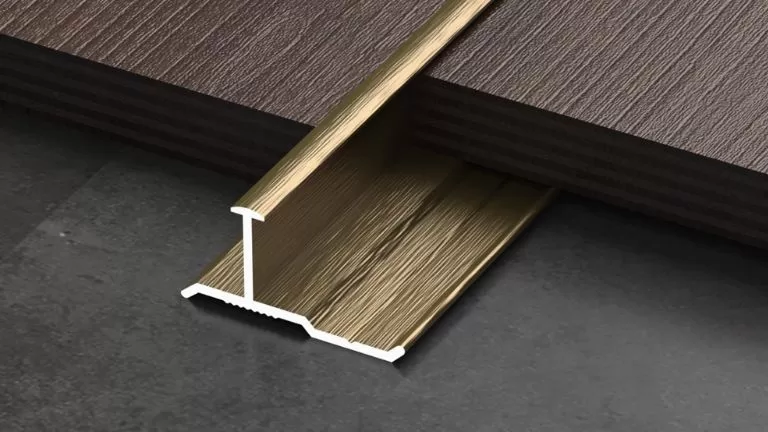

Aluminum H Trim

H-Shaped Tile Trim bridges two tiled surfaces at the same height, providing a uniform and stable finish. It combines durability and a clean appearance, ideal for kitchens, bathrooms, and other spaces.

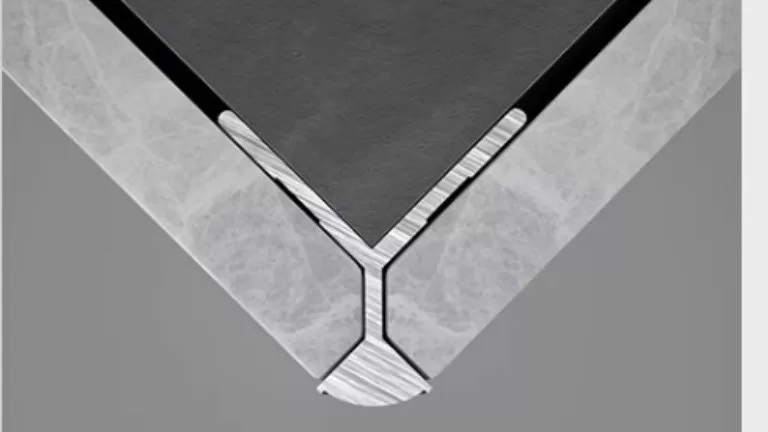

Aluminum Y Angle Trim

Y-Shaped Tile Trim combines functionality with elegance, enabling multiple surfaces to merge seamlessly. This trim is best suited for projects requiring both structural integrity and a stylish finish.

Outside Corner Trim

Outside Corner Trim is designed for external corners to provide a clean, polished look while protecting tile edges. This trim ensures durability and creates a professional finish for tiled surfaces.

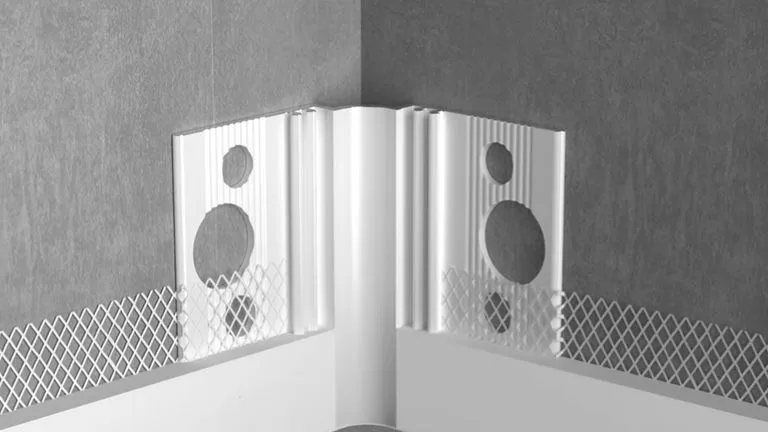

Inside Corner Trim

Inside Corner Trim is specialized for internal corners, creating a seamless and refined finish while adding extra protection. It ensures durability and enhances the overall aesthetic of tiled spaces.

Aluminum Tile Trim Processing Capabilities

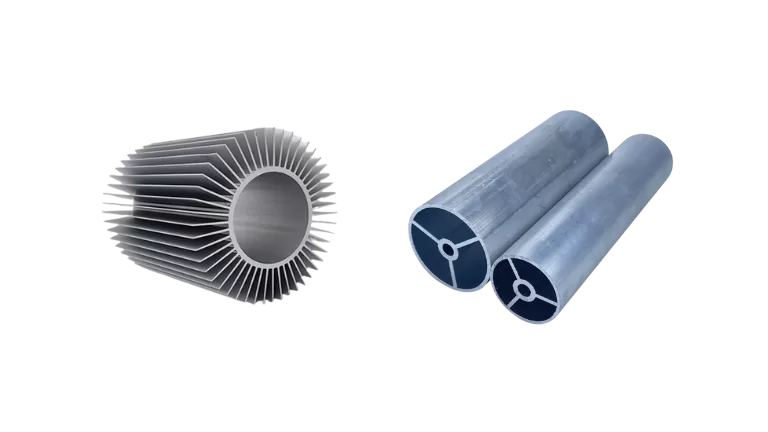

As a premier aluminum extrusion manufacturer in China, we specialize in producing high-quality aluminum tile trims to meet diverse industry needs. Our capabilities include custom mold design and manufacturing, allowing us to create extrusion shapes tailored to client specifications with precision. From raw aluminum extrusion to surface treatments and advanced machining, our comprehensive, in-house manufacturing processes ensure that every aluminum tile trim meets stringent quality standards while addressing the specific needs of each project.

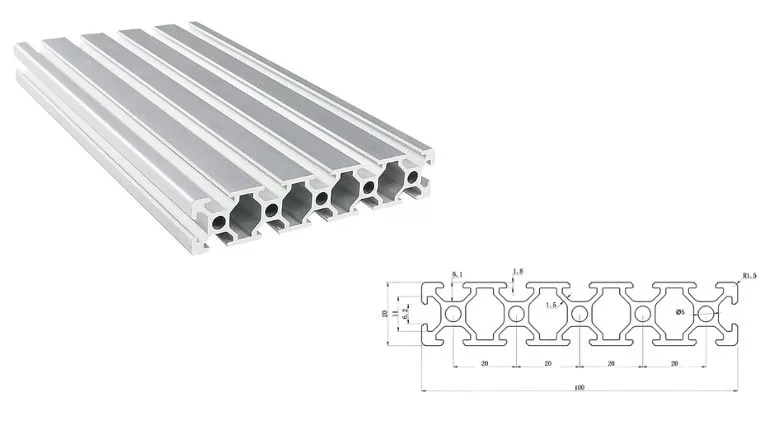

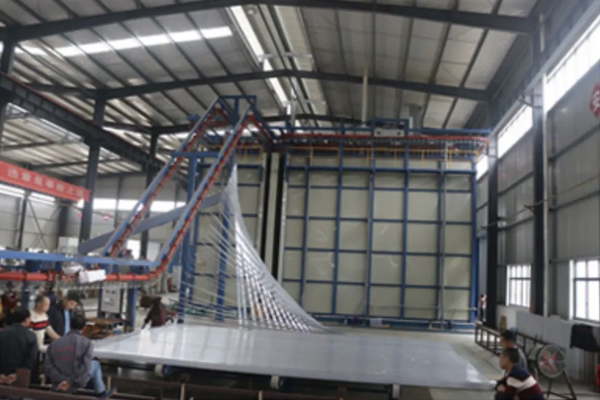

Our production facility houses over 40 advanced extrusion lines, featuring cutting-edge equipment such as a powerful 6000-ton extrusion press. This enables the creation of aluminum profiles in various sizes and forms, ranging from standard industrial applications to specialized products like thermal break profiles for high-end doors and windows. The flexibility of our extrusion capability ensures we can cater to a broad spectrum of industries, including construction and precision engineering.

Our production facility houses over 40 advanced extrusion lines, featuring cutting-edge equipment such as a powerful 6000-ton extrusion press. This enables the creation of aluminum profiles in various sizes and forms, ranging from standard industrial applications to specialized products like thermal break profiles for high-end doors and windows. The flexibility of our extrusion capability ensures we can cater to a broad spectrum of industries, including construction and precision engineering.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

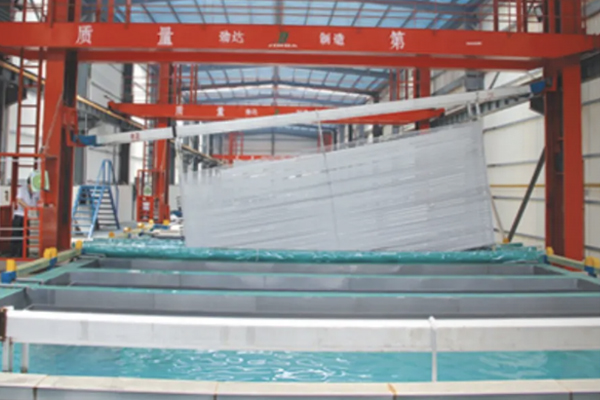

For superior durability and visual appeal, we offer various surface treatment solutions. These include anodizing for added corrosion resistance, powder coating for vibrant finishes, fluorocarbon coating for enhanced weather resistance, and wood grain transfer technology for elegant, natural-looking designs. These treatments are customizable to fit specific aesthetic and functional needs, ensuring that profiles not only perform well but also look exceptional.

To provide complete aluminum profile solutions, we offer extensive further processing capabilities. Our services include CNC machining, milling, threading, drilling, precision cutting, punching, welding, and assembly. This range of fabrication options allows us to deliver ready-to-use profiles tailored to exact project specifications, offering unmatched flexibility and reliability to our customers.

Aluminum Tile Trim Surface Color

Through colored anodizing treatment, Aluminum Tile Trim surfaces can achieve a wide range of colors and textures, including classic black, soft cream, luxurious gold, and more. This process not only adds diverse aesthetic options but also enhances corrosion resistance and durability. Whether it’s a smooth polished finish or a delicate brushed texture, these trims can meet the demands of various design styles and functional needs.

With a muted, non-reflective surface, matt black offers a subtle yet high-end aesthetic. It is popular for creating simple and refined interior designs, blending seamlessly with diverse color palettes.

White tile trims are perfect for achieving a clean and bright appearance. The neutral tone integrates effortlessly with tiles and walls, making it suitable for Scandinavian, modern, and other minimalist styles.

Cream Aluminum Tile Trim

The soft cream shade adds warmth and a touch of elegance to spaces. This versatile color harmonizes beautifully with warm-toned tiles or wooden accents, creating a cozy and inviting atmosphere.

Gold anodized finishes give trims a luxurious and regal appearance, commonly used in European, upscale, or neoclassical designs. The choice of matte gold or polished gold offers more personalization for sophisticated interiors.

A brushed finish adds fine linear texture for a refined metallic look. Combined with natural aluminum tones or other coated colors, it exudes modernity and a sense of technological sophistication, often used in industrial or futuristic designs.

Polished surfaces enhance the metallic feel, presenting a mirror-like shine. This glossy finish is perfect for both contemporary and vintage styles, bringing attention-grabbing elegance and grandeur to any space.

Our Factory

Get a Quote Now

Custom Aluminum Profile Process

Step 1: Our engineer will review your detailed size or drawing and provide a cross-sectional drawing for your confirmation.

Step 2: We open dies for your custom extrusion, create a sample, and send it to you for approval.

Step 3: If modifications are needed, we adjust the die size until you are satisfied with the sample.

Step 4: We inspect the raw material using a spectrum analyzer and proceed with extrusion production, providing weekly progress updates.

Step 5: Depending on your desired surface finish, we offer anodizing, electrophoresis, powder coating, or PVDF options.

Step 6: To ensure safe transportation, we carefully pack your products to avoid any damage.

RFQ

Aluminum Tile Trim is primarily made from 6063 T5 aluminum alloy, which is renowned for its excellent extrusion properties and ability to deliver a smooth, high-quality surface finish. This alloy offers a perfect balance of lightweight strength, durability, and corrosion resistance, making it ideal for both indoor and outdoor applications. Its structural integrity and aesthetic appeal make 6063 T5 the preferred material for creating elegant and reliable edge protection in tiling projects.

We offer a selection of Aluminum Tile Trim for edge and corner finishing, with some standard molds readily available for production. Additionally, we maintain stock of several commonly used profiles to meet immediate project needs. For custom or specific requirements, we also have on-site molds to accommodate unique designs.

To explore our range of products and check availability, please visit our website or contact us directly for more details. Our team will assist you in finding the perfect solution for your project.

For Aluminum Tile Trim orders, the Minimum Order Quantity (MOQ) is 200 kilograms for production. However, if the required product is available in stock, there is no MOQ restriction, allowing you to purchase according to your immediate needs.

For more details or to check stock availability, feel free to visit our website or contact us directly. We are here to assist with your project requirements.

Aluminum Tile Trim is typically packed in cardboard boxes for protection during transit, after which the boxes are securely placed on pallets for efficient handling and shipping. We also offer customized packaging solutions to meet specific requirements upon request.

For further details or custom packaging arrangements, please contact us. Our team will ensure your products are packed safely and tailored to your needs.

Mold production typically takes 7 days. After the sample is confirmed, producing a full container load of 26 tons generally requires 14 days for extrusion alone. If surface treatment is required, an additional 3 days will be needed. For machining, extra time will be required depending on the complexity and volume of the machining work. The exact additional time for machining will be determined based on the specific processing requirements.

Aluminum profiles are naturally corrosion-resistant due to the formation of a thin, protective oxide layer when exposed to air or water. This oxide layer is stable and self-repairing, meaning that even if the surface is scratched or cut (such as at exposed ends or during processing), the aluminum will not rust or corrode like iron or steel. Instead, the exposed areas will quickly form a new oxide layer, providing continuous protection against further oxidation.

With proper design, installation, and maintenance, aluminum profiles can last for decades, even in challenging environments. For example, untreated aluminum can easily withstand 20-30 years in outdoor applications, while profiles with surface treatments like anodizing or powder coating can last even longer, often exceeding 50 years. This makes aluminum an excellent choice for applications where durability and long-term performance are essential.

The price of aluminum profiles consists of several components: raw material costs, extrusion processing fees, surface treatment fees, machining costs, and additional packaging fees. Among these, the cost of aluminum as a raw material tends to fluctuate frequently, while other fees remain relatively stable. Due to these fluctuations, our quotations are typically valid for 7 days.

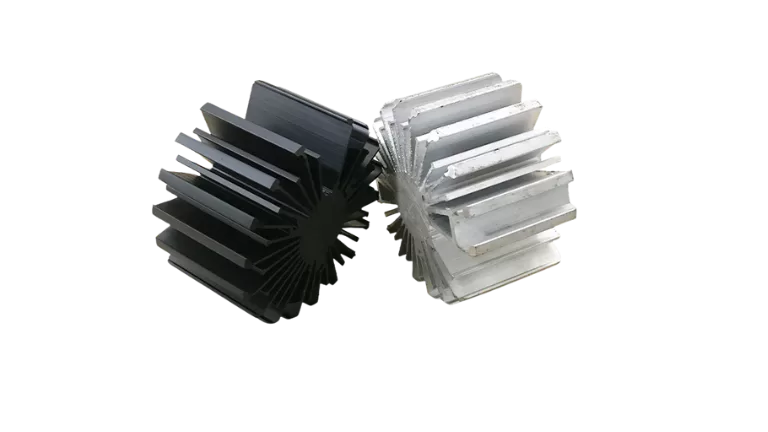

Pricing can be structured in different ways depending on the product and requirements. It can be calculated by weight (e.g., cost per ton), by length (e.g., cost per meter), or by piece (e.g., cost per unit). For products involving extensive machining, such as heat sinks, pricing is generally calculated on a per-piece basis to accurately reflect the additional processing costs. This flexible pricing approach ensures the quote is tailored to the specific needs of the customer.

We can manufacture aluminum profiles in compliance with technical requirements that meet European standards (EN), American standards (ASTM/AA), or other standards as specified by the customer. Custom production is tailored to ensure that the profiles meet the specific standard requirements requested.

Our production equipment is designed for the metric system. If the drawings provided are in the imperial system, we will convert them into metric units for production to ensure accuracy.

It is important to note that while we can machine imperial-threaded holes for fasteners, if you require us to supply matching imperial fasteners, they may not always be available in stock. Custom orders for imperial fasteners typically require a large volume for production. Please consider this when planning your project.

For custom aluminum extrusion projects, we accept a variety of drawing formats, including CAD files, STEP files, and PDF files. However, for extrusions that require additional machining processes, it’s recommended to provide STEP files, as they ensure precise 3D modeling for machining accuracy.

While PDF files are acceptable, converting them into CAD drawings may result in the loss of certain details, requiring us to manually redraw the design, which could increase lead time. For the fastest and most accurate quotation, we recommend providing CAD files (e.g., DWG/DXF) and STEP files to ensure efficient design evaluation and pricing.