Electrophoresis Aluminum Profiles

Overview

Aluminum profiles undergo electroplating surface treatment to enhance their appearance, durability, and corrosion resistance. The electroplating process involves immersing the aluminum profiles in an electrolyte solution and applying an electric current to deposit a thin layer of metal onto their surface. The electrolyte solution typically contains metal ions, such as chromium or nickel, which form a protective coating on the aluminum. This plating layer not only improves the aesthetic appeal of the profiles by providing a lustrous and reflective surface but also adds a protective barrier against environmental factors, such as moisture and oxidation. Additionally, the electroplating process can also be customized to achieve specific requirements, such as color variations or additional surface properties. Overall, the electroplating surface treatment for aluminum profiles offers a cost-effective solution to enhance their visual appeal and increase their longevity in various applications.

Film thickness

| Grade | Minimum anodized film thickness | Minimum electrophoretic film thickness | Minimum total film thickness |

|---|---|---|---|

| A | 9um | 12um | 21um |

| B | 9um | 7um | 16um |

| C | 6um | 21um | 15um |

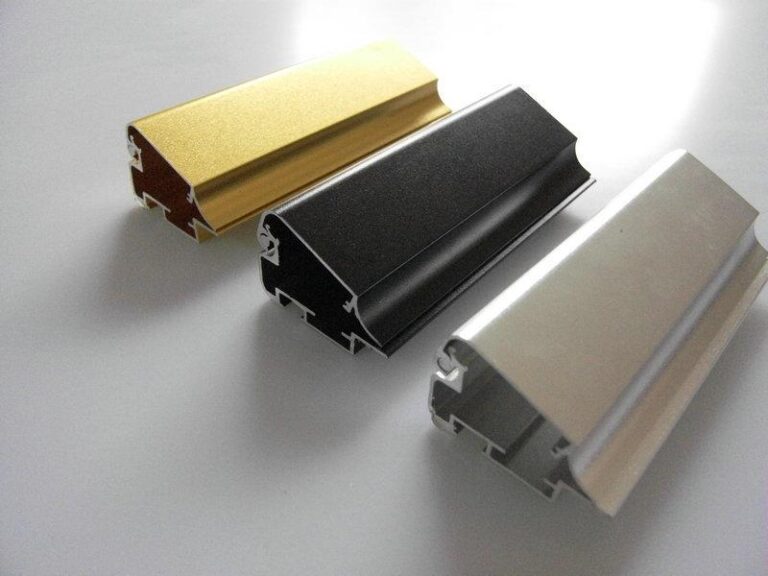

Colors Options

Electroplating of aluminum profiles offers a wide range of color options to enhance their appearance and meet specific design requirements. Through the electroplating process, various metal coatings can be applied to achieve different colors on the surface of the aluminum.

One popular option is chrome plating, which creates a shiny, reflective surface with a silver color. Chrome-plated aluminum profiles are often used in applications where a modern, sleek look is desired, such as automotive trims or high-end furniture.

Another common choice is nickel plating, which can produce a range of colors depending on the specific process and additives used. Nickel can create a bright, silver-colored surface, similar to chrome, or it can be alloyed with other metals to produce different shades, such as gold, black, or even green. These variations in color allow for versatility in design and can be employed in various industries, including architecture, electronics, and consumer goods.

In addition to chrome and nickel, other metals can be used for plating aluminum profiles to achieve specific colors. For example, gold plating provides a luxurious, warm gold-colored surface, while copper plating offers a reddish-brown appearance. These color options allow for customization and can be used to create visual accents or match specific design themes.

Advantages

Electroplating treatment of aluminum profiles offers several advantages for their surface enhancement.

Firstly, it significantly improves the aesthetic appeal of the profiles by providing a smooth, lustrous, and reflective surface. This enhances their visual appeal and makes them more appealing for various applications, including architectural, automotive, and decorative uses.

Secondly, the electroplating process adds a protective layer to the aluminum surface, enhancing its durability and corrosion resistance. The deposited metal layer acts as a barrier, protecting the underlying aluminum from environmental factors such as moisture, oxidation, and chemical exposure. This significantly extends the lifespan of the aluminum profiles and ensures their long-term performance in challenging environments.

Additionally, electroplating allows for customization and versatility in the surface properties of aluminum profiles. Different metals can be used for plating, providing options for achieving specific requirements. For example, chrome plating can offer a highly reflective and visually appealing surface, while nickel plating provides enhanced corrosion resistance.

Factory

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer based in China. We specialize in various stages of aluminum profile production, from mold design and melting to extrusion, oxidation, electrophoresis, coating, and polishing, providing a comprehensive range of services.

Our product range encompasses aluminum profiles suitable for windows and doors (including thermal break section), industrial applications (T-slot, channel, tubing), and photovoltaic systems. Situated in Jiangxi, our spacious production facility covers 30,000 square meters and employs over 200 skilled professionals, enabling us to produce more than 10,000 metric tons of aluminum profiles annually.

At HTS NEW MATERIALS, we also offer various surface treatments, including anodizing, electrophoretic coating, powder coating, PVDF coating, and wood grain transfer printing, to enhance both functionality and appearance. Whether it’s for construction, industry, or renewable energy, our high-quality aluminum profiles are ready to meet your specific needs.