Corner Brackets for Window Aluminum Profiles Angle Joint

Overview

Corner brackets are engineered pieces designed to connect and reinforce the joints where the corners of a frame meet. Typically made from materials like aluminum or steel, these brackets ensure that the frame maintains its shape and structural integrity. They are used not only in window frames but also in a variety of applications such as furniture, cabinetry, and other structures requiring strong right-angle joints.

Corner Brackets in Window Framing Assembly

In aluminum window frames, corner brackets are crucial. They provide the necessary reinforcement to keep the frame square and prevent the joints from separating under stress or movement. This is especially important in areas with high winds, heavy rain, or seismic activity. A well-joined window frame with quality corner brackets will resist warping and maintain its shape, ensuring that the window operates smoothly and efficiently.

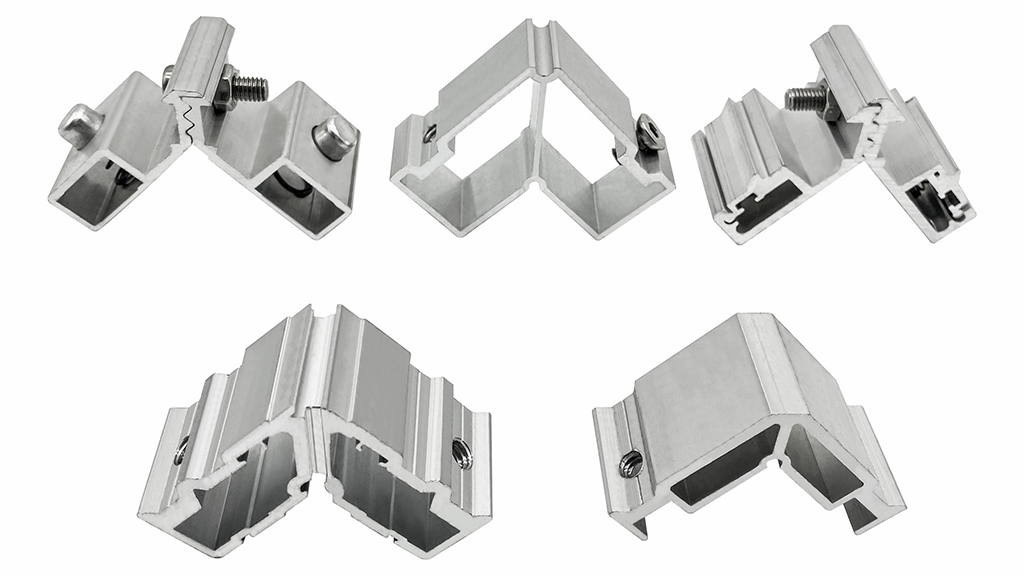

Casting and Extrusion Corner Brackets

Cast aluminum corner brackets are made by pouring molten aluminum into a mold where it solidifies into the desired shape. This process allows for complex geometries and intricate designs, but the resulting parts can have a less uniform microstructure, which may lead to potential weak spots and less consistent mechanical properties.

On the other hand, extruded aluminum corner brackets are created by forcing heated aluminum through a die, which shapes it as it emerges in a continuous profile that is then cut to the required length. Extrusion typically results in a more uniform grain structure, imparting greater strength and resistance to stress. Additionally, extruded brackets can be produced at a faster rate and are generally more cost-effective for high-volume production. However, the extrusion process may be limited to simpler shapes compared to the vast design possibilities offered by casting.

Different Types of Corner Brackets

Corner brackets come in a range of styles and sizes, each suited to specific applications:

- Flat Corner Brackets: These are typically used in scenarios where the bracket can be placed on a flat surface. They are commonly found in framing and shelving.

- L-Shaped Brackets: The most common type for window frames, L-shaped brackets fit snugly into the interior corner, providing a strong, 90-degree angle support.

- T-Brackets: These are used when three pieces come together at a single joint, offering additional support where needed.

- Adjustable Corner Brackets: These brackets can be manipulated to fit a range of angles, not just 90 degrees, making them versatile for custom window frame designs.

- Locking Corner Brackets: These brackets come with a locking mechanism to ensure that once they are in place, they provide a secure hold that is resistant to tampering or accidental dislodging.

How to Use Corner Brackets

- 1 Measure and Cut: Ensure your aluminum window frame pieces are cut to the precise length needed for your window dimensions.

- Dry Fit: Before securing any brackets, place the frame pieces together to ensure a perfect fit.

- Secure the Brackets: Depending on the type of corner bracket, you may need to screw, bolt, or snap them into place. Follow the manufacturer’s instructions for the best results.

- Check Alignment: Use a square tool to confirm that all corners are at a perfect right angle.

- Tighten and Test: Once all brackets are in place, tighten all connections and test the frame for stability.

About Us

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer based in China. We specialize in various stages of aluminum profile production, from mold design and melting to extrusion, oxidation, electrophoresis, coating, and polishing, providing a comprehensive range of services.

Our product range encompasses aluminum profiles suitable for windows and doors (including thermal break section), industrial applications (T-slot, channel, tubing), and photovoltaic systems. Situated in Jiangxi, our spacious production facility covers 30,000 square meters and employs over 200 skilled professionals, enabling us to produce more than 10,000 metric tons of aluminum profiles annually.

At HTS NEW MATERIALS, we also offer various surface treatments, including anodizing, electrophoretic coating, powder coating, PVDF coating, and wood grain transfer printing, to enhance both functionality and appearance. Whether it’s for construction, industry, or renewable energy, our high-quality aluminum profiles are ready to meet your specific needs.