Applications of T-Slot Aluminum Profiles

Overview

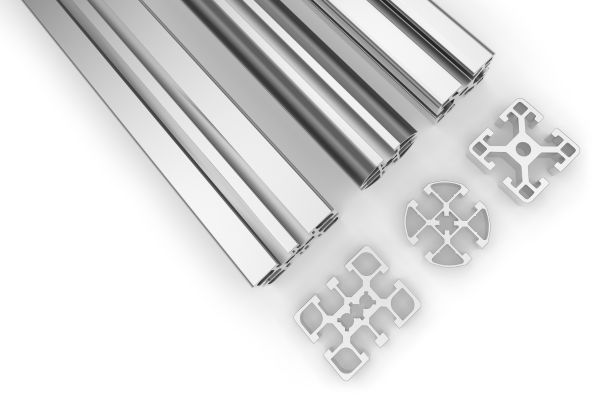

T-slot aluminum profiles are a specialized form of industrial aluminum profiles that have revolutionized the design and construction of structures across various sectors. Named for the T-shaped slots that run along their length, these profiles allow for the easy attachment of panels, connectors, and other components, creating a highly modular and customizable system.

The Mechanics of T-Slot Aluminum Profiles

The genius of the T-slot design lies in its simplicity and functionality. The slots serve as a universal interface for attaching a multitude of accessories without welding or extensive machining. This feature enables quick assembly and reconfiguration, which is invaluable in dynamic industrial environments where flexibility is key.

Applications in Manufacturing and Automation

In manufacturing, T-slot aluminum profiles are extensively used to construct workbenches, machine guards, and custom enclosures. Their modularity allows for tailored setups that can evolve with the changing needs of production lines. Automation systems also benefit from the adaptability of T-slot profiles, as they can be easily reconfigured to accommodate new processes or equipment.

Versatility in Material Handling Systems

Material handling systems, such as conveyor frames, carts, and shelving, rely on T-slot aluminum profiles for their structural elements. The ability to adjust and expand these systems with minimal downtime is critical in maintaining efficient operations in warehouses and distribution centers.

Exhibit and Display Industry

The exhibit and display industry favors T-slot aluminum profiles for constructing trade show booths and display stands. The ease of assembly and disassembly, combined with the lightweight nature of aluminum, makes T-slot profiles an ideal choice for temporary structures that require frequent setup and breakdown.

Framework for Prototyping and Testing

Engineers and product developers use T-slot aluminum profiles to create prototypes and testing rigs. The profiles’ versatility facilitates quick iterations and modifications, which accelerates the development process and leads to more innovative solutions.

Supporting Research and Education

In educational settings and research labs, T-slot aluminum profiles are used to build experimental setups, laboratory equipment, and educational models. Their reusability and ease of use make them an economical and practical choice for academic institutions.

Advantages in Custom Furniture and Interior Design

Custom furniture makers and interior designers increasingly turn to T-slot aluminum profiles for creating bespoke pieces and architectural elements. The profiles’ clean lines and modern aesthetic, along with the ability to integrate with various materials, offer endless design possibilities.

How to Connect T-slot profiles

T-slot aluminum profiles are designed with a specific channel that allows for modular connections using various fasteners and accessories. Here’s an overview of the common methods used to connect T-slot profiles:

T-Nuts and Bolts

The most fundamental method of connecting T-slot profiles involves T-nuts and bolts. T-nuts are specially designed to slide into the T-slot channel and turn 90 degrees when a bolt is inserted and tightened, locking them into place. This provides a secure and adjustable connection point for joining profiles or attaching components.

Corner Brackets and Connectors

For creating right-angle connections, corner brackets and gussets are commonly used. These can be either external or internal. External brackets are placed on the outside of the profile connection and secured with bolts and T-nuts. Internal connectors slide into the ends of the profiles and are tightened with set screws, creating a clean, flush finish.

End-to-End Connectors

When profiles need to be connected end to end, a variety of connectors are available, such as butt connectors, expansion connectors, or joining plates. These connectors can provide a strong bond by using friction, set screws, or additional bolts and T-nuts to secure the profiles together.

Anchor Fasteners

Anchor fasteners are another option for joining profiles end to end. They are inserted into the end of one profile and then tightened, expanding to lock into place. The other profile is then slid over the anchor fastener and secured.

Quick Connectors

Anchor fasteners are another option for joining profiles end to end. They are inserted into the end of one profile and then tightened, expanding to lock into place. The other profile is then slid over the anchor fastener and secured.

Panel and Door Mounting

To mount panels, doors, or other flat components, special T-slot panel mounts or holders can be used. These are designed to grip the edges of the panel and secure it to the profile frame, often without the need for additional drilling or machining.

Linear Bearings and Slides

To mount panels, doors, or other flat components, special T-slot panel mounts or holders can be used. These are designed to grip the edges of the panel and secure it to the profile frame, often without the need for additional drilling or machining.

Advantage of T-slot Aluminum Profile

The T-slot aluminum profile system offers numerous advantages that make it an attractive choice for various construction and design applications. Some of these advantages include:

Versatility

T-slot profiles can be used to build a wide range of structures, from simple frames to complex machinery. The modular nature of the system allows for a high degree of customization, enabling users to create solutions tailored to their specific needs.

Ease of Assembly

The profiles are designed for easy assembly, often requiring no special tools or skills. The T-slot and T-nut system enables components to be connected with simple hand tools, making it accessible for both professionals and hobbyists.

Adjustability and Reusability

Connections made with T-slot profiles are not permanent, allowing for easy disassembly, adjustment, and reconfiguration. This reusability makes it an economical choice for projects that require frequent changes or updates.

Durability and Strength

Made from high-strength aluminum alloys, T-slot profiles are both lightweight and robust. They provide excellent structural integrity, making them suitable for heavy-duty applications while also being resistant to corrosion.

Aesthetic Appeal

With a clean, anodized finish, T-slot aluminum profiles offer a professional and modern appearance. This makes them ideal for applications where aesthetics are important, such as in retail displays or office furnishings.

No Welding Required

Unlike traditional steel construction, which often requires welding, T-slot profiles can be assembled without welding. This eliminates the need for specialized welding equipment or expertise and makes the assembly process cleaner and safer.

Compatibility with Accessories

A wide range of accessories is available for T-slot profiles, including brackets, hinges, handles, and various mounting options. This compatibility with accessories expands the functionality and application possibilities of the T-slot system.

Precision and Consistency

T-slot profiles are manufactured with high precision, ensuring consistent dimensions and tolerances. This uniformity is critical for creating accurate and repeatable structures, particularly in automated processes and machinery.

Reduced Fabrication Time

The simplicity of cutting and assembling T-slot profiles can significantly reduce fabrication time compared to traditional methods. This efficiency can lead to faster project completion and reduced labor costs.

Factory

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer based in China. We specialize in various stages of aluminum profile production, from mold design and melting to extrusion, oxidation, electrophoresis, coating, and polishing, providing a comprehensive range of services.

Our product range encompasses aluminum profiles suitable for windows and doors (including thermal break section), industrial applications (T-slot, channel, tubing), and photovoltaic systems. Situated in Jiangxi, our spacious production facility covers 30,000 square meters and employs over 200 skilled professionals, enabling us to produce more than 10,000 metric tons of aluminum profiles annually.

At HTS NEW MATERIALS, we also offer various surface treatments, including anodizing, electrophoretic coating, powder coating, PVDF coating, and wood grain transfer printing, to enhance both functionality and appearance. Whether it’s for construction, industry, or renewable energy, our high-quality aluminum profiles are ready to meet your specific needs.