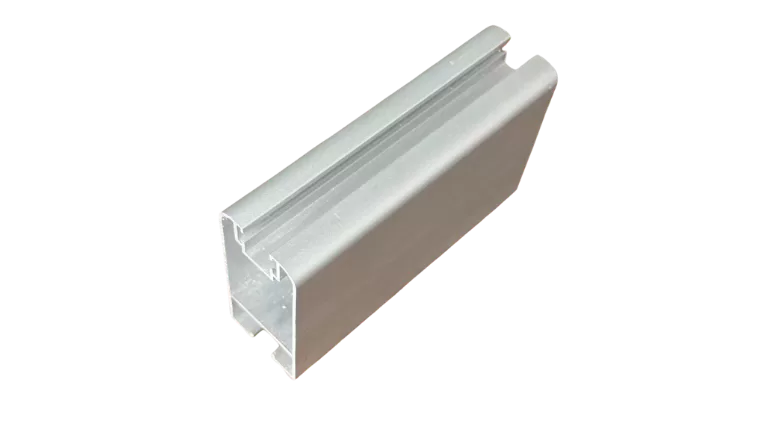

Custom Aluminum Windows Profiles | Sections Extrusions

Aluminum window profiles are essential in modern architecture, offering lightweight durability, corrosion resistance, and design flexibility. Extruded from high-quality alloys, they provide exceptional strength and structural integrity for long-lasting performance.

✔ Lightweight & Strong – Combines low weight with high load-bearing capacity.

✔ Weather-Resistant – Withstands harsh conditions without rust or degradation.

✔ Sleek & Customizable – Enables slim frames and diverse window styles (sliding, casement, tilt & turn).

✔ Low Maintenance – Resistant to warping and decay, ensuring hassle-free longevity.

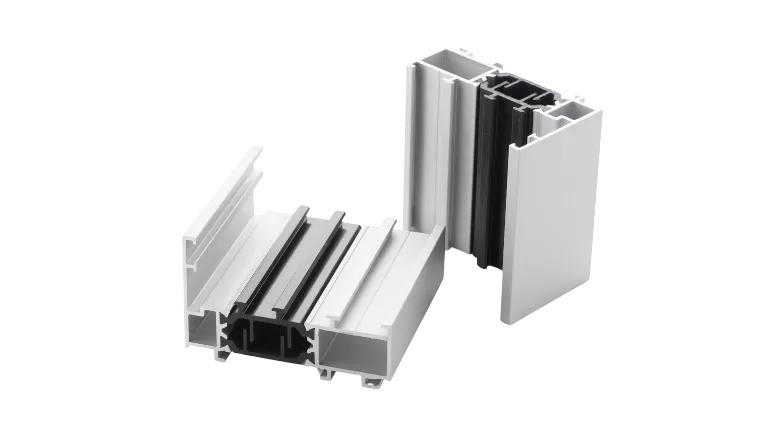

Aluminum Alloy Window Frame Extrusions

We specialize in manufacturing aluminum profiles for various window frame structures, including sliding windows, casement windows, thermal break windows, and tilt & turn windows. With an extensive existing mold library for standard window profiles, we also offer customized aluminum profile solutions tailored to specific design requirements. Our comprehensive technical support covers the entire process from design to production, providing door and window manufacturers with high-quality aluminum profile solutions.

Aluminum Section Surface Treatment

The quality of window aluminum profiles is determined not only by material selection and extrusion precision but also critically by surface treatment. We provide comprehensive surface finishing solutions including anodizing, electrophoresis, powder coating, PVDF fluorocarbon coating, and wood grain finishes.

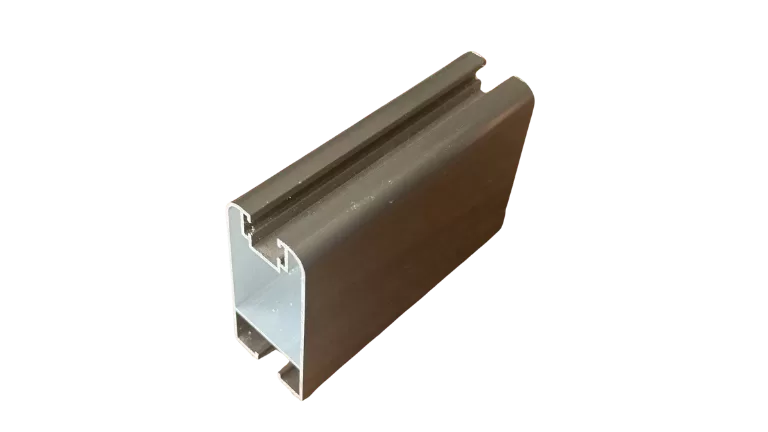

Anodizing

The aluminum profiles are immersed in an acidic solution and undergo electrolytic oxidation to form an oxide film. Anodizing enhances the corrosion resistance, hardness, and surface smoothness of the aluminum profiles. It can also be used with dyeing agents to achieve different colors.

Class of oxide film: AA10; AA15; AA20

Surface type: Matte; flat

Color: Silver white; bronze; champagne

Fetures: Corrosion resistant; durable; shining and decorative

Electrophoretic

The charged aluminum profiles are immersed in a coating solution in an electrolytic tank. Through electrophoresis, the coating evenly adheres to the aluminum surface. Electrophoretic coating provides good weather resistance, color stability, and a smooth and uniform coating.

Corrosion resistance of composite film: ≥9.5 level

Paint film cohesive: Zero lever

Paint film hardness: ≥3H

Surface: Matte; flat; high brightness

Color: Silver white; bronze; champagne

Features: Corrosion resistant; durable; smooth and shining

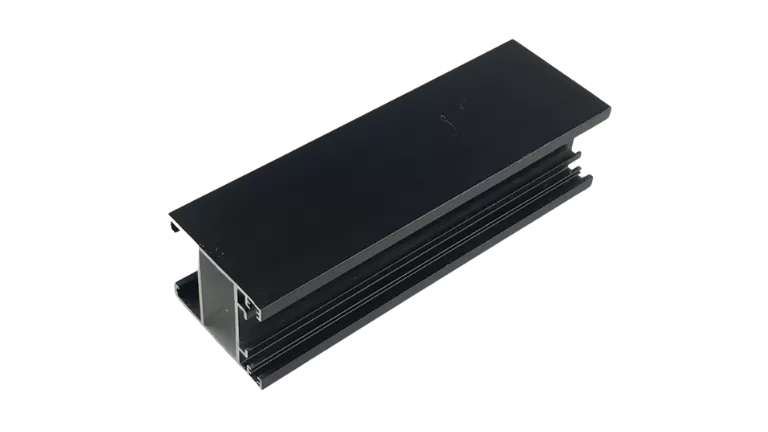

Powder Coating

Powdered coating material is sprayed onto the aluminum profiles, and then melted and cured at high temperatures. Powder coating offers durability, corrosion resistance, and a pleasing appearance. It is also environmentally friendly.

Coat thickness:40-120um

Coat shock resistance: No cracking or fall off after shock test

Coat cohesion: Zero lever

Surface type: Highly glossy; semi glossy; matte

Color: Ral color

Features: Variety of colors

PVDF Coating

PVDF coating, a type of spray coating, utilizes a PVDF resin-based paint that provides exceptional resistance to weathering, UV radiation, and chemicals, making it suitable for demanding outdoor applications.

Coat thickness:30-65um

Coat shock resistance: No cracking or fall off after shock test

Coat cohesion: Zero lever

Glossiness: 60°

Features: With metallic luster, bright color, high weather resistance

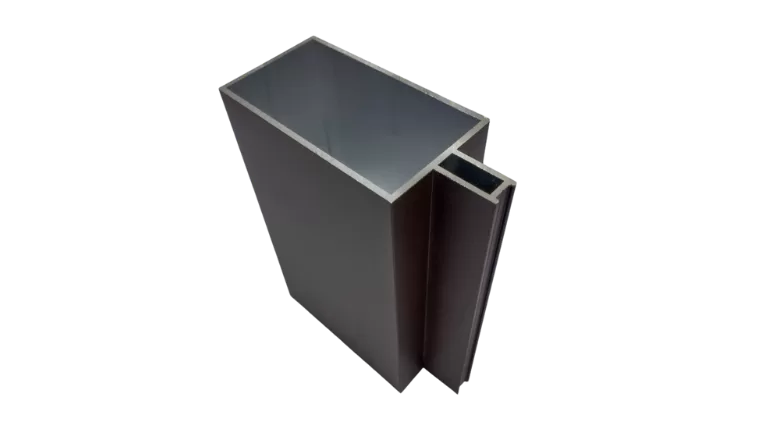

Wood Grain Transfer

This process involves transferring wood grain patterns or textures onto the aluminum profiles using a transfer method. It gives the aluminum profiles the appearance of wood while retaining the advantages of aluminum, such as weather resistance and corrosion resistance.

Surface texture: Wooden; marble

features: Wood-like visual experience

Aluminum Window profile specification

| Material | 6060, 6063, 6061 aluminum alloy |

| Temper | T5, T6 |

| Thickness |

General profiles thickness: 0.8mm—1.4mm; Anodizing protection thickness: 8-12 micron; Normal powder coated thickness: 60-100 micron |

| Surface treatment | Anodizing, Electroplating, Polishing, Sandblasted, Powder Coating, Brushed, PVDF, Wood Grain Transfer |

| Color | Customized Color |

| MOQ | 500KG |

| Delivery time | 15-20 days after sample confirmed & down payment, or negotiated |

| Port | Guangzhou,Ningbo, Shanghai |

Window Aluminum Profile Processing Capabilities

Our factory is equipped with 40 extrusion production lines to efficiently manufacture window aluminum profiles. We have one anodizing and electrophoresis line, as well as two vertical and two horizontal spraying machines for surface treatment. Additionally, we operate two sandblasting machines and six wood grain transfer printing lines, allowing us to provide a variety of aesthetic finishes for our window profiles. To support our production, we also have furnaces for casting aluminum bars, aging furnaces, annealing furnaces, water cooling treatment equipment, and machining tools, ensuring comprehensive capabilities for high-quality output.

Extrusion Process

Our factory operates 40+ extrusion presses (600T to 6000T), specializing in manufacturing aluminum profiles for window and door systems. Smaller presses (600T/800T) produce precision profiles for lightweight designs, while larger presses (4000T/6000T) handle robust structural sections. This capacity ensures we can meet all technical requirements for high-performance window and door applications.

Surface Treatmen

We offer comprehensive surface treatment capabilities to enhance the durability and aesthetics of our aluminum profiles:

- 1 Anodizing & Electrophoresis Line for superior corrosion resistance

- 4 Powder Coating Lines (2 vertical + 2 horizontal) for uniform, durable finishes

- 6 Wood Grain Transfer Lines for premium decorative effects

- 1 PVDF Fluorocarbon Coating Line for exceptional weather resistance

- 2 Sandblasting Lines for textured surface preparation

This complete in-house finishing system ensures we can meet all quality and design requirements for architectural aluminum profiles.

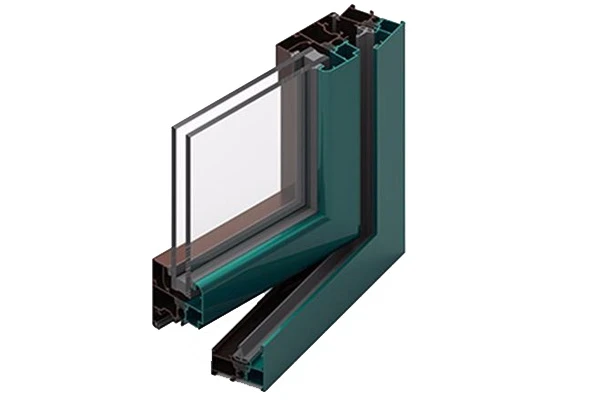

Thermal Break Aluminum Profile Production

To meet the growing demand for energy-efficient window and door systems, we operate 2 dedicated thermal break aluminum profile production lines equipped with advanced polyamide strip insertion (PA66 GF25) technology.

Aluminum Alloys for Window Profiles

The most widely used aluminum alloys for window and door profiles are 6063-T5 and 6061-T6, chosen for their optimal balance of strength, formability, and corrosion resistance.

The most widely used aluminum alloys for window and door profiles are 6063-T5 and 6061-T6, chosen for their optimal balance of strength, formability, and corrosion resistance.

- 6063-T5: The standard alloy for architectural profiles, offering excellent extrudability, smooth surface finish, and good mechanical properties after heat treatment.

- 6061-T6: Used for structural components requiring higher strength, with superior load-bearing capacity while maintaining weldability.

Both alloys undergo precise alloying and tempering processes to ensure consistent performance in fenestration applications, complying with international standards like EN 755, ASTM B221, and GB/T 5237.

Factory Show

Custom Window Manufacturing Services

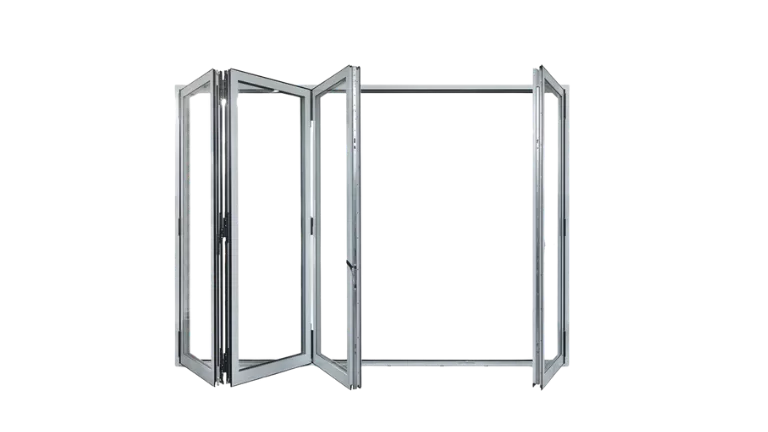

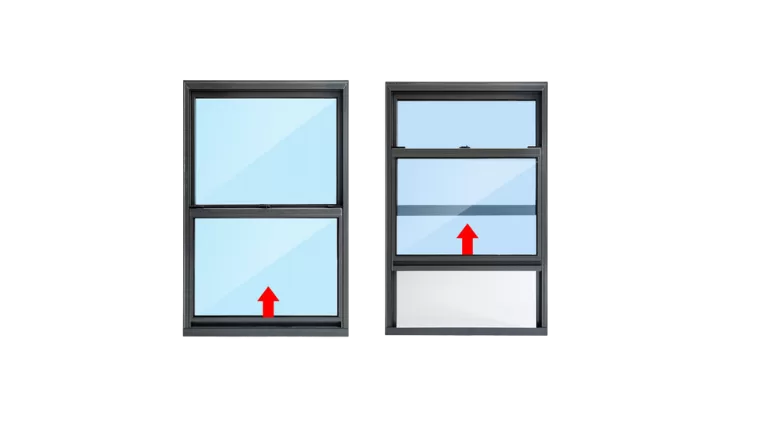

Our Window & Door Division specializes in global customization of high-quality windows, including glass integration. We support a wide range of window types to meet diverse architectural needs:

Available Window Styles

- Sliding Windows

- Casement (Awning/Crank-out) Windows

- Top-Hung & Bottom-Hung Windows

- Tilt & Turn Windows

- Double-Hung & Single-Hung Windows

- Lift & Slide Windows

- Fixed Windows

Customization Process

Provide Design Details:

- Submit technical drawings or specify frame dimensions (width/height/depth).

- Indicate operational type (e.g., sliding, casement).

Surface Treatment Options:

- Anodizing (silver, bronze, black)

- Powder Coating (RAL/color-matching)

- Wood Grain Transfer

- PVDF Fluorocarbon Coating

Glass Integration:

- Double/triple glazing, tempered, Low-E, laminated, or decorative glass.

RFQ of Extruded Window Aluminum Profile

| Property | 6060-T5(Lightweight) | 6063-T5(Standard) | 6061-T6(Structural) |

|---|---|---|---|

| Chemical Composition | Si: 0.3-0.6%<br>Fe: ≤0.35%<br>Cu: ≤0.1%<br>Mn: ≤0.1%<br>Mg: 0.35-0.6%<br>Cr: ≤0.05%<br>Zn: ≤0.15%<br>Ti: ≤0.1%<br>Al: Balance | Si: 0.2-0.6%<br>Fe: ≤0.35%<br>Cu: ≤0.1%<br>Mn: ≤0.1%<br>Mg: 0.45-0.9%<br>Cr: ≤0.1%<br>Zn: ≤0.1%<br>Ti: ≤0.1%<br>Al: Balance | Si: 0.4-0.8%<br>Fe: ≤0.7%<br>Cu: 0.15-0.4%<br>Mn: ≤0.15%<br>Mg: 0.8-1.2%<br>Cr: 0.04-0.35%<br>Zn: ≤0.25%<br>Ti: ≤0.15%<br>Al: Balance |

| Tensile Strength | ~160 MPa (23 ksi) | ~186 MPa (27 ksi) | ~310 MPa (45 ksi) |

| Yield Strength | ~110 MPa (16 ksi) | ~145 MPa (21 ksi) | ~276 MPa (40 ksi) |

| Elongation | 10% | 12% | 10% |

| Extrudability | Excellent | Excellent (complex shapes) | Good (simpler sections) |

| Surface Finish | Very smooth | Smooth, ideal for coatings | Slightly rougher |

| Corrosion Resistance | Very High | Very High | High |

| Typical Use | Thin-wall profiles, Europe | Window/door frames, trim | Heavy-duty frames, hinges |

For custom aluminum extrusion projects, we accept a variety of drawing formats, including CAD files, STEP files, and PDF files. However, for extrusions that require additional machining processes, it’s recommended to provide STEP files, as they ensure precise 3D modeling for machining accuracy.

While PDF files are acceptable, converting them into CAD drawings may result in the loss of certain details, requiring us to manually redraw the design, which could increase lead time. For the fastest and most accurate quotation, we recommend providing CAD files (e.g., DWG/DXF) and STEP files to ensure efficient design evaluation and pricing.

Mold fees are an essential part of the custom aluminum extrusion process. Since every order requires a uniquely designed mold tailored to specific requirements, these molds cannot be used for other products. Therefore, the mold fee is necessary and non-negotiable.

We require 100% upfront payment of the mold fee before mold development begins to ensure timely production. However, as a token of appreciation for your support, we offer a refund of the mold fee or equivalent discounts once the order reaches a certain production volume. Specific policies can be discussed based on your order volume and collaboration details.

Our minimum order quantity (MOQ) varies depending on the size of the product. For smaller-sized products, the MOQ is typically 500kg, while for larger-sized products, it is 2 tons.

We will specify the exact MOQ requirements during the quotation process. If your order quantity does not meet the MOQ, we can still arrange production, but an additional fee will be applied to cover mold preheating and production setup time. Rest assured, this extra fee will be reasonable, and we aim to keep it as minimal as possible to ensure smooth cooperation.

Packaging can be customized according to your needs. Options include using protective film or paper to separate and protect the surface, or foam film for additional surface protection. Products can be palletized or packed into cartons, and the quantity per pallet or carton can be specified by the customer.

The standard packaging involves bundling several pieces together with plastic wrap and then securing them onto pallets. Any packaging requirements beyond the standard will be accommodated, and the associated costs will be clearly provided to the customer.

Mold production typically takes 7 days. After the sample is confirmed, producing a full container load of 26 tons generally requires 14 days for extrusion alone. If surface treatment is required, an additional 3 days will be needed. For machining, extra time will be required depending on the complexity and volume of the machining work. The exact additional time for machining will be determined based on the specific processing requirements.

Aluminum profiles are naturally corrosion-resistant due to the formation of a thin, protective oxide layer when exposed to air or water. This oxide layer is stable and self-repairing, meaning that even if the surface is scratched or cut (such as at exposed ends or during processing), the aluminum will not rust or corrode like iron or steel. Instead, the exposed areas will quickly form a new oxide layer, providing continuous protection against further oxidation.

With proper design, installation, and maintenance, aluminum profiles can last for decades, even in challenging environments. For example, untreated aluminum can easily withstand 20-30 years in outdoor applications, while profiles with surface treatments like anodizing or powder coating can last even longer, often exceeding 50 years. This makes aluminum an excellent choice for applications where durability and long-term performance are essential.

The price of aluminum profiles consists of several components: raw material costs, extrusion processing fees, surface treatment fees, machining costs, and additional packaging fees. Among these, the cost of aluminum as a raw material tends to fluctuate frequently, while other fees remain relatively stable. Due to these fluctuations, our quotations are typically valid for 7 days.

Pricing can be structured in different ways depending on the product and requirements. It can be calculated by weight (e.g., cost per ton), by length (e.g., cost per meter), or by piece (e.g., cost per unit). For products involving extensive machining, such as heat sinks, pricing is generally calculated on a per-piece basis to accurately reflect the additional processing costs. This flexible pricing approach ensures the quote is tailored to the specific needs of the customer.

We can manufacture aluminum profiles in compliance with technical requirements that meet European standards (EN), American standards (ASTM/AA), or other standards as specified by the customer. Custom production is tailored to ensure that the profiles meet the specific standard requirements requested.

Our production equipment is designed for the metric system. If the drawings provided are in the imperial system, we will convert them into metric units for production to ensure accuracy.

It is important to note that while we can machine imperial-threaded holes for fasteners, if you require us to supply matching imperial fasteners, they may not always be available in stock. Custom orders for imperial fasteners typically require a large volume for production. Please consider this when planning your project.

Yes, we currently have standard molds for Chinese-style window and door profiles in stock. However, since profile designs vary by country and market requirements, we recommend contacting our sales team to discuss your specific needs.

We can provide:

- Existing Chinese-standard molds for immediate production.

- Custom mold development tailored to your regional design preferences.

Contact our sales team for details on compatibility, lead times, or new mold fabrication. We ensure solutions aligned with your local market standards.