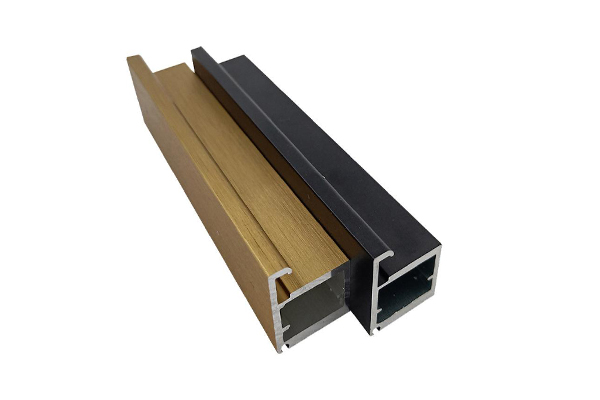

Aluminum Door Frame Profile

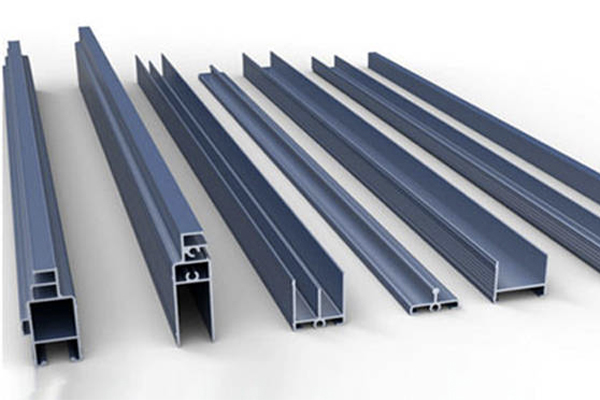

The Aluminum Door Frame Profile is a superior choice for constructing robust and visually appealing door frames. Crafted from premium-grade aluminum, it boasts exceptional durability and resistance against corrosion, ensuring longevity and low maintenance. Its sleek and modern design effortlessly enhances the aesthetics of any architectural project, be it residential or commercial.

With easy installation and a wide range of customizable options, the Aluminum Door Frame Profile offers versatility and flexibility to meet various design requirements. Architects and designers can choose from a variety of finishes, colors, and profiles to match their desired style and create a cohesive look. The profile’s strength and stability provide a secure foundation for doors, offering peace of mind in terms of safety and security.

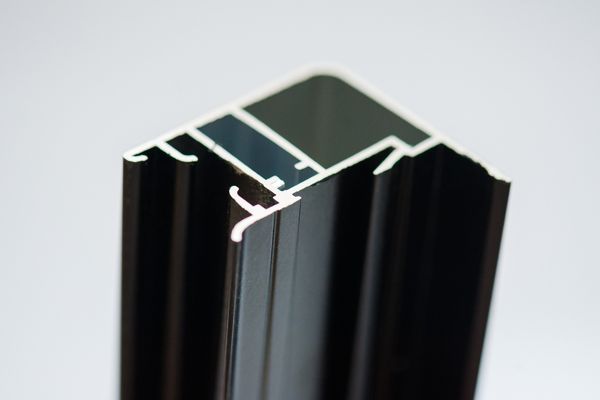

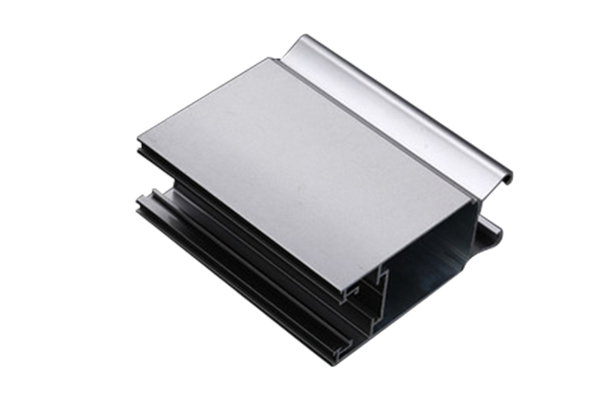

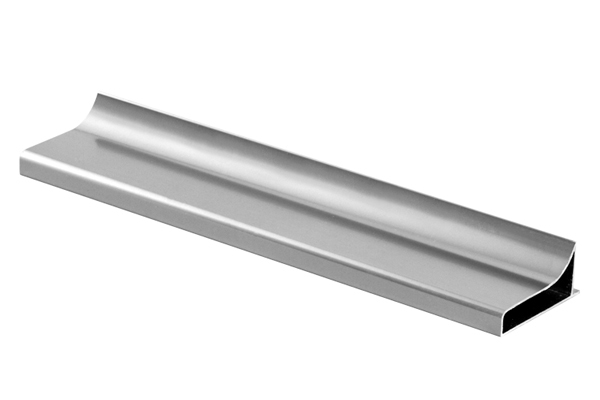

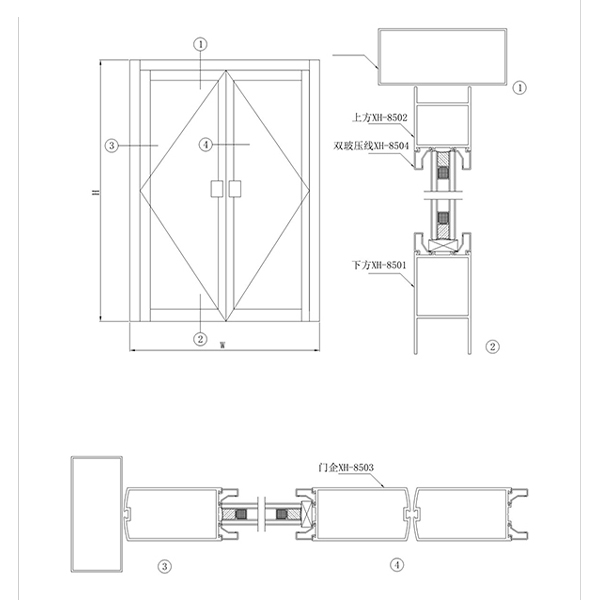

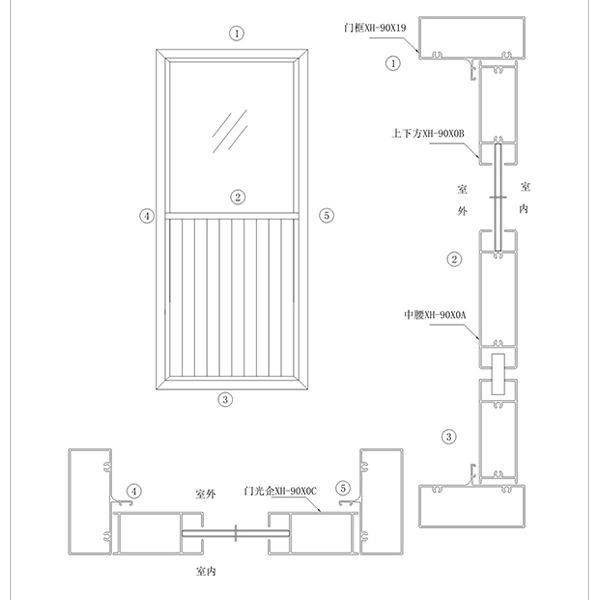

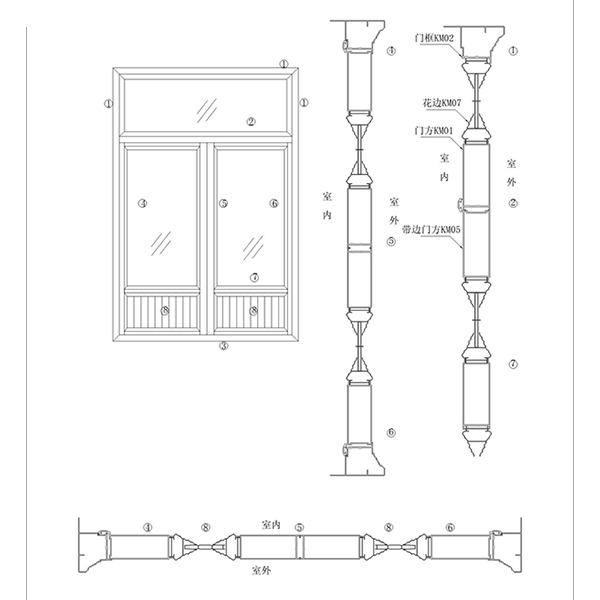

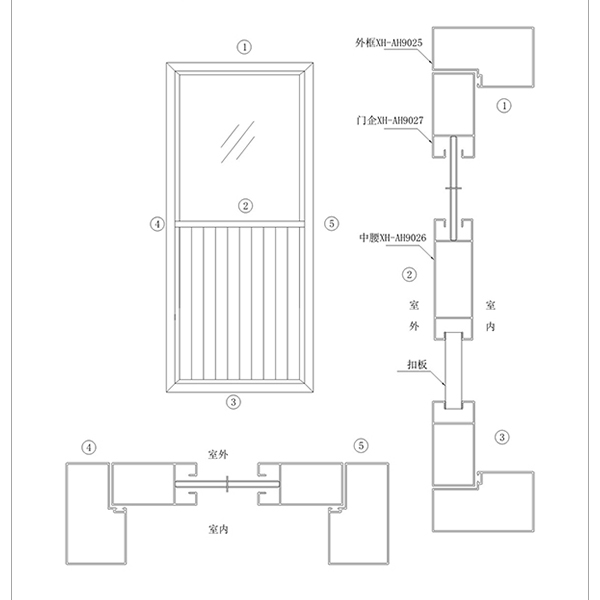

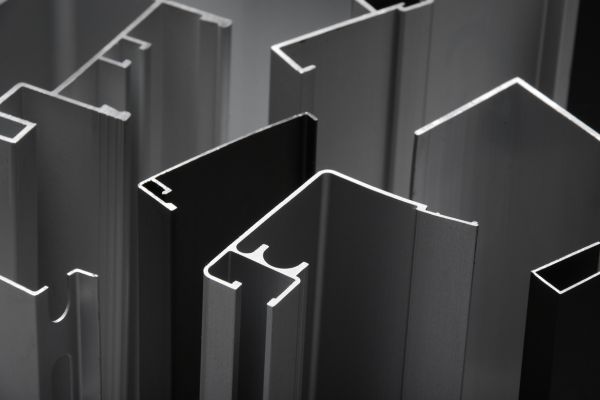

Door Aluminium Profile Section

Customize Your Aluminum Profile

Specification

| Material | 6000 Series aluminum alloy |

| Temper | T3-T8 |

| Thickness |

General profiles thickness: 0.8mm—1.4mm; Anodizing protection thickness: 8-12 micron; Normal powder coated thickness: 60-100 micron |

| Surface treatment | Anodizing, Electroplating, Polishing, Sandblasted, Powder coating, Brushed, PVDF, etc. |

| Color | Customized Color |

| MOQ | 500KG |

| Delivery time | 15-20 days after sample confirmed & down payment, or negotiated |

| Port | Guangzhou,Ningbo, Shanghai |

Finished Aluminum Frame Doors

Reliable Windows Aluminium Profiles Supplier

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer from China. With expertise in mold design, melting, extrusion, oxidation, electrophoresis, coating, and polishing, we offer a comprehensive range of services.

Our product portfolio includes aluminum profiles for windows and doors, industrial applications, and photovoltaic systems. Located in Jiangxi, our production facility spans 30,000 square meters and employs over 200 skilled professionals, allowing us to produce over 10,000 metric tons of aluminum profiles annually.

Surface

Surface treatment of extruded aluminum profiles holds significant importance across various industries. These treatment methods enhance the aesthetics of aluminum materials and improve their durability and performance. Whether used for structural components, automotive parts, or architectural elements, the choice of the appropriate surface treatment for aluminum profiles significantly impacts both their performance and appearance, thus holding a pivotal role in various industries.

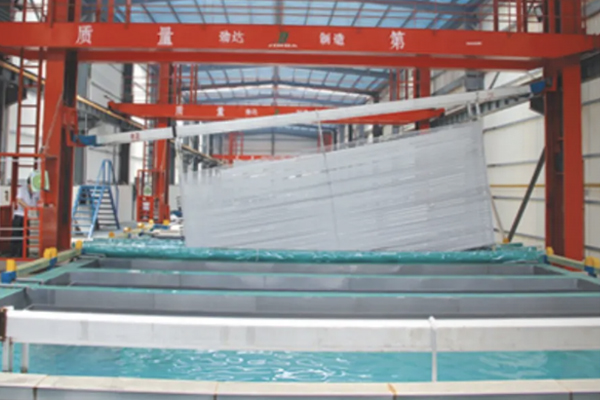

Anodizing

The aluminum profiles are immersed in an acidic solution and undergo electrolytic oxidation to form an oxide film. Anodizing enhances the corrosion resistance, hardness, and surface smoothness of the aluminum profiles. It can also be used with dyeing agents to achieve different colors.

Class of oxide film: AA10; AA15; AA20

Surface type: Matte; flat

Color: Silver white; bronze; champagne

Fetures: Corrosion resistant; durable; shining and decorative

Electrophoretic Coating

The charged aluminum profiles are immersed in a coating solution in an electrolytic tank. Through electrophoresis, the coating evenly adheres to the aluminum surface. Electrophoretic coating provides good weather resistance, color stability, and a smooth and uniform coating.

Corrosion resistance of composite film: ≥9.5 level

Paint film cohesive: Zero lever

Paint film hardness: ≥3H

Surface: Matte; flat; high brightness

Color: Silver white; bronze; champagne

Features: Corrosion resistant; durable; smooth and shining

Powder Coating

Powdered coating material is sprayed onto the aluminum profiles, and then melted and cured at high temperatures. Powder coating offers durability, corrosion resistance, and a pleasing appearance. It is also environmentally friendly.

Coat thickness:40-120um

Coat shock resistance: No cracking or fall off after shock test

Coat cohesion: Zero lever

Surface type: Highly glossy; semi glossy; matte

Color: Ral color

Features: Variety of colors

PVDF Coating

PVDF coating, a type of spray coating, utilizes a PVDF resin-based paint that provides exceptional resistance to weathering, UV radiation, and chemicals, making it suitable for demanding outdoor applications.

Coat thickness:30-65um

Coat shock resistance: No cracking or fall off after shock test

Coat cohesion: Zero lever

Glossiness: 60°

Features: With metallic luster, bright color, high weather resistance

Wood Grain Transfer

This process involves transferring wood grain patterns or textures onto the aluminum profiles using a transfer method. It gives the aluminum profiles the appearance of wood while retaining the advantages of aluminum, such as weather resistance and corrosion resistance.

Surface texture: Wooden; marble

features: Wood-like visual experience

Factory

We specialize in manufacturing high-quality, precision-engineered aluminum profiles for various industries. With state-of-the-art equipment and a skilled workforce, we produce complex profiles with exceptional dimensional accuracy using premium-grade aluminum alloys. Our customization options allow us to create unique profiles with intricate shapes, precise tolerances, and various surface finishes, tailored to your specific requirements. Quality is paramount to us, and we adhere to rigorous quality control measures throughout the manufacturing process. Our commitment to environmental sustainability is reflected in our eco-friendly practices, such as recycling aluminum scraps and optimizing energy consumption.

Raw Material

The aluminum profiles for doors and windows typically use common aluminum alloy grades, including 6061, 6063, and 6082. These aluminum alloy grades offer excellent mechanical properties, processability, and corrosion resistance, making them well-suited for manufacturing door and window profiles.

6061 Aluminum Alloy: It has high strength, excellent corrosion resistance, and weldability. It is suitable for manufacturing door and window profiles that require high strength and compressive capabilities.

6063 Aluminum Alloy: It is commonly used in the production of door and window profiles, offering good formability and corrosion resistance. It is suitable for creating profiles of various shapes and contours.

6082 Aluminum Alloy: It has high strength, good corrosion resistance, and mechanical properties. It is suitable for manufacturing door and window profiles that need to withstand high pressure and heavy loads.

Advantages of Using Aluminum Door

Aluminum doors offer a range of benefits that make them a popular choice for both residential and commercial applications. Here are some of the advantages of aluminum doors:

Durability: Aluminum is known for its exceptional durability and strength. Aluminum doors are highly resistant to corrosion, rust, and other environmental factors, making them suitable for various climates. They can withstand heavy usage and remain in excellent condition for years.

Lightweight: Despite its strength, aluminum is lightweight compared to other door materials such as wood or steel. This lightweight nature makes aluminum doors easy to install and operate. It also reduces the strain on hinges and other hardware components, increasing their lifespan.

Low Maintenance: Aluminum doors require minimal maintenance. They do not need to be repainted or stained regularly, unlike wooden doors. Aluminum’s resistance to corrosion means that it will not rot or warp over time, further reducing the need for repairs or replacements.

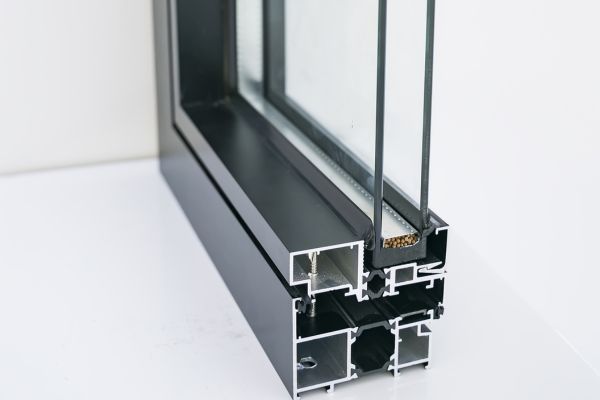

Energy Efficiency: Aluminum doors offer excellent thermal performance, contributing to energy efficiency. They can be fitted with thermal breaks and insulated glass panels, providing enhanced insulation and reducing heat transfer. This helps in maintaining comfortable indoor temperatures and can lead to energy savings by reducing the reliance on heating or cooling systems.

Design Versatility: Aluminum doors come in a wide range of styles, colors, and finishes, allowing for flexibility in design. Whether you prefer a modern, sleek look or a more traditional aesthetic, aluminum doors can be customized to match your desired appearance. Additionally, aluminum frames can accommodate large glass panels, providing ample natural light and creating a visually appealing entrance.

Security: Aluminum doors offer a high level of security. They are sturdy and can be reinforced with additional security features such as multipoint locking systems and laminated glass. These enhancements provide enhanced protection against break-ins and intrusions.

Environmental Friendliness: Aluminum is a recyclable material, making aluminum doors an eco-friendly choice. By choosing aluminum doors, you contribute to reducing waste and the demand for new raw materials. Additionally, the energy required to recycle aluminum is significantly lower compared to producing new aluminum, making it a sustainable option.

How to Produce Aluminum Profile

Aluminum profiles for doors and windows are manufactured using high-quality aluminum alloys, specifically designed for their structural integrity, durability, and corrosion resistance. The primary raw material used in the production of these profiles is aluminum extrusion billets.

Aluminum extrusion billets are cylindrical logs or ingots made from a blend of aluminum and various alloying elements. These alloying elements, such as silicon, magnesium, manganese, and copper, are added in precise proportions to enhance the strength, ductility, and other desired properties of the final aluminum profiles.

The billets undergo a series of processes to convert them into the desired profiles for doors and windows. The first step is heating the billets to a specific temperature, making them soft and malleable. Then, they are forced through a specially designed die under high pressure, using an extrusion press. The die imparts the desired shape and cross-sectional profile to the aluminum, resulting in the extruded profiles.

After extrusion, the profiles undergo various finishing processes, such as cutting, machining, surface treatment, and powder coating. These processes further enhance the aesthetics, functionality, and durability of the profiles, making them suitable for use in doors and windows.

How to Select Aluminum Profiles

Define Your Requirements: Determine your specific requirements for the aluminum profiles. Consider factors such as the intended application, load-bearing capacity, thermal insulation needs, aesthetic preferences, and any specific industry standards or certifications that may be required.

Assess Material Quality: Check the material grade of the aluminum profiles. High-quality profiles often use standardized aluminum alloy grades such as 6061, 6063, or 6082. Verify if the profiles are made from pure aluminum or if they are alloyed with other elements to enhance their properties.

Physical Inspection: Physically inspect the profiles to evaluate their quality. Look for smooth and uniform surfaces, free from visible defects like scratches, dents, or irregularities. Check the dimensions and tolerances to ensure they meet your specifications.

Surface Treatment and Coating: Examine any surface treatments or coatings applied to the profiles. Anodized or powder-coated finishes are common for enhanced protection and aesthetics. Assess the quality and durability of the coating, ensuring it is uniform and resistant to corrosion, fading, and scratching.

Structural Integrity: Assess the strength and structural integrity of the profiles. Consider their load-bearing capacity, rigidity, and resistance to deformation. Profiles with proper heat treatment and extrusion techniques tend to exhibit better structural properties.

Certification and Compliance: Check if the aluminum profiles meet relevant industry standards and certifications. Look for certifications like ISO 9001 for quality management systems or specific industry certifications that demonstrate adherence to recognized quality standards.

How does custom door aluminum extrusion work

Step 1: Our engineer will review your detailed size or drawing and provide a cross-sectional drawing for your confirmation.

Step 2: We open dies for your custom extrusion, create a sample, and send it to you for approval.

Step 3: If modifications are needed, we adjust the die size until you are satisfied with the sample.

Step 4: We inspect the raw material using a spectrum analyzer and proceed with extrusion production, providing weekly progress updates.

Step 5: Depending on your desired surface finish, we offer anodizing, electrophoresis, powder coating, or PVDF options.

Step 6: To ensure safe transportation, we carefully pack your products to avoid any damage.