Window Aluminum Section Profile Specification

Overview

Aluminum alloy section are the fundamental materials used in the fabrication of aluminum alloy doors and windows, forming the core structure of such doors and windows. The specifications, dimensional accuracy, chemical composition, mechanical properties, and surface quality of aluminum alloy section significantly impact the manufacturing quality, performance, and lifespan of aluminum alloy doors and windows.

Aluminum Alloy Selection

The choice of aluminum alloy is fundamental to the performance of window sections. Two common alloys are 6063 and 6061. The 6063 alloy, with its emphasis on extrudability and corrosion resistance, is ideal for intricate profiles. Meanwhile, the 6061 alloy, renowned for its strength and machinability, finds applications in areas where structural integrity is paramount.

6061 Aluminum Alloy

6061 is an aluminum alloy that primarily consists of aluminum, with magnesium and silicon as its primary alloying elements. Magnesium content typically ranges from 1.0% to 1.4%, and silicon content falls within the range of 0.4% to 0.8%.

Strength: 6061 is known for its excellent strength, comparable to certain steel alloys. This makes it suitable for applications where structural integrity is crucial.

Machinability: The alloy exhibits good machinability, allowing for precise shaping and finishing.

6063 Aluminum Alloy

The 6063 aluminum alloy is primarily composed of aluminum, with magnesium and silicon as its key alloying elements. Magnesium content typically ranges between 0.45% and 0.9%, while silicon content falls within the range of 0.2% to 0.6%. These alloying elements contribute to the alloy’s excellent extrudability and formability.

Extrudability: 6063 is renowned for its exceptional extrudability, making it a preferred choice for the intricate profiles often required in window sections.

Corrosion Resistance: The alloy exhibits good corrosion resistance, especially when subjected to various atmospheric conditions.

Heat Treatment

Heat treatment enhances the mechanical properties of aluminum alloys. Common processes include T5 and T6 treatments. T5 results in improved strength and corrosion resistance, while T6 provides even greater strength, making it suitable for applications with higher structural demands.

T5 heat treatment plays a pivotal role in enhancing their mechanical characteristics. The process involves subjecting the aluminum alloy to solution heat treatment, followed by rapid quenching and artificial aging. This meticulous treatment not only increases the strength and hardness of the profiles but also ensures an optimal balance with formability. For applications in the construction and architectural industries, where doors and windows require both structural integrity and malleability for design flexibility, T5 heat-treated aluminum profiles stand as a preferred choice.

T6 heat treatment becomes instrumental. This process includes solution heat treatment, quenching, natural aging at room temperature, and subsequent artificial aging. The T6 treatment imparts a higher level of strength to the profiles, making them well-suited for applications where structural robustness is a priority. While there might be a slight reduction in formability compared to T5, the T6 heat-treated aluminum profiles find applications in aerospace, automotive, and other industries where durability and strength are paramount considerations for doors and windows.

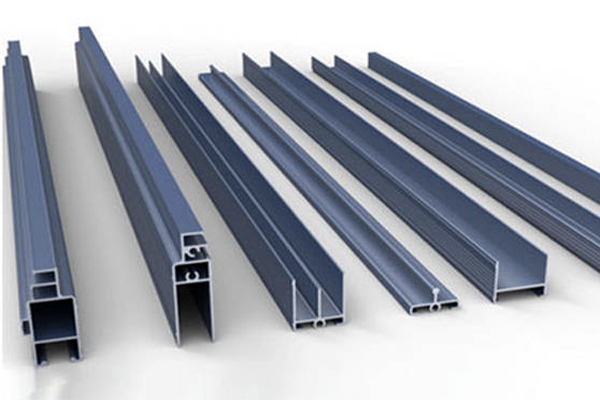

Width Series

Aluminum window profiles are available in various width series, such as 55mm, 60mm, 63mm, 65mm, 70mm, 75mm, 80mm, 90mm, 100mm, 110mm, and 120mm. The selection of a specific series depends on factors like architectural design, load-bearing requirements, and aesthetic preferences.

For minimalist designs, narrower width series like 55mm or 60mm are often preferred. For applications requiring increased structural stability and load-bearing capacity, wider series such as 90mm, 100mm, or 120mm may be more suitable. It’s essential to strike a balance between aesthetics and functionality.

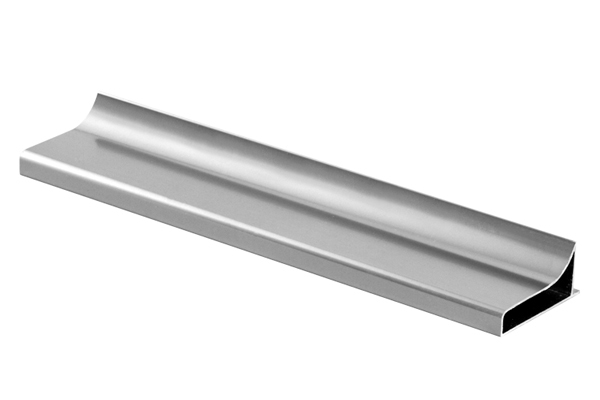

Two-Track Window Aluminum Profile

Structure: A two-track system consists of two parallel tracks, usually positioned at the top and bottom. This design allows doors or windows to slide within, commonly used for double sliding doors or windows.

Advantages: Simplified structure, easy to operate, and maintain. Suitable for straightforward door and window layouts.

Three-Track Window Aluminum Profile

Structure: A three-track system includes three tracks, often comprising two upper tracks and one lower track. This design enables doors or windows to slide in two directions, providing more opening options.

Advantages: Allows for more flexible door and window operations. For example, one door or window can slide to a central position while keeping the other track fully open.

Multi-Track Window Aluminum Profile

Structure: Multi-track systems have more than three tracks, offering increased flexibility. This design can support multiple doors or windows moving simultaneously.

Advantages: Suitable for larger openings, providing various opening configurations. Ideal for spacious areas like balconies or terraces.

Thickness

The thickness of aluminum window section directly influences their strength and durability. External profiles, whether for doors or windows, typically have a minimum thickness of 2.2mm, while internal profiles maintain a minimum of 2.0mm for doors and 1.4mm for windows.

Surface Treatments

Surface treatment technologies for aluminum alloy profiles vary significantly due to differences in principles, leading to distinct processes. Based on the nature of the protective layer and process characteristics, surface treatments for aluminum profiles can be categorized into three major types: anodizing treatment, anodizing combined with electrophoretic coating, and organic coating treatment. The organic coating treatment includes powder coating, fluorocarbon paint spraying, and wood grain treatment. Each of these methods offers unique properties and applications, providing a range of options for enhancing the appearance, durability, and functionality of aluminum alloy profiles.

Anodizing

Anodizing is a surface treatment method for aluminum profiles that involves creating a controlled oxide layer on the metal surface through an electrochemical process. This layer enhances corrosion resistance, durability, and provides the aluminum with a decorative finish. Anodized aluminum profiles are known for their increased hardness and resistance to wear, making them suitable for various applications, particularly in architectural settings where both aesthetics and performance are crucial.

Electrophoretic Coating (Electrocoating)

Electrophoretic coating, commonly known as e-coating or electrophoresis, is a method where aluminum profiles are immersed in a paint bath containing positively charged paint particles. The aluminum profile, acting as the cathode, attracts and bonds with the paint particles, resulting in a uniform and corrosion-resistant coating. This method offers excellent coverage, a smooth finish, and is environmentally friendly, making it a preferred choice for applications where consistent color and protection against corrosion are essential.

Powder Coating

Powder coating involves applying a dry powder to the aluminum surface, which is then cured under heat to form a durable, protective layer. This process results in a uniform, high-quality finish that is resistant to chipping, scratching, and fading. Powder coating provides a wide range of color options, making it a versatile choice for architectural and design applications. It is valued for its environmental friendliness, as it produces minimal waste and does not contain solvents.

Fluorocarbon Coating (PVDF Coating)

Fluorocarbon coating, or PVDF coating, is a high-performance finishing option for aluminum profiles. It involves applying a fluorocarbon resin-based paint, which forms a strong, weather-resistant surface when cured. PVDF coatings provide exceptional durability, resistance to UV radiation, and color retention, making them suitable for exterior applications in challenging environmental conditions. This coating is often chosen for high-end architectural projects where long-term performance and aesthetic integrity are paramount.

Wood Grain Transfer

Wood grain transfer is a decorative surface treatment where a realistic wood grain pattern is transferred onto the aluminum profile through a heat and pressure process. This technique allows aluminum profiles to mimic the appearance of natural wood while retaining the advantages of metal, such as durability and low maintenance. Wood grain transfer is widely used in applications where a warm and natural aesthetic is desired, combining the elegance of wood with the practicality of aluminum.

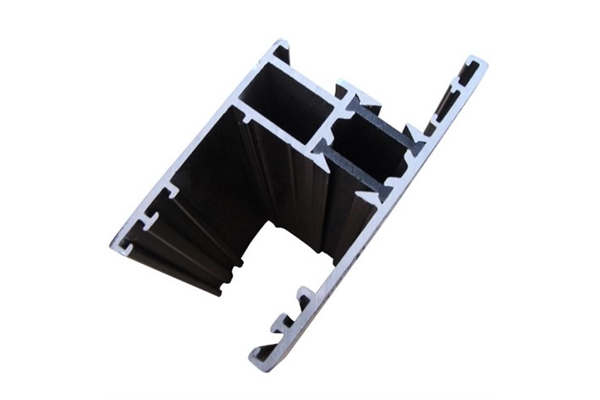

Thermal Break Aluminum Section

Thermal break aluminum sections feature a specialized design with a thermal barrier, typically composed of insulating materials like polyamide, strategically placed between the inner and outer aluminum components. This innovative structure disrupts heat transfer, reducing thermal conductivity and significantly improving energy efficiency. The benefits extend to enhanced insulation properties, maintaining optimal indoor temperatures while reducing energy consumption. These sections also address condensation concerns by minimizing temperature differentials. Importantly, thermal break technology doesn’t compromise the inherent strength of aluminum, making these sections suitable for various architectural applications. In essence, thermal break aluminum sections exemplify a holistic solution, seamlessly combining energy conservation, environmental sustainability, and structural integrity in modern construction.

Factory

We specialize in manufacturing high-quality, precision-engineered aluminum profiles for various industries. With state-of-the-art equipment and a skilled workforce, we produce complex profiles with exceptional dimensional accuracy using premium-grade aluminum alloys. Our customization options allow us to create unique profiles with intricate shapes, precise tolerances, and various surface finishes, tailored to your specific requirements. Quality is paramount to us, and we adhere to rigorous quality control measures throughout the manufacturing process. Our commitment to environmental sustainability is reflected in our eco-friendly practices, such as recycling aluminum scraps and optimizing energy consumption.