Extruded Aluminum Window Frame

Structure

Sliding Window Frame

The Sliding Window redefines convenience and modern design. Operating horizontally, it effortlessly glides to open, maximizing space utilization. Its sleek profile and smooth functionality make it an excellent choice for contemporary homes and offices, offering unobstructed views and efficient ventilation. Ideal for those who value both aesthetics and practicality in their windows.

Casement Window Frame

The Casement Window epitomizes timeless sophistication. Its hinged design, swinging open like a door, adds a touch of classic charm while enabling excellent ventilation control. This window style suits various architectural themes, offering versatility and energy efficiency. With options for top-hung, side-hung, or bottom-hung sashes, it caters to diverse preferences, making it a quintessential choice for those seeking elegance and functionality in their windows.

Awning Window Frame

The Awning Window stands as a testament to functional elegance. Through its innovative top-hinged design, it opens outward, inviting in breezes while providing a shield against rain. This proves particularly advantageous for spaces like kitchens and bathrooms, where ventilation remains paramount even during light showers. Beyond its practicality, the Awning Window contributes a touch of contemporary aesthetics to various settings, making it a versatile and sought-after choice for both residential and commercial spaces.

Tilt & Turn Window Frame

The Tilt & Turn Window stands at the forefront of modern innovation. This versatile window type allows for two distinct opening modes: tilting inward at the top for gentle ventilation and turning inward from the side for easy cleaning and enhanced airflow. Its practicality is matched by its contemporary aesthetics, making it a popular choice for spaces where functionality and style converge. Whether it's about improving indoor air quality or embracing sleek design, the Tilt & Turn Window offers a seamless blend of form and function for today's discerning homeowners.

Folding Window Frame

The Folding Window introduces a new dimension to space and design. With its innovative folding mechanism, it smoothly transforms from a solid barrier to an open expanse, seamlessly connecting indoors and outdoors. This window style is a testament to versatility, offering panoramic views and ample ventilation when fully opened, while conserving space when closed. Its contemporary aesthetic and ability to merge convenience with aesthetics make it an ideal choice for those who seek a harmonious integration of architecture and nature in their living or work spaces.

Single Hung Window Frame

The Single Hung Window is a blend of simplicity and functionality. The bottom sash is movable, allowing controlled airflow, while the top sash remains fixed. This classic design offers a timeless appeal, making it a popular choice for traditional and modern homes alike. Its straightforward operation and clean lines add a touch of elegance to any space, while its energy efficiency ensures comfort and savings. The Single Hung Window embodies a balance of style and practicality, perfect for those who appreciate understated beauty and reliable performance.

Double Hung Window Frame

The Double Hung Window marries tradition with adaptability. Both upper and lower sashes are operable, facilitating efficient airflow and easy cleaning. Its timeless design suits various architectural styles, providing a classic look while incorporating modern functionalities. This window type offers versatility for controlling ventilation, making it ideal for bedrooms, living spaces, and more. With its harmonious blend of aesthetics and practicality, the Double Hung Window continues to be a favored choice, offering a seamless connection between the past and the present in any home or building.

Fixed Window Frame

The Fixed Window captures the essence of architectural refinement. It remains immobile, serving as a visual frame to panoramic views and a source of abundant natural light. This design choice embodies a sleek, modern aesthetic, enhancing the visual appeal of interiors while providing a sense of spaciousness. The Fixed Window, with its seamless blend of form and function, is a testament to the power of simplicity in elevating both residential and commercial spaces.

Advantages of Aluminium Window Frames

Aluminum is a highly durable material that is resistant to rust, corrosion, and weathering. This makes aluminum window frames suitable for various environments, including coastal areas where saltwater exposure can be a concern.

Aluminum is a strong material, allowing for the creation of slim and sleek window frames that can support larger glass panes. This means you can have more expansive views and maximize natural light without compromising structural integrity.

Aluminum window frames are relatively low maintenance. They do not require painting or sealing like some other materials, and they can be easily cleaned with mild soap and water.

Despite its strength, aluminum is lightweight, which can make installation easier and reduce the stress on the building’s structure.

Aluminum window frames can be finished with various colors and textures through processes like powder coating or anodizing. This allows for customization to match the aesthetic of the building’s interior and exterior.

Aluminum is non-combustible and offers a higher level of fire resistance compared to some other materials, contributing to overall building safety.

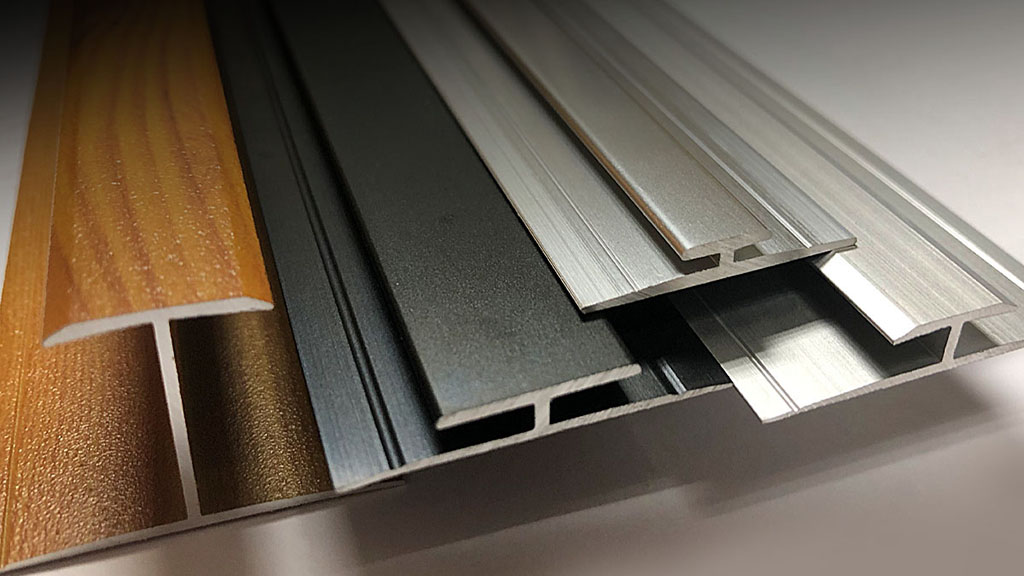

Surface Treatments

Surface treatment for aluminum window profiles serves two important purposes: protection and customization. There are several straightforward methods for this. Anodizing involves creating a protective oxide layer through an electrochemical process, providing corrosion resistance. Electrophoretic coating (e-coating) ensures even coverage and enhanced durability. Powder coating uses dry powder for a tough, colorful finish. PVDF coating offers excellent weather resistance. Wood grain transfer printing replicates a wood texture for a natural look. Each of these methods caters to different needs, from safeguarding against the elements to achieving a desired aesthetic for aluminum window profiles.

Anodized aluminum window frame

Anodized aluminum profile window frames are a type of window framing system made from aluminum that has undergone an anodization process. Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of aluminum, making it more durable, corrosion-resistant, and often providing it with a decorative finish. Anodized aluminum profiles are commonly used in the construction industry for various applications, including window and door frames.

1. Anodization Process:

Anodized aluminum is created through an electrochemical process called anodization. During anodization, the aluminum profile is immersed in an electrolytic solution and subjected to an electric current. This process thickens the naturally occurring oxide layer on the surface of aluminum, creating a more robust and corrosion-resistant surface.

2. Color Options:

Anodized aluminum can be treated to achieve a variety of colors and finishes. This process involves using organic and inorganic dyes that penetrate the porous anodized layer, resulting in a wide range of color choices. Common colors include silver, bronze, black, gold, and more.

In addition to standard colors, anodized aluminum profiles can also be finished with different textures, such as matte, brushed, or polished. These finishes can enhance the visual and tactile qualities of the frames.

3. Advantages:

- Corrosion Resistance: The anodized layer provides excellent protection against corrosion, making it suitable for outdoor and high-moisture environments.

- Aesthetic Appeal: Anodized finishes offer a modern and sleek appearance that can enhance the overall aesthetics of a building.

- Low Maintenance: The durable surface is easy to clean and requires minimal maintenance over its lifespan.

- Strength: Aluminum is inherently strong, allowing for the creation of slim and lightweight frames that can support large glass panels.

- Environmental Friendliness: Anodizing is an environmentally friendly process that produces minimal waste and avoids the use of harmful chemicals.

Electrophoresis aluminum window frame

Electrophoresis aluminum profile window frames are a type of window framing system made from aluminum that has undergone an electrophoresis coating process. This specialized coating process enhances the durability, aesthetics, and corrosion resistance of the aluminum, making it a popular choice for window frames in various architectural and construction projects.

1. Process:

Electrophoresis is an electrocoating process that involves immersing the aluminum profiles in a bath containing a water-based paint or coating solution. An electric field is applied, causing the paint particles to migrate and uniformly adhere to the surface of the aluminum through an electrochemical reaction. This results in a consistent and tightly bonded coating.

2. Color Option:

Manufacturers often provide a selection of standard colors that are readily available. These colors can include variations of silver, white, black, gray, bronze, and more. It can be customized in terms of color, texture, and gloss, allowing for a wide range of aesthetic options to match the design of the building.

3. Benefits of Electrophoresis Aluminum Profile Window Frames:

- Durability: The electrophoretic coating provides excellent durability and is resistant to chipping, scratching, and fading, ensuring the window frames maintain their appearance over time.

- Corrosion Resistance: The coated aluminum frames are highly resistant to corrosion, making them suitable for both interior and exterior applications, even in environments with high humidity or exposure to harsh weather conditions.

- Aesthetic Variety: Electrophoresis coatings can be customized in terms of color, texture, and gloss, allowing for a wide range of aesthetic options to match the design of the building.

- Smooth Finish: The electrophoresis process results in a smooth and even finish on all sides and edges of the aluminum profiles.

- Environmental Considerations: Electrophoresis coatings are water-based and contain fewer volatile organic compounds (VOCs), making them environmentally friendly.

- UV Resistance: Many electrophoretic coatings offer good UV resistance, preventing color fading or degradation due to prolonged sun exposure.

- Low Maintenance: The coating is relatively easy to clean with mild soap and water, maintaining the appearance of the frames with minimal effort.

Powder coated aluminum window frame

Powder-coated aluminum profile window frames are another popular choice in the construction industry for creating durable, attractive, and corrosion-resistant window framing systems. Powder coating is a finishing process that involves applying a dry powder paint onto the surface of aluminum profiles. The coated profiles are then cured under heat, allowing the powder to melt, flow, and form a hard and smooth finish.

1. Process:

The powder coating process involves several steps:

- Preparation: The aluminum profiles are cleaned and treated to ensure proper adhesion of the powder coating.

- Powder Application: The dry powder paint is electrostatically charged and sprayed onto the surface of the profiles, where it adheres due to the electrostatic attraction.

- Curing: The coated profiles are then cured in an oven, where the powder melts, flows, and chemically reacts to form a durable and smooth finish.

- Cooling and Inspection: After curing, the profiles are cooled, inspected for quality, and packaged for shipping.

2. Color Option:

Powder-coated aluminum profile window frames provide an extensive palette of color options that cater to a wide spectrum of architectural visions and design aesthetics. From timeless neutrals like pristine whites and sleek blacks, which lend an air of sophistication and adaptability to any setting, to metallic finishes including silvers, bronzes, and golds that infuse an element of luxury and opulence into the overall ambiance. Earthy tones like beiges and browns establish a warm and inviting atmosphere, while bolder choices such as reds, blues, and greens introduce vibrant energy or soothing tranquility, depending on the desired effect.

Moreover, the customization possibilities extend beyond the standard offerings. Manufacturers often provide the option for custom color matching, enabling architects and designers to choose hues that align precisely with their vision. The availability of textured finishes adds an additional layer of creativity, allowing for not only a diverse color palette but also varying tactile experiences. Gloss levels, ranging from high-gloss to matte, further empower creators to tailor the appearance of the frames to perfectly complement the surrounding environment.

3. Benefits of Powder-Coated Aluminum Profile Window Frames:

- Durability: Powder-coated finishes are highly durable, resistant to chipping, scratching, and fading, ensuring the window frames maintain their appearance over time.

- Corrosion Resistance: The coating provides excellent protection against corrosion, making powder-coated frames suitable for exterior applications and areas with high humidity.

- Color Variety: Powder-coated finishes come in a wide range of colors, allowing you to choose a color that matches the building’s design and aesthetic.

- Texture Options: Powder coatings can have different textures, such as smooth, matte, textured, or even a metallic appearance.

- Environmental Considerations: Powder coating is an environmentally friendly process, as it produces minimal waste and doesn’t involve the use of solvents or volatile organic compounds (VOCs).

- UV Resistance: Many powder-coated finishes offer good UV resistance, which helps prevent color fading or degradation due to sun exposure.

PVDF coated aluminum window frame

PVDF (Polyvinylidene Fluoride) coated aluminum profile window frames offer a premium and highly durable finish for architectural applications. PVDF coating is a type of high-performance, weather-resistant paint that provides exceptional protection against environmental elements, making it suitable for exterior use.

1. PVDF Coating:

PVDF is a fluoropolymer resin that is known for its outstanding chemical resistance, UV stability, and weathering performance. When applied as a coating to aluminum profiles, it creates a durable, long-lasting, and visually appealing finish.

2. Benefits:

- Weather Resistance: PVDF coatings are highly resistant to fading, chalking, and discoloration caused by exposure to sunlight, moisture, and pollutants.

- Durability: The robust nature of PVDF coatings ensures that the window frames maintain their appearance and structural integrity over many years.

- Color Retention: PVDF coatings have excellent color retention properties, maintaining the intended color of the frames for an extended period.

- Chemical Resistance: PVDF coatings are resistant to chemicals, pollutants, and atmospheric agents, further enhancing their longevity.

- Low Maintenance: The smooth surface of PVDF coatings is easy to clean and maintain, requiring minimal effort to keep the frames looking new.

- Aesthetic Variety: PVDF coatings offer a wide range of color options, allowing you to choose the desired look for your architectural project.

- Architectural Versatility: PVDF coated aluminum profiles are suitable for various architectural styles and designs, enhancing both residential and commercial buildings.

Wooden finish aluminum window frame

Wooden finish aluminum profile window frames combine the aesthetics of natural wood with the durability and low-maintenance benefits of aluminum. These frames are designed to mimic the appearance of real wood while offering the advantages of aluminum construction. Here’s more about wooden finish aluminum profile window frames:

1. Visual Resemblance:

Wooden finish aluminum profiles are created using advanced manufacturing techniques that replicate the texture, grain patterns, and colors of different wood types. This allows you to achieve the warm and inviting look of wood without the associated maintenance challenges.

2. Benefits:

- Durability: Aluminum profiles are naturally resistant to rust, corrosion, and weathering, ensuring that the wooden finish retains its appearance over time.

- Low Maintenance: Unlike real wood, the finish doesn’t require periodic staining, sealing, or painting. Cleaning with mild soap and water is usually sufficient to maintain the appearance.

- Versatility: Wooden finish aluminum frames can be used in various architectural styles, from traditional to contemporary, and in both interior and exterior applications.

- Environmentally Friendly: The manufacturing process uses less natural resources compared to real wood and avoids the need for frequent refinishing.

- Customization: These frames can often be customized in terms of color, grain pattern, and texture to suit specific design preferences.

3. Customization:

Manufacturers may offer a range of wood colors and patterns, allowing you to choose the specific wood look that suits your project. Some manufacturers might also provide customization options based on specific design requirements.

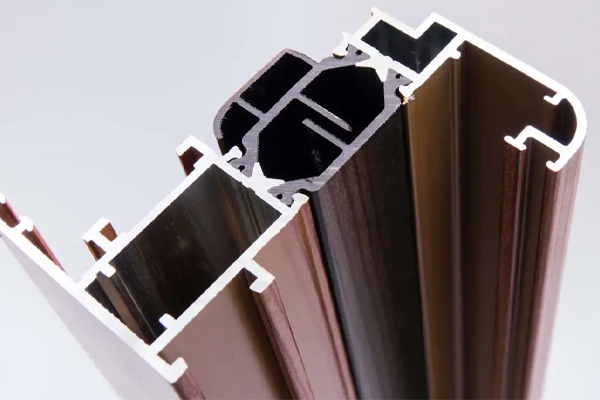

Thermal break aluminum profile window frames are advanced construction components designed to enhance the energy efficiency of buildings by reducing heat transfer through the frames. They consist of an innovative design that includes a thermal barrier or “break” within the aluminum structure. This break effectively separates the interior and exterior sides of the frame, minimizing the transfer of heat, cold, and sound.

1. Structure:

A thermal break is a non-metallic, insulating material that is placed between the inner and outer sections of the aluminum frame. The thermal break creates a barrier that significantly reduces the conductivity of heat and cold between the exterior and interior surfaces of the frame.

2. Benefits:

- Energy Efficiency: Thermal break aluminum frames prevent heat from transferring through the frame, resulting in improved insulation and reduced energy consumption for heating and cooling.

- Condensation Prevention: The thermal barrier helps prevent condensation from forming on the interior side of the frame, which can contribute to mold growth and damage.

- Enhanced Comfort: By minimizing heat transfer, thermal break frames create more comfortable indoor spaces by maintaining consistent temperatures near windows.

- Noise Reduction: The insulating properties of thermal breaks also contribute to reducing the transmission of sound, leading to quieter indoor environments.

- Reduced Thermal Bridging: Thermal bridging occurs when heat flows through a material that is more conductive, such as aluminum. Thermal breaks reduce this bridging effect.

- Sustainability: Improved energy efficiency can lead to reduced carbon emissions and lower energy bills, making thermal break aluminum frames an environmentally conscious choice.

How to custom window aluminum frame

Step 1: Our engineer will review your detailed size or drawing and provide a cross-sectional drawing for your confirmation.

Step 2: We open dies for your custom extrusion, create a sample, and send it to you for approval.

Step 3: If modifications are needed, we adjust the die size until you are satisfied with the sample.

Step 4: We inspect the raw material using a spectrum analyzer and proceed with extrusion production, providing weekly progress updates.

Step 5: Depending on your desired surface finish, we offer anodizing, electrophoresis, powder coating, or PVDF options.

Step 6: To ensure safe transportation, we carefully pack your products to avoid any damage.

Window frame aluminum frame factory

We specialize in manufacturing high-quality, precision-engineered aluminum profiles for various industries. With state-of-the-art equipment and a skilled workforce, we produce complex profiles with exceptional dimensional accuracy using premium-grade aluminum alloys. Our customization options allow us to create unique profiles with intricate shapes, precise tolerances, and various surface finishes, tailored to your specific requirements. Quality is paramount to us, and we adhere to rigorous quality control measures throughout the manufacturing process. Our commitment to environmental sustainability is reflected in our eco-friendly practices, such as recycling aluminum scraps and optimizing energy consumption.