Custom Extruded Aluminum Housing

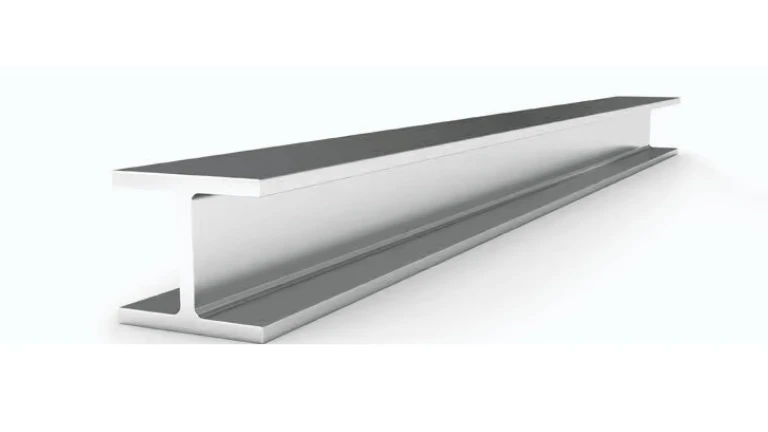

Extruded aluminum housings are durable, lightweight, and versatile structures designed to protect electronic components, sensors, power modules, and other devices. Manufactured using precision extrusion processes, these housings combine strength, corrosion resistance, and excellent heat dissipation, making them ideal for industries like electronics, telecommunications, automotive, and industrial automation.

As highly customizable enclosures, extruded aluminum housings provide superior protection against mechanical damage, environmental factors, and electromagnetic interference (EMI) compared to plastic or sheet metal alternatives. Their professional appearance and adaptability make them suitable for both consumer and industrial applications.

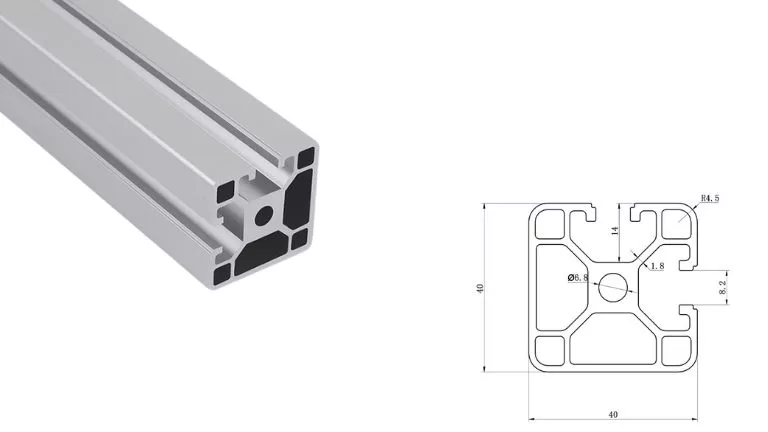

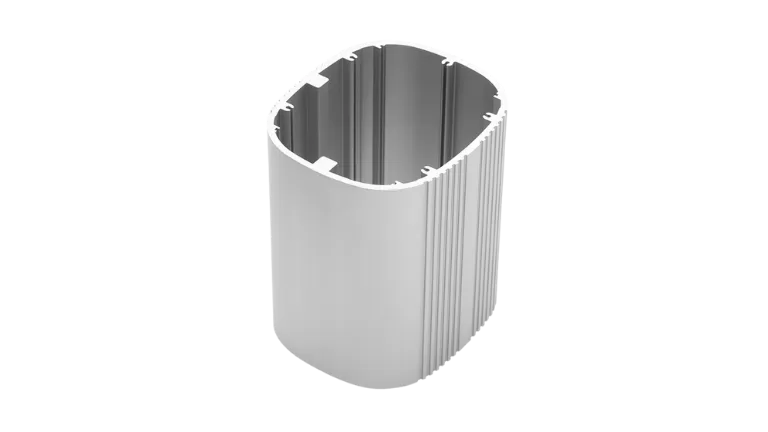

Round Housings

Round extruded aluminum housings are widely used in electromechanical products due to their sleek, compact design and excellent structural integrity. These housings provide seamless protection for motors, sensors, and other cylindrical components, offering superior durability and light weight. Their round shape also ensures efficient assembly and facilitates easier integration into rotational or mechanical systems.

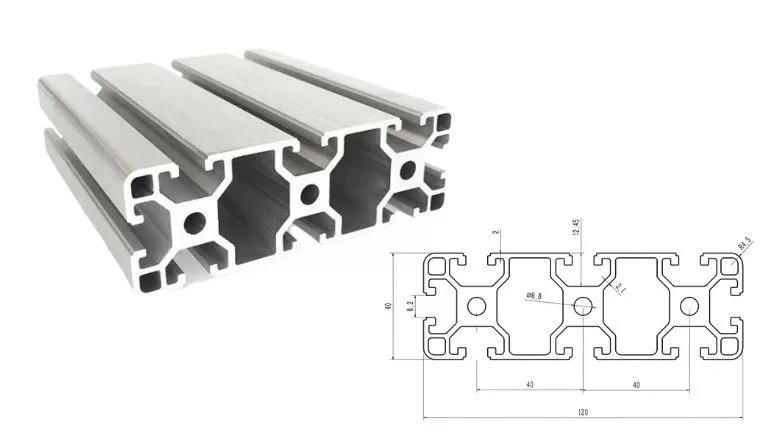

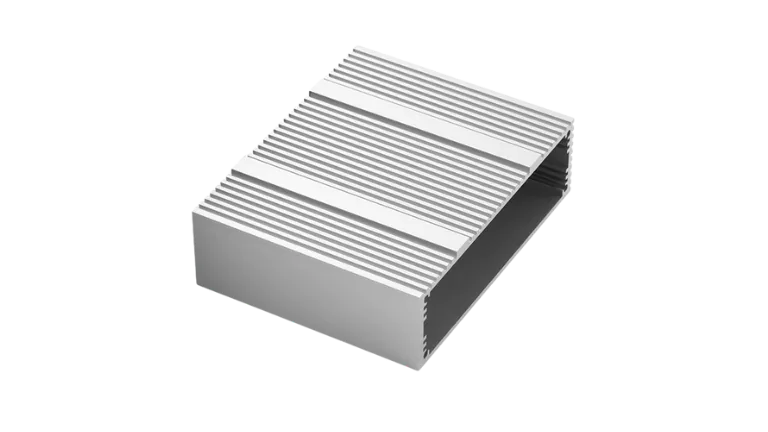

Rectangular or box-shaped extruded aluminum housings are ideal for electronic products such as communicators, modules, and control systems. With precise dimensions and customizable compartments, these housings provide excellent protection against environmental factors and electromagnetic interference (EMI). Their versatile design allows for easy mounting of circuit boards and components, making them a popular choice in consumer electronics and industrial control devices.

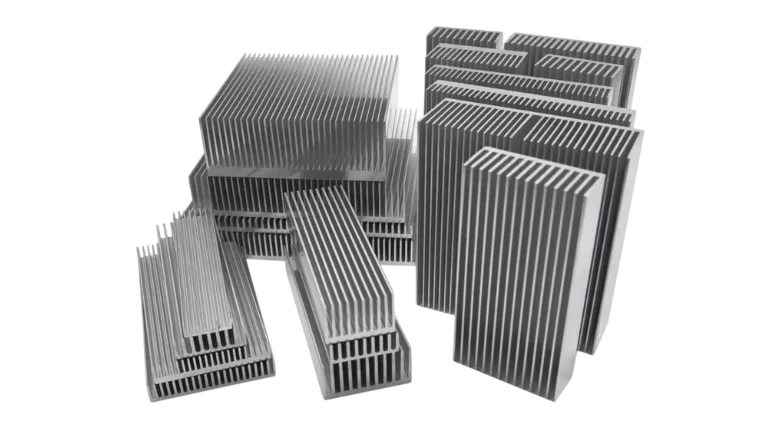

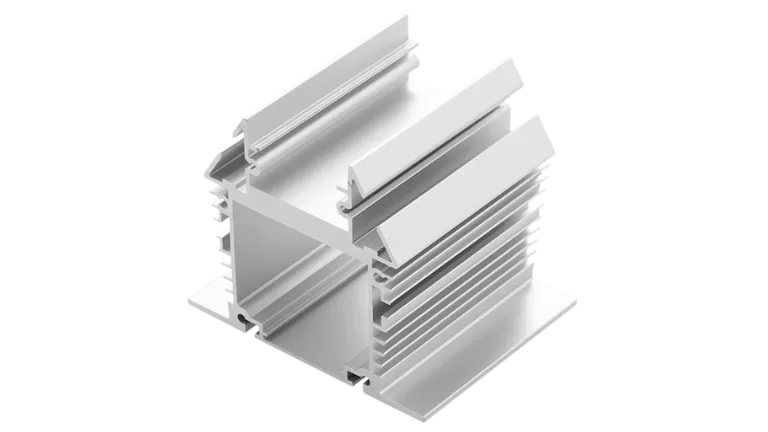

Extruded aluminum housings with integrated cooling fins are engineered for applications requiring excellent heat dissipation. These housings are perfect for power modules, LED drivers, and high-heat electronics where thermal management is critical. The extended fins significantly increase the surface area for efficient heat transfer, ensuring reliable performance even in high-temperature environments.

Extruded Aluminum Housing Processing Capabilities

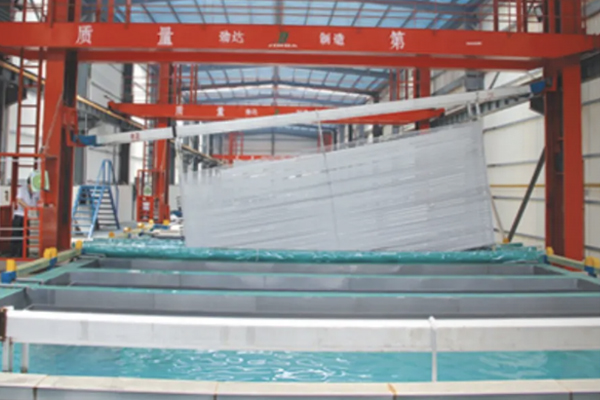

As a leading aluminum extrusion manufacturer based in China, we specialize in producing high-quality extruded aluminum housings for a wide range of applications. Our capabilities begin with custom mold design and development, ensuring precise shapes that meet the unique requirements of each project. From raw extrusion to surface finishing and advanced machining, our fully integrated manufacturing processes allow us to deliver aluminum housings with exceptional performance and durability.

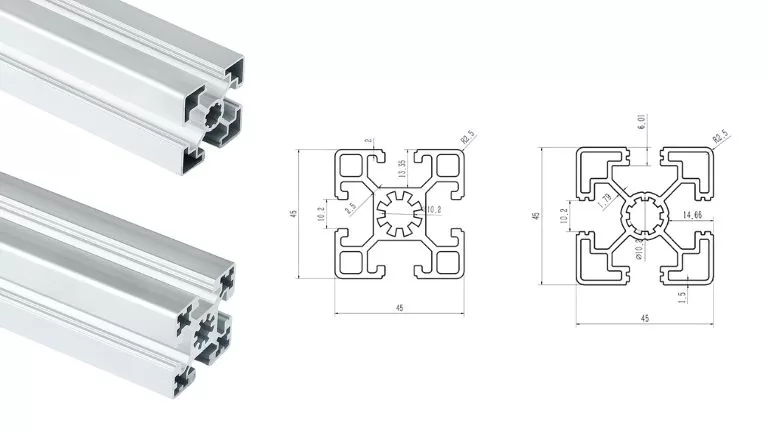

Our production facilities are equipped with over 40 advanced extrusion lines, including powerful 6000-ton extrusion presses. This ensures we can create extruded aluminum housings in various shapes and sizes, such as cylindrical bodies, rectangular enclosures, and heat-dissipation designs with fins. Whether you need housings for electronics, power modules, or industrial systems, we provide tailored solutions to match your exact specifications.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

We offer a range of surface treatment options, including anodizing, powder coating, and sandblasting, to enhance the appearance, durability, and corrosion resistance of our extruded aluminum housings. These treatments ensure excellent performance in challenging environments while providing a sleek, professional finish. Additionally, we can apply custom colors and textures to match specific design requirements, ensuring the housings meet both functional and aesthetic needs. Our surface treatments are rigorously tested to ensure long-lasting protection and quality in a variety of applications.

To meet exacting standards, our advanced machining and fabrication processes ensure accuracy in every detail, from threading and drilling to CNC machining. We also offer assembly-ready solutions, delivering housings that are prepared for seamless integration into your devices and systems. With enhanced precision capabilities, we accommodate complex designs and tight tolerances, ensuring reliable performance for sensitive electronic and industrial components. Additionally, our in-house inspection processes guarantee that every housing meets strict quality standards before delivery.

Customization Options

We provide a comprehensive range of customization options for extruded aluminum housings to meet your unique requirements. From materials to finishing touches, every detail can be tailored to deliver the perfect solution for your project.

Material Options

Choose from high-quality aluminum alloys such as 6063, 6061, or 6005 to meet the specific performance demands of your application. Each alloy offers excellent strength, corrosion resistance, and thermal conductivity, making them ideal for electronics, industrial, or automotive applications. Additionally, we offer heat treatment options, such as T5 and T6 tempering, to further enhance the mechanical properties, hardness, and durability of the material, ensuring it meets the rigorous requirements of your project.

Custom Mold Development

We provide custom mold design and development services to create extruded aluminum housing profiles in any shape or configuration. Whether you need cylindrical, rectangular, or complex custom designs, we can develop molds based on your provided drawings or physical samples. With a streamlined process and advanced equipment, we typically complete mold production within approximately 7 days, ensuring fast and precise manufacturing to meet your project timeline.

Surface Treatment Options

Enhance the durability, appearance, and corrosion resistance of your extruded aluminum housings with a wide range of surface treatments. These treatments not only improve performance in challenging environments but also allow for customization to suit aesthetic or functional needs. Our options include:

Anodizing (clear, black, colored, etc.)

Provides superior corrosion resistance while creating a decorative and protective oxide layer. Anodizing can also be customized in various colors to match your brand or design requirements, with a long-lasting finish that resists scratches and wear.

Powder Coating

Offers a durable and decorative finish that is both eco-friendly and resistant to chipping, fading, and abrasion. Available in a variety of colors and textures, powder coating improves visual appeal while ensuring the housing can withstand harsh environmental conditions.

Sandblasting

Creates a uniform, matte texture on the surface, enhancing the aesthetic appeal and preparing the housing for further treatments like anodizing or painting. The process removes surface imperfections, resulting in a clean and smooth finish that adds to the design’s sophistication.

Brushing and Polishing

Produces a sleek, professional look by creating a fine texture or mirror-like finish on the surface. Brushing emphasizes a modern, industrial look, while polishing results in a highly reflective, premium appearance suited for high-end applications.

Chemical Etching

Allows for deeper surface patterns, unique textures, or intricate designs, perfect for branding or customized finishes. This method enhances the housing’s aesthetic appeal while maintaining excellent functionality and durability.

Surface Machining Services Options

We offer precision machining to create housing designs with complex geometries and tight tolerances. This includes services such as:

Threading and drilling

CNC machining

Slotting, tapping, and engraving

These processes ensure housings are assembly-ready and meet specific component requirements.

Logo Customization

Personalize your extruded aluminum housings with custom logos or branding. Options include laser engraving, screen printing, or embossed/engraved profiles, allowing you to enhance your product’s identity.

Packaging Options

Tailor your packaging to match your needs with options like customized boxes, foam inserts, shrink wrapping, or protective films. We also provide eco-friendly packaging solutions to support sustainable initiatives while ensuring safe transportation.

Our Factory

Custom Extrusion from Us

At HTS NEW MATERIALS, we specialize in providing custom aluminum extrusions designed to meet your unique requirements. With advanced production facilities and over 40 extrusion lines, we deliver premium, precision-engineered profiles for a wide range of industries, including aerospace, automotive, construction, and more.

Our custom extrusion services include:

- Tailored Cross-Sections: Create unique aluminum profiles with our expert die-making capabilities, customized to suit your specific project needs.

- Diverse Surface Finishes: Enhance both the appearance and durability of your profiles with options like anodizing, powder coating, polishing, and more.

- Precision Machining: Ensure exact dimensional accuracy with cutting, drilling, milling, and advanced machining services.

- Flexible Tempers: Select from a variety of heat treatments, including T5, T6, and others, to achieve the ideal mechanical properties for your application.

Partner with HTS NEW MATERIALS for innovative, cost-effective, and dependable custom aluminum extrusion solutions that drive the success of your project.

RFQ of Extruded Aluminum Profile

When choosing between extruded and die-cast aluminum housings, it’s important to understand how they differ in terms of material properties, manufacturing methods, design flexibility, and applications. Below is a breakdown of the key differences:

1. Manufacturing Process

- Extruded Aluminum Housing:

The extrusion process involves forcing heated aluminum billets through a custom die to create long profiles with a consistent cross-section. These profiles are then cut, machined, or shaped into a variety of housing designs. - Die Cast Aluminum Housing:

Die casting involves injecting molten aluminum under high pressure into a steel mold (die) to form a specific shape. The process produces fully formed parts in a single step, often requiring less secondary machining.

2. Material Usage and Properties

- Extruded Aluminum:

Uses aluminum alloys such as 6063, 6061, and 6005, which are known for their excellent corrosion resistance, high strength-to-weight ratio, and superior thermal conductivity. Ideal for housings requiring lightweight and high thermal performance, such as LED housings and electronic enclosures. - Die Cast Aluminum:

Uses alloys like ADC12 and A380, which tend to have higher density and slightly reduced corrosion resistance but provide excellent casting properties. These are ideal for creating complex, integrated shapes with good dimensional stability.

3. Design Complexity

- Extruded Aluminum:

Best suited for simple, linear designs with a consistent cross-section, such as cylindrical or rectangular housings. While additional machining can add complexity, designs are mostly limited to the extrusion profile. - Die Cast Aluminum:

Offers significantly more design freedom, allowing highly detailed and complex geometries, such as curves, thin walls, and intricate patterns. Perfect for parts requiring integrated features like mounting holes or thin walls.

4. Dimensional Accuracy and Surface Finish

- Extruded Aluminum:

Requires post-processing, like CNC machining, to achieve tight dimensional tolerances and specific designs. Usually, the surface finish is uniform, but additional finishing (like anodizing or powder coating) enhances its final appearance. - Die Cast Aluminum:

Achieves tight tolerances and detailed shapes directly from the mold. Features a smoother surface out of the die, but finishing options like coating or polishing may still be added for aesthetics.

5. Cost and Production Volume

- Extruded Aluminum:

Suitable for medium to high production volumes where long and consistent profiles are needed. The upfront cost for dies is lower than die casting, making it more economical for certain designs. - Die Cast Aluminum:

Involves higher mold costs and is best suited for high-volume production. The cost per part decreases significantly with larger batch sizes due to the efficiency of the single-step process.

6. Applications

- Extruded Aluminum:

Commonly used for housings requiring excellent heat dissipation, such as LED heat sinks, electronics enclosures, and industrial casings. - Die Cast Aluminum:

Used in housings with complex shapes or highly integrated designs, such as automotive parts, engine housings, and intricate enclosures for machinery or appliances.

Conclusion

- Extruded Aluminum Housing is ideal for applications where simplicity, lightweight features, and excellent thermal conductivity are essential.

- Die Cast Aluminum Housing is better suited for complex and detailed designs requiring high-dimensional accuracy and integrated features.

The choice between the two depends on your specific requirements, including design, performance, production volume, and budget.

When selecting a material for housing applications, it is crucial to consider factors such as weight, strength, heat dissipation, appearance, and processing flexibility. Below is a detailed comparison of extruded aluminum housings, plastic housings, and steel housings.

| Characteristic | Extruded Aluminum Housing | Plastic Housing | Steel Housing |

|---|---|---|---|

| Weight | Lightweight, easy to handle and install. | Lightest, but lower strength. | Heavy, leading to more difficult transport and installation. |

| Strength and Durability | High strength and excellent resistance to deformation, offering long-term durability. | Low strength, prone to cracking or breaking under stress. | Excellent strength, highly resistant to external forces. |

| Heat Dissipation | Superior thermal conductivity, ideal for applications requiring efficient heat dissipation. | Poor heat dissipation, especially in enclosed environments. | Moderate heat dissipation, slower thermal conductivity. |

| Corrosion Resistance | Outstanding corrosion resistance, further enhanced with anodizing treatments. | Poor corrosion resistance, prone to degradation over time. | Requires coating or galvanizing to resist corrosion. |

| Premium Appearance | Modern and customizable design with a sleek, high-end look. | Simple with a plain visual appearance, less premium. | Suitable for industrial-style designs, but lacks modern aesthetics. |

| Processing Flexibility | Highly customizable, allowing for complex shapes and precise designs through advanced machining and extrusion techniques. | Moderate customizability, with some limitations in processing certain features or geometries. | Low flexibility, with higher processing costs for custom designs. |

| Electromagnetic Shielding | Excellent shielding against interference, suitable for electronic components. | Lacks electromagnetic shielding capabilities. | Superior shielding performance, even exceeding aluminum housings in some applications. |

| Applications | Versatile for indoor and outdoor use, applicable in electronics, industrial environments, and more. | Commonly used in indoor applications due to limited durability and strength. | Best for heavy-duty industrial equipment housings and environments requiring high mechanical strength. |

1. Industrial Products

- Industrial Control Boxes: Used for PLC controllers, relays, or industrial sensors, offering robust protection in demanding environments.

- Electrical Equipment Casings: Provide reliable protection for panels, displays, and input terminals.

- Industrial Automation Products: Serve as protective enclosures for automation control devices and modular systems, ensuring operational safety and durability.

2. Communication Equipment

- Wireless and Wired Network Devices: Casings for signal amplifiers, routers, and other networking equipment.

- Telecom Base Station Modules: Designed to withstand harsh outdoor conditions while protecting internal communication modules.

- Fiber Transceivers and Radio Devices: Durable housings for equipment like optical modules and small wireless communication devices.

3. Consumer Electronics

- Audio Amplifiers: Sealed housings that enhance both heat dissipation and protective performance.

- Portable Power Devices: Protective casings for power banks, handheld devices, and adapters.

- Smart Home Devices: Enclosures for systems such as smart hubs, wireless products, and control modules.

4. Automotive and Transportation

- Automotive Electronics: Housings for electronic modules like Battery Management Systems (BMS) or electric motor controllers.

- Motor Controller and Display Protection Casings: Provides robust shielding for on-board systems.

- Rail Transit Equipment: Enclosures for communication devices, signal amplifiers, or other critical railway components.

5. Medical Devices

- Diagnostic and Testing Equipment: Compact housings for medical devices such as portable diagnostic tools.

- Infusion Pumps and Monitoring Devices: Protective casings for medical monitoring equipment, including ECG machines.

- Medical Instrument Modules: Modular aluminum brackets for sensitive medical instruments.

6. Power and Renewable Energy

- Energy Storage System Casings: Protective enclosures for battery packs and inverter systems.

- LED Driver Enclosures: Reliable housings for LED drivers ensuring thermal regulation and durability.

- Solar Power Control Equipment: Casings for solar inverters, battery management systems, and charging piles.

7. Outdoor Devices and Instruments

- Surveillance and Security Cameras: Rugged, weather-resistant housings for outdoor monitoring equipment.

- Rainproof and Dustproof Sensor Casings: Protection for outdoor sensors used in harsh weather or industrial sites.

- Meteorological and Environmental Monitoring Instruments: Enclosures for devices used to monitor climate or pollution.

For custom aluminum extrusion projects, we accept a variety of drawing formats, including CAD files, STEP files, and PDF files. However, for extrusions that require additional machining processes, it’s recommended to provide STEP files, as they ensure precise 3D modeling for machining accuracy.

While PDF files are acceptable, converting them into CAD drawings may result in the loss of certain details, requiring us to manually redraw the design, which could increase lead time. For the fastest and most accurate quotation, we recommend providing CAD files (e.g., DWG/DXF) and STEP files to ensure efficient design evaluation and pricing.

Mold fees are an essential part of the custom aluminum extrusion process. Since every order requires a uniquely designed mold tailored to specific requirements, these molds cannot be used for other products. Therefore, the mold fee is necessary and non-negotiable.

We require 100% upfront payment of the mold fee before mold development begins to ensure timely production. However, as a token of appreciation for your support, we offer a refund of the mold fee or equivalent discounts once the order reaches a certain production volume. Specific policies can be discussed based on your order volume and collaboration details.

Our minimum order quantity (MOQ) varies depending on the size of the product. For smaller-sized products, the MOQ is typically 500kg, while for larger-sized products, it is 2 tons.

We will specify the exact MOQ requirements during the quotation process. If your order quantity does not meet the MOQ, we can still arrange production, but an additional fee will be applied to cover mold preheating and production setup time. Rest assured, this extra fee will be reasonable, and we aim to keep it as minimal as possible to ensure smooth cooperation.

Mold production typically takes 7 days. After the sample is confirmed, producing a full container load of 26 tons generally requires 14 days for extrusion alone. If surface treatment is required, an additional 3 days will be needed. For machining, extra time will be required depending on the complexity and volume of the machining work. The exact additional time for machining will be determined based on the specific processing requirements.

Aluminum profiles are naturally corrosion-resistant due to the formation of a thin, protective oxide layer when exposed to air or water. This oxide layer is stable and self-repairing, meaning that even if the surface is scratched or cut (such as at exposed ends or during processing), the aluminum will not rust or corrode like iron or steel. Instead, the exposed areas will quickly form a new oxide layer, providing continuous protection against further oxidation.

With proper design, installation, and maintenance, aluminum profiles can last for decades, even in challenging environments. For example, untreated aluminum can easily withstand 20-30 years in outdoor applications, while profiles with surface treatments like anodizing or powder coating can last even longer, often exceeding 50 years. This makes aluminum an excellent choice for applications where durability and long-term performance are essential.

The price of aluminum profiles consists of several components: raw material costs, extrusion processing fees, surface treatment fees, machining costs, and additional packaging fees. Among these, the cost of aluminum as a raw material tends to fluctuate frequently, while other fees remain relatively stable. Due to these fluctuations, our quotations are typically valid for 7 days.

Pricing can be structured in different ways depending on the product and requirements. It can be calculated by weight (e.g., cost per ton), by length (e.g., cost per meter), or by piece (e.g., cost per unit). For products involving extensive machining, such as heat sinks, pricing is generally calculated on a per-piece basis to accurately reflect the additional processing costs. This flexible pricing approach ensures the quote is tailored to the specific needs of the customer.

We can manufacture aluminum profiles in compliance with technical requirements that meet European standards (EN), American standards (ASTM/AA), or other standards as specified by the customer. Custom production is tailored to ensure that the profiles meet the specific standard requirements requested.

Our production equipment is designed for the metric system. If the drawings provided are in the imperial system, we will convert them into metric units for production to ensure accuracy.

It is important to note that while we can machine imperial-threaded holes for fasteners, if you require us to supply matching imperial fasteners, they may not always be available in stock. Custom orders for imperial fasteners typically require a large volume for production. Please consider this when planning your project.