Custom Colored Anodized Aluminum Profile

Colored anodizing of aluminum profiles is a process that forms a durable anodic oxide layer on the surface, enhancing resistance to corrosion, wear, and fading. The process allows for vibrant, customizable colors and various surface finishes, such as matte or glossy, while maintaining aluminum’s lightweight properties. Widely used in architecture, electronics, and automotive industries, colored anodized aluminum offers an eco-friendly and long-lasting solution for both functional and aesthetic applications.

HTS-ALU, a leading aluminum profile manufacturer in China, specializes in producing custom profiles with high-quality colored anodized finishes, meeting diverse industry needs worldwide.

Anodized Colors for Aluminum Profiles

The anodized colors of aluminum profiles depend on the base material and its alloy composition, with 6-series (6000 series) alloys being the most widely used for anodizing, followed by 5-series and 7-series alloys.

6-Series Aluminum Alloys (Al-Mg-Si):

The 6-series alloys, such as 6061 and 6063, are the most common for anodized aluminum profiles due to their excellent balance of strength, corrosion resistance, and processing ease. These alloys produce a high-quality anodized finish with consistent colors, including natural silver, champagne, black, bronze, gold, and custom dyed tones. The anodized layer is uniform and durable, making it ideal for architectural and industrial applications.

5-Series Aluminum Alloys (Al-Mg):

The 5-series alloys, like 5052 and 5754, contain magnesium, offering exceptional corrosion resistance, especially in marine and chemical environments. These alloys have good anodizing performance, although the color tones may appear slightly less uniform or duller compared to the 6-series. Common colors for anodized 5-series aluminum include silver, gray, and other natural tones, widely used in demanding industries like transportation and marine applications.

7-Series Aluminum Alloys (Al-Zn-Mg):

The 7-series alloys, such as 7075, are known for their high strength but are less commonly anodized due to their reduced corrosion resistance and susceptibility to color inconsistencies. When anodized, these alloys typically achieve natural silver or gray tones, with variations depending on the specific alloy and anodizing process. They are used in aerospace, automotive, and high-performance applications where strength is the priority.

Aluminum Profile Colored Anodizing Capabilities

HTS-ALU is equipped with 12 advanced anodizing tanks, allowing us to provide a wide range of anodizing solutions tailored to different applications. Our capabilities include standard anodizing, colored anodizing, and hard anodizing, meeting diverse customer requirements for both aesthetics and performance.

Our colored anodizing process delivers vibrant, customizable tones such as silver, black, gold, bronze, champagne, and other tailored colors. This process creates uniform finishes that are not only visually appealing but also durable with anodic layer thickness ranging from 10–25μm.

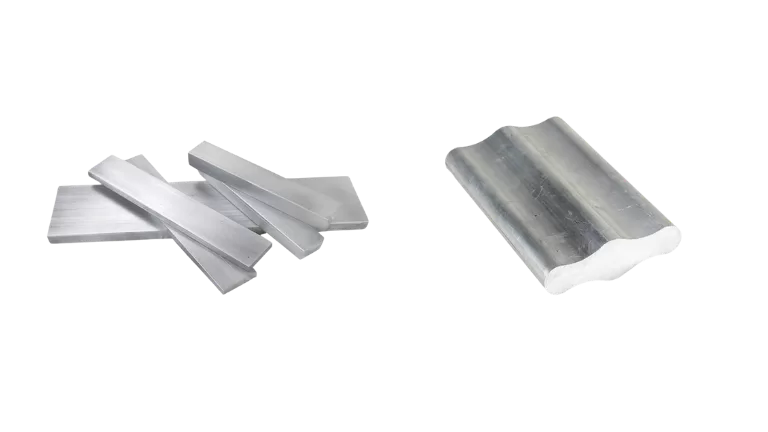

Pre-Anodizing Treatments: Brushing and Sandblasting

Before anodizing, we offer brushing and sandblasting (blasting) treatments to enhance the surface texture of aluminum profiles and achieve a refined, high-quality finish.

Brushing: This process creates a smooth, textured linear grain on the aluminum surface, giving an elegant and uniform appearance. Brushing not only enhances the look but also helps hide minor surface imperfections, making it ideal for decorative applications.

Sandblasting: Sandblasting involves using high-pressure abrasives to achieve a matte, uniform surface. This process effectively removes surface irregularities and creates a premium, fine-textured finish, which improves the adhesion of the anodized layer and enhances its overall durability.

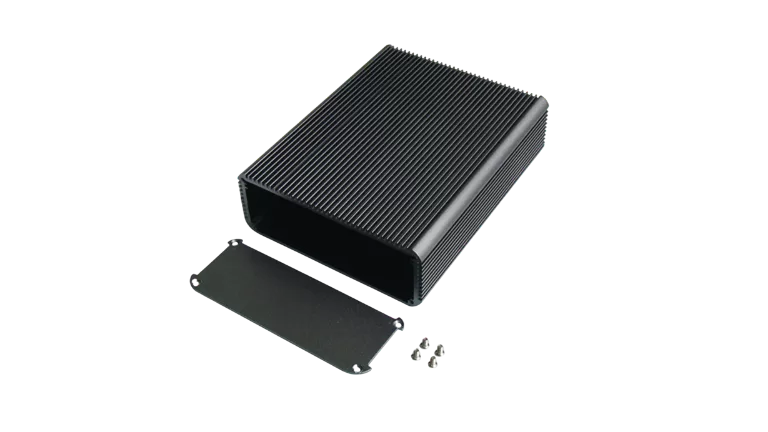

Custom Colored Anodized Aluminum Extrusions

At HTS-ALU, we provide custom anodized aluminum profiles designed to meet your unique needs. With 12 advanced anodizing tanks and over 40 extrusion lines, we serve industries like aerospace, automotive, and construction with high-quality, precision-engineered solutions.

Tailored Designs: Create unique aluminum profiles with our expert extrusion and die-making capabilities, designed to match your exact project needs.

Custom Colored Anodizing: Achieve vibrant, durable finishes with options like standard anodizing, hard anodizing, and custom-colored layers, with thicknesses ranging from 10–60μm for both decorative and industrial applications.

Diverse Surface Finishes: In addition to anodizing, enhance the appearance and performance of your profiles with options like powder coating, polishing, and brushing.

Precision Machining: Ensure exact dimensional accuracy through cutting, drilling, milling, and advanced machining services.

Aluminum Profile Processing Capabilities

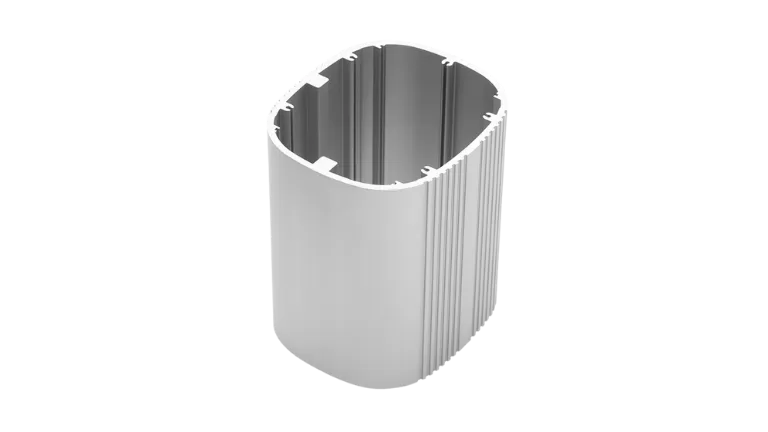

As a leading aluminum extrusion manufacturer based in China, we are committed to providing high-quality aluminum profiles for a wide range of industries. Our capabilities start with custom mold design and manufacturing, ensuring precise extrusion shapes that meet the specific needs of our clients. From raw extrusion to surface finishing and advanced machining, our fully integrated manufacturing processes enable us to deliver aluminum profiles that meet exacting standards and cater to the unique requirements of each project.

Our production facility houses over 40 advanced extrusion lines, featuring cutting-edge equipment such as a powerful 6000-ton extrusion press. This enables the creation of aluminum profiles in various sizes and forms, ranging from standard industrial applications to specialized products like thermal break profiles for high-end doors and windows. The flexibility of our extrusion capability ensures we can cater to a broad spectrum of industries, including construction and precision engineering.

Our production facility houses over 40 advanced extrusion lines, featuring cutting-edge equipment such as a powerful 6000-ton extrusion press. This enables the creation of aluminum profiles in various sizes and forms, ranging from standard industrial applications to specialized products like thermal break profiles for high-end doors and windows. The flexibility of our extrusion capability ensures we can cater to a broad spectrum of industries, including construction and precision engineering.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

For superior durability and visual appeal, our primary surface treatment is anodizing, which enhances corrosion resistance, strengthens the aluminum surface, and provides a range of attractive finishes. We specialize in standard anodizing, colored anodizing, and hard anodizing, with customizable layer thicknesses from 10–60μm to meet both functional and aesthetic requirements. Compared to other treatments, anodizing ensures long-lasting performance, UV resistance, and vibrant, durable finishes, making it the perfect choice for enhancing both the look and functionality of aluminum profiles.

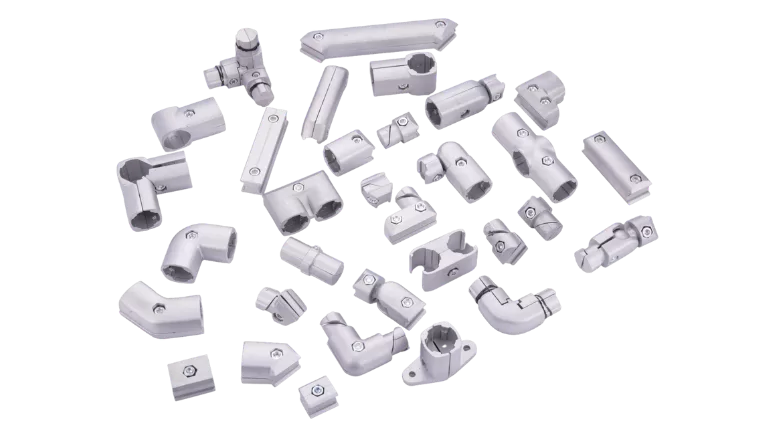

To provide complete aluminum profile solutions, we offer extensive further processing capabilities. Our services include CNC machining, milling, threading, drilling, precision cutting, punching, welding, and assembly. This range of fabrication options allows us to deliver ready-to-use profiles tailored to exact project specifications, offering unmatched flexibility and reliability to our customers.

RFQ of Extruded Aluminum Profile

HTS New Materials, based in Jiangxi Province, China, is a leading aluminum extrusion manufacturer with over 40 advanced production lines and powerful equipment, including a 6000-ton extrusion press. We produce a wide range of aluminum profiles for industries such as construction, industrial applications, and high-end doors and windows, including thermal break profiles. Our services extend to comprehensive surface treatments like anodizing, powder coating, fluorocarbon coating, and wood grain transfer, as well as advanced machining and fabrication capabilities such as CNC machining, drilling, and welding. Committed to quality and innovation, we deliver tailored aluminum solutions to meet the diverse needs of clients globally.

The primary aluminum alloys used for extrusion belong to the 6xxx series, specifically 6061, 6063, 6060,6082 and 6066. These alloys are highly favored due to their excellent extrudability, good mechanical properties, and corrosion resistance.

- 6061: A versatile alloy with higher strength, suitable for structural and transportation applications.

- 6063: Known as the “architectural alloy,” it offers excellent surface finish and is widely used for decorative and structural purposes.

- 6060: Similar to 6063 but with slightly lower strength, ideal for intricate and thin-walled profiles.

- 6066: A high-strength alloy within the 6xxx series, often used in more demanding structural applications.

- 6082: A strong alloy with better mechanical properties compared to 6061 and excellent corrosion resistance, commonly used in high-load structural applications and in marine environments.

The 7xxx series alloys, such as 7075, are used in applications requiring extremely high strength and performance, such as aerospace and high-end engineering projects. However, they have lower corrosion resistance when compared to 6xxx alloys and are therefore less commonly used for general extrusion applications.

While 1xxx, 3xxx, and 5xxx series alloys can be extruded, they are generally used infrequently for extrusion due to their lower strength or other limitations compared to 6xxx and 7xxx alloys. These series are mainly used in specialized applications. Additionally, if extrusion products from these series are requested, higher minimum order quantities (MOQ) are typically required for custom production, as their demand is relatively low.

The heat treatment of aluminum extrusions determines their mechanical properties, strength, and suitability for specific applications. Among the various heat treatment methods, T5, T6, and T66 are the most commonly used. Here’s an in-depth look:

| Heat Treatment State | Cooling Method | Strength | Key Features and Benefits | Applications |

|---|---|---|---|---|

| T5 | Air cooling (fan) | Moderate | Adequate strength, good dimensional stability, used for architectural purposes. | Windows, doors, curtain walls, building structures. |

| T6 | Water quenching (fast) | High | Higher strength and hardness, ideal for industrial and structural uses. | Automotive, aerospace, machinery, transport parts. |

| T66 | Water quenching (fast) | Very high | Optimized mechanical properties for higher strength and performance demands. | Automotive, rail transportation, high-end machinery. |

Other Heat Treatment States

- T4: Solution heat-treated and naturally aged. Used in applications requiring intermediate strength and enhanced formability.

- T7: Overaged for better stress-corrosion resistance, often used for aerospace and marine purposes.

- O (Annealed): Very soft condition suitable for extensive forming or bending requirements.

- F (As-Fabricated): No heat treatment applied, used in non-critical applications with low strength requirements.

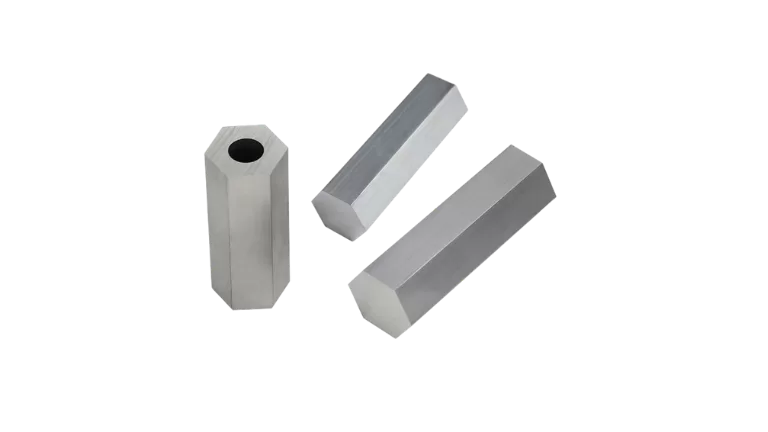

We provide a wide range of machining services for aluminum extrusions to meet specific requirements. These include cutting off/section removal, slotting, drilling holes, tapping threads, bending, and localized stamping to create deformations. For example, we can trim extruded profiles to custom lengths, mill precise grooves, create threaded holes for fasteners, bend profiles into specific shapes, or apply localized stamping to achieve custom forms or deformation.

In addition to these processes, we also offer TIG/MIG welding to join aluminum components for a solid structure. Furthermore, our services include assembly of common accessories, such as brackets, corner connectors, screws, hinges, end caps, and rubber seals, providing complete and ready-to-install profile solutions tailored to your project needs. This ensures that we can handle everything from simple cuts to highly customized fabrication and assembly, all with precision and efficiency.

For custom aluminum extrusion projects, we accept a variety of drawing formats, including CAD files, STEP files, and PDF files. However, for extrusions that require additional machining processes, it’s recommended to provide STEP files, as they ensure precise 3D modeling for machining accuracy.

While PDF files are acceptable, converting them into CAD drawings may result in the loss of certain details, requiring us to manually redraw the design, which could increase lead time. For the fastest and most accurate quotation, we recommend providing CAD files (e.g., DWG/DXF) and STEP files to ensure efficient design evaluation and pricing.

Mold fees are an essential part of the custom aluminum extrusion process. Since every order requires a uniquely designed mold tailored to specific requirements, these molds cannot be used for other products. Therefore, the mold fee is necessary and non-negotiable.

We require 100% upfront payment of the mold fee before mold development begins to ensure timely production. However, as a token of appreciation for your support, we offer a refund of the mold fee or equivalent discounts once the order reaches a certain production volume. Specific policies can be discussed based on your order volume and collaboration details.

Our minimum order quantity (MOQ) varies depending on the size of the product. For smaller-sized products, the MOQ is typically 500kg, while for larger-sized products, it is 2 tons.

We will specify the exact MOQ requirements during the quotation process. If your order quantity does not meet the MOQ, we can still arrange production, but an additional fee will be applied to cover mold preheating and production setup time. Rest assured, this extra fee will be reasonable, and we aim to keep it as minimal as possible to ensure smooth cooperation.

Packaging can be customized according to your needs. Options include using protective film or paper to separate and protect the surface, or foam film for additional surface protection. Products can be palletized or packed into cartons, and the quantity per pallet or carton can be specified by the customer.

The standard packaging involves bundling several pieces together with plastic wrap and then securing them onto pallets. Any packaging requirements beyond the standard will be accommodated, and the associated costs will be clearly provided to the customer.

Mold production typically takes 7 days. After the sample is confirmed, producing a full container load of 26 tons generally requires 14 days for extrusion alone. If surface treatment is required, an additional 3 days will be needed. For machining, extra time will be required depending on the complexity and volume of the machining work. The exact additional time for machining will be determined based on the specific processing requirements.

Aluminum profiles are naturally corrosion-resistant due to the formation of a thin, protective oxide layer when exposed to air or water. This oxide layer is stable and self-repairing, meaning that even if the surface is scratched or cut (such as at exposed ends or during processing), the aluminum will not rust or corrode like iron or steel. Instead, the exposed areas will quickly form a new oxide layer, providing continuous protection against further oxidation.

With proper design, installation, and maintenance, aluminum profiles can last for decades, even in challenging environments. For example, untreated aluminum can easily withstand 20-30 years in outdoor applications, while profiles with surface treatments like anodizing or powder coating can last even longer, often exceeding 50 years. This makes aluminum an excellent choice for applications where durability and long-term performance are essential.

The price of aluminum profiles consists of several components: raw material costs, extrusion processing fees, surface treatment fees, machining costs, and additional packaging fees. Among these, the cost of aluminum as a raw material tends to fluctuate frequently, while other fees remain relatively stable. Due to these fluctuations, our quotations are typically valid for 7 days.

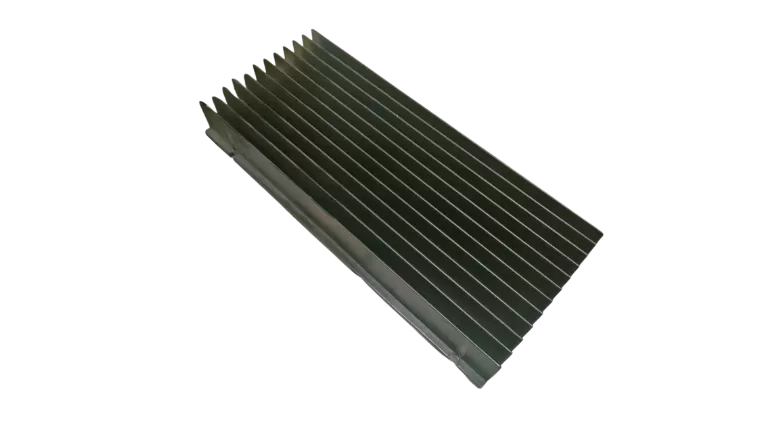

Pricing can be structured in different ways depending on the product and requirements. It can be calculated by weight (e.g., cost per ton), by length (e.g., cost per meter), or by piece (e.g., cost per unit). For products involving extensive machining, such as heat sinks, pricing is generally calculated on a per-piece basis to accurately reflect the additional processing costs. This flexible pricing approach ensures the quote is tailored to the specific needs of the customer.

We can manufacture aluminum profiles in compliance with technical requirements that meet European standards (EN), American standards (ASTM/AA), or other standards as specified by the customer. Custom production is tailored to ensure that the profiles meet the specific standard requirements requested.

Our production equipment is designed for the metric system. If the drawings provided are in the imperial system, we will convert them into metric units for production to ensure accuracy.

It is important to note that while we can machine imperial-threaded holes for fasteners, if you require us to supply matching imperial fasteners, they may not always be available in stock. Custom orders for imperial fasteners typically require a large volume for production. Please consider this when planning your project.

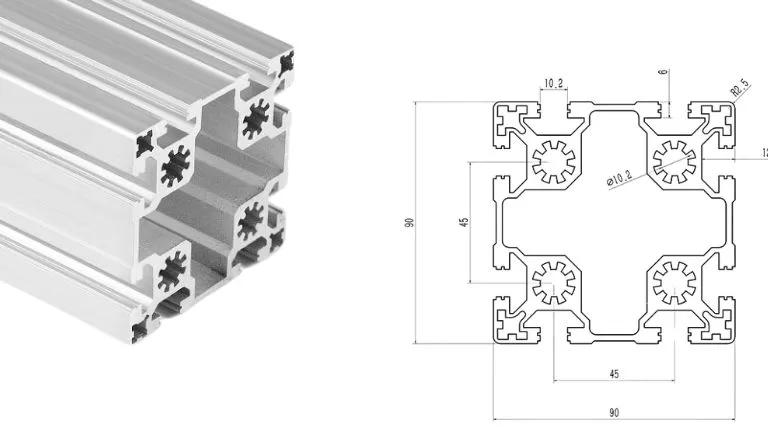

The majority of aluminum profiles we produce are custom-made and do not have existing molds. However, for some standard profiles such as square tubes, round tubes, U-channels, and T-SLOT profiles, we do have existing molds, and in some cases, small quantities in stock.

For certain specialized profiles, like ladder aluminum profiles, we have some molds that may be used across similar designs. For curtain wall and window/door profiles, we have developed a number of molds, though most are tailored to the Chinese domestic market.

Additionally, for furniture-related profiles, such as cabinet handles, cabinet door frames, skirting boards, tile edge trims, wall panel trims, stair anti-slip strips, partition aluminum profiles, corrugated aluminum profile (like long-span profiles), LED light channels, and photovoltaic frame supports, we offer a selection of ready-made designs and some existing molds.

While we have limited stock of standard profiles like square tubes, round tubes, U-channels, and T-SLOT profiles, we recommend contacting our sales team for details on availability and further assistance.