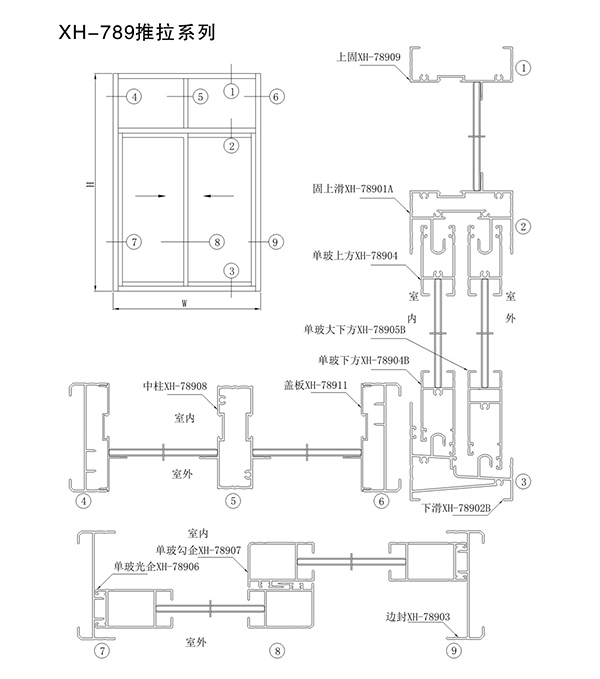

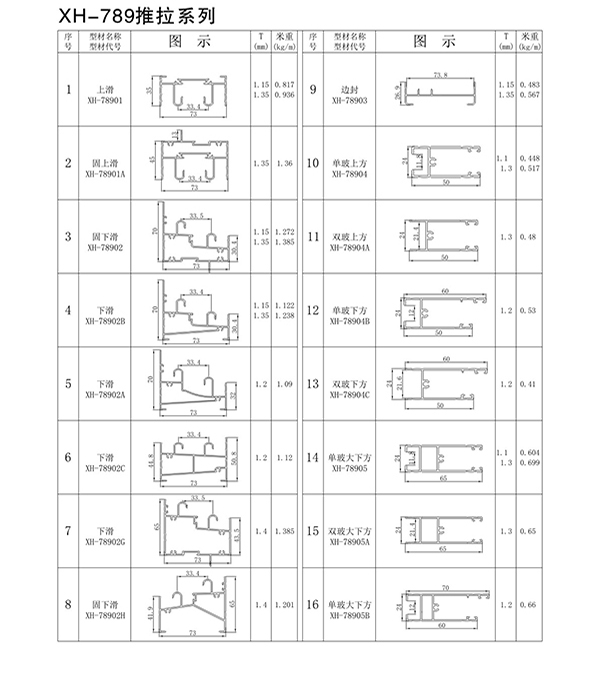

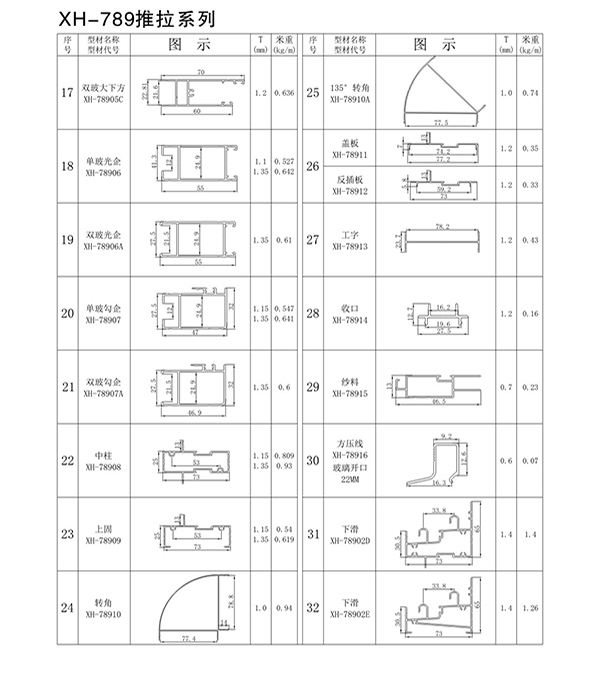

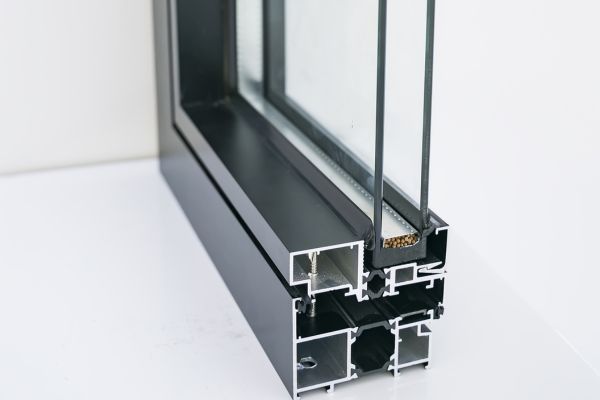

789 Aluminum Profile for Sliding Window

The 789 series sliding windows are one of the most common types of aluminum alloy windows. Here is a cross-sectional diagram of the 789 series aluminum profiles. The surface treatment can be customized according to requirements.

Surface

Surface treatment for aluminum window profiles serves two important purposes: protection and customization. There are several straightforward methods for this. Anodizing involves creating a protective oxide layer through an electrochemical process, providing corrosion resistance. Electrophoretic coating (e-coating) ensures even coverage and enhanced durability. Powder coating uses dry powder for a tough, colorful finish. PVDF coating offers excellent weather resistance. Wood grain transfer printing replicates a wood texture for a natural look. Each of these methods caters to different needs, from safeguarding against the elements to achieving a desired aesthetic for aluminum window profiles.

Anodizing

The aluminum profiles are immersed in an acidic solution and undergo electrolytic oxidation to form an oxide film. Anodizing enhances the corrosion resistance, hardness, and surface smoothness of the aluminum profiles. It can also be used with dyeing agents to achieve different colors.

Class of oxide film: AA10; AA15; AA20

Surface type: Matte; flat

Color: Silver white; bronze; champagne

Fetures: Corrosion resistant; durable; shining and decorative

Electrophoretic Coating

The charged aluminum profiles are immersed in a coating solution in an electrolytic tank. Through electrophoresis, the coating evenly adheres to the aluminum surface. Electrophoretic coating provides good weather resistance, color stability, and a smooth and uniform coating.

Corrosion resistance of composite film: ≥9.5 level

Paint film cohesive: Zero lever

Paint film hardness: ≥3H

Surface: Matte; flat; high brightness

Color: Silver white; bronze; champagne

Features: Corrosion resistant; durable; smooth and shining

Powder Coating

Powdered coating material is sprayed onto the aluminum profiles, and then melted and cured at high temperatures. Powder coating offers durability, corrosion resistance, and a pleasing appearance. It is also environmentally friendly.

Coat thickness:40-120um

Coat shock resistance: No cracking or fall off after shock test

Coat cohesion: Zero lever

Surface type: Highly glossy; semi glossy; matte

Color: Ral color

Features: Variety of colors

PVDF Coating

PVDF coating, a type of spray coating, utilizes a PVDF resin-based paint that provides exceptional resistance to weathering, UV radiation, and chemicals, making it suitable for demanding outdoor applications.

Coat thickness:30-65um

Coat shock resistance: No cracking or fall off after shock test

Coat cohesion: Zero lever

Glossiness: 60°

Features: With metallic luster, bright color, high weather resistance

Wood Grain Transfer

This process involves transferring wood grain patterns or textures onto the aluminum profiles using a transfer method. It gives the aluminum profiles the appearance of wood while retaining the advantages of aluminum, such as weather resistance and corrosion resistance.

Surface texture: Wooden; marble

features: Wood-like visual experience

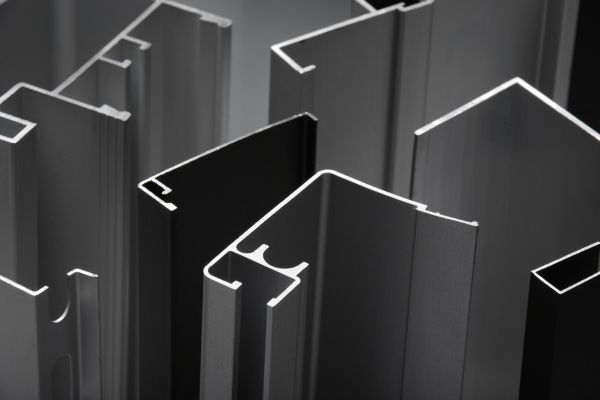

Factory

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer based in China. We specialize in various stages of aluminum profile production, from mold design and melting to extrusion, oxidation, electrophoresis, coating, and polishing, providing a comprehensive range of services.

Our product range encompasses aluminum profiles suitable for windows and doors (including thermal break section), industrial applications (T-slot, channel, tubing), and photovoltaic systems. Situated in Jiangxi, our spacious production facility covers 30,000 square meters and employs over 200 skilled professionals, enabling us to produce more than 10,000 metric tons of aluminum profiles annually.

At HTS NEW MATERIALS, we also offer various surface treatments, including anodizing, electrophoretic coating, powder coating, PVDF coating, and wood grain transfer printing, to enhance both functionality and appearance. Whether it’s for construction, industry, or renewable energy, our high-quality aluminum profiles are ready to meet your specific needs.