V-Slot Aluminium Extrusion Profiles

V-slot aluminium extrusions are versatile, high-precision structural aluminum profiles designed with a V-shaped groove along their length. These extrusions are commonly used in modular framing systems, industrial automation, 3D printers, CNC machines, robotics, and DIY projects due to their unique compatibility with various fastening systems and accessories.

The V-shaped groove serves as a guide for linear motion, enabling the direct integration of wheels, bearings, and T-nuts to create moving components without the need for additional tracks or guides. This reduces complexity, streamlines assembly, and opens endless possibilities for designing compact and efficient structures.

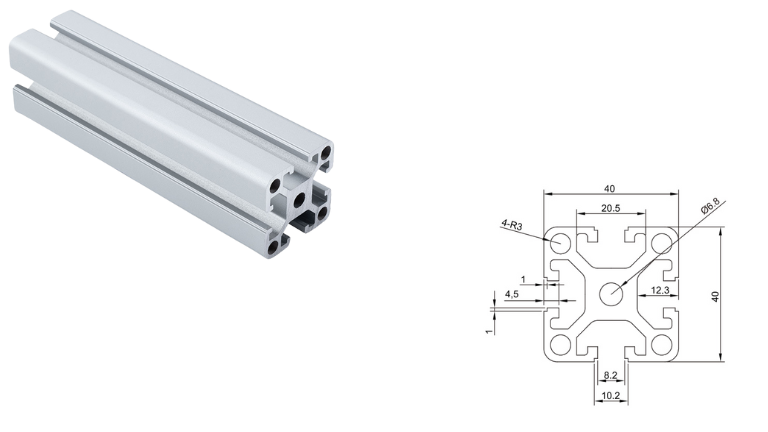

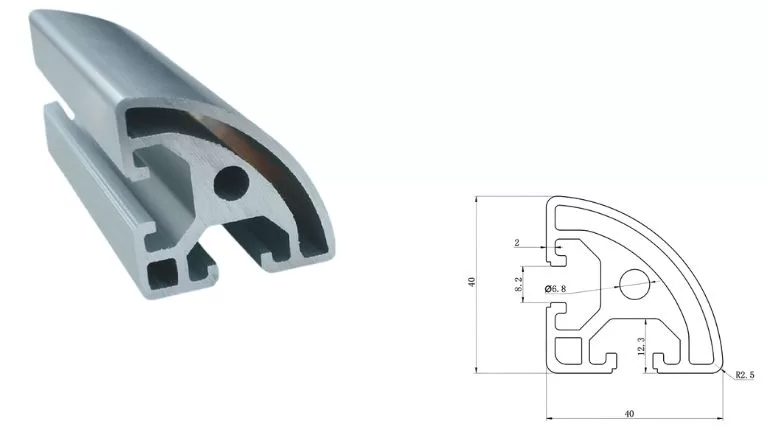

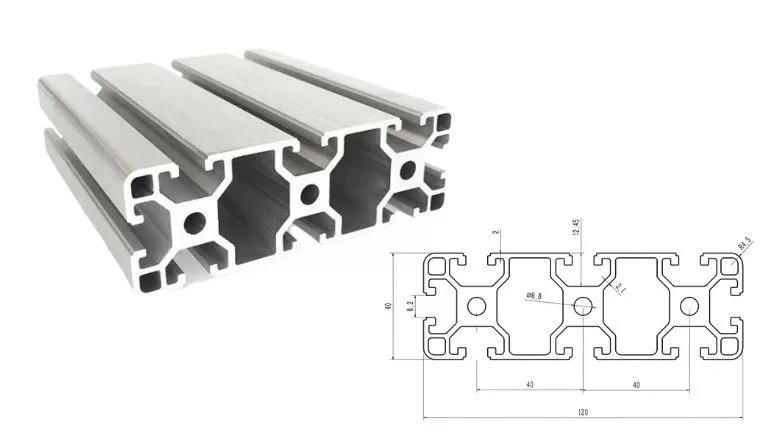

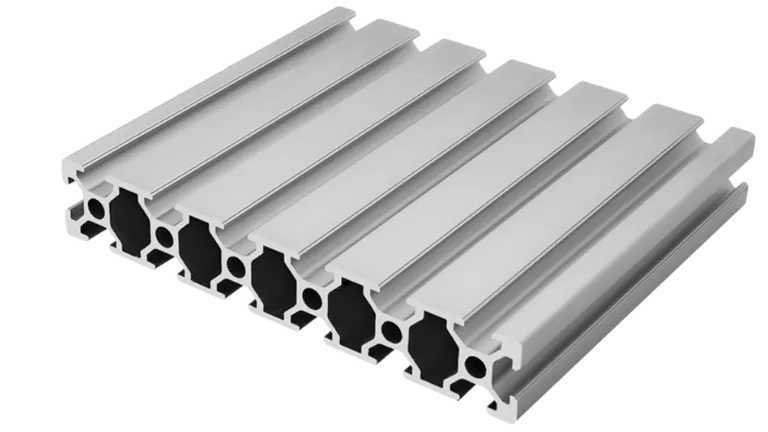

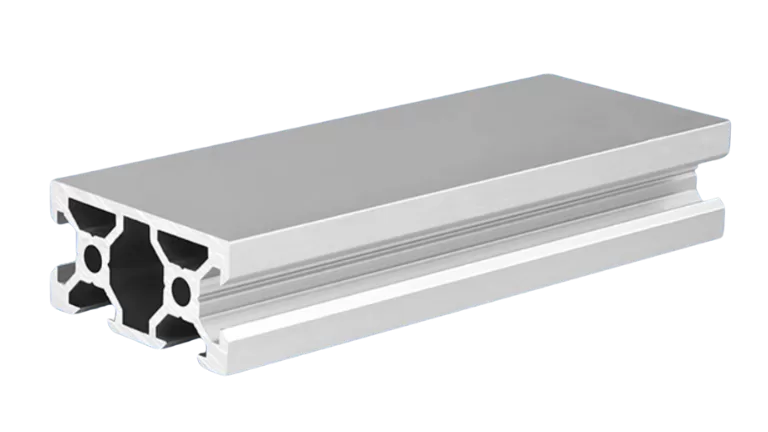

V-Slot Aluminium Profile Sizes

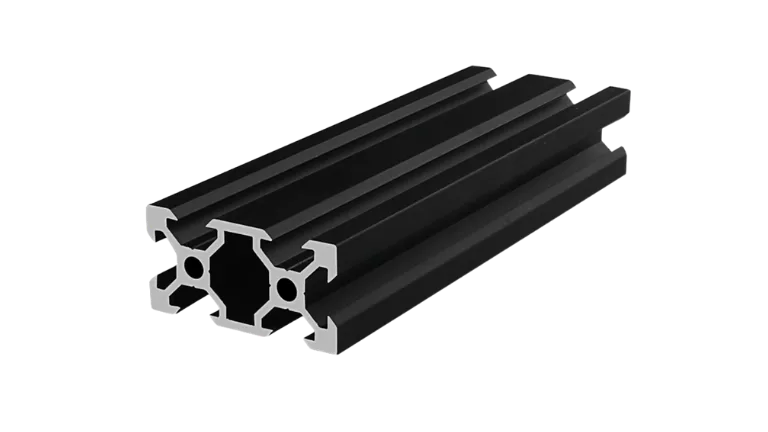

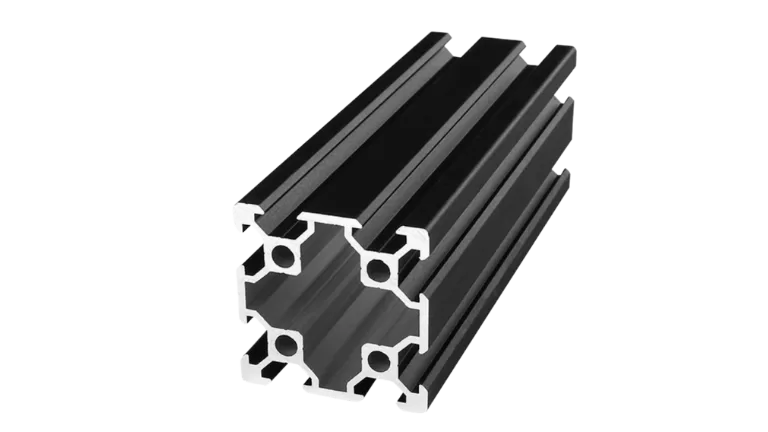

V-Slot 20120

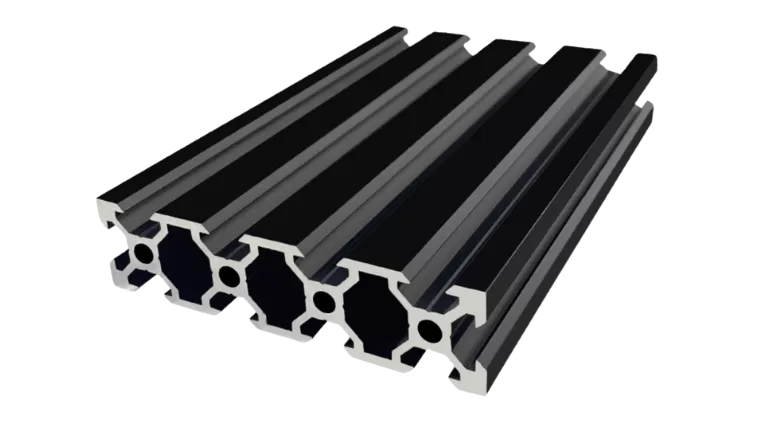

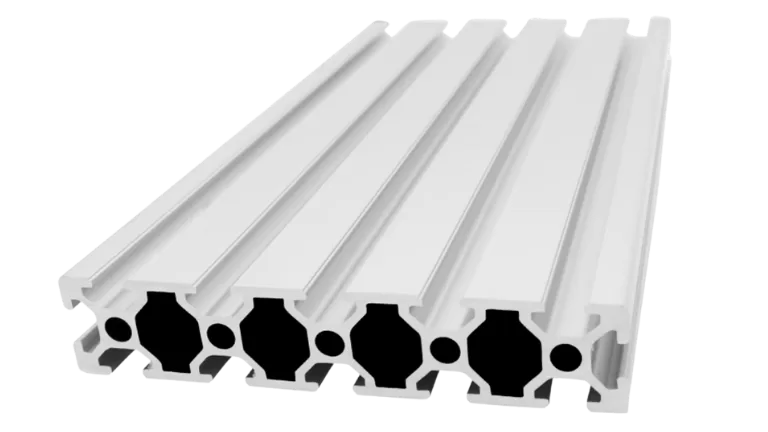

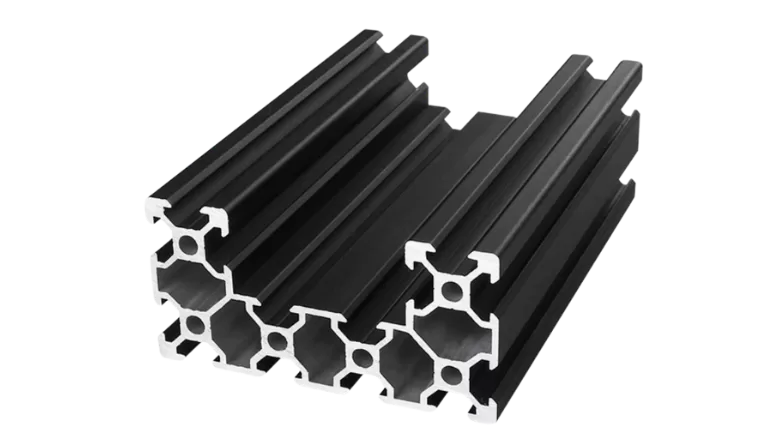

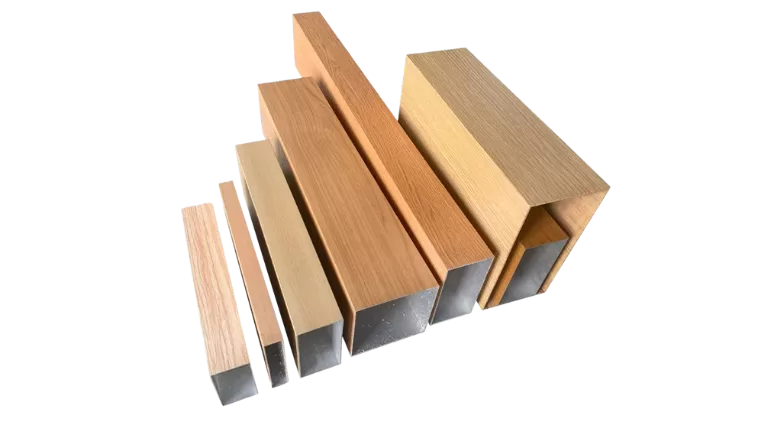

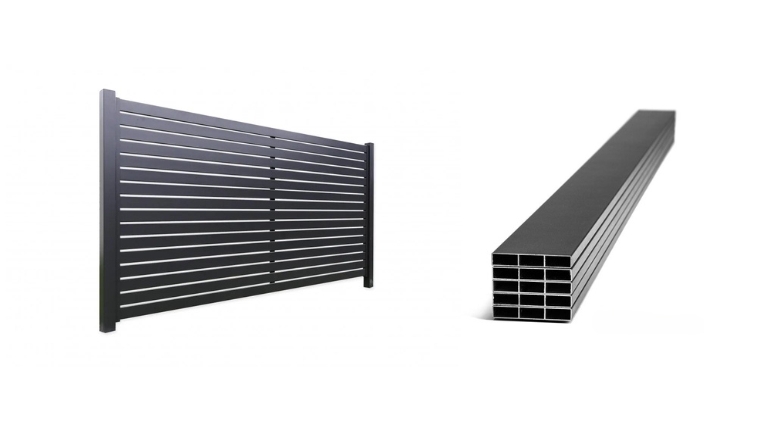

V-Slot Close One Side

Aluminium V-Slot Profile Process

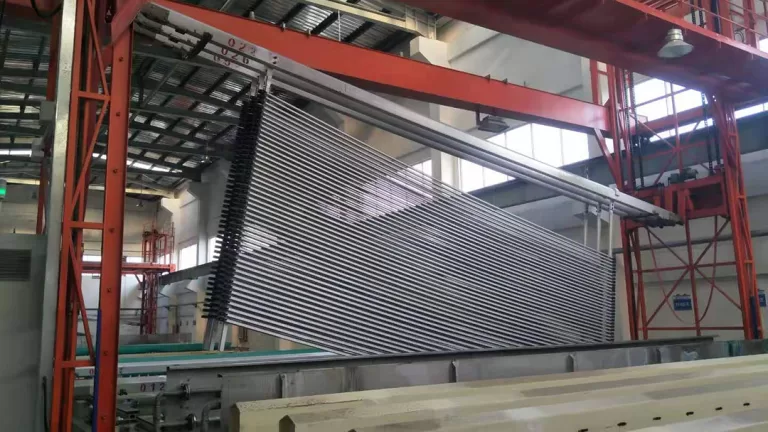

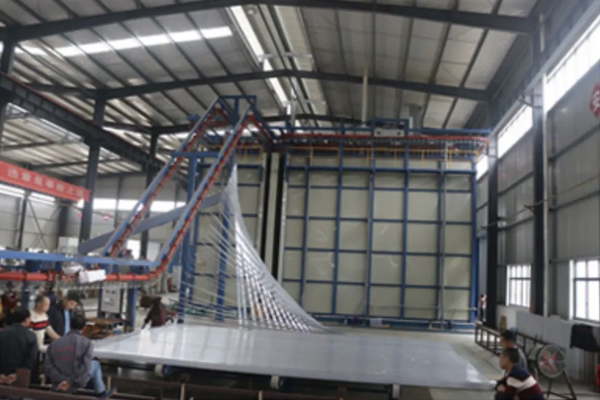

V-Slot Extrusion

HTS-ALU is a leading aluminum extrusion factory located in China, specializing in the production of high-quality V-Slot Aluminum Extrusions. Our facility is equipped with 40 advanced extrusion production lines, including a massive 6000-ton extrusion press that enables us to handle a wide range of profiles and meet diverse customer needs. With years of experience in extrusion, we ensure precision and consistency in every product we deliver.

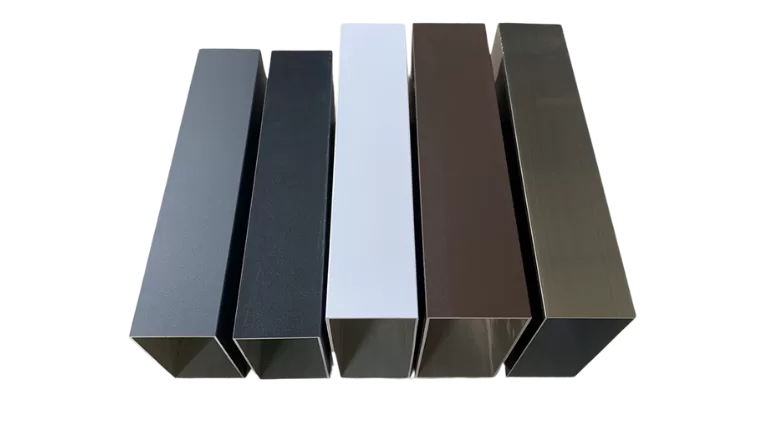

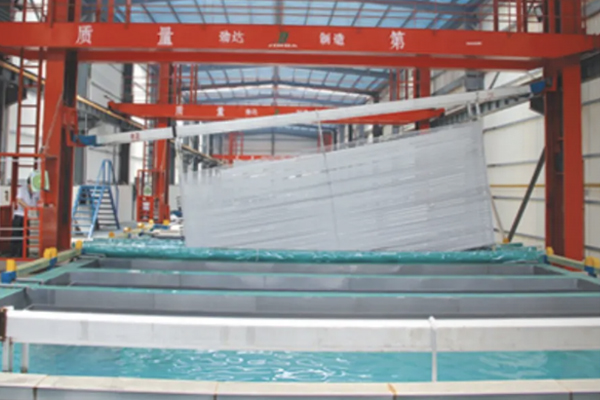

V-Slot Anodizing

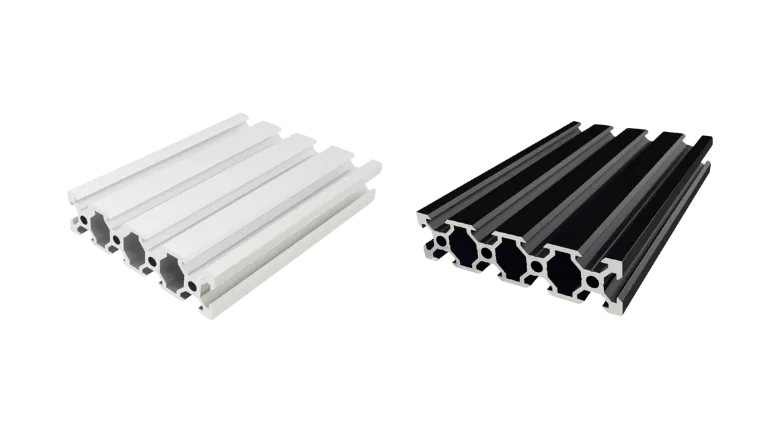

Our company has 10 anodizing tanks, allowing us to provide a variety of surface treatments for aluminum profiles. These include standard anodizing, colored anodizing, and hard anodizing to meet different application requirements. For T-slot aluminum profiles, the most common finishes are natural silver anodizing and black dyed anodizing. These finishes not only enhance corrosion resistance but also improve the aesthetic appeal of the profiles.

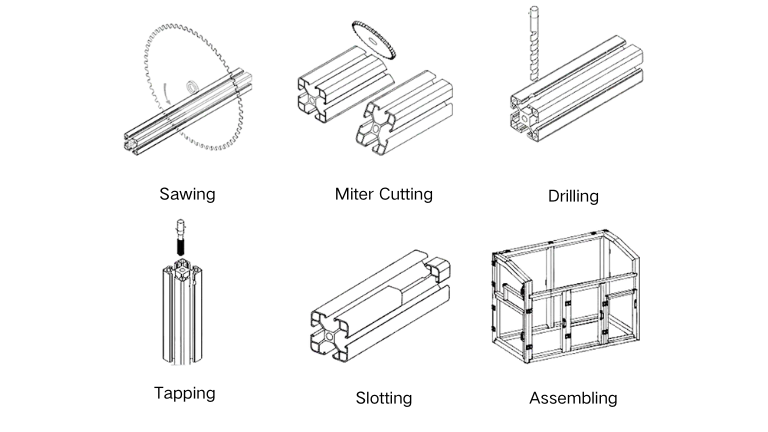

Machining

HTS-ALU is a leading aluminum extrusion factory located in China, specializing in the production of high-quality V-Slot Aluminum Extrusions. Our facility is equipped with 40 advanced extrusion production lines, including a massive 6000-ton extrusion press that enables us to handle a wide range of profiles and meet diverse customer needs. With years of experience in extrusion, we ensure precision and consistency in every product we deliver.

Applications of V-Slot Aluminium Extrusions

3D Printers:

V-Slot aluminium extrusions are widely used in the construction of 3D printers due to their lightweight, strong, and modular nature. The precisely machined V-shaped groove allows linear motion systems like rollers to move smoothly, making it an ideal framework for the chassis and moving parts of 3D printers.

CNC Machines & Engraving Machines:

V-Slot profiles are a popular choice for CNC machines and engraving machines, such as laser engravers and routers. The rigidity of aluminium combined with the capability for linear bearings to glide on the V-slot grooves ensures precise movement, durability, and reliable performance for various cutting and engraving applications.

Laser Cutters:

Aluminum V-Slot extrusions offer exceptional stability and alignment capabilities, making them ideal for lightweight and precision-based systems like laser cutters. Their modular design allows customization of the frame size and integration of the laser head with precision motion components.

Robotics Projects:

Modular, lightweight, and strong, V-Slot extrusions are perfect for use in robotic systems and automation. Their compatibility with a variety of hardware and connectors enables rapid prototyping and building of robotics projects, such as robotic arms or automated conveyor systems.

Workstations & Industrial Frames:

V-Slot extrusions are excellent for constructing modular workstations, tool holders, and customized industrial frames. Their versatility allows for easy integration of accessories, providing practical and functional work environments.

Camera Sliders & DIY Projects:

The V-Groove feature of these extrusions is also heavily utilized in camera sliders for smooth, controlled motion. Additionally, DIY enthusiasts employ V-Slot aluminium extrusions in making adjustable furniture, household products, and creative hobby projects due to their modular and user-friendly properties.

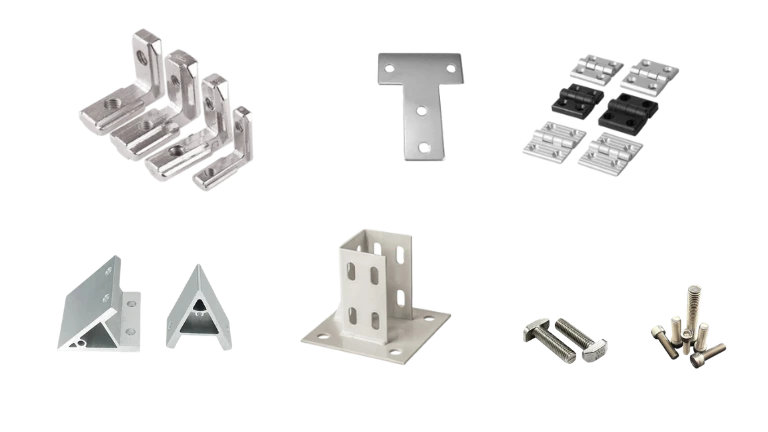

Common Accessories for Aluminium V-Slot

The core component for sliding rails, the V-Slot Roller ensures smooth and precise linear motion. It is essential for building systems that require reliable movement, such as 3D printers and CNC machines.

T-Nuts

T-shaped nuts are designed to slide into the V-slot groove and serve as the main fastening element. These are typically used with bolts, enabling easy installation and adjustment of other components.

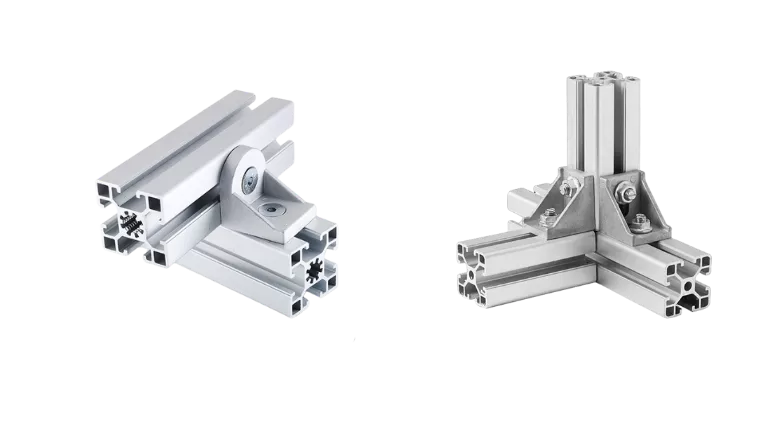

Connectors

Commonly available as L-shaped brackets or adjustable angle connectors, these accessories are used to expand and reinforce the structure of the aluminum frame. They provide strong and stable joints for various configurations.

End Caps

Made of plastic or metal, end caps are used to cover the open ends of the aluminum extrusions. They protect against dirt, sharp edges, and external damage, while also contributing to a more polished and professional appearance.

Cable Clips and Wire Mounts

These accessories help organize cables and wires neatly along the aluminum frame. They prevent clutter in the installation area and allow for safer wiring and a tidier workspace.

Our Factory

Custom Aluminum Extrusion from Us

At HTS NEW MATERIALS, we specialize in providing custom aluminum extrusions designed to meet your unique requirements. With advanced production facilities and over 40 extrusion lines, we deliver premium, precision-engineered profiles for a wide range of industries, including aerospace, automotive, construction, and more.

Our custom extrusion services include:

- Tailored Cross-Sections: Create unique aluminum profiles with our expert die-making capabilities, customized to suit your specific project needs.

- Diverse Surface Finishes: Enhance both the appearance and durability of your profiles with options like anodizing, powder coating, polishing, and more.

- Precision Machining: Ensure exact dimensional accuracy with cutting, drilling, milling, and advanced machining services.

- Flexible Tempers: Select from a variety of heat treatments, including T5, T6, and others, to achieve the ideal mechanical properties for your application.

Partner with HTS NEW MATERIALS for innovative, cost-effective, and dependable custom aluminum extrusion solutions that drive the success of your project.

RFQ of Extruded Aluminum Profile

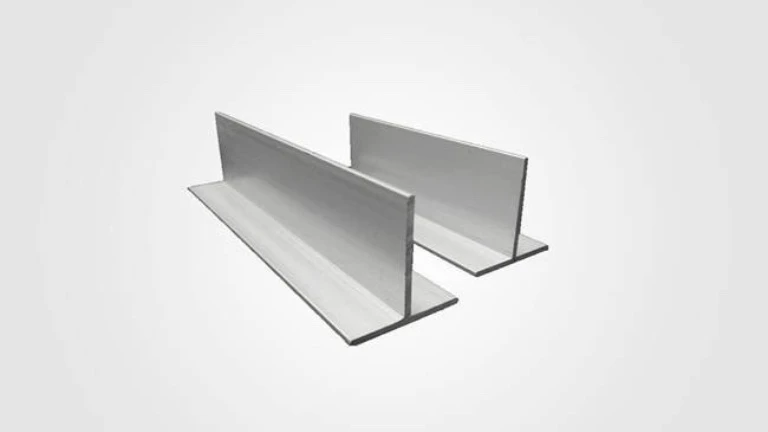

V-Slot and T-Slot aluminium extrusions are both versatile modular framing systems widely used in industries like automation, 3D printing, robotics, and CNC machines. While they look similar, there are key differences in their design, applications, and functionality.

1. Groove Design

V-Slot:

V-Slot features a V-shaped groove in the inner corners of the slot. The unique V-groove allows linear motion bearings or wheels to glide smoothly along the profile, enabling both structural support and guided motion in one system.T-Slot:

T-Slot has a T-shaped groove, designed primarily for fastening and assembly. T-Nuts and bolts slide into the groove to attach brackets, panels, or other accessories, but it is not intended for linear motion systems.

2. Functionality

V-Slot:

V-Slot profiles are designed for linear motion applications. The V-groove works as a built-in rail system, eliminating the need for additional guide rails. This makes it ideal for applications like 3D printers, laser cutters, and CNC machines where smooth, precise movement is required.T-Slot:

T-Slot profiles are primarily used as modular framing systems. They are excellent for building structures like workbenches, machine frames, enclosures, and shelving. T-Slot is not designed for motion applications but excels in flexibility and rigidity for structural projects.

3. Applications

V-Slot:

Suitable for systems requiring motion and flexibility, such as:- 3D Printers

- Laser Engraving Machines

- CNC Machines

- Robot Arms

- Camera Sliders

T-Slot:

Ideal for modular structures and heavy-duty applications, such as:- Industrial Framing

- Machine Enclosures

- Workstations

- Shelving and Display Systems

- Custom DIY Projects

4. Compatibility

V-Slot:

V-Slot is compatible with special accessories like V-wheels, linear bearings, and motion kits, as well as standard connectors and T-nuts for structural assembly.T-Slot:

T-Slot relies heavily on T-nuts, bolts, brackets, and panels for assembly. It is less versatile for motion integration compared to V-Slot.

5. Material and Finish

- Both V-Slot and T-Slot:

Typically made from 6063-T5 aluminium alloy for excellent strength, corrosion resistance, and anodizing compatibility. Both are available in natural silver anodized and black finishes.

Summary Comparison Table

| Feature | V-Slot | T-Slot |

|---|---|---|

| Groove Shape | V-shaped groove | T-shaped groove |

| Primary Function | Linear motion + framing | Modular framing system |

| Linear Motion | Built-in capability with V-wheels | Not designed for linear motion |

| Best Applications | 3D printers, CNC, laser cutters, robotics | Workbenches, enclosures, industrial structures |

| Accessories | V-wheels, motion kits, T-nuts, brackets | T-nuts, bolts, brackets, panels |

The following aluminum alloys are commonly used in manufacturing V-Slot Aluminium Extrusions due to their excellent mechanical properties, durability, and machinability:

6063-T5 Aluminium Alloy

- Features: 6063-T5 is the most common alloy used for V-Slot profiles. It offers a great balance of strength, corrosion resistance, and surface finish quality, making it ideal for extrusion and anodizing.

- Applications: Used widely for frameworks like CNC machines, 3D printers, and other structural applications.

- Surface Treatment: Good for both natural silver anodizing and black dyed finishes.

6061-T6 Aluminium Alloy

- Features: 6061-T6 provides higher strength and hardness compared to 6063-T5. While not as easy to extrude as 6063, it is excellent for projects requiring more robust structural integrity.

- Applications: Suitable for heavy-duty projects, industrial automation, and robust mechanical frameworks.

6005-T6 Aluminium Alloy

- Features: This alloy offers better strength and toughness than 6063 but slightly less corrosion resistance. It’s an excellent alternative for medium-duty applications where strength and stability are critical.

- Applications: Used in applications requiring more rigidity while maintaining good extrusion and anodizing properties.

6082-T6 Aluminium Alloy

- Features: Known for its structural strength, this alloy has excellent corrosion resistance and is weldable. Its toughness makes it a good choice for heavy-load applications.

- Applications: Frequently employed in industrial fabrications and custom-built machine structures.

1050 and 1070 Aluminium (Occasionally Used)

- Features: These pure aluminum alloys are sometimes used for lightweight, non-structural purposes in V-Slot projects. They have excellent corrosion resistance but lower strength compared to 6xxx series alloys.

- Applications: Ideal for decorative or non-load-bearing parts.

Why Commonly 6xxx Series Aluminum?

The 6xxx series aluminum alloys, such as 6063, 6061, and 6005, are ideal for V-Slot applications due to their:

- High extrudability.

- Great anodizing properties for surface finishes.

- Balanced strength and corrosion resistance.

- Cost-effectiveness for large-scale production.

In conclusion, 6063-T5 is the most popular choice for its versatility and surface finish capabilities, while stronger alloys like 6061-T6 or 6082-T6 are chosen for applications demanding higher durability and strength.

For custom aluminum extrusion projects, we accept a variety of drawing formats, including CAD files, STEP files, and PDF files. However, for extrusions that require additional machining processes, it’s recommended to provide STEP files, as they ensure precise 3D modeling for machining accuracy.

While PDF files are acceptable, converting them into CAD drawings may result in the loss of certain details, requiring us to manually redraw the design, which could increase lead time. For the fastest and most accurate quotation, we recommend providing CAD files (e.g., DWG/DXF) and STEP files to ensure efficient design evaluation and pricing.

Mold fees are an essential part of the custom aluminum extrusion process. Since every order requires a uniquely designed mold tailored to specific requirements, these molds cannot be used for other products. Therefore, the mold fee is necessary and non-negotiable.

We require 100% upfront payment of the mold fee before mold development begins to ensure timely production. However, as a token of appreciation for your support, we offer a refund of the mold fee or equivalent discounts once the order reaches a certain production volume. Specific policies can be discussed based on your order volume and collaboration details.

Our minimum order quantity (MOQ) varies depending on the size of the product. For smaller-sized products, the MOQ is typically 500kg, while for larger-sized products, it is 2 tons.

We will specify the exact MOQ requirements during the quotation process. If your order quantity does not meet the MOQ, we can still arrange production, but an additional fee will be applied to cover mold preheating and production setup time. Rest assured, this extra fee will be reasonable, and we aim to keep it as minimal as possible to ensure smooth cooperation.

Packaging can be customized according to your needs. Options include using protective film or paper to separate and protect the surface, or foam film for additional surface protection. Products can be palletized or packed into cartons, and the quantity per pallet or carton can be specified by the customer.

The standard packaging involves bundling several pieces together with plastic wrap and then securing them onto pallets. Any packaging requirements beyond the standard will be accommodated, and the associated costs will be clearly provided to the customer.

Mold production typically takes 7 days. After the sample is confirmed, producing a full container load of 26 tons generally requires 14 days for extrusion alone. If surface treatment is required, an additional 3 days will be needed. For machining, extra time will be required depending on the complexity and volume of the machining work. The exact additional time for machining will be determined based on the specific processing requirements.

Aluminum profiles are naturally corrosion-resistant due to the formation of a thin, protective oxide layer when exposed to air or water. This oxide layer is stable and self-repairing, meaning that even if the surface is scratched or cut (such as at exposed ends or during processing), the aluminum will not rust or corrode like iron or steel. Instead, the exposed areas will quickly form a new oxide layer, providing continuous protection against further oxidation.

With proper design, installation, and maintenance, aluminum profiles can last for decades, even in challenging environments. For example, untreated aluminum can easily withstand 20-30 years in outdoor applications, while profiles with surface treatments like anodizing or powder coating can last even longer, often exceeding 50 years. This makes aluminum an excellent choice for applications where durability and long-term performance are essential.

The price of aluminum profiles consists of several components: raw material costs, extrusion processing fees, surface treatment fees, machining costs, and additional packaging fees. Among these, the cost of aluminum as a raw material tends to fluctuate frequently, while other fees remain relatively stable. Due to these fluctuations, our quotations are typically valid for 7 days.

Pricing can be structured in different ways depending on the product and requirements. It can be calculated by weight (e.g., cost per ton), by length (e.g., cost per meter), or by piece (e.g., cost per unit). For products involving extensive machining, such as heat sinks, pricing is generally calculated on a per-piece basis to accurately reflect the additional processing costs. This flexible pricing approach ensures the quote is tailored to the specific needs of the customer.

Our production equipment is designed for the metric system. If the drawings provided are in the imperial system, we will convert them into metric units for production to ensure accuracy.

It is important to note that while we can machine imperial-threaded holes for fasteners, if you require us to supply matching imperial fasteners, they may not always be available in stock. Custom orders for imperial fasteners typically require a large volume for production. Please consider this when planning your project.

The V-Slot Aluminium Extrusions listed on this page are available in stock. Both natural silver anodized and black dyed finishes are readily available to meet the most common application needs.

All stock profiles are made from 6063-T5 aluminium alloy, which offers excellent strength, corrosion resistance, and surface finish quality.

For other materials or specific alloy grades, customization is required. If you require a different alloy, please contact us for a tailored solution to suit your project needs.