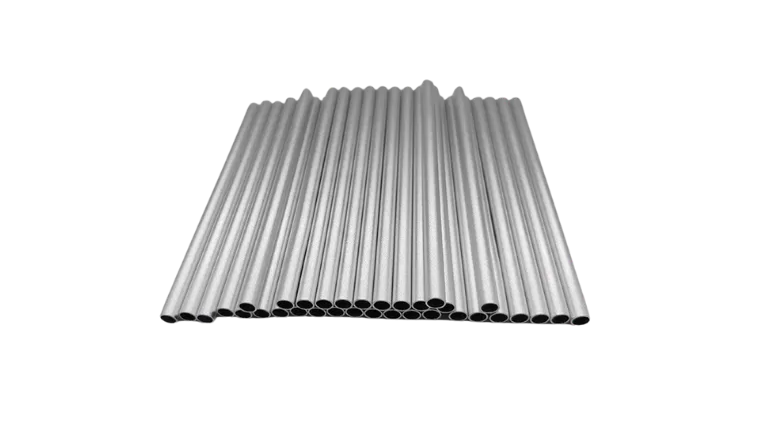

Durable Custom Telescoping Aluminum Round Tubing

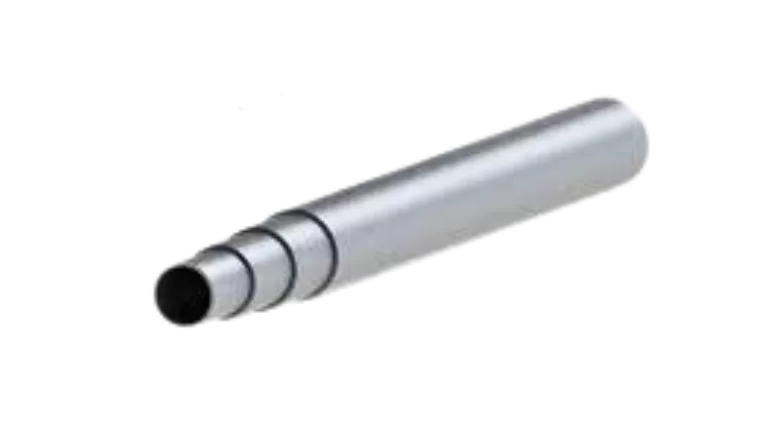

Telescoping aluminum round tubing is a hollow, circular aluminum tube with a retractable structure. Its precise design allows for smooth sliding and locking of multiple nested sections. It boasts lightweight properties, high strength, corrosion resistance, and flexible adjustability. It is widely used in industrial equipment, outdoor gear, consumer electronics, and other fields to meet the need for structural flexibility and reliability in various scenarios.

Based in China, HTS-ALU specializes in custom aluminum profile extrusion, offering a wide range of telescoping aluminum tubing, along with comprehensive surface treatment and precision machining solutions.

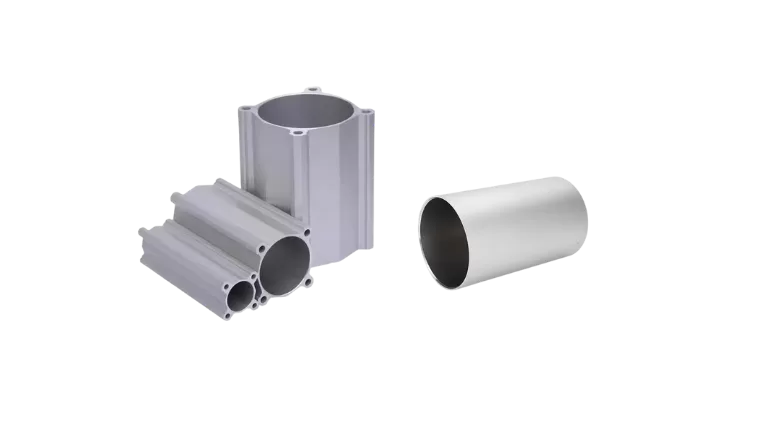

Telescoping Round Tubing Manufacture

We are a professional manufacturer focused on custom telescoping aluminum round tubing . With years of industry experience and advanced extrusion technology, we provide tailored solutions for a wide range of applications. Our telescopic aluminum tubes are trusted for their strength, smooth extension, and lightweight design. Made from high-quality aluminum, they are durable and highly resistant to corrosion. We offer various sizes, surface finishes, and precision machining to meet your specific needs. Our experienced team is always ready to help you find the best telescopic tube solution for your project.

Telescoping Round Tubing Specifications

| Parameter | Available Options/Range | Remarks |

|---|---|---|

| Alloy Grade | 6061, 6063, 6005, others upon request | Customizable |

| Outer Diameter (OD) | 8 mm-100 mm (0.31"-3.94") | Larger sizes upon request |

| Wall Thickness | 0.8 mm-5 mm (0.03"-0.20") | Varies by application |

| Length | Up to 6 meters(236")per piece | Custom cut lengths available |

| Surface Treatment | Anodized (various colors), Powder-coated, Mill finish, Polished, Brushed | Custom colors & textures |

| Tolerances | OD:+/-0.08 mm;Wall:+/-0.10 mm | Custom tolerances available |

| Connection Options | Plain ends, Swaged ends, Threaded ends, Locking mechanisms | As per design |

| Machining Services | Cutting, Drilling, Punching, Slotting, Bending | As per drawing/specification |

| Packing | Standard export packaging, Custom packaging available |

Applications of Telescoping Round Tubing

Our custom Telescoping Aluminum Round Tubing is widely used across various industries for its versatility and convenience. Its adjustable design allows for flexible use in applications where variable length or compact storage is required, including:

1. Industrial & Construction:

1. Industrial & Construction:

Adjustable supports, scaffolding, extension rods, and modular barriers.

2. Photography & Film:

Extendable light stands, boom poles, backdrop supports, and camera tripod extensions.

3. Outdoor & Camping:

Telescopic tent poles, awning frames, and collapsible camping furniture for easy transport and setup.

4. Cleaning & Maintenance:

Extendable handles for window cleaning tools and dusters, ensuring efficiency even at height.

Telescoping Round Tubing Process

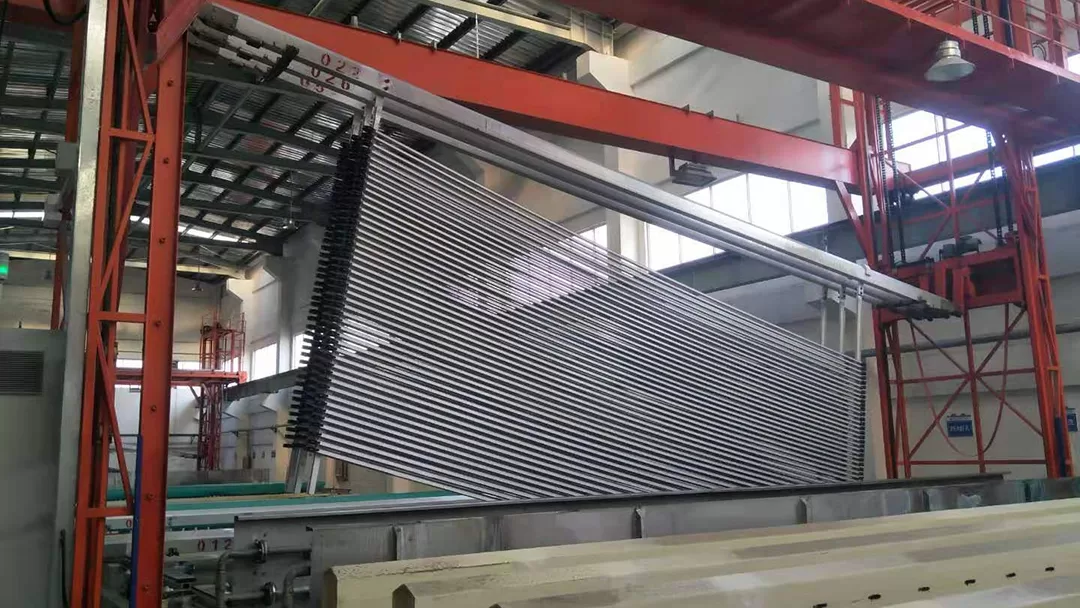

Aluminum Extrusion

At HTS-ALU, we design custom aluminum extrusion dies to achieve your specified diameters (Φ20–Φ100mm) and wall thicknesses (0.8–3mm), ensuring telescoping tubes with high coaxial accuracy (≤0.1mm). By precisely heating and extruding the aluminum, we form smooth, seamless tubes in 3 or 5 sections in one step. With 40 advanced lines, including a 6000-ton press, we deliver high-precision aluminum profiles tailored to your needs.

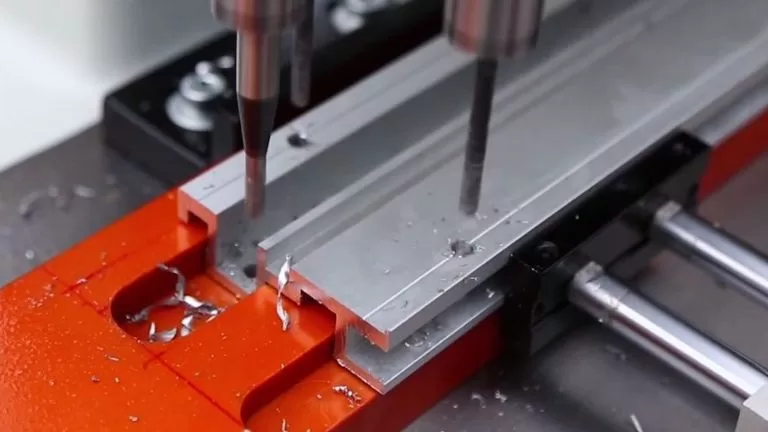

Fine machining

We provide precision cutting to your required lengths (100–500mm), with end-face squareness within 0.2mm. Tubes are chamfered and deburred for safe, smooth movement, and the inner surface is polished (Ra≤1.6μm) for reduced friction. We machine locking holes or slots as needed, and strictly control fit tolerances (0.1–0.3mm) to ensure smooth, stable telescoping.

Surface Treatment

We offer a range of surface treatments for telescoping aluminum round tubes to enhance appearance and durability. Common options include anodizing (for corrosion resistance and a smooth metallic finish), powder coating (available in various colors), brushing, polishing, and sandblasting. All surfaces are carefully treated to ensure a uniform, high-quality finish that provides long-lasting protection and an attractive appearance for your application.

Telescopic round tube raw material

Our telescoping aluminum round tubes are manufactured from premium 6061 and 6063 aluminum alloys. These alloys offer an excellent balance of strength (tensile strength: 200–250 MPa), corrosion resistance, and lightweight characteristics (density: 2.7 g/cm³), making them ideal for precision applications. We use well-inspected billets to ensure consistent quality, smooth surfaces, and reliable performance in all telescoping tube structures.

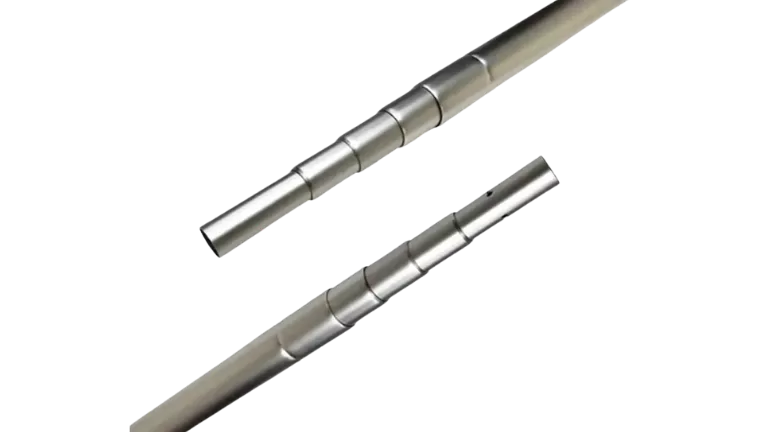

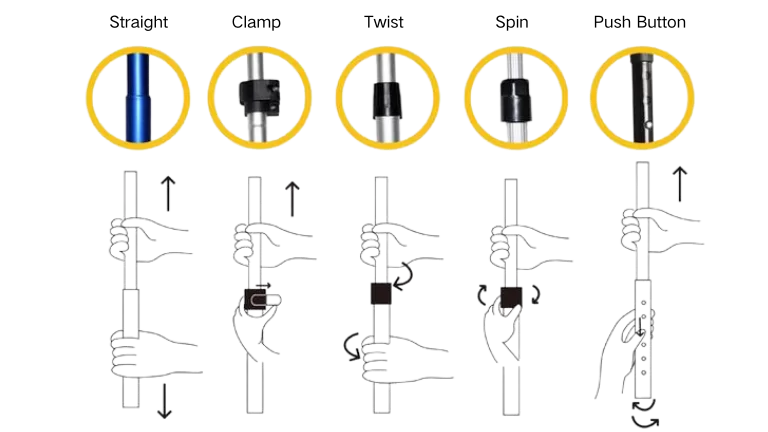

Telescopic round tube Locking Types

Our telescoping aluminum round tubes feature various self-locking designs to securely hold the desired length. Common self-locking options include spring pins, push-button locks, and twist-lock mechanisms, which are integrated directly into the tube. These solutions ensure quick, convenient adjustment and stable positioning for a wide range of applications.

Key Features & Advantages

1. Strong and Lightweight

Manufactured from premium aluminum alloys such as 6061 or 6063, our tubes offer an excellent balance of high strength and low weight, making handling and transportation effortless.

2. Smooth Telescopic Action

Precision extrusion and strict quality control guarantee seamless extension and retraction, with minimal play between sections.

3. Corrosion Resistance

Each tube is treated with anodizing or powder coating, giving enhanced durability for both indoor and outdoor use.

4. Long Service Life

High-quality materials ensure your products withstand rigorous use, reducing replacement and maintenance costs.