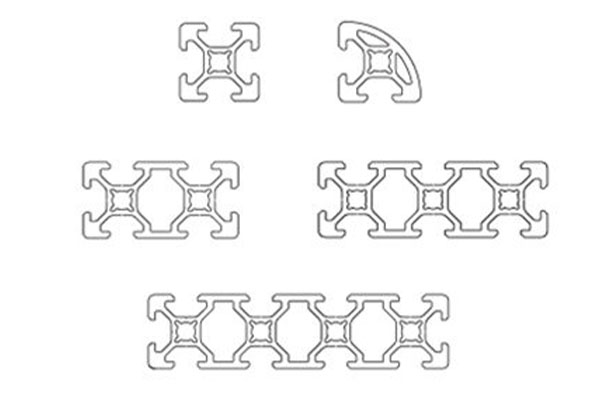

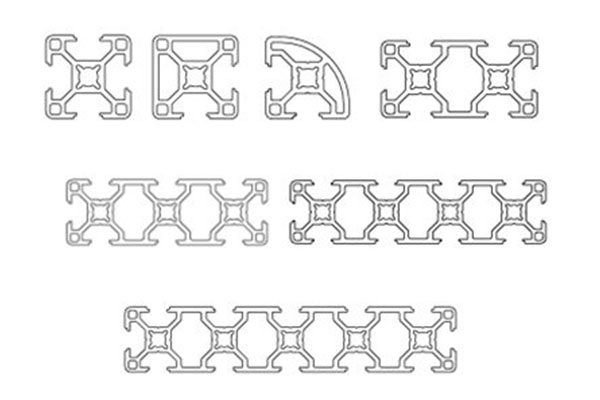

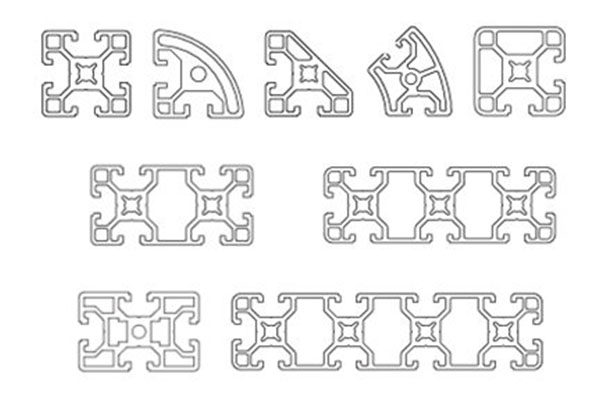

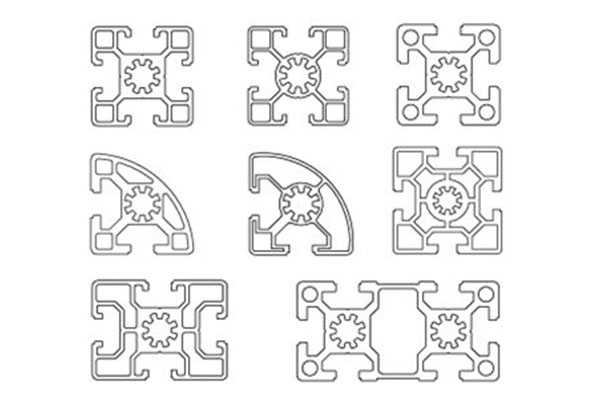

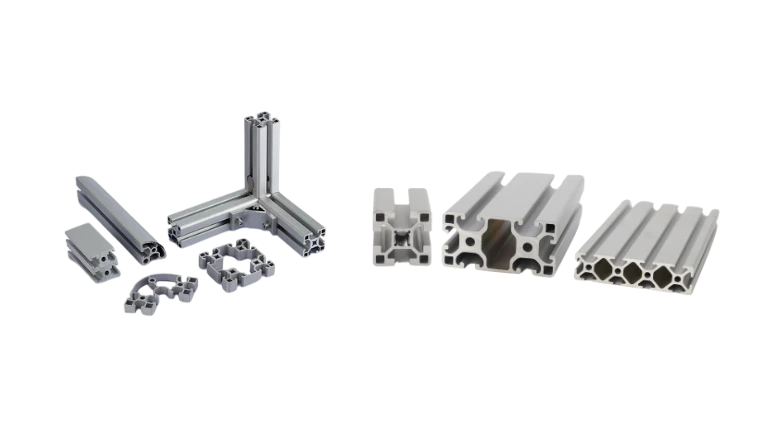

T-slot Aluminium Extrusion

T-slot aluminum extrusion is a type of structures and frameworks material made from lightweight and durable aluminum alloy. It features a series of T-shaped slots along the profiles, allowing for easy assembly and customization of structures. T-slot aluminum extrusion is widely used in various industries for building frameworks, enclosures, and machine assemblies. It provides a versatile and modular solution, eliminating the need for welding or complex machining.

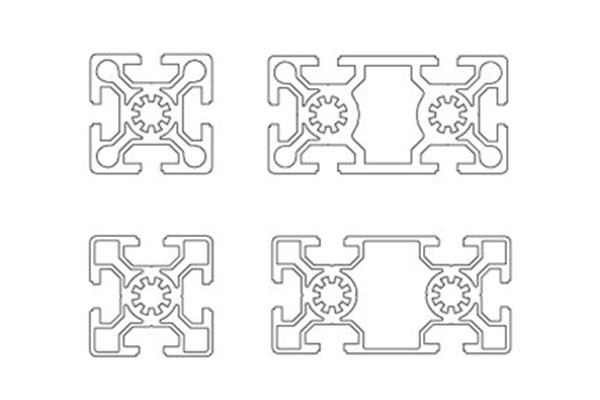

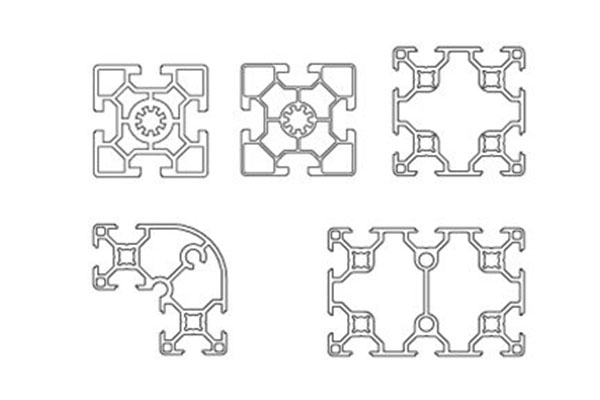

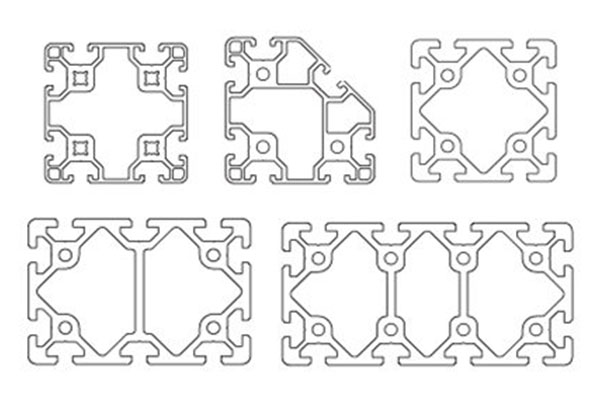

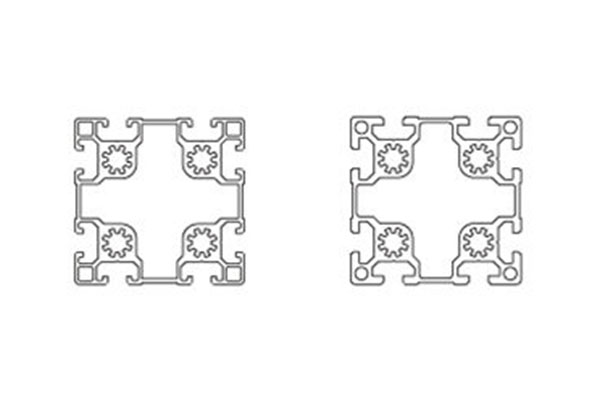

The T-slot profiles are available in a wide range of sizes, shapes, and configurations, allowing for endless design possibilities. Common profiles include 20×20 mm, 30×30 mm, 40×40 mm, and 80×80 mm, although many other sizes are available.

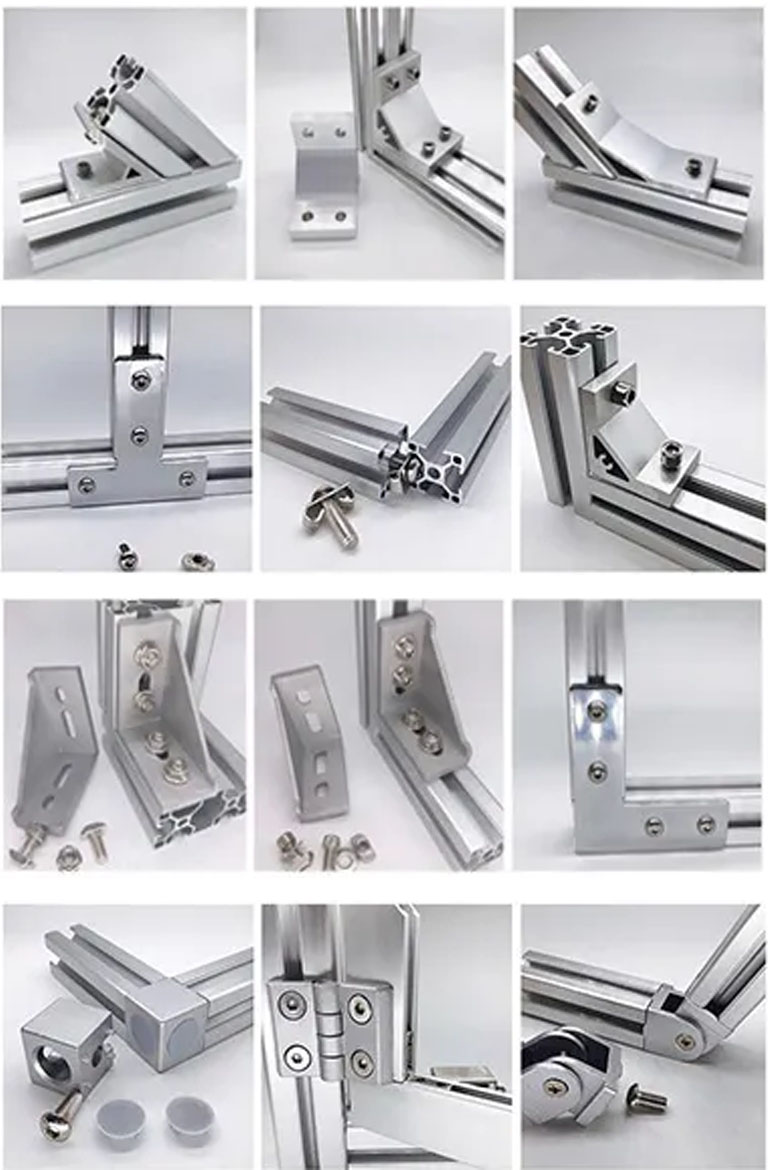

T-slot Aluminum Profiles Connection

T-slot aluminum profiles are commonly used for constructing mechanical structures and frameworks. They have a T-shaped cross-section and can be used to build various custom frames and structures. The profiles can be quickly assembled using a variety of accessories. The connections of T-slot aluminum profiles are achieved using compatible connecting elements. Here are several common methods:

1. T-nut connection: T-slot aluminum profiles have slots that can accommodate T-nuts. By sliding the T-nuts into the slots and using screws to connect two profiles, a reliable connection can be achieved. This connection method is widely used and suitable for various simple connection needs.

2. Slide-in connection: Slide-in connectors offer a quick and convenient connection method. The connectors can be slid into the T-slot, and by rotating a handle or wrench, the connector can be secured in the desired position. This connection method allows for easy disassembly and reconfiguration, making it suitable for applications that require frequent structural changes.

3. Corner connection: Corner connectors usually consist of two parts. One part is fixed within the T-slot, while the corresponding part is fixed on the other profile to be connected. By combining the two parts, an angled connection can be achieved. This connection method is suitable for constructing angled structures or connecting two profiles to form a stable angle.

4. Manual clamping connection: Manual clamping connectors typically consist of a handle and a clamping block. The clamping block can be manually tightened within the T-slot to connect two profiles. This connection method is simple and user-friendly, suitable for applications with lower clamping force requirements.

5. Automatic clamping connection: Automatic clamping connectors use springs or other mechanical structures to automatically clamp the profiles within the T-slot. This connection method provides higher connection force and stability, suitable for applications that require stronger and more secure connections.

T-slot Aluminum Profile System

T-slot aluminum profiles have a wide range of applications due to their versatility, strength, and ease of use. Here are some common uses of T-slot aluminum profiles:

Machine Frames

T-slot aluminum profiles are frequently used to construct frames for machines and equipment. These profiles provide a sturdy and flexible framework that can be easily customized and modified as needed. They are commonly used in CNC machines, 3D printers, industrial automation systems, and other manufacturing equipment.

Industrial Workstation

Industrial workstations: T-slot aluminum profiles are ideal for building ergonomic workstations and assembly lines. They allow for the creation of customized work surfaces, shelves, tool holders, and other accessories that can be easily adjusted and reconfigured to suit the specific needs of the operators.

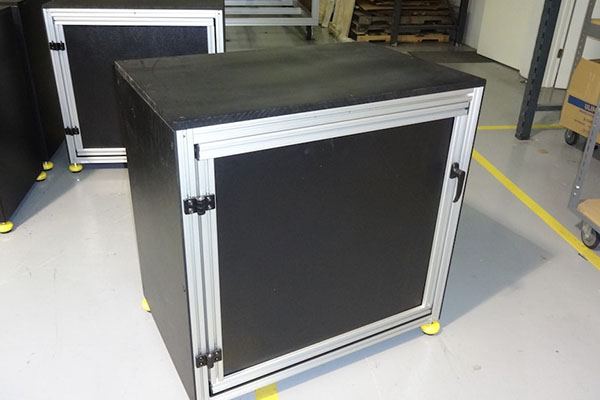

Enclosure & Guarding

T-slot aluminum profiles are often used to construct enclosures and guarding systems to protect equipment, machinery, or sensitive areas. These profiles can be combined with panels, doors, and safety components to create robust and secure enclosures for various industrial applications.

Display System

Display systems: T-slot aluminum profiles are widely utilized in the construction of exhibition booths, retail displays, and signage systems. They offer a modular and aesthetically pleasing solution for creating versatile display structures that can be easily assembled, disassembled, and reconfigured for different events or promotions.

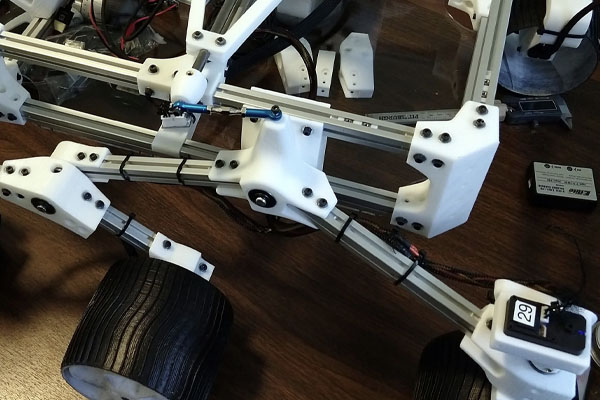

Robotic & Automation

T-slot aluminum profiles are frequently employed in the construction of robotic arms, automation frameworks, and conveyor systems. Their inherent rigidity, lightweight nature, and compatibility with various accessories make them suitable for creating precise and adaptable automation solutions.

Furniture & Fixtures

T-slot aluminum profiles are increasingly being used in the design and construction of modern furniture and fixtures. They provide a sleek and contemporary appearance while offering flexibility in terms of assembly and customization. T-slot profiles are used in the production of office desks, workbenches, shelving units, and display cabinets.

Customize Your T-slot Aluminum Profile

Specification

| Material | 6000 Series aluminum alloy |

| Temper | T3-T8 |

| Shape | T Profile 15/20/30/40/45/50/60/80/90/100/160 series etc. |

| Color | Standard: black, silver and grey, or customized |

| Length | customized length |

| Color | Customized Color |

| Application | Decorations, Robot Frame, workstations, Building, Industrial, Machinery, Automation parts, CNC, etc |

| MOQ | 500KG |

| Delivery time | 15-20 days after sample confirmed & down payment, or negotiated |

| Port | Guangzhou,Ningbo, Shanghai |

Reliable T-slot Aluminium Profiles Supplier

HTS NEW MATERIALS is a professional aluminum extrusion profile manufacturer from China. With expertise in mold design, melting, extrusion, oxidation, electrophoresis, coating, and polishing, we offer a comprehensive range of services.

Our product portfolio includes aluminum profiles for windows and doors, industrial applications, and photovoltaic systems. Located in Jiangxi, our production facility spans 30,000 square meters and employs over 200 skilled professionals, allowing us to produce over 10,000 metric tons of aluminum profiles annually.

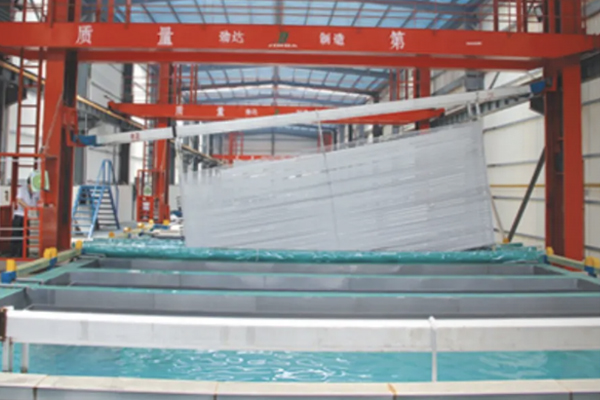

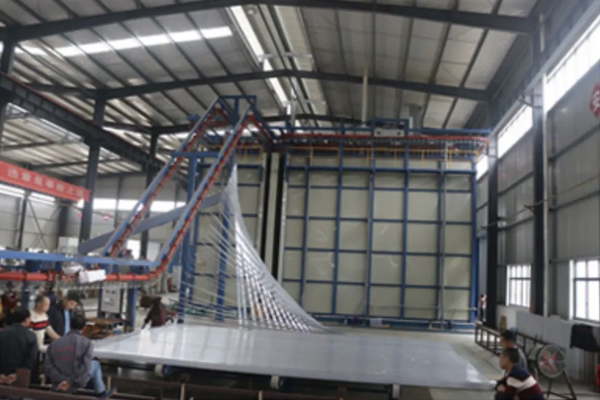

Factory

We specialize in manufacturing high-quality, precision-engineered aluminum profiles for various industries. With state-of-the-art equipment and a skilled workforce, we produce complex profiles with exceptional dimensional accuracy using premium-grade aluminum alloys. Our customization options allow us to create unique profiles with intricate shapes, precise tolerances, and various surface finishes, tailored to your specific requirements. Quality is paramount to us, and we adhere to rigorous quality control measures throughout the manufacturing process. Our commitment to environmental sustainability is reflected in our eco-friendly practices, such as recycling aluminum scraps and optimizing energy consumption.

Raw Material

The aluminum used for T-slot aluminum profiles is usually in the form of aluminum billets, which are solid blocks of aluminum alloy. These billets undergo a series of processes, including heating, extrusion, and cooling, to form the desired shape of the T-slot profile. The extrusion process involves forcing the heated aluminum billet through a specially designed die to create the T-shaped cross-section of the profile.

The specific aluminum alloy used for T-slot aluminum profiles may vary depending on the manufacturer and the intended application. Commonly used aluminum alloys include 6061 and 6063, as mentioned earlier. These alloys offer a good balance of strength, machinability, and corrosion resistance, making them suitable for a wide range of structural and industrial applications.

6061 Aluminum Alloy: This is one of the most commonly used aluminum alloys, known for its excellent mechanical properties and corrosion resistance. It is suitable for a wide range of applications, including structural frameworks, conveyor systems, and mechanical components.

6063 Aluminum Alloy: This aluminum alloy offers good machinability and surface appearance, making it suitable for applications that require a higher surface quality, such as display racks, door and window frames, etc.

How to Produce Aluminum Profile

Aluminum profiles for doors and windows are manufactured using high-quality aluminum alloys, specifically designed for their structural integrity, durability, and corrosion resistance. The primary raw material used in the production of these profiles is aluminum extrusion billets.

Aluminum extrusion billets are cylindrical logs or ingots made from a blend of aluminum and various alloying elements. These alloying elements, such as silicon, magnesium, manganese, and copper, are added in precise proportions to enhance the strength, ductility, and other desired properties of the final aluminum profiles.

The billets undergo a series of processes to convert them into the desired profiles for doors and windows. The first step is heating the billets to a specific temperature, making them soft and malleable. Then, they are forced through a specially designed die under high pressure, using an extrusion press. The die imparts the desired shape and cross-sectional profile to the aluminum, resulting in the extruded profiles.

After extrusion, the profiles undergo various finishing processes, such as cutting, machining, surface treatment, and powder coating. These processes further enhance the aesthetics, functionality, and durability of the profiles, making them suitable for use in doors and windows.