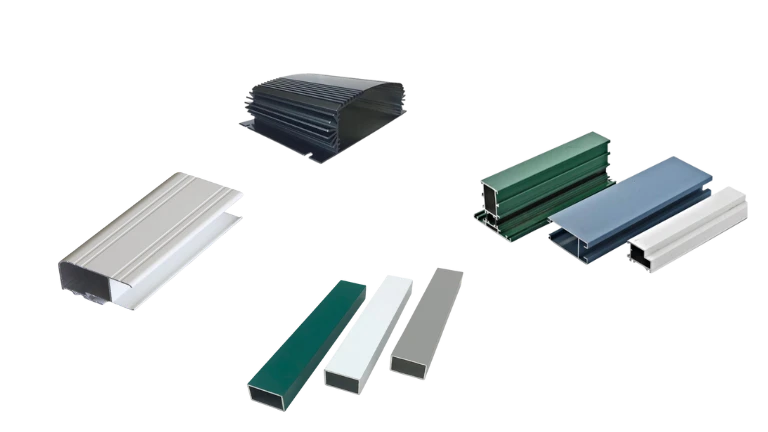

Powder Coated Aluminum Extrusion Profiles

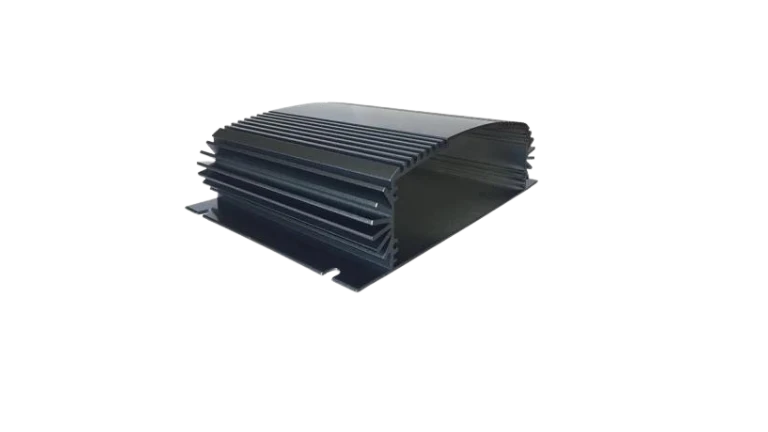

Powder coating is a commonly used surface treatment for extruded aluminum profiles. This surface treatment has the following characteristics:

Corrosion Resistance: Forms a strong protective layer that safeguards against moisture and chemicals.

Enhanced Durability: Increases surface hardness, making the aluminum resistant to scratches and wear.

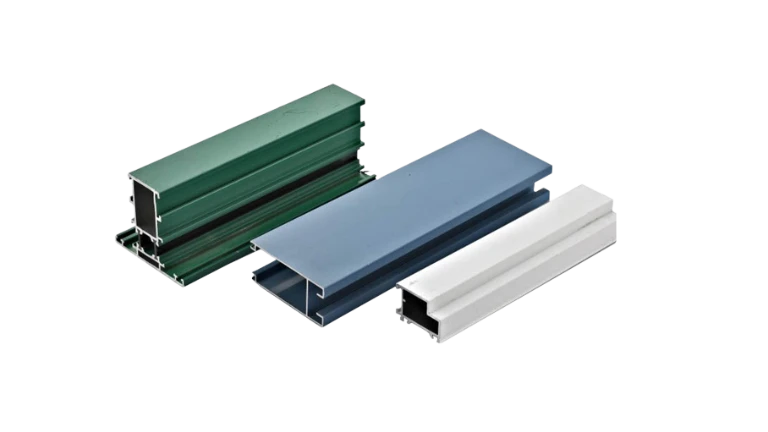

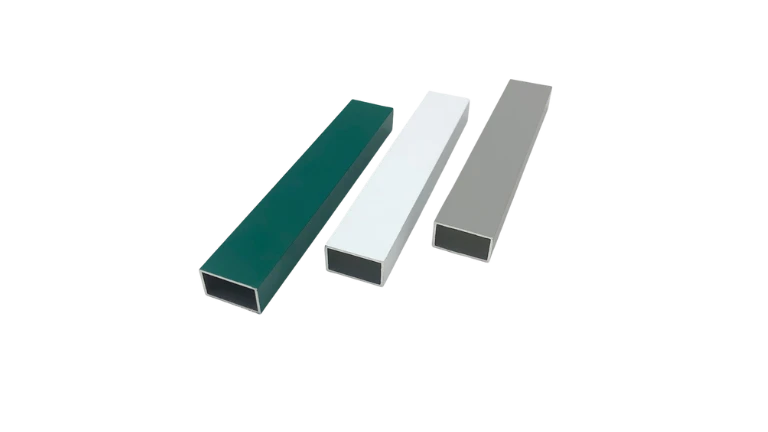

Variety of Colors and Finishes: Offers a wide selection of colors and textures, ensuring vibrant and consistent finishes that resist fading.

Ease of Maintenance: Creates smooth surfaces that are easy to clean and maintain.

Environmental Friendliness: Produces minimal waste and avoids harmful chemicals, making it an eco-friendly process.

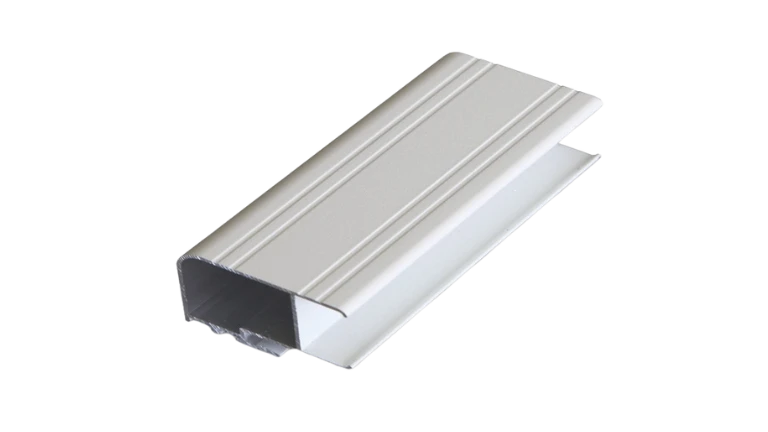

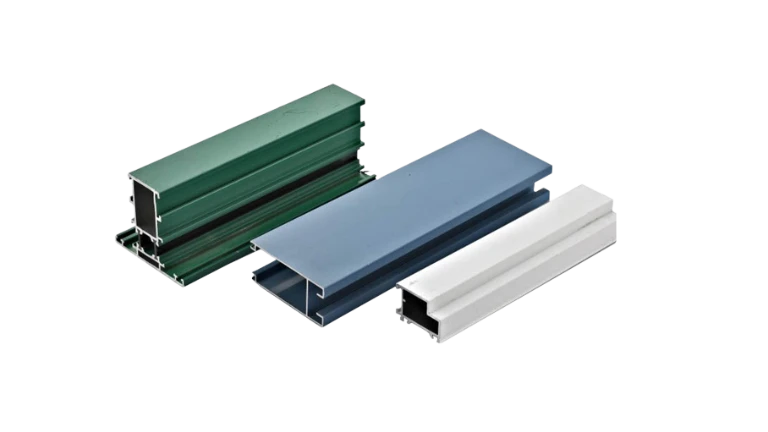

Powder Coated Finish Aluminum Profiles

Powder coating is a common surface treatment for extruded aluminum profiles, offering numerous benefits. It forms a strong protective layer that enhances corrosion resistance and increases surface hardness, making the profiles durable and scratch-resistant. The process provides a wide range of vibrant and UV-resistant colors and finishes. Additionally, powder-coated surfaces are easy to clean and maintain. Being environmentally friendly, the method produces minimal waste and avoids harmful chemicals, making it a sustainable choice for both functionality and aesthetics.

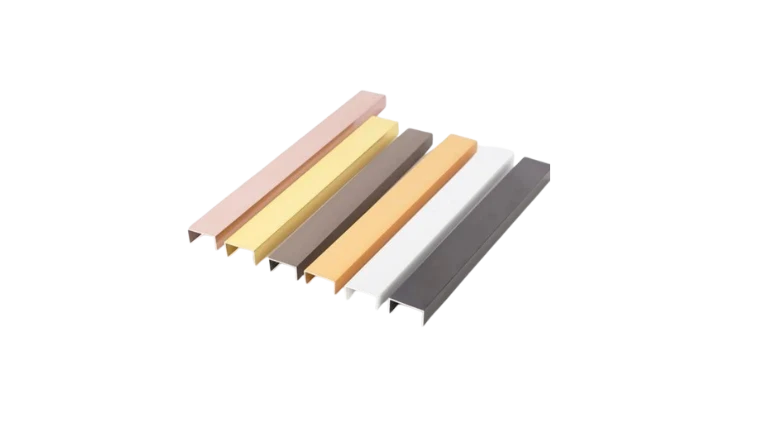

Powder-Coated Aluminum Profiles Color Options

Powder coating for aluminum profiles provides a diverse array of color choices, leveraging the RAL color chart, an international standard for precise color matching. This standardized system ensures a wide and consistent selection of colors, catering to various design and aesthetic requirements. Popular RAL colors include RAL 9010 (Pure White), RAL 9005 (Jet Black), RAL 7016 (Anthracite Grey), and RAL 1015 (Light Ivory), among many others.

The coating thickness for powder-coated aluminum profiles spans from 40 to 120 microns (µm). This thickness range affects the coating's durability, with thinner layers suitable for light-duty applications and thicker layers providing enhanced protection against wear and corrosion. In addition to thickness, powder coatings are available in different gloss levels: matte (low gloss), satin (medium gloss), and gloss (high gloss). Matte finishes deliver a subtle, non-reflective surface that resists fingerprints and smudges, making them ideal for industrial settings and minimalist designs.

Factory Show

Let our expertise in custom aluminum profiles take your projects to the next level.

Vertical Powder Coating Production Line

We employ a vertical powder coating production line for aluminum profiles, which offers several distinct advantages. Unlike traditional horizontal lines, the vertical setup minimizes floor space requirements, enabling more efficient use of available area. This configuration also allows for the continuous and uniform coating of long aluminum profiles, enhancing production efficiency and consistency in coating quality. The vertical orientation significantly reduces the risk of dust and contaminants settling on the profiles during the coating process, resulting in cleaner and higher-quality finishes. Moreover, the automated nature of the vertical line facilitates better control over the coating thickness and curing process, ensuring optimal performance and durability of the powder-coated aluminum profiles.

Features of Powder Coating for Aluminum Profiles

Powder coating for aluminum profiles is renowned for its exceptional characteristics that cater to both aesthetic and functional needs. It offers a wide range of color choices and finishes, including matte, satin, and glossy, which ensures versatility in design applications. Environmentally friendly, powder coatings are free from solvents and emit low levels of volatile organic compounds (VOCs), making them a sustainable choice. The coating provides robust protection against corrosion, UV degradation, and mechanical wear, significantly extending the lifespan of aluminum products. Additionally, its uniform application results in a consistent and smooth finish, devoid of drip marks or runs, which are common in liquid coatings. The efficient use of materials in powder coating also leads to minimal waste, further enhancing its appeal as an eco-conscious alternative.

Powder Coating Process for Aluminum Profiles

The powder coating process for aluminum profiles involves several meticulously controlled steps to ensure a high-quality, durable finish. Below is a detailed overview of the process:

Pre-Treatment:

- Cleaning and Degreasing: The aluminum profiles are first cleaned to remove any oils, dirt, or contaminants. This step is crucial for ensuring proper adhesion of the powder coating.

- Rinsing: After cleaning, the profiles are thoroughly rinsed to remove any residual chemicals.

- Etching and Phosphating: The surface is then etched to create a rough texture, enhancing the adhesion of the coating. Phosphating can also be applied to improve corrosion resistance.

Drying:

- The cleaned and pre-treated profiles are passed through a drying oven to remove any moisture. This step ensures that the surface is completely dry before the powder application.

Powder Application:

- Electrostatic Spraying: In the spray booth, an electrostatic gun charges the powder particles, which are then attracted to the grounded aluminum profiles. This results in an even and uniform coating layer.

- Coating Thickness Control: The thickness of the applied powder coating can be precisely controlled during this stage, typically ranging from 40 to 120 microns.

Curing:

- Curing Oven: The coated profiles are then moved to a curing oven where they are exposed to high temperatures, typically between 180-200°C (356-392°F). The heat causes the powder to melt and form a smooth, hard finish.

- Curing Time: The profiles remain in the oven for about 15-20 minutes, allowing the coating to fully cure and bond to the substrate.

Cooling:

- After curing, the profiles are cooled down to room temperature. This cooling phase ensures that the coating hardens properly and is ready for handling.

Inspection and Quality Control:

- Each profile undergoes a thorough inspection to ensure that the coating is uniform, free of defects, and meets the desired thickness and performance standards. Tests for adhesion, color consistency, and other properties may be conducted.

Packaging and Final Handling:

- The finished profiles are then carefully packaged to prevent damage during transportation and storage. Proper handling ensures that the profiles retain their high-quality finish until they reach the end user.

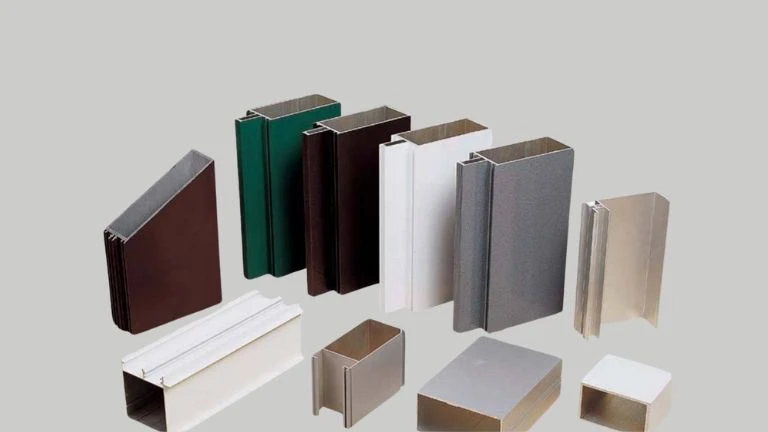

Custom Your Aluminum Profile

Our aluminum extrusion factory, located in Nanchang, Jiangxi Province, covers an extensive area of 30,000 square meters and is home to a dedicated workforce of over 120 skilled individuals.

Advanced Extrusion Lines

Boasting over 30 high-precision extrusion production lines from Japan and Germany, we ensure unmatched quality and efficiency.

Custom Mold Design and Processing

We tailor-make molds based on client designs or samples, providing prototypes for confirmation to meet precise specifications.

Comprehensive Surface Treatment Techniques

Our surface treatment capabilities include anodizing, electroplating, sandblasting, powder coating, fluorocarbon painting, and wood grain transfer printing to enhance product durability and aesthetics.

Over Two Decades of Expertise

Since 2013, we have been manufacturing aluminum profiles, accumulating vast experience in producing a wide array of profiles for windows, doors, and various industrial applications.

Custom Aluminum Profile Solution

Precision Aluminum Extrusion Process

Design and Manufacture of Moulds

Material for Extruded Aluminum