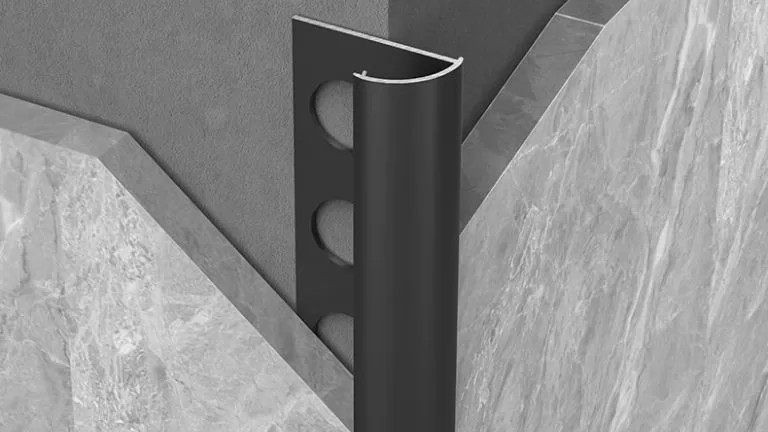

Round Aluminum Tile Trim - Perfect for Beading Applications

Round Tile Trim Overview

Round Aluminum Tile Edge Trim is a type of aluminum profile specifically designed for tiling projects to enhance edge finishing, protect tile edges from wear and damage, and provide smooth transitions between surfaces or heights. It improves the overall durability and aesthetics of tile installations while preventing edge chipping caused by impacts or daily use.

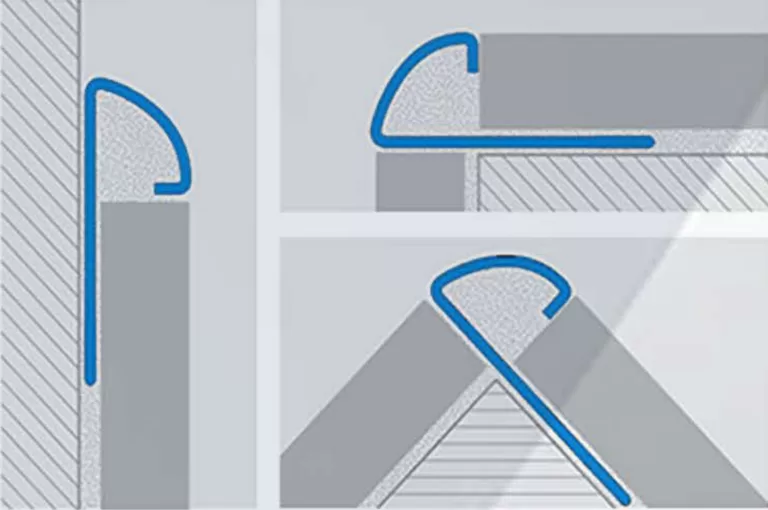

Featuring a curved surface design, round edge trim creates a smooth and rounded edge effect, making it ideal for wall and floor corner decorations. It is particularly suited for high-end design applications, offering a refined and elegant finish. The soft edge design not only enhances visual appeal but also reduces dust accumulation, ensuring both functionality and cleanliness.

Installation Method

1. Select a ROUND EDGE TRIM based on the tile thickness and the desired finish style.

2. Cut the ROUND EDGE TRIM to the required length and spread adhesive on the surface where the profile will be installed.

3. Firmly press the anchoring flange of the ROUND SHAPE TRIM into the adhesive.

4. Position the tiles, aligning them with the trim, and leave a 2 mm gap. Immediately clean off any excess adhesive from the surface of the trim.

5. Use plaster to fill the gaps between the trim and the tiles to prevent water accumulation. Immediately wipe off any excess plaster from the profile’s surface.

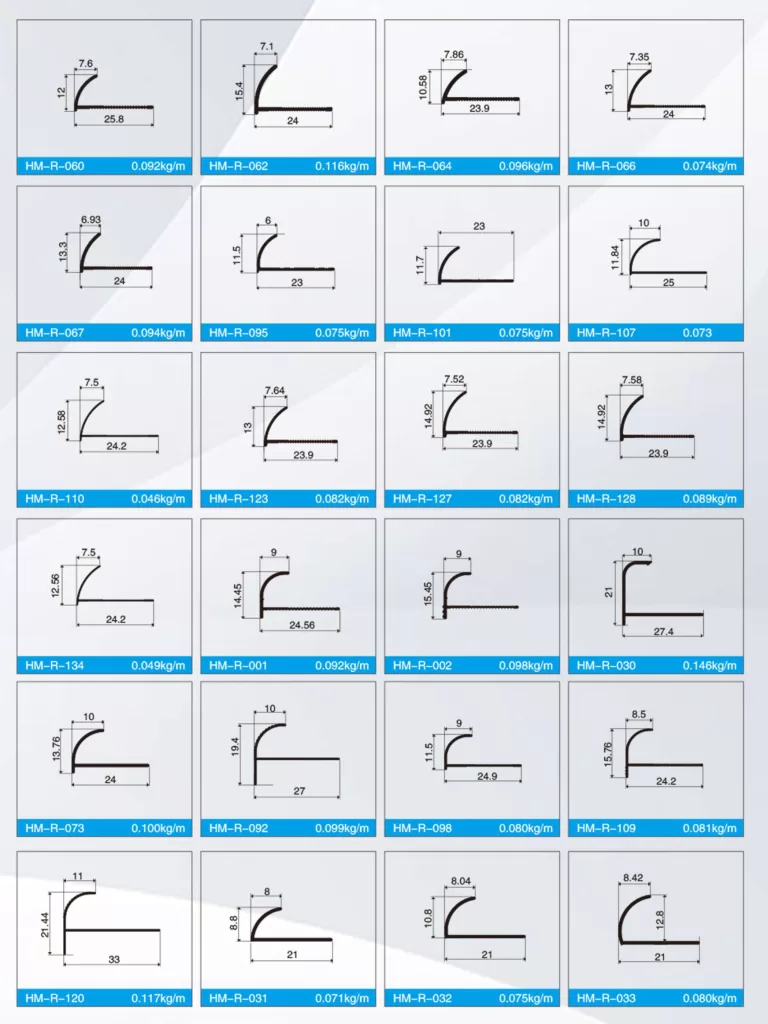

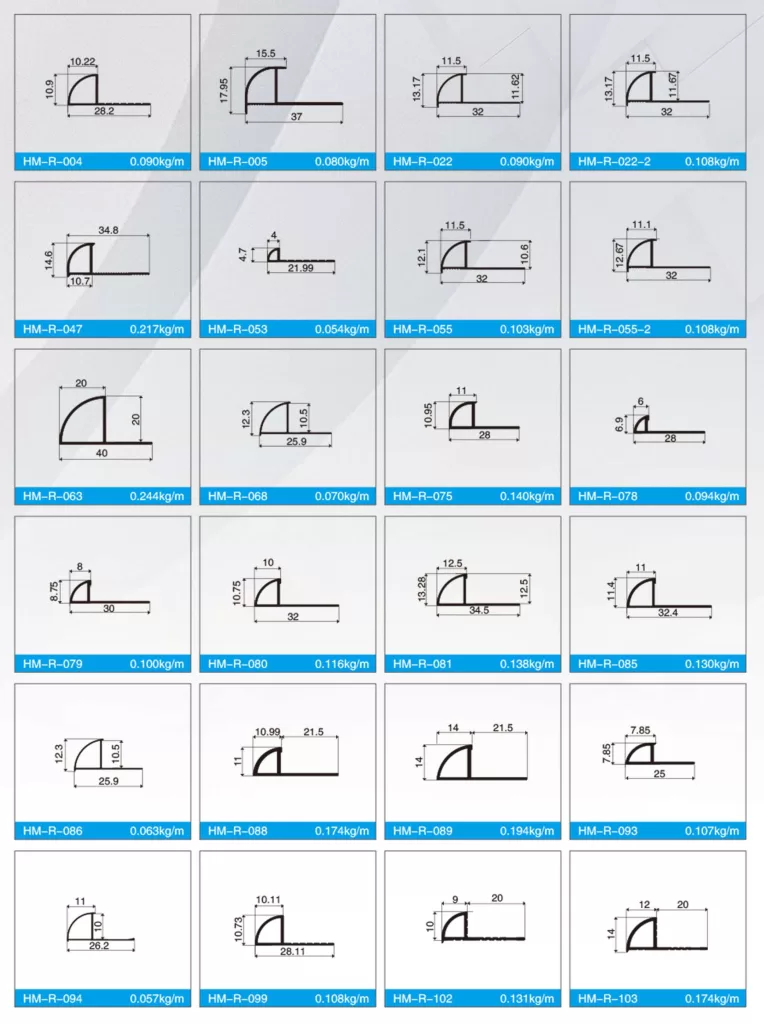

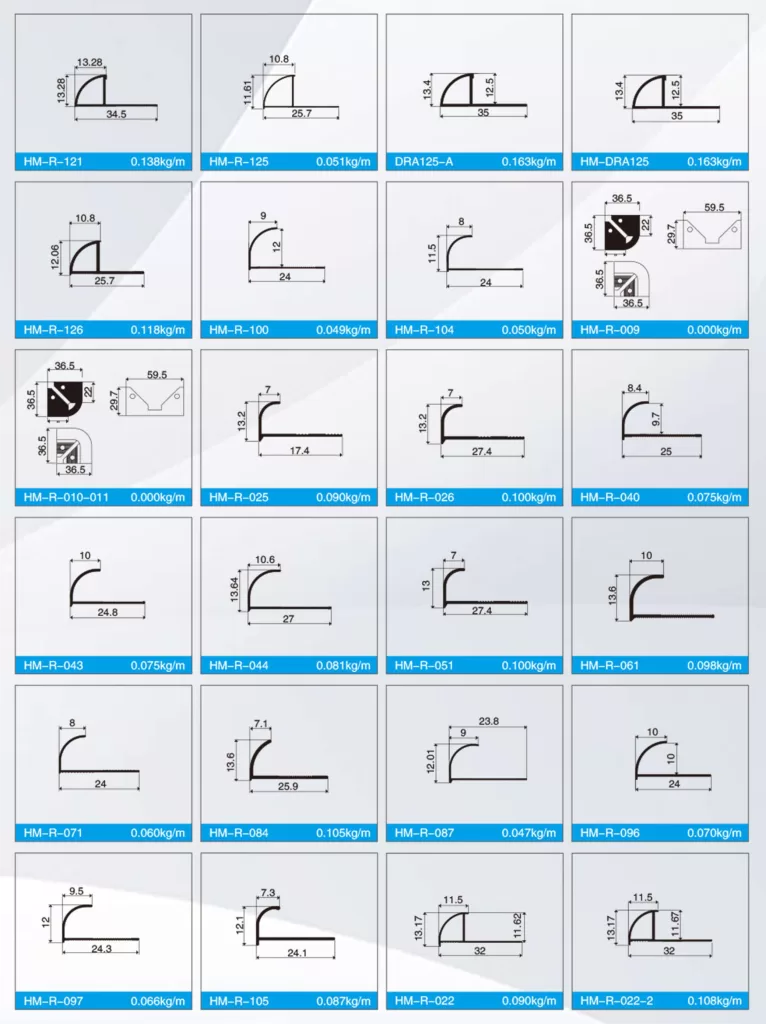

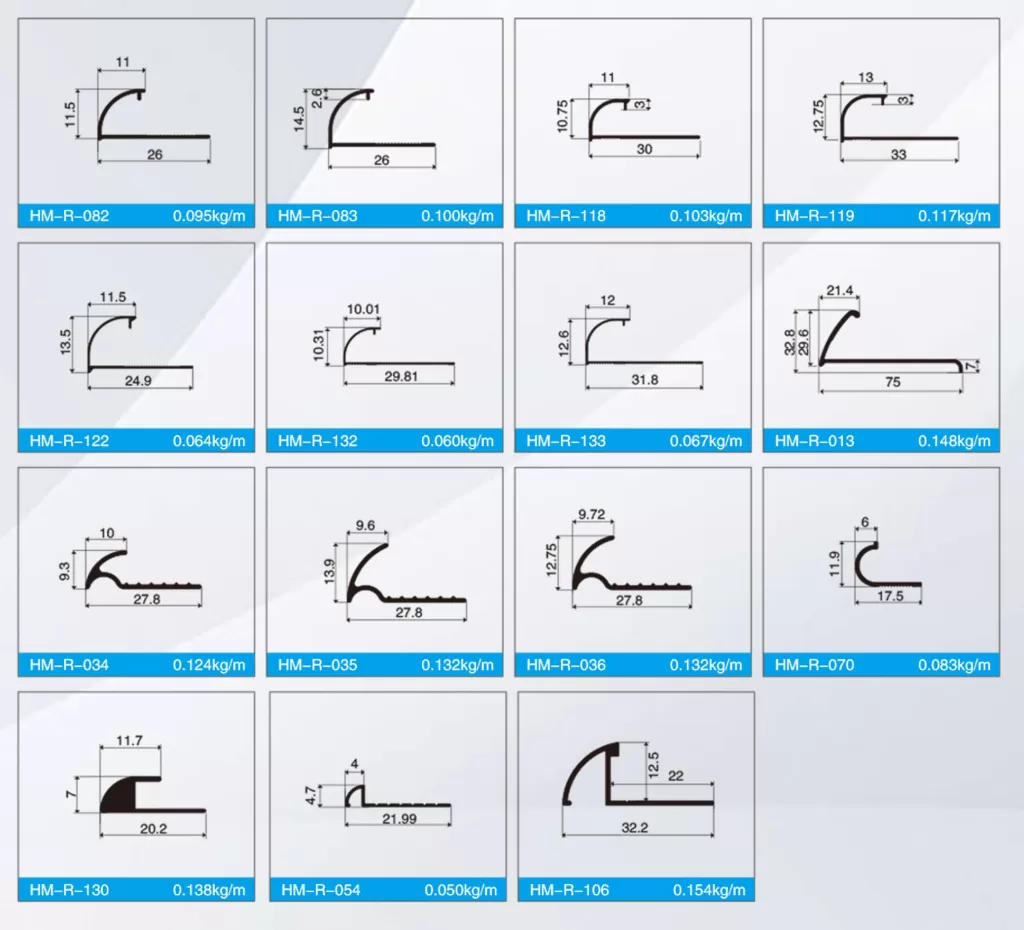

Round Aluminum Tile Beading Specification

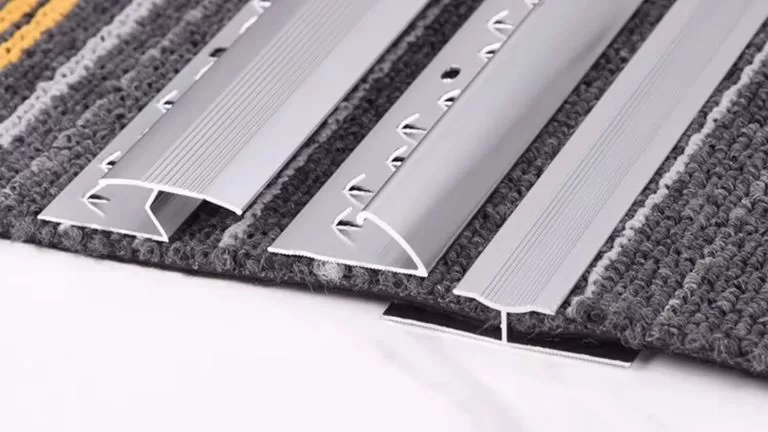

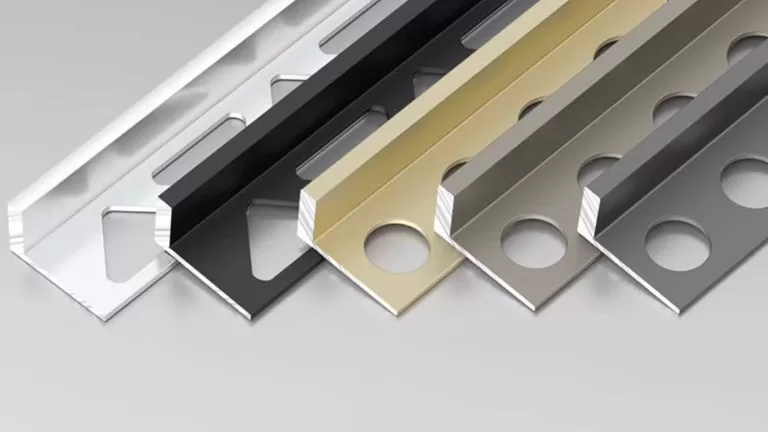

Other Aluminum Trim | Beading Strips

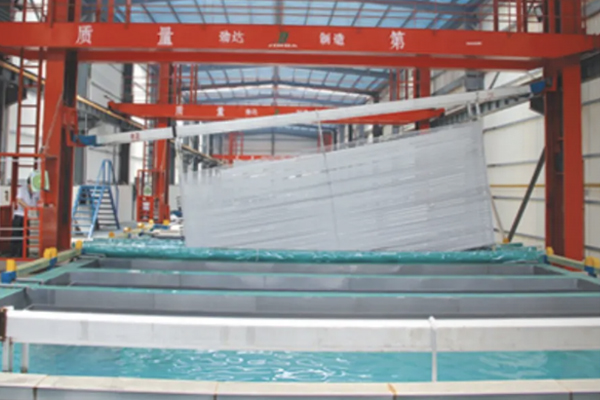

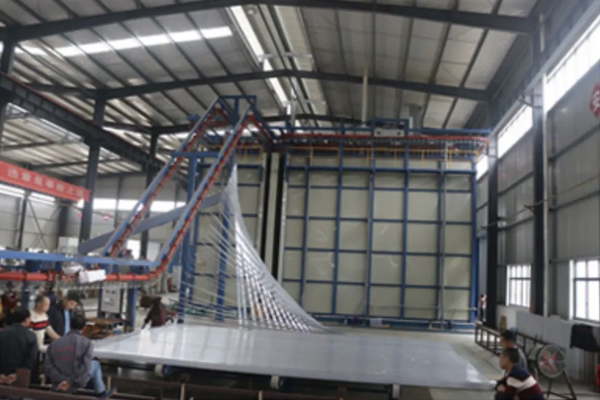

Our Factory

HTS NEW MATERIALS is a top-tier manufacturer of aluminum extrusion profiles in China, specializing in a wide range of architectural and industrial aluminum profiles, including decorative trims. With over 40 production lines and the largest 6000-ton extrusion press in the country, we are committed to delivering superior-quality products. Our expertise covers mold design and production, advanced surface treatments, and precision machining services, making us a trusted partner for all your aluminum profile needs.

Custom Produce

- With over 40 extrusion production lines, we have the capability to meet high-volume demands and ensure timely delivery.

- Our largest extrusion press boasts a capacity of 6000 tons, enabling us to produce large and complex aluminum profiles.

- We possess the expertise to design and manufacture custom molds, ensuring precision and quality in every profile we produce.

- We offer a full range of aluminum surface treatments, including anodizing, electrophoresis, powder coating, PVDF coating, and wood grain transfer printing, to meet various aesthetic and functional requirements.

- Beyond extrusion, we provide extensive machining services such as cutting, drilling, milling, and finishing, delivering ready-to-use custom aluminum profiles.

- With over 20 years in the custom aluminum profiles industry, our experience and expertise ensure exceptional quality, reliability, and customer satisfaction.