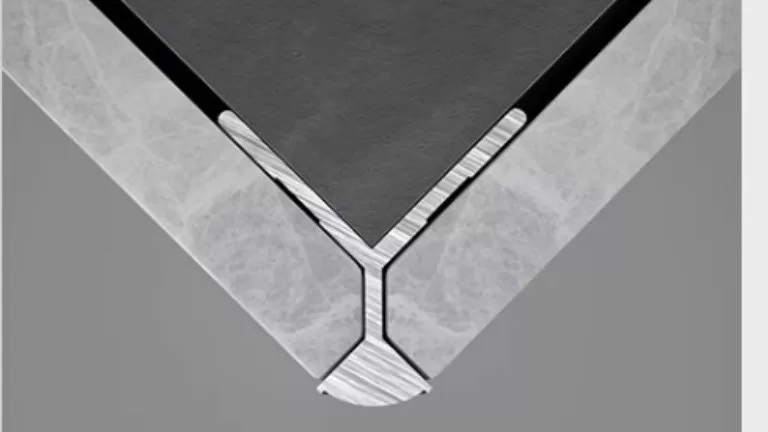

Aluminum Y Angle Tile Trim for Outer Corner Finishing

Aluminum Y Angle Tile Trim

Aluminum Tile Edge Trim is a finishing solution that protects and enhances tiled edges. It conceals sharp edges, prevents damage, and provides a polished finish. Suitable for wall and floor tiles in residential, commercial, and industrial spaces, it ensures durable edges and smooth transitions between tiles and other materials, with various styles and finishes available.

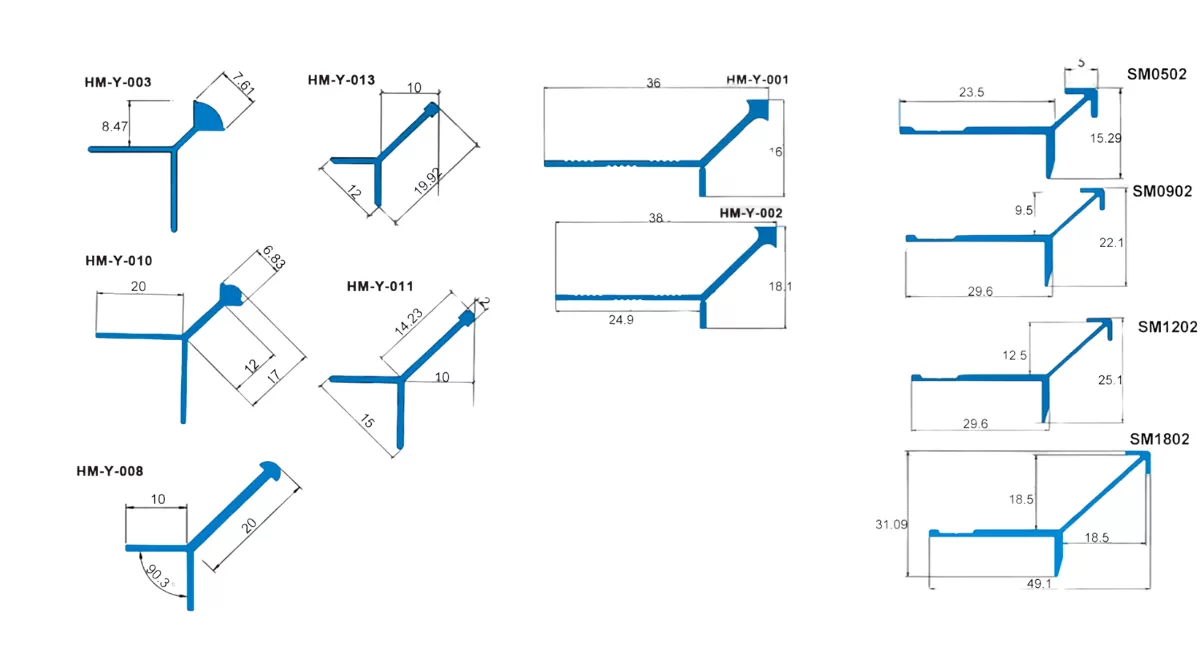

Y-ANGLE TRIM features a unique Y-shaped design to connect three tiled surfaces. It safeguards edges, adds a modern touch, and is ideal for kitchens, bathrooms, and contemporary interiors requiring a geometric detail.

HTS-ALU is a leading aluminum profile supplier specializing in Aluminum Tile Edge Trims, including Y-ANGLE TRIM. These customizable profiles meet diverse project needs across residential, commercial, and industrial applications, offering a balance of functionality and aesthetics trusted by designers, architects, and contractors.

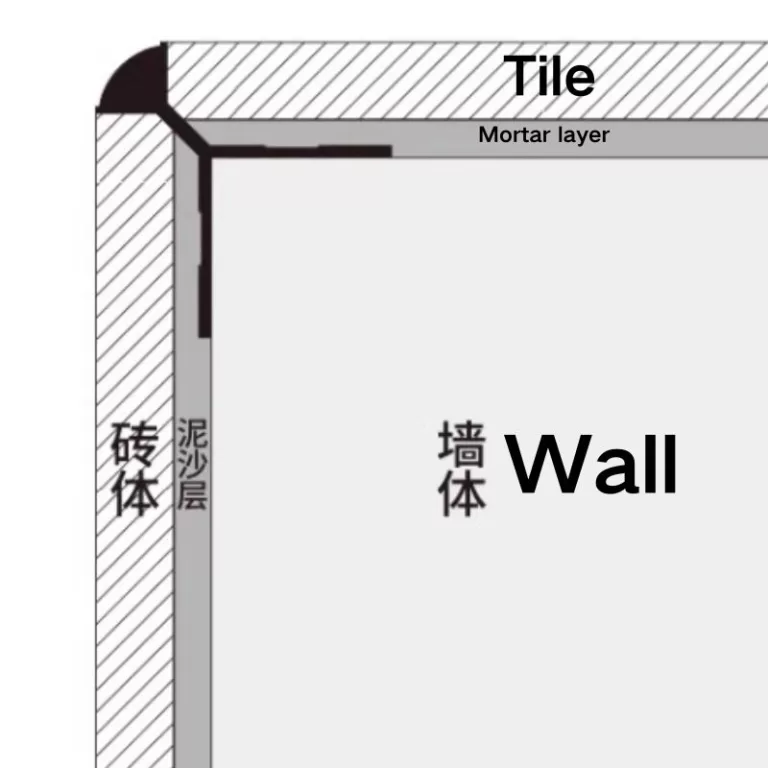

Installation Method

1. Prepare Surface: Clean the wall and tile edges. Cut the Aluminum Y Angle Tile Trim to the right length.

.

2. Apply Mortar: Spread mortar evenly on the wall where the tile and trim go..

.

3. Position Trim: Press the trim into the mortar at the corner or edge, aligning it with the wall and tiles..

.

4. Install Tiles: Press tiles into the mortar next to the trim. Adjust for a neat fit..

.

5. Clean and Finish: Let the mortar dry. Wipe off extra mortar with a damp sponge.

Aluminum Y Angle Tile Trim Specification

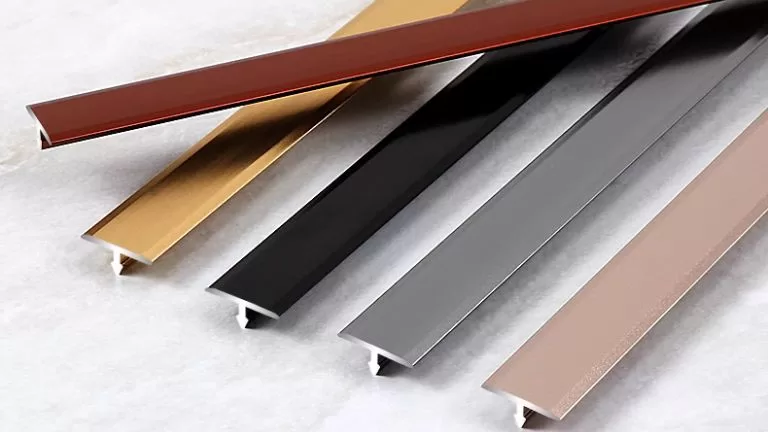

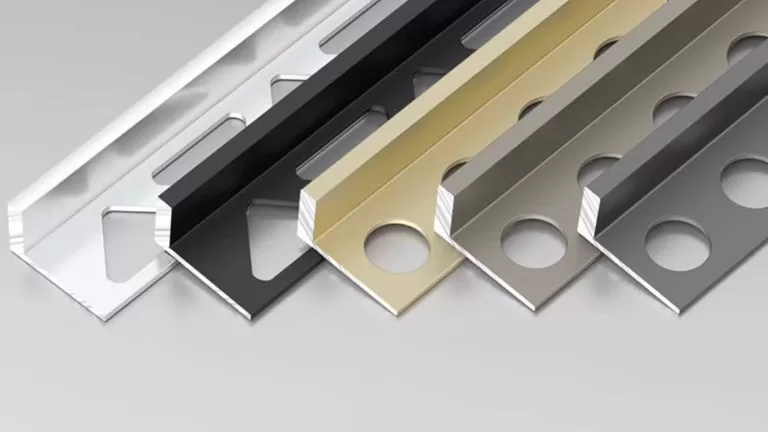

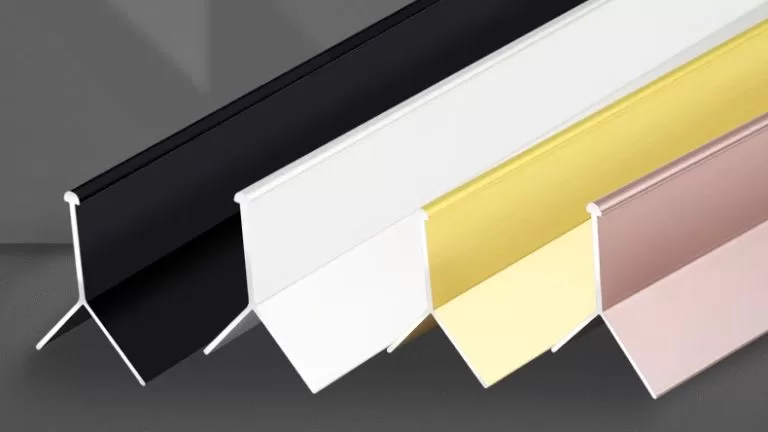

Other Aluminum Trim | Beading Strips

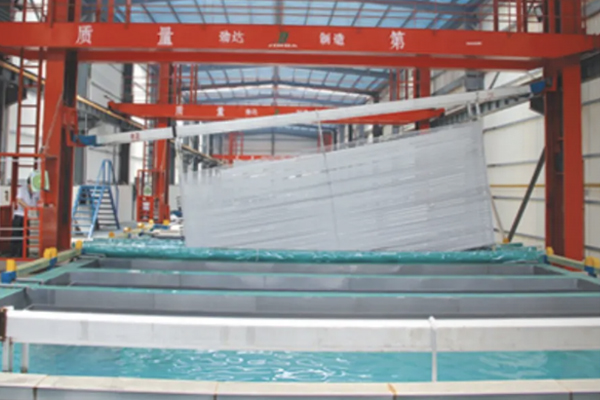

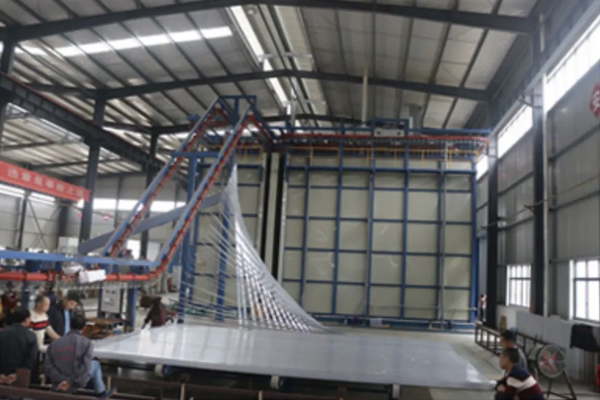

Our Factory

Custom Produce

- With over 40 extrusion production lines, we have the capability to meet high-volume demands and ensure timely delivery.

- Our largest extrusion press boasts a capacity of 6000 tons, enabling us to produce large and complex aluminum profiles.

- We possess the expertise to design and manufacture custom molds, ensuring precision and quality in every profile we produce.

- We offer a full range of aluminum surface treatments, including anodizing, electrophoresis, powder coating, PVDF coating, and wood grain transfer printing, to meet various aesthetic and functional requirements.

- Beyond extrusion, we provide extensive machining services such as cutting, drilling, milling, and finishing, delivering ready-to-use custom aluminum profiles.

- With over 20 years in the custom aluminum profiles industry, our experience and expertise ensure exceptional quality, reliability, and customer satisfaction.