Aluminum Sign Channel

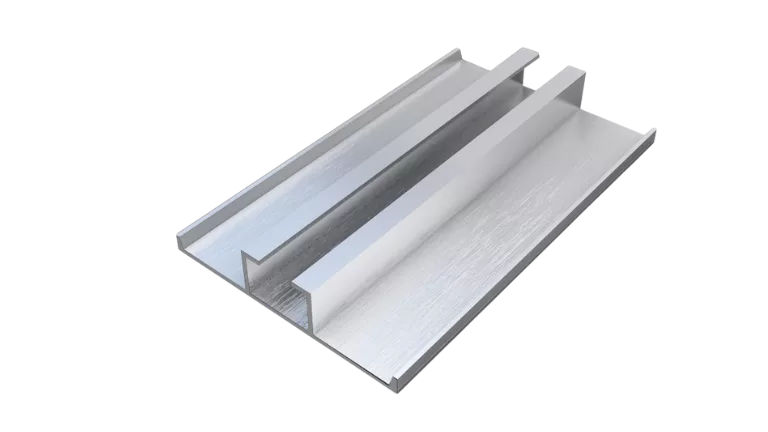

The Aluminum Sign Channel is a high-quality extruded profile specifically designed for mounting and securing aluminum signage panels. Its grooved design ensures a precise and stable fit, keeping aluminum signs securely in place while providing a modern, professional appearance. Lightweight yet extremely durable, the channel is tailored to meet the rigorous demands of both indoor and outdoor environments. Additionally, its corrosion-resistant aluminum composition makes it highly reliable for long-term use.

The installation of Aluminum Sign Channels is straightforward and flexible, offering a variety of mounting options. They can be back-mounted onto pole systems for use in traffic signage or directional posts or flat-mounted directly to walls and frames for more static and decorative applications. This adaptability ensures that the channel can fit a wide array of applications in both commercial and industrial settings, meeting the specific needs of any project.

Aluminum Sign Channels are extensively used in fields like architectural signage, wayfinding systems, traffic control, and commercial displays. They deliver a polished and visually appealing finish for aluminum panels while remaining resilient in harsh conditions. Thanks to their strength, weather resistance, and professional aesthetic, these channels are the go-to solution for creating durable and functional signage systems worldwide.

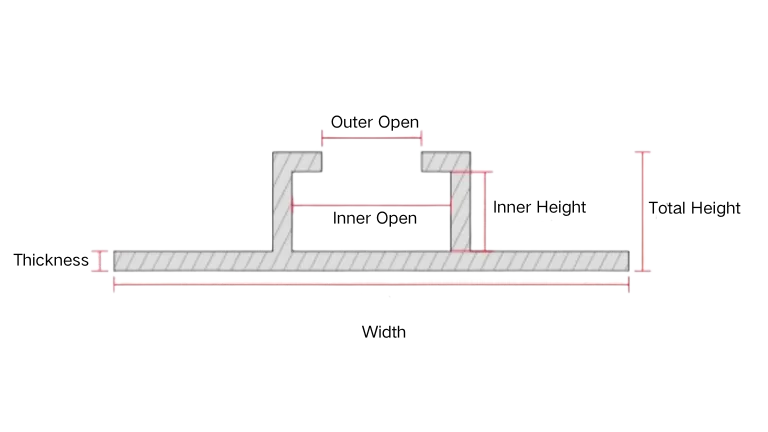

In-Stock Aluminum Sign Channel Specifications

| Specification | Width | Thickness | Total Height | Inner Opening | Outer Opening | Inner Height | Applicable Screws | Notes |

|---|---|---|---|---|---|---|---|---|

| 60*1.5 | 60 | 1.5 | 12.5 | 18 | 10.8 | 8.8 | M10 Hexagonal Screw | Suitable for small signs |

| 60*2.0 | 60 | 1.8 | 12.8 | 18 | 10.8 | 8.8 | M10 Hexagonal Screw | Suitable for small to medium signs |

| 65*2.0 | 65 | 1.8 | 13.7 | 19 | 12 | 9.5 | M12 Hexagonal Screw | Suitable for medium signs |

| 65*2.5 | 65 | 2.4 | 16 | 20 | 12.6 | 10.5 | M12 Hexagonal Screw | Suitable for medium signs and some cabinets |

| 80*3.0 | 80 | 2.8 | 16 | 20 | 13 | 10.3 | M12 Hexagonal Screw | Suitable for large signs |

Custom Aluminum Sign Channels

HTS-ALU is a China-based custom aluminum profile factory with 40 extrusion production lines, complete surface treatment capabilities, and machining services. We are dedicated to providing comprehensive customization services for Aluminum Sign Channels. Whether you have specific designs, samples, or specialized material preferences, we can deliver high-precision, fully customized products tailored to your project requirements.

What We Offer:

Full Customization Based on Drawings or Samples

- Provide your technical drawings or an existing sample, and we’ll create a precise custom mold to match your desired profile.

Customizable Materials

Wide Range of Surface Finishes

- Enhance the durability and appearance of your Aluminum Sign Channels with surface treatments such as:

- Anodizing for corrosion resistance

- Electrophoresis Coating for a glossy, protective finish

- Powder Coating in various colors

- Polishing, Brushing, and more for a sleek look

- Enhance the durability and appearance of your Aluminum Sign Channels with surface treatments such as:

High Precision Production

- With advanced extrusion and machining technology, we ensure your custom channels are produced with superior dimensional accuracy and performance.

Tailored Solutions for Every Industry

- Whether for indoor or outdoor signage applications, we deliver durable and reliable products that meet your specific installation and environmental needs.

Our production facility houses over 40 advanced extrusion lines, featuring cutting-edge equipment such as a powerful 6000-ton extrusion press. This enables the creation of aluminum profiles in various sizes and forms, ranging from standard industrial applications to specialized products like thermal break profiles for high-end doors and windows. The flexibility of our extrusion capability ensures we can cater to a broad spectrum of industries, including construction and precision engineering.

Our production facility houses over 40 advanced extrusion lines, featuring cutting-edge equipment such as a powerful 6000-ton extrusion press. This enables the creation of aluminum profiles in various sizes and forms, ranging from standard industrial applications to specialized products like thermal break profiles for high-end doors and windows. The flexibility of our extrusion capability ensures we can cater to a broad spectrum of industries, including construction and precision engineering.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

To provide complete aluminum profile solutions, we offer extensive further processing capabilities. Our services include CNC machining, milling, threading, drilling, precision cutting, punching, welding, and assembly. This range of fabrication options allows us to deliver ready-to-use profiles tailored to exact project specifications, offering unmatched flexibility and reliability to our customers.

For superior durability and visual appeal, we offer various surface treatment solutions. These include anodizing for added corrosion resistance, powder coating for vibrant finishes, fluorocarbon coating for enhanced weather resistance, and wood grain transfer technology for elegant, natural-looking designs. These treatments are customizable to fit specific aesthetic and functional needs, ensuring that profiles not only perform well but also look exceptional.

Installation Guide for Aluminum Sign Channel

Fixing the Signboard to the Aluminum Channel:

- Insert the signboard into the aluminum channel and secure it using rivets or bolts to ensure a firm attachment.

- For larger signboards, multiple aluminum channels can be arranged horizontally in a symmetrical manner to evenly distribute the load and improve stability.

Connecting the Aluminum Channel to the Support Post or Frame:

- Use pre-drilled holes on the aluminum channel to fix it to traffic poles or support frames with bolts.

- In high-wind scenarios or installations requiring enhanced wind resistance, reinforcement support components can be utilized for additional stability.

Aluminum vs. Steel vs. Plastic Channels

| Feature | Aluminum | Steel | Plastic |

|---|---|---|---|

| Weight | Lightweight, easy to install | Heavy, hard to handle | Very light, low strength |

| Corrosion Resistance | Excellent, ideal for outdoors | Prone to rust, needs protection | Resistant but ages in sun |

| Strength | High, versatile | Strongest | Limited to small signs |

| Processing | Easy to cut and drill | Needs special tools | Very flexible |

| Cost | Moderate, cost-effective | High | Low |

| Recyclability | 100% recyclable | Partly recyclable | Non-recyclable |

Common Uses of Aluminum Sign Channel

1. Road Traffic Signs

Aluminum sign channels are widely used to secure highway warning signs, speed limit signs, construction zone indicators, and other traffic control signage. They provide a sturdy framework for road signs, including directional signs, restriction markers, and caution signs.

2. Parking Lot Signs

Ideal for parking guidance signs, parking restriction boards, and other signage systems in both underground and open-air parking areas.

3. Street and Park Signs

Frequently used in public areas for pedestrian direction signs, street name plates, and park information signs to ensure clear and durable signage.

4. Large Highway Signboards

Aluminum channels offer strong support for large reflective highway signs, enabling their attachment to poles or overhead structures for enhanced visibility.

5. Railway and Airport Signage

Used for signage in railway stations and airports, such as traffic direction boards, safety zone demarcations, and signal posts, ensuring clear and durable guidance in high-traffic environments.