I Shaped Aluminum Trim for Dividing Strip

I Shaped Aluminum Trim Overview

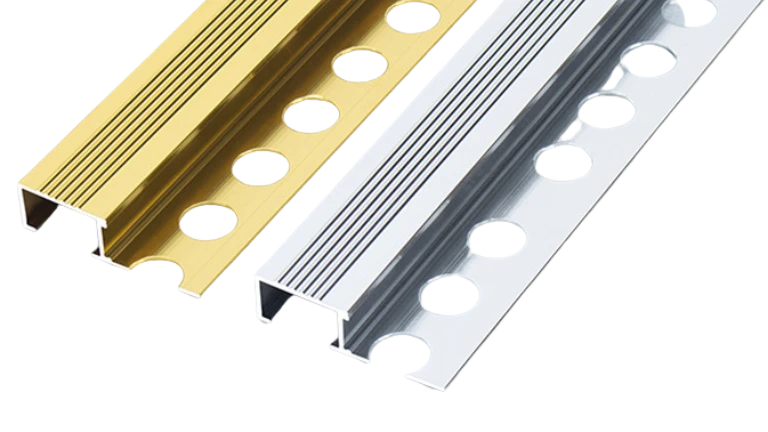

Aluminum Tile Edge Trim is a vital finishing profile designed to protect and enhance the edges of tiled surfaces. Acting as both a protective shield and a decorative feature, it effectively hides sharp or uneven tile edges, reduces the likelihood of chipping, and provides a sleek, professional appearance. These trims are highly versatile, suitable for wall and floor tiles in residential, commercial, and industrial spaces. They ensure long-lasting durability and clean, finished transitions. Available in a variety of profiles, finishes, and colors, aluminum tile edge trims offer the perfect blend of functionality and aesthetics by seamlessly connecting tiles with adjacent materials.

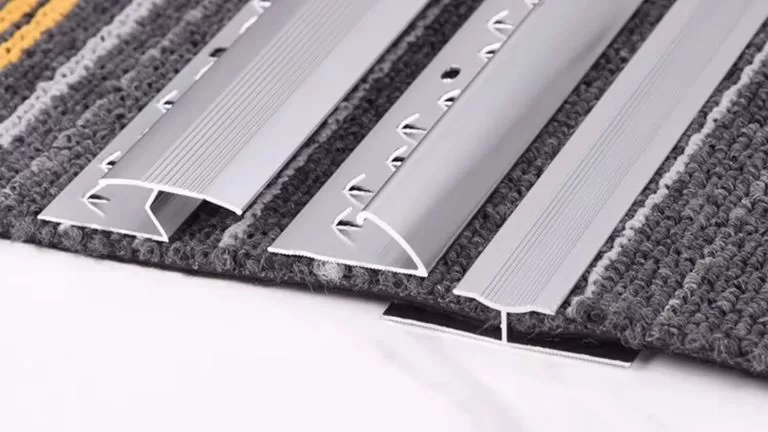

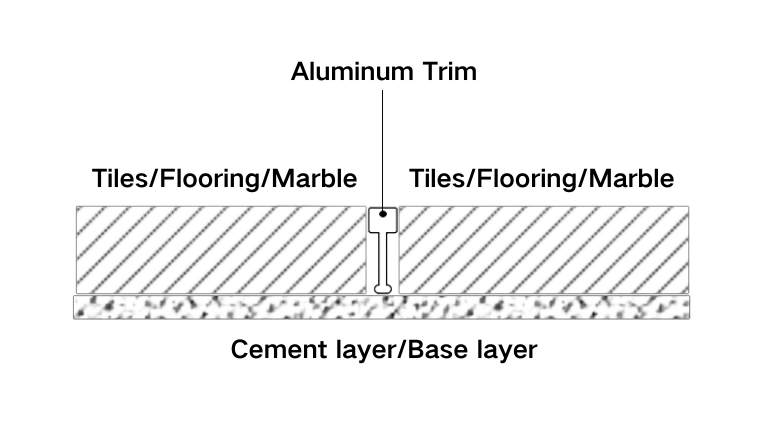

I-shaped aluminum trims for dividing strips are an excellent choice for bridging gaps between two different flooring types or surfaces at the same level. These trims provide a smooth and neat separation while protecting the edge of the floors from wear and tear. With their minimalistic and practical design, I-shaped trims are widely used to achieve an elegant and professional look in diverse spaces.

HTS-ALU is a leading aluminum profile manufacturer in China, offering a vast array of architectural decorative trims, including reliable I-shaped dividing strips.

Installation Method

- Select a dividing strip that matches the height of the flooring for a seamless transition.

- Measure and trim the profile to the required length, then align it along the edge of the installed flooring or position it from above.

- Proceed with the flooring installation, ensuring the surface remains flush with the dividing strip.

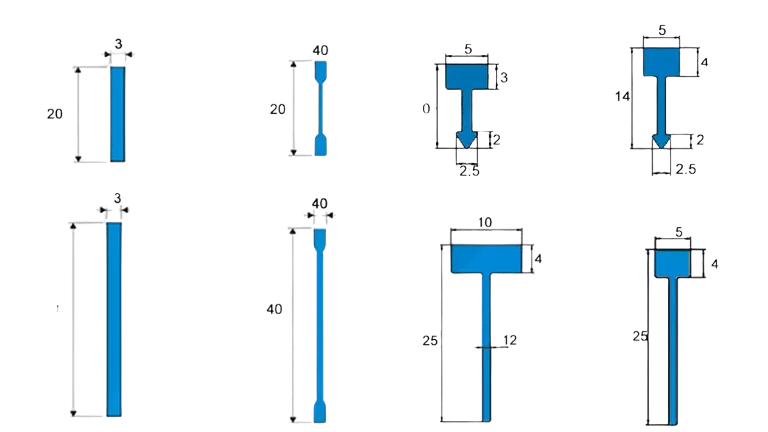

T Shaped Aluminum Strip Specification

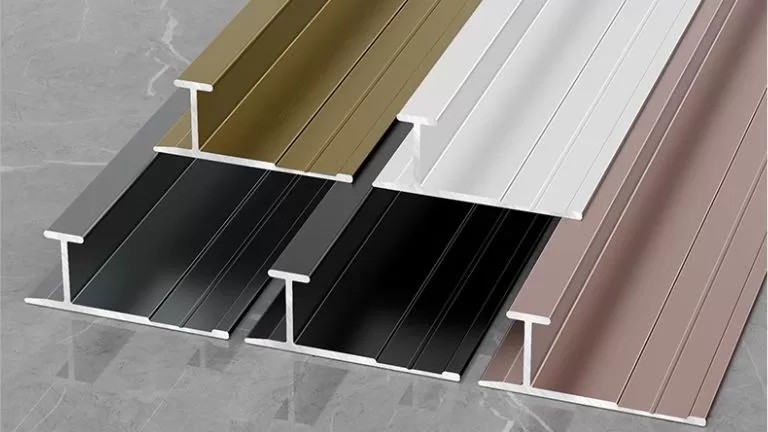

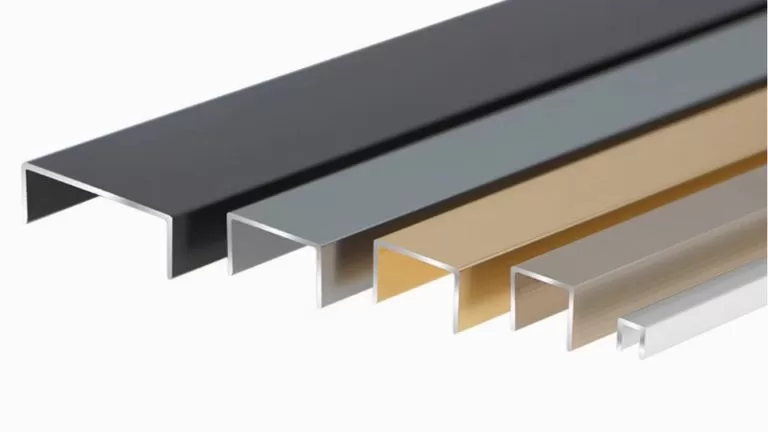

Other Aluminum Trim | Beading Strips

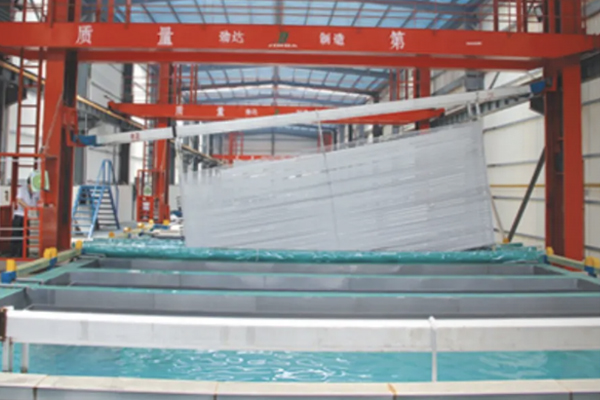

Our Factory

HTS NEW MATERIALS stands out as a premier supplier of aluminum extrusion profiles in China, offering an extensive selection of architectural and industrial aluminum profiles alongside decorative trims. Backed by over 40 state-of-the-art production lines and the country’s most advanced 6000-ton extrusion press, we deliver exceptional products designed to meet diverse project needs. With expertise in mold design, precision machining, and advanced surface treatments, we aim to be your reliable partner for all aluminum profile requirements.

Custom Produce

- With over 40 extrusion production lines, we have the capability to meet high-volume demands and ensure timely delivery.

- Our largest extrusion press boasts a capacity of 6000 tons, enabling us to produce large and complex aluminum profiles.

- We possess the expertise to design and manufacture custom molds, ensuring precision and quality in every profile we produce.

- We offer a full range of aluminum surface treatments, including anodizing, electrophoresis, powder coating, PVDF coating, and wood grain transfer printing, to meet various aesthetic and functional requirements.

- Beyond extrusion, we provide extensive machining services such as cutting, drilling, milling, and finishing, delivering ready-to-use custom aluminum profiles.

- With over 20 years in the custom aluminum profiles industry, our experience and expertise ensure exceptional quality, reliability, and customer satisfaction.