Extruded Aluminum Corner & Edging Decorative Trim | Transition Strip

Aluminum Trim refers to edge-wrapping or decorative materials made from aluminum alloys through extrusion or bending processes. These trims are characterized by their lightweight, high strength, corrosion resistance, ease of fabrication, and strong decorative appeal. They are commonly used for edge wrapping, decoration, Beading, edge protection, and fixing, making them an essential component in various applications.

Aluminum Trim is widely utilized in construction, home furnishings, furniture, automotive interiors, and commercial settings. Its durability and aesthetic versatility make it a popular choice across industries.

HTS-ALU, based in China, is a dedicated aluminum profile manufacturer offering a wide range of Aluminum Trim products to meet diverse needs.

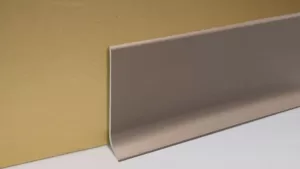

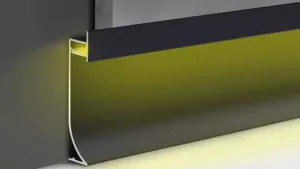

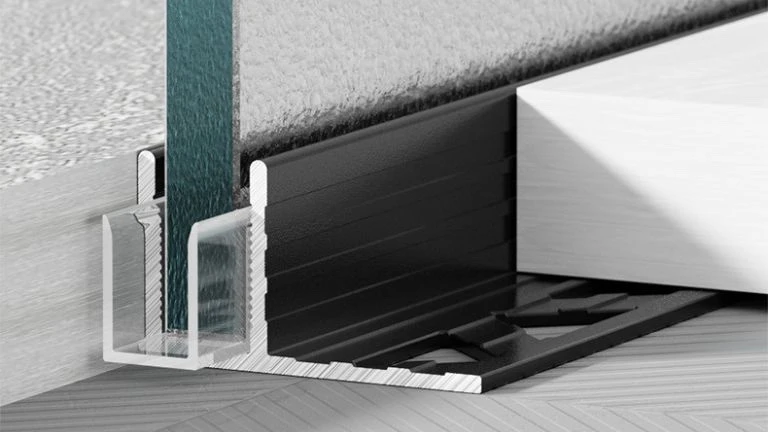

Aluminium Wall Skirting, also known as aluminum baseboard trim, offers a modern and durable solution for finishing the junction between walls and floors. Resistant to moisture and wear, Aluminium Wall Skirting is ideal for areas prone to water exposure, such as bathrooms and kitchens. Its sleek, metallic finish adds a contemporary touch to any space, while its sturdy construction ensures long-lasting protection and minimal maintenance. Furthermore, Aluminium Wall Skirting is easy to install and comes in various styles to complement any interior design, making it a practical and aesthetically pleasing choice for both residential and commercial spaces.

Aluminium Skirting Regular Style

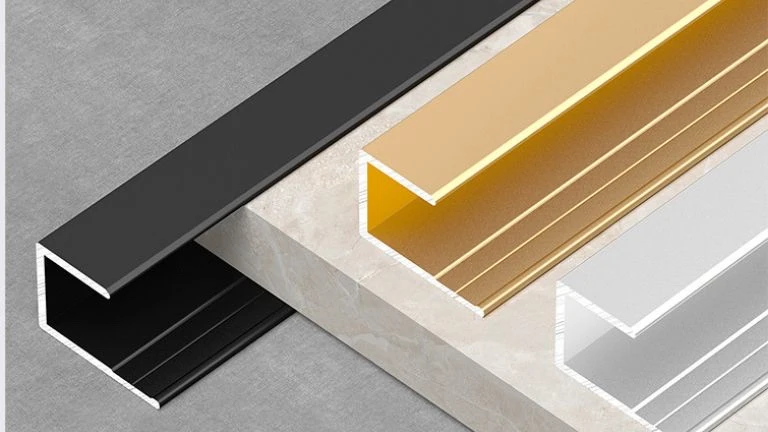

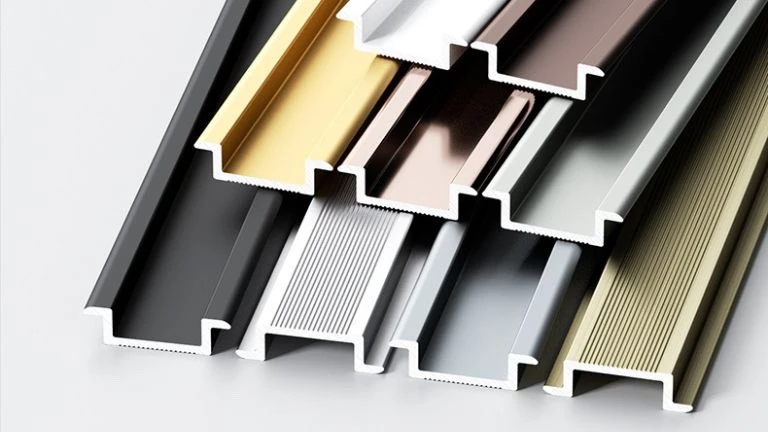

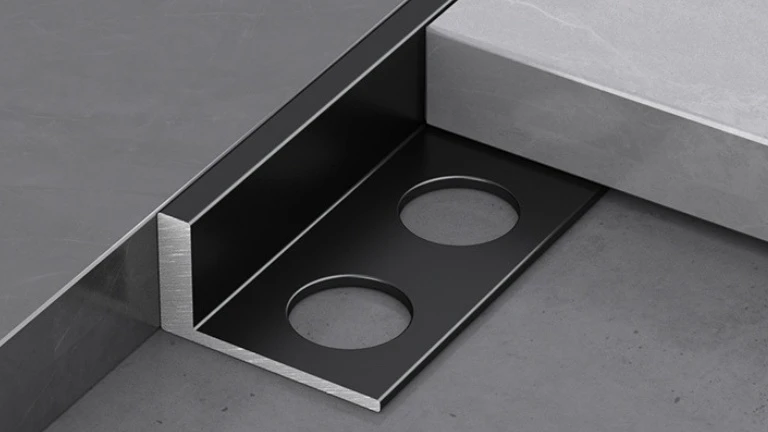

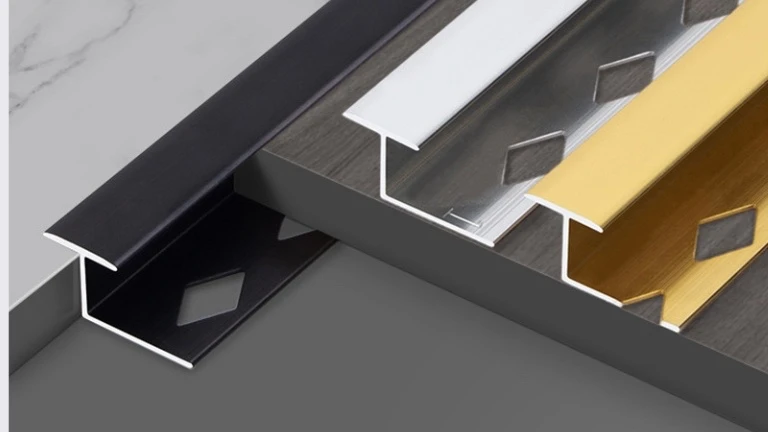

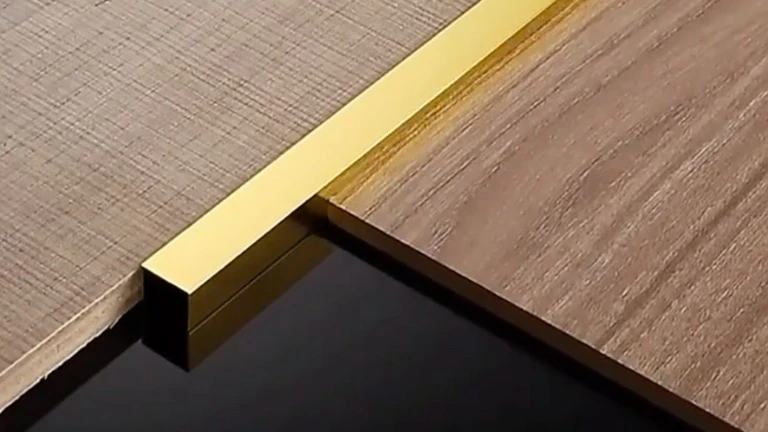

Aluminum tile trim is designed to enhance and protect the edges of tile installations. Made from durable aluminum, it prevents chipping and wear, while providing a clean, polished finish. Available in various sizes and styles, it seamlessly complements any interior design, making it ideal for kitchens, bathrooms, and other tiled areas.

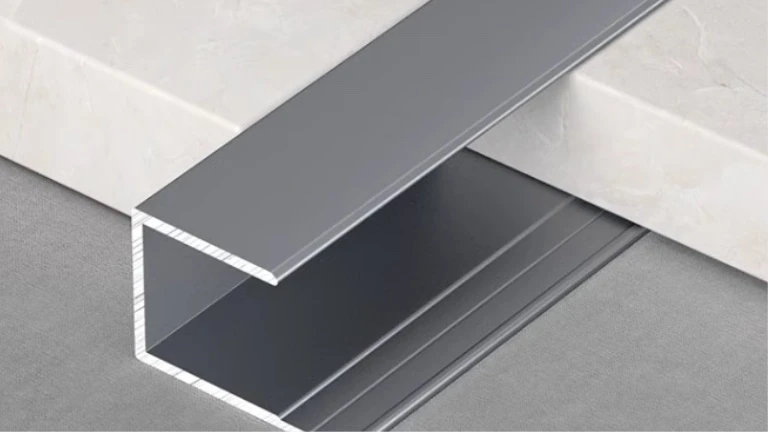

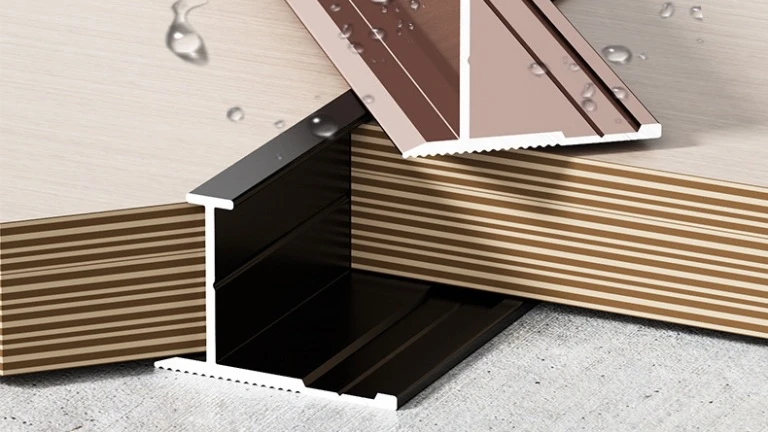

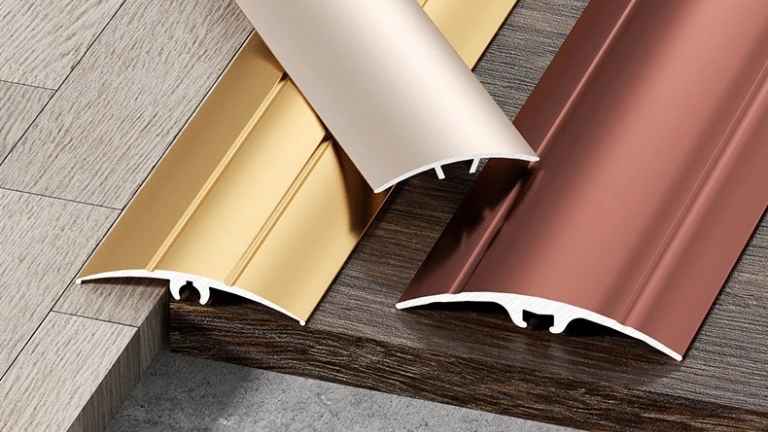

Aluminium Floor Transition Trims

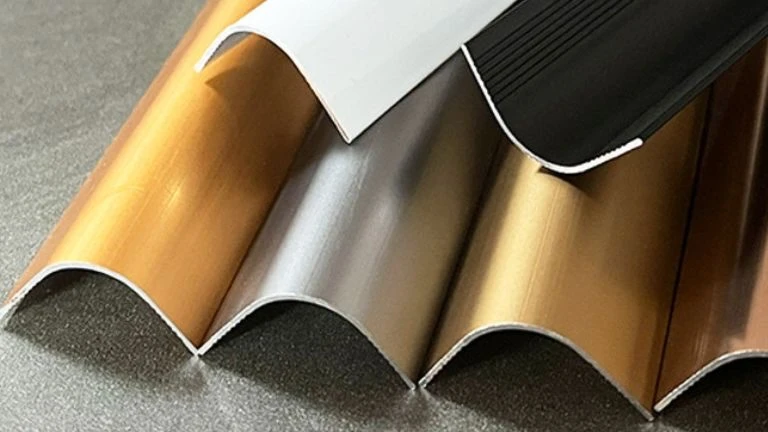

Aluminium floor trims are essential for achieving a smooth transition between different flooring surfaces, protecting edges, and ensuring a finished look. These durable trims are resistant to wear and tear, making them ideal for high-traffic areas. Available in various profiles and finishes, aluminium floor trims can seamlessly match any decor style, enhancing both the functionality and aesthetics of floor installations.

Aluminum carpet trim is designed to secure and protect the edges of carpeting, providing a smooth transition to other types of flooring. This durable trim prevents fraying and wear along carpet edges, ensuring a neat and professional finish. Lightweight yet strong, aluminum carpet trim is easy to install and available in various styles to match different decor themes, making it a practical choice for both residential and commercial settings.

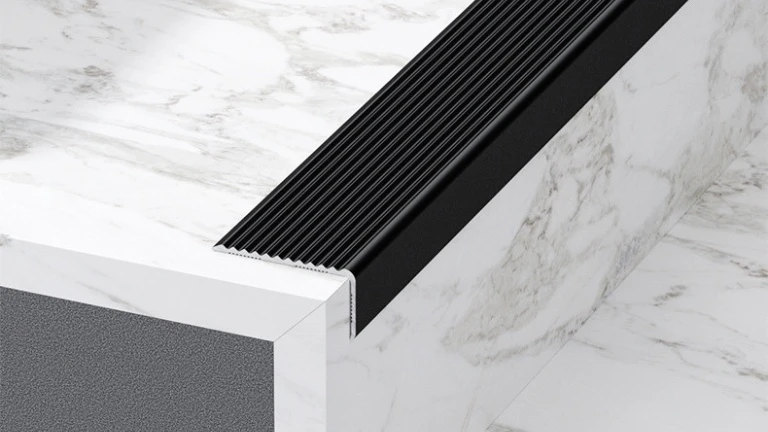

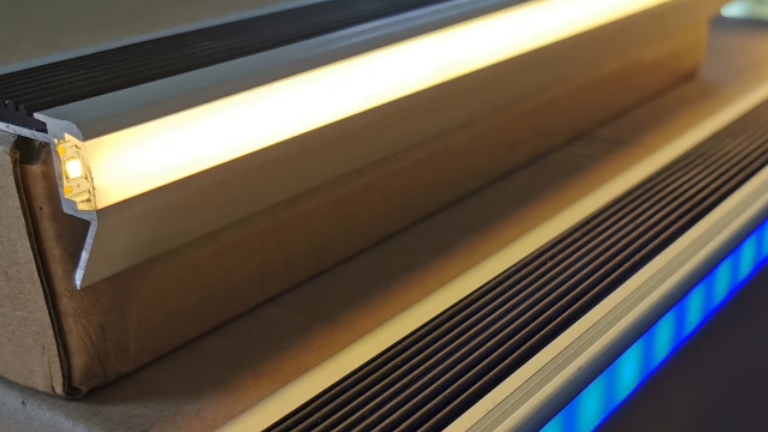

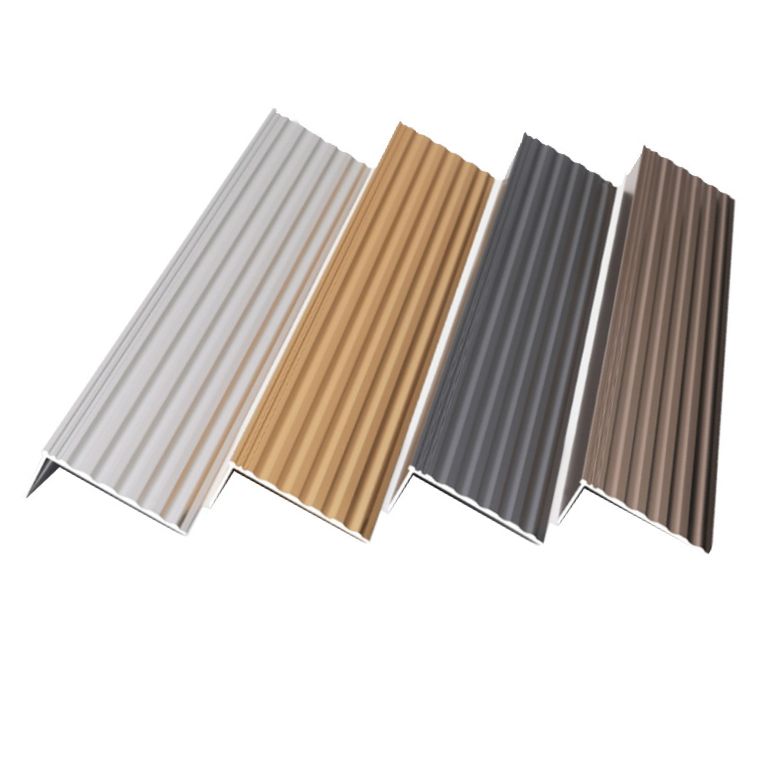

Aluminium stair edge trim is a robust solution designed to enhance safety and durability on staircases. It caps the edges of stairs, preventing wear and offering a firm grip to reduce slip hazards. Its strong aluminum construction ensures long-lasting performance and resistance to corrosion, making it suitable for both indoor and outdoor staircases. Available in various finishes, aluminium stair edge trim can be seamlessly integrated into any architectural style, providing both functional and aesthetic benefits.

Aluminium stair edge trim is a robust solution designed to enhance safety and durability on staircases. It caps the edges of stairs, preventing wear and offering a firm grip to reduce slip hazards. Its strong aluminum construction ensures long-lasting performance and resistance to corrosion, making it suitable for both indoor and outdoor staircases. Available in various finishes, aluminium stair edge trim can be seamlessly integrated into any architectural style, providing both functional and aesthetic benefits.

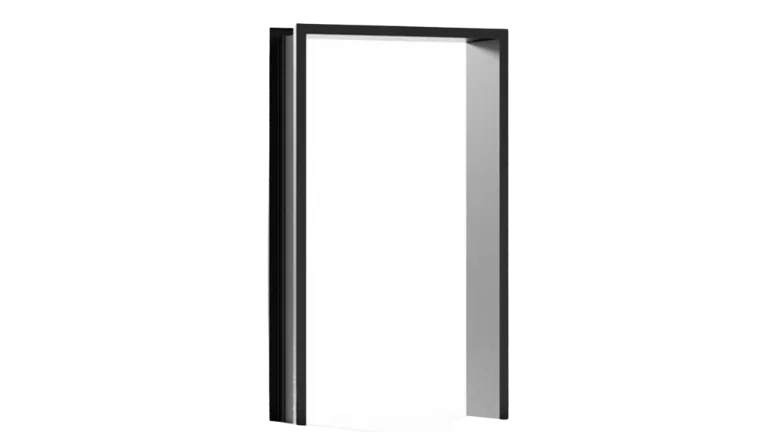

Aluminium Drywall Transition Trim

Aluminium drywall trim is designed to provide a clean, crisp finish to the edges and corners of drywall installations. This trim enhances the durability and aesthetic appeal of wall surfaces by protecting the drywall from chipping and cracking. Made from lightweight yet sturdy aluminum, it is resistant to corrosion and easy to install. Available in a variety of profiles, aluminium drywall trim can be used to create seamless transitions between different surfaces, making it a popular choice for both residential and commercial construction projects.

Aluminum Fascia Trim

Aluminum fascia trim is a durable and low-maintenance solution used to enhance the appearance and protect the edges of a roof’s fascia boards. It covers the wooden fascia, shielding it from the elements and preventing moisture damage and rot. This trim is lightweight, resistant to corrosion, and available in a variety of colors and finishes to match or complement the home’s exterior. Aluminum fascia trim not only extends the life of the roof’s edges but also adds a clean, finished look to the building’s overall aesthetic.

Aluminum Window Trim

Aluminum window trim is a sturdy and stylish option used to frame and finish the edges of windows. It provides a protective barrier against the elements, enhances insulation, and adds a polished look to the exterior and interior window installations. Aluminum trim is popular due to its durability, resistance to corrosion, and minimal maintenance requirements. Available in a variety of colors and finishes, it can be easily customized to suit different architectural styles, making it a versatile choice for both residential and commercial buildings.

Aluminium caravan trim is a crucial component used in the assembly and finishing of caravans and motorhomes. It provides a robust, weather-resistant seal around windows, doors, and joints, protecting the interior from moisture and debris. Lightweight and durable, aluminium trim helps maintain the structural integrity of the vehicle while offering a sleek, polished appearance. Its corrosion-resistant properties ensure long-lasting performance, making it an ideal choice for the mobile lifestyle of caravan enthusiasts.

Aluminium Trailer Trim

Aluminium trailer trim is essential for reinforcing and protecting the edges and corners of trailers. This trim not only enhances the structural durability of the trailer by guarding against wear and tear but also improves its aesthetic appeal. Made from lightweight yet robust aluminium, the trim is resistant to rust and corrosion, making it ideal for withstanding harsh weather conditions and frequent use. Its easy installation and low maintenance requirements make aluminium trailer trim a practical choice for both utility and recreational trailers.

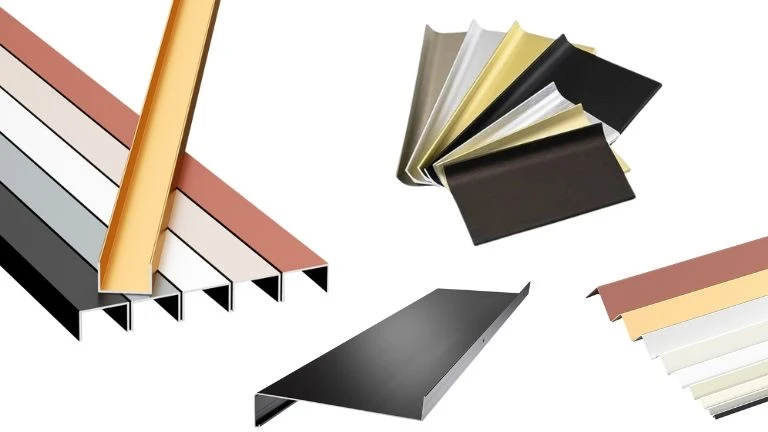

Customize Your Extrusion Aluminum Edge Strips

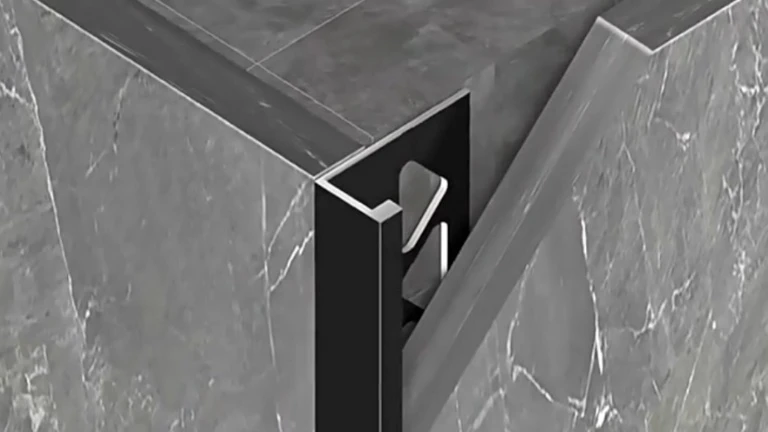

Aluminum outside corner trim protects building edges from weather damage and wear, offering a durable and corrosion-resistant solution that enhances exterior aesthetics.

Aluminum interior corner trim ensures a neat junction between walls, providing a moisture-resistant finish that complements any indoor decor with its variety of styles.

Aluminum Alloy Trim Color Options

Aluminum edge trim combines functionality with aesthetic versatility, making it ideal for both interior and exterior applications. It is available in brushed, matte, and polished finishes, offering a wide selection of styles to suit any design preference. Enhanced by surface treatments such as anodizing, powder coating, wood grain finishing, and fluorocarbon coating, the trim can be customized in various colors and textures to meet specific project requirements.

Natural Aluminum – This is the classic, metallic silver color of raw aluminum, which offers a sleek, modern look.

Black – A popular choice for a bold, contrasting finish.

White – Ideal for a clean and seamless appearance, especially in modern interiors.

Bronze – Perfect for a more traditional or rustic aesthetic.

Gold – Adds a touch of luxury and warmth to the trim.

Custom Colors – Many manufacturers offer custom powder-coating services, allowing for virtually any color to be applied to aluminum edge trim, ensuring a perfect match with other design elements.

Factory Show

HTS NEW MATERIALS is a leading aluminum extrusion profile manufacturer in China, equipped with over 40 production lines and the nation's largest 6000-ton extrusion press. We specialize in providing high-quality solutions, supported by expertise in mold design, precision processing, advanced surface treatments, and comprehensive machining services.

Aluminium Profile Solutions

At HTS Aluminium, we pride ourselves on our ability to deliver custom aluminium profile solutions tailored to the unique needs of each client. Our bespoke services are grounded in a deep understanding of our clients’ visions, which we bring to life by transforming drawings or samples into precision-engineered aluminium profiles.

Precision Aluminum Extrusion Process

Our state-of-the-art manufacturing facility is equipped with advanced extrusion presses and precision cutting tools, allowing us to handle even the most complex profiles with exceptional accuracy. Our team of skilled technicians brings years of industry experience to the table, ensuring that every extruded aluminium profile meets the highest standards of quality and precision.

Design and Manufacture of Moulds

We at HTS Aluminium specialize in the design and manufacture of custom moulds based on client specifications. Once a mould is created, we conduct trial productions and send samples to our clients for confirmation. This meticulous process ensures that the final product perfectly aligns with our clients’ expectations.

Material for Extruded Aluminum

Quality begins with the raw materials, and at HTS Aluminium, we use only the highest standard aluminium alloys for our extrusions. Our profiles are commonly crafted from a selection of industry-standard grades, each offering a balance of strength, durability, and corrosion resistance to meet various application requirements.

5052: Offers excellent corrosion resistance, good weldability, and moderate-to-high strength. It is a popular choice for marine and automotive applications.

Silicon (Si): 0.25% (Maximum)

Iron (Fe): 0.40% (Maximum)

Copper (Cu): 0.10% (Maximum)

Manganese (Mn): 0.10% (Maximum)

Magnesium (Mg): 2.2-2.8%

Chromium (Cr): 0.15-0.35%

Zinc (Zn): 0.10% (Maximum)

Remaining Balance: Aluminum (Al)

6061: A versatile alloy with good mechanical properties, weldability, and corrosion resistance. It is widely used for structural applications and in the automotive industry.

Silicon (Si): 0.40-0.80%

Iron (Fe): 0.70% (Maximum)

Copper (Cu): 0.15-0.40%

Manganese (Mn): 0.15% (Maximum)

Magnesium (Mg): 0.8-1.2%

Chromium (Cr): 0.04-0.35%

Zinc (Zn): 0.25% (Maximum)

Titanium (Ti): 0.15% (Maximum)

Remaining Balance: Aluminum (Al)

6063: Often referred to as an architectural alloy, it has a smooth surface finish and is commonly used in window and door frames.

Silicon (Si): 0.20-0.60%

Iron (Fe): 0.35% (Maximum)

Copper (Cu): 0.10% (Maximum)

Manganese (Mn): 0.10% (Maximum)

Magnesium (Mg): 0.45-0.90%

Chromium (Cr): 0.10% (Maximum)

Zinc (Zn): 0.10% (Maximum)

Titanium (Ti): 0.10% (Maximum)

Remaining Balance: Aluminum (Al)

7075: One of the strongest aluminum alloys available, with zinc as the main alloying element. It is used in applications where strength is critical, such as in aerospace and military components.

Zinc (Zn): 5.1-6.1%

Magnesium (Mg): 2.1-2.9%

Copper (Cu): 1.2-2.0%

Chromium (Cr): 0.18-0.28%

Silicon (Si): 0.40% (Maximum)

Iron (Fe): 0.50% (Maximum)

Manganese (Mn): 0.30% (Maximum)

Titanium (Ti): 0.20% (Maximum)

Other elements: Each 0.05% (Maximum), Total 0.15% (Maximum)

Remaining Balance: Aluminum (Al)

Heat Treatment Options

Our aluminium profiles can undergo a range of heat treatment options to enhance their properties. From T5 to T6 treatments, we tailor the process to achieve the desired level of hardness, strength, and elasticity. Each treatment option is designed to bring out the best in the material, ensuring that the final product stands up to the demands of its application.

T5 Heat Treatment

Process: Cooled from an elevated temperature shaping process and then artificially aged.

Characteristics: Increases the strength of the aluminum by accelerating the aging process, resulting in a material that has moderate strength and good formability.

T6 Heat Treatment

Process: Solution heat-treated and then artificially aged.

Characteristics: Provides a significant increase in strength compared to T5 by altering the microstructure of the aluminum. This results in a high-strength material with good machinability and fair formability.

Aluminum Profile Surface Treatment

To ensure the longevity and aesthetic appeal of our telescopic aluminum profiles, we offer a range of surface treatments including:

Anodizing: The Protective Shield

What is Anodizing? Anodizing is an electrochemical process that thickens and toughens the naturally occurring protective oxide on the surface of aluminum profiles. This treatment enhances corrosion resistance and wear resistance, making the aluminum surface harder and more durable.

Key Advantages

Improved corrosion resistance

Enhanced surface hardness

Aesthetic appeal with a variety of color options

Better adhesion for paints and primers

Increased thermal insulation properties

Electroplating: The Metal Finish

What is Electroplating? Electroplating involves the deposition of a metal coating on the extruded aluminum profile. This process can be used to improve corrosion resistance, increase surface hardness, and add a decorative finish.

Key Advantages

Enhanced corrosion resistance

Decorative finishes with various metal types

Increased surface hardness

Improved wear resistance

Sandblasting: The Texture Artist

What is Sandblasting? Sandblasting is a mechanical process where abrasive materials are blasted onto the aluminum surface at high velocity to clean or modify its texture. This is often used to prepare the surface for further treatments or to achieve a specific aesthetic look.

Key Advantages

Uniform surface finish

Improved surface cleanliness

Enhanced paint and coating adhesion

Aesthetic texture options

Powder Coating: The Colorful Protector

What is Powder Coating? Powder coating is a dry finishing process where a powder material is electrostatically applied to the aluminum surface and then cured under heat to form a skin-like coating. This method provides a durable, uniform, and attractive finish.

Key Advantages

Wide range of color options

Uniform, durable finish

Excellent resistance to chipping, scratching, and corrosion

Eco-friendly process with minimal VOC emissions

Fluorocarbon Painting: The Weather Warrior

What is Fluorocarbon Painting? Fluorocarbon painting involves applying a fluorocarbon resin-based paint to the aluminum profile, which offers exceptional weather resistance, making it ideal for outdoor applications.

Key Advantages

Outstanding weather resistance

Excellent color and gloss retention

Resistance to UV radiation and corrosion

Suitable for extreme environmental conditions

Wood Grain Transfer: The Natural Look

What is Wood Grain Transfer? Wood grain transfer is a process where a wood grain pattern is applied to the aluminum profile through heat transfer. This provides the natural appearance of wood while maintaining the benefits of aluminum.

Key Advantages

Aesthetic appeal of natural wood

Durable and maintenance-free

Resistance to corrosion and weathering

Ideal for architectural applications where wood-like finish is desired

Custom Aluminum Extrusion Process

At HTS Aluminum Profiles, we specialize in delivering custom aluminum extrusion solutions tailored to your specific needs. Here’s a step-by-step guide to our customization process:

Step 1: Initial Consultation

Your journey begins with an initial consultation where we discuss your project requirements. We encourage you to share your design concepts, application needs, and any critical parameters that the aluminum profile must meet. This collaborative approach ensures that we fully understand your vision and objectives.

Step 2: Design and Engineering

Leveraging our extensive experience in aluminum extrusion, our skilled engineers work closely with you to refine your design. We consider factors such as the aluminum alloy grade, temper, and mechanical properties required for your application. Our team uses advanced CAD software to create precise technical drawings and 3D models of the proposed profile.

Step 3: Die Fabrication

Once the design is finalized, we proceed to manufacture the custom extrusion dies. Our precision die-making process ensures that the final profile will match your specifications with high accuracy. We employ state-of-the-art CNC machines to craft dies that can withstand the rigors of extrusion while maintaining tight tolerances.

Step 4: Aluminum Extrusion

With the dies ready, the actual extrusion process begins. We select the appropriate aluminum alloy and heat it to the precise extrusion temperature. The heated billet is then pressed through the die to create the custom profile. Our extrusion presses, ranging from 600 to 3600 tons, are capable of producing a wide range of profile sizes and shapes.

Step 5: Surface Treatment and Finishing

Following extrusion, the profiles undergo various surface treatments as per your requirements. Options include anodizing, electroplating, sandblasting, powder coating, fluorocarbon painting, and wood grain transfer printing. These processes enhance the profiles’ durability, corrosion resistance, and aesthetic appeal.

Step 6: Quality Assurance

Quality is at the heart of everything we do. Each custom aluminum profile is subjected to rigorous quality checks to ensure it meets ISO standards and our European quality certifications. We perform dimensional inspections, mechanical testing, and surface finish evaluations to guarantee that your profiles are delivered without defects.

Step 7: Packing and Delivery

After passing all quality inspections, the aluminum profiles are carefully packed to prevent any damage during transit. We use robust packaging materials and methods tailored to the profiles’ dimensions and your delivery preferences. Our logistics team then manages the safe and timely delivery of your custom aluminum profiles to your specified location.

Step 8: After-Sales Support

Our commitment to your satisfaction extends beyond delivery. We offer comprehensive after-sales support to address any concerns or additional requirements you may have. Our customer service team is always ready to assist you with any questions or feedback.

Partner with Us

We are committed to delivering precision-engineered aluminum profiles that meet the highest standards of quality. From initial design to final delivery, we provide a seamless and personalized experience, ensuring that your custom aluminum solutions are produced efficiently and to your satisfaction.

Take the next step in your project and contact us for a consultation on your custom aluminum extrusion needs.