Extruded Aluminum Framing Materials

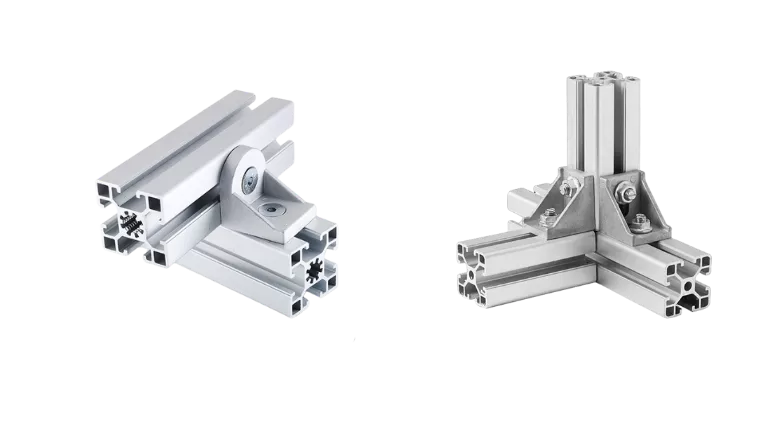

Extruded Aluminum Framing is a modular framing system composed of T-slot aluminum profiles manufactured through the aluminum extrusion process, along with an assortment of compatible accessories. Known for its flexibility, high strength, lightweight design, and ease of assembly, this system has become a cornerstone in modern industrial equipment frameworks, automation systems, research projects, and commercial display solutions. Due to its reusable and reconfigurable nature, it is often referred to as the "Lego for industries."

This framing system is widely used in applications such as industrial equipment supports, workbenches, laboratory structures, and small modular device frameworks. Compared to traditional frameworks such as steel or wood, extruded aluminum framing offers significant advantages in terms of customizability, convenience, and corrosion resistance. Its adaptability and eco-friendly qualities make it a go-to solution for industries looking for efficiency, durability, and sustainable practices.

Benefits of Extruded Aluminum Framing

Modular Design

Extruded aluminum framing features a T-slot design, enabling quick assembly with standard components like bolts and sliders. Its no-welding requirement allows for easy reuse, reconfiguration, and customization, ensuring exceptional flexibility for various applications.

Lightweight and Strong

Weighing only one-third as much as steel, extruded aluminum offers high strength and rigidity. Its lightweight nature makes it ideal for applications ranging from light to medium-heavy loads, while simplifying transportation and installation.

Excellent Corrosion Resistance

Naturally resistant to oxidation, aluminum performs well in humid or chemically harsh environments. Anodizing can further enhance surface durability, ensuring long-lasting performance in demanding conditions.

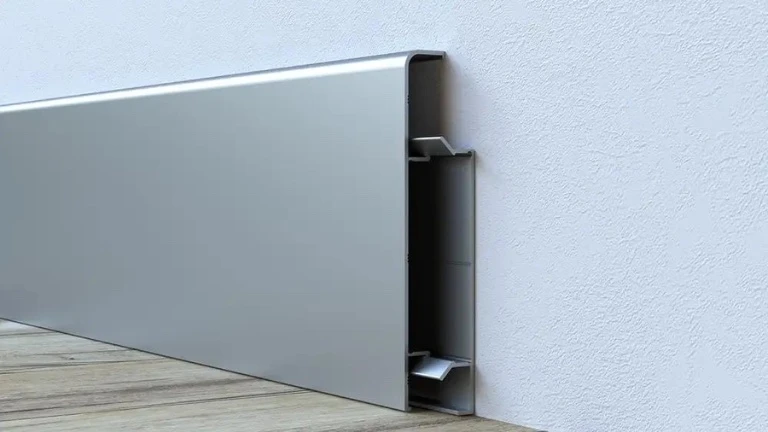

Sleek and Modern Aesthetics

With smooth surfaces, clean lines, and a modern industrial look, extruded aluminum framing delivers a premium feel. It can also be customized with a variety of surface finishes, textures, and colors to meet specific design needs.

Extensive Accessory Compatibility

A wide range of accessories, such as connectors, casters, support feet, and panel slots, make aluminum framing highly versatile. These allow for quick extensions and customized configurations in complex structures or specialized systems.

Environmentally Friendly and Sustainable

Aluminum is 100% recyclable, making it an eco-friendly solution aligned with circular economy principles. Its reusability supports sustainable practices, reducing material waste and environmental impact.

Applications of Extruded Aluminum Framing

Extruded aluminum framing, particularly T-slot aluminum profiles, is widely used across industries due to its versatility, strength, and ease of assembly. Here are some common applications:

1. Industrial Automation and Machine Building

- Machine frames

- Conveyor systems

- Equipment enclosures

- Robot arms and workstations

- Test stands and automation setups

2. Workstations and Modular Furniture

- Adjustable workbenches

- Ergonomic workstations

- Inspection tables and shelving

- Modular office and industrial furniture

3. Safety Enclosures and Guarding Systems

- Safety fences and machine guarding systems

- Protective barriers for hazardous equipment

- Customized enclosures to meet workplace safety standards

4. Transportation and Logistics Systems

- Packing and sorting stations

- Custom carts and trolleys

- Storage racks and industrial shelving

5. Construction and Architectural Design

- Lightweight structural frameworks

- Partition walls and displays

- Customized trade show booths and exhibits

- Solar panel mounting systems

6. DIY and Hobbyist Projects

- Custom shelving and furniture

- Home automation projects

- Maker space and prototyping purposes

7. Cleanrooms and Laboratories

- Contamination-free enclosures

- Modular cleanroom frames

- Laboratory furniture and equipment mounts

8. Other Custom Applications

- Aerospace and automotive assembly jigs

- Recreational vehicle (RV) or boat structures

- Agricultural and greenhouse frameworks

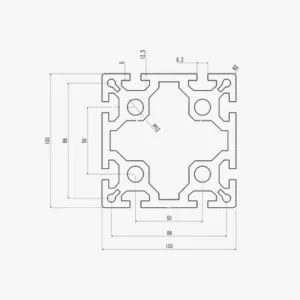

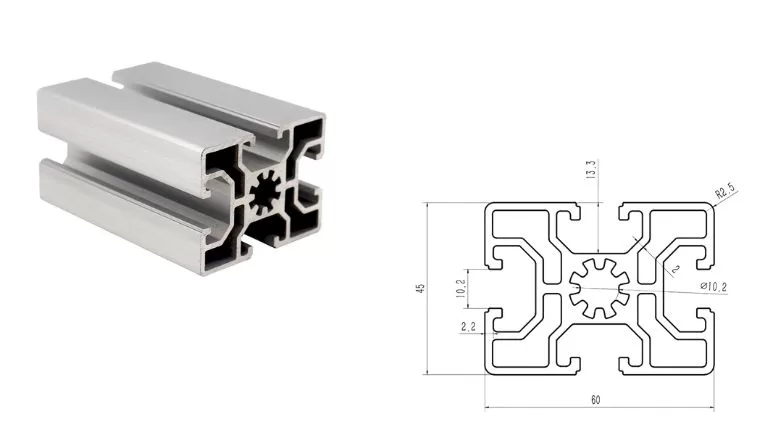

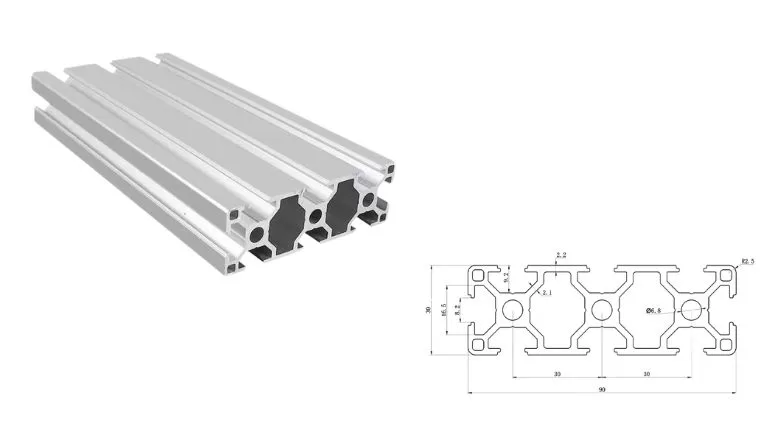

T-Slot for Extruded Aluminum Framing

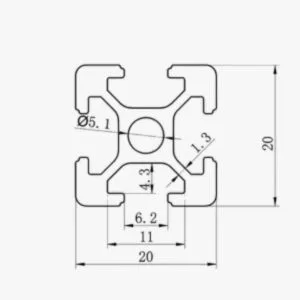

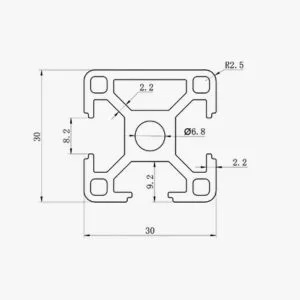

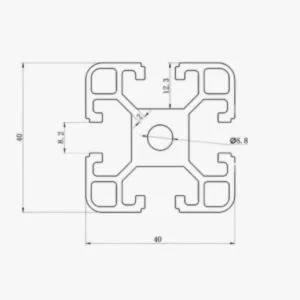

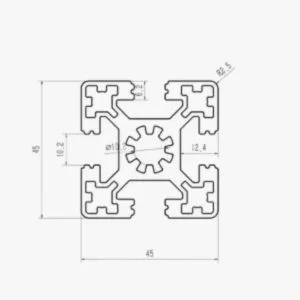

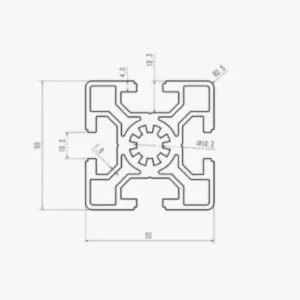

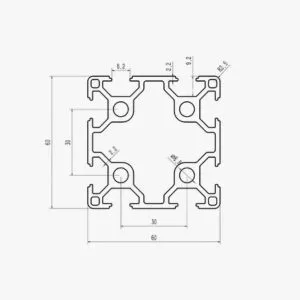

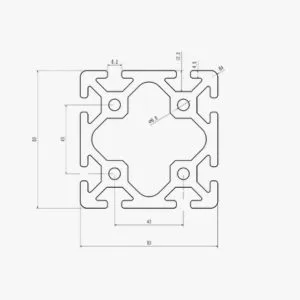

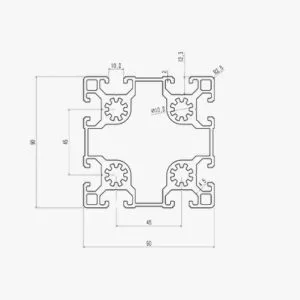

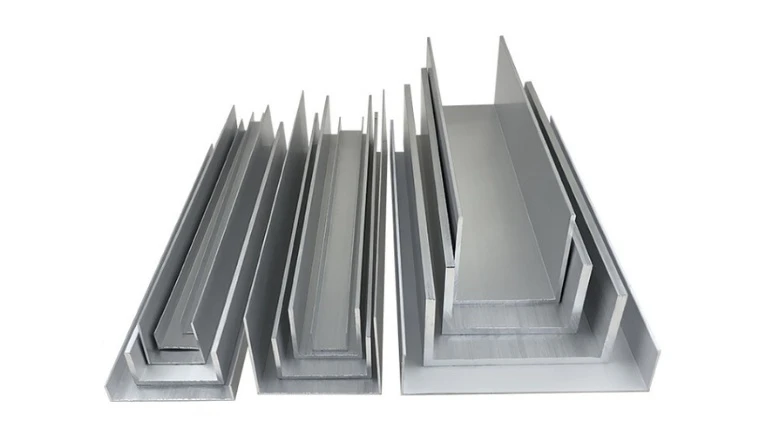

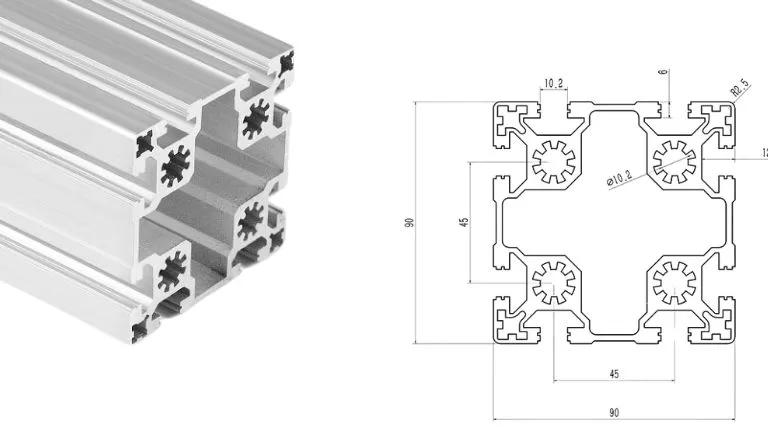

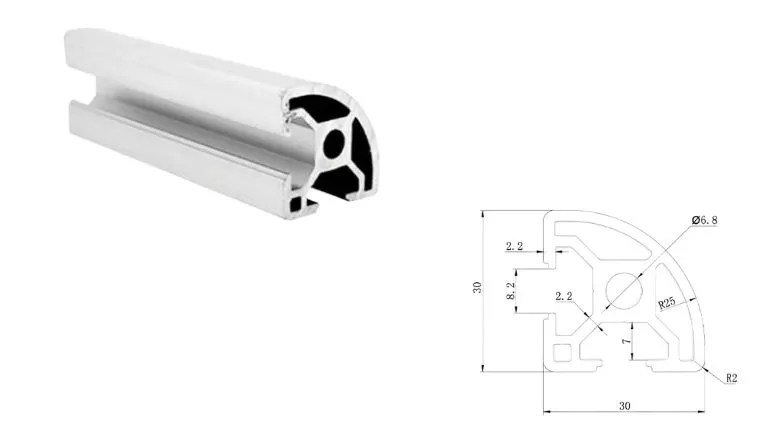

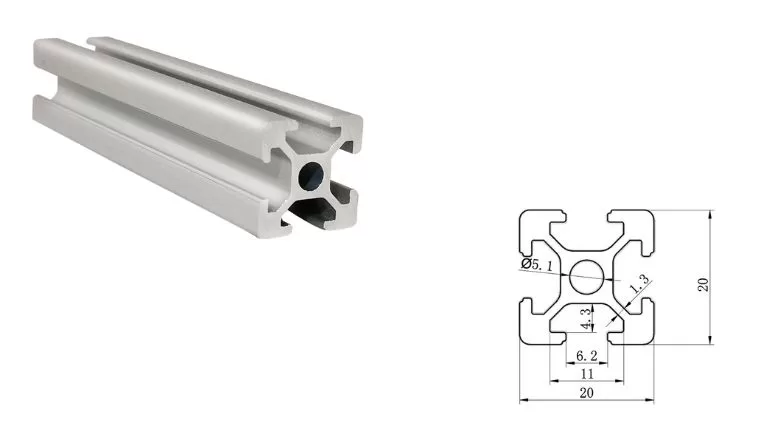

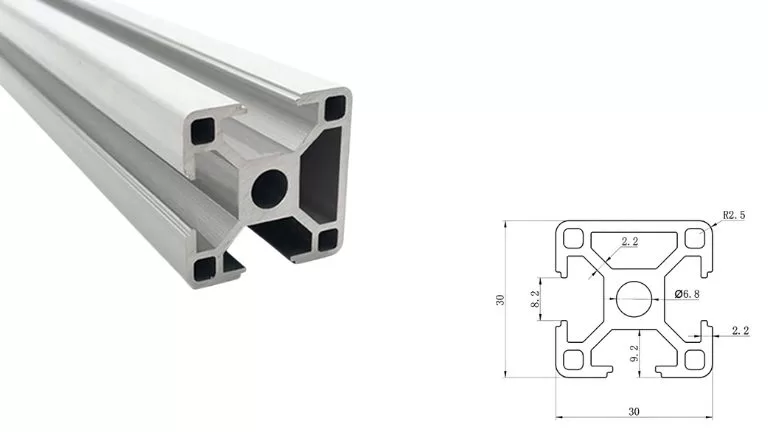

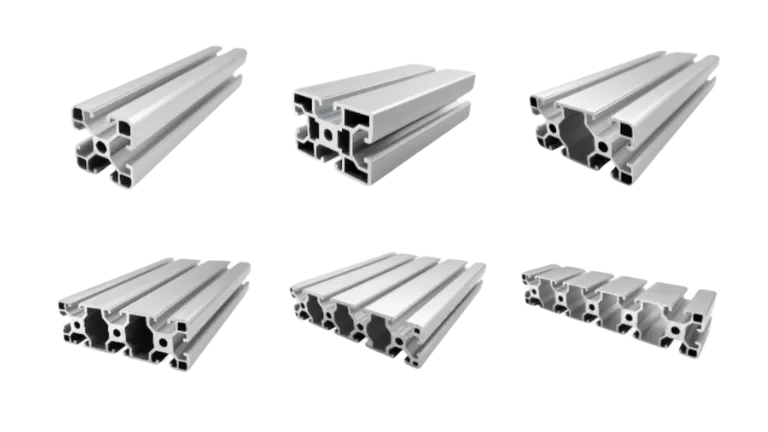

T-slot aluminum profiles come in different size series, such as 20, 30, and 40 series, catering to various strength and application requirements across industries. These versatile profiles can be customized further with derivative models, including one-sided or two-sided sealed profiles, which improve aesthetics and enhance structural functionality. Corner T-slot profiles are specifically designed for rounded transitions at external corners, creating smooth curves and a cleaner appearance while preserving the modularity and connectivity of the system.

V-slot profiles, in contrast, feature a beveled groove design that functions as both a structural channel and a linear motion track. Commonly used in 3D printers, CNC machines, and other motion-based systems.

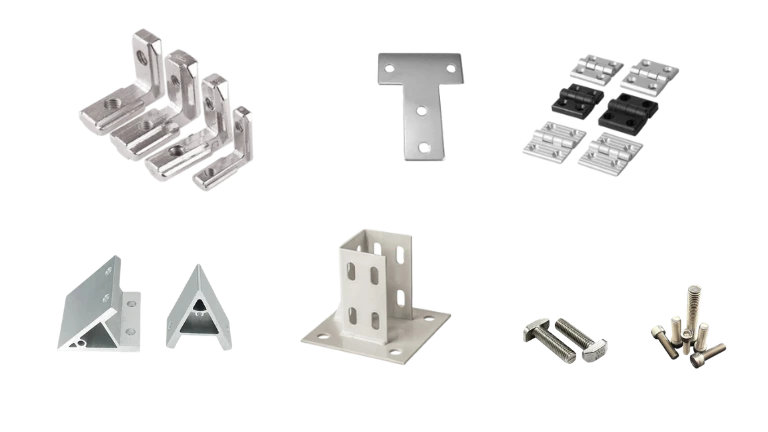

Extruded aluminum framing systems rely on a variety of connector types to assemble structures efficiently and securely. These connectors are designed to work seamlessly with T-slot aluminum profiles and provide flexibility for various structural designs. Common types of connectors include:

Corner Brackets: Used for joining profiles at 90-degree angles, offering strong and stable connections for frames and enclosures.

Internal Connectors: Hidden connectors that fit inside the T-slot groove to create a clean and flush exterior, suitable for applications requiring a streamlined appearance.

Angle Brackets: Adjustable or fixed brackets for creating angled or multi-directional joints.

Joining Plates: Flat plates used to connect two or more profiles, often used for reinforcement or extending the length of the structure.

Anchor Fasteners: Specialized hardware that allows profiles to be joined perpendicularly by anchoring into the T-slot channel.

Drop-in T-Nuts: Essential for assembling or modifying structures, these slide into the T-slot grooves and work as a base for bolts or screws.

Hinges: Allow for dynamic or pivoting connections, ideal for creating doors, lids, or movable sections within the frame.

End Caps: Used to cap off profile ends, protecting the structure and providing a finished look while sometimes doubling as connectors for end-to-end joints.

Connection Methods for Extruded Aluminum Framing

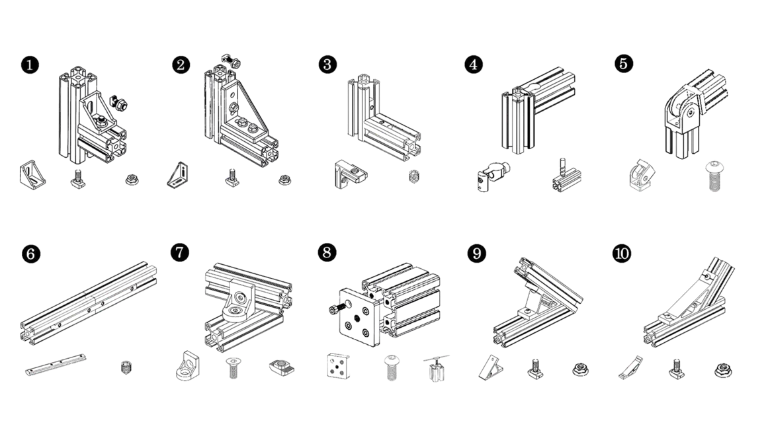

Extruded aluminum framing systems are designed for modular and flexible assembly, relying on a variety of connection methods to suit different structural needs. The main connection methods include:

T-Nut and Bolt Connections

This is the most common and versatile connection method. T-nuts slide into the T-slot groove of the aluminum profile and provide a threaded base for bolts, which secure the profiles or accessories together. This method is simple, strong, and easy to adjust or disassemble when needed.

Internal (Concealed) Connectors

Internal connectors fit inside the T-slot groove, offering a secure and hidden connection. This method is often used where a clean, flush exterior is preferred. Internal connectors include anchor fasteners or straight joining bars for connecting two profiles at right angles or inline.

Corner Brackets

Corner brackets are external connectors that allow profiles to join at 90-degree angles. These brackets are bolted to the profiles using screws and are ideal for building strong, rigid frames. They are commonly used in applications requiring visible and easily adjustable connections.

Joining Plates

Flat joining plates are used to connect two or more profiles side-by-side or at complex angles. They are mounted externally and secured with bolts, providing additional reinforcement in high-load applications or for extending profile lengths.

End-to-End Connections

End-to-end connectors, such as threaded rods or butt connectors, are used to join two profiles linearly. These ensure alignment and stability while allowing for flexible lengthening of profiles in a compact form.

Pivot and Sliding Connections

For applications requiring movement, such as adjustable arms or doors, pivot connections and linear sliding mechanisms are used. Hinges, swivel joints, or V-slot systems (for sliding motion) are commonly employed.

Welding or Fixed Joints (Less Common)

Though not frequently used in standard modular systems, welding or fixed gussets can be employed where extremely rigid or permanent connections are required.

Extruded Aluminum Framing Solution

HTS-ALU is a leading aluminum profile manufacturer in China, equipped with 40 advanced extrusion production lines and full surface treatment and machining capabilities, including anodizing, powder coating, sandblasting, drilling, tapping, and CNC processing.

We provide versatile extruded T-slot aluminum profiles and accessories widely used in industrial automation, machine enclosures, workstations, and DIY projects. Our large stock inventory allows for immediate shipping, with profiles custom-cut to your specifications and paired with the required connectors for easy assembly.

Whether for large industrial projects or small custom orders, we’re ready to meet your needs. We offer worldwide shipping, including for small orders, as long as customers cover the shipping costs, ensuring reliable service and high-quality solutions, no matter where you are.

Aluminum Profile Processing Capabilities

As a leading aluminum extrusion manufacturer based in China, we are committed to providing high-quality aluminum profiles for a wide range of industries. Our capabilities start with custom mold design and manufacturing, ensuring precise extrusion shapes that meet the specific needs of our clients. From raw extrusion to surface finishing and advanced machining, our fully integrated manufacturing processes enable us to deliver aluminum profiles that meet exacting standards and cater to the unique requirements of each project.

Our production facility houses over 40 advanced extrusion lines, featuring cutting-edge equipment such as a powerful 6000-ton extrusion press. This enables the creation of aluminum profiles in various sizes and forms, ranging from standard industrial applications to specialized products like thermal break profiles for high-end doors and windows. The flexibility of our extrusion capability ensures we can cater to a broad spectrum of industries, including construction and precision engineering.

Our production facility houses over 40 advanced extrusion lines, featuring cutting-edge equipment such as a powerful 6000-ton extrusion press. This enables the creation of aluminum profiles in various sizes and forms, ranging from standard industrial applications to specialized products like thermal break profiles for high-end doors and windows. The flexibility of our extrusion capability ensures we can cater to a broad spectrum of industries, including construction and precision engineering.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

We possess the expertise to design and produce extrusion molds in-house, ensuring precision and efficiency in aluminum profile manufacturing. Our experienced team works closely with clients to develop custom molds based on drawings or samples, ensuring optimal performance for their specific requirements. Typically, the mold production process takes about 7 days, after which we provide samples for client confirmation before beginning full-scale production.

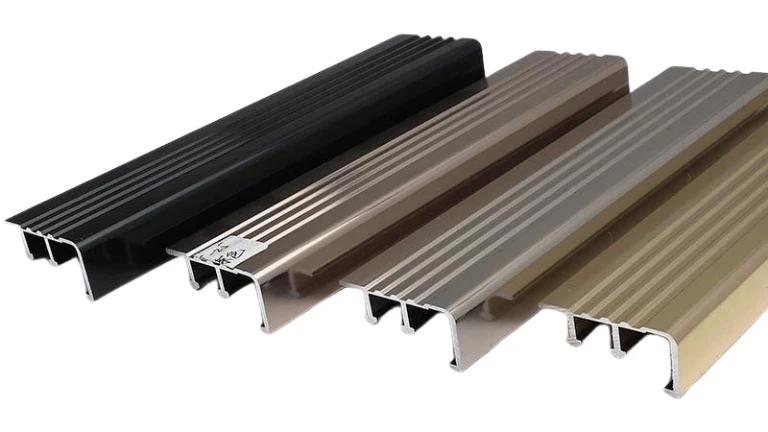

For superior durability and visual appeal, we offer various surface treatment solutions. These include anodizing for added corrosion resistance, powder coating for vibrant finishes, fluorocarbon coating for enhanced weather resistance, and wood grain transfer technology for elegant, natural-looking designs. These treatments are customizable to fit specific aesthetic and functional needs, ensuring that profiles not only perform well but also look exceptional.

To provide complete aluminum profile solutions, we offer extensive further processing capabilities. Our services include CNC machining, milling, threading, drilling, precision cutting, punching, welding, and assembly. This range of fabrication options allows us to deliver ready-to-use profiles tailored to exact project specifications, offering unmatched flexibility and reliability to our customers.

RFQ of Extruded Aluminum Profile

Our standard in-stock T-slot aluminum profiles are made from 6063-T5 alloy, a material renowned for its excellent strength, corrosion resistance, and surface finish. It is highly versatile and ideal for most industrial applications, including machine enclosures, workstations, conveyor systems, and DIY projects.

For specialized requirements, we offer customization in other aluminum grades and materials:

- 6061-T6: Offers higher strength and better fatigue resistance compared to 6063-T5, making it ideal for heavy-duty applications or structural frameworks.

- 6082: Known for its improved mechanical properties and corrosion resistance, suitable for applications under dynamic loads or in harsh environments.

- 6005: Perfect for projects requiring high strength and excellent finish, commonly used in custom structural applications.

- Other Alloys on Request: If you have specific material requirements, such as alloys with specific thermal conductivity or hardness properties, we can work with you to fulfill your needs.

- Other Materials: For projects that need materials beyond aluminum, we can explore solutions involving different metals or composites to meet your technical needs.

With our full production capabilities, including 40 extrusion lines and comprehensive surface treatment and machining facilities, we can develop T-slot profiles in the material that best suits your project’s requirements. Whether it’s high strength, superior corrosion resistance, or machinability you’re after, we are committed to delivering solutions tailored to your unique application.

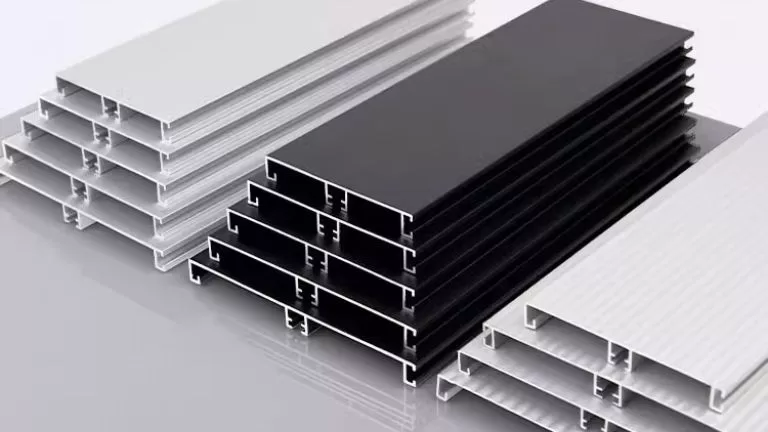

Our T-slot aluminum profiles are typically finished with two standard surface treatments:

- Silver Anodized (Natural Finish): Provides a clean, corrosion-resistant surface with a sleek silver appearance, ideal for most industrial and aesthetic applications.

- Black Matte Anodized: Gives a modern, non-reflective black finish, offering excellent durability and scratch resistance for a refined and professional look.

In addition to these standard options, we also provide customized surface treatments to meet specific project requirements. Available custom finishes include:

- Colored Anodizing: Various colors such as gold, bronze, or blue for decorative or branding purposes.

- Powder Coating: For enhanced protection, weather resistance, and additional color options with a smooth or textured finish.

- Sandblasting: Provides a uniform, matte texture for a premium appearance.

- Electrophoresis: Offers a glossy finish with superior corrosion resistance, suitable for outdoor applications.

- Polishing or Brushing: For a high-gloss or satin aesthetic, commonly used in consumer-facing products.

We can tailor the surface treatment to match your design and performance requirements, ensuring your profiles not only function perfectly but also look great in their intended application.

We offer comprehensive machining services for T-slot aluminum profiles to ensure they’re ready for assembly and perfectly suited to your project specifications. Our advanced equipment and skilled team can provide the following customization options:

- Custom Cutting: Profiles can be cut to the exact lengths you need, ensuring a precise fit for your application.

- Angle Cutting: Special angled cuts can be made based on your specifications, ideal for creating frames or structures with non-standard designs.

- Drilling and Tapping: Pre-drilled holes and threading can be added to simplify the assembly process and save time on-site.

- Slotting and Milling: We can machine special grooves or slots into profiles for unique applications or to accommodate additional components.

- Countersinking and Chamfering: For smooth and flush finishes, perfect for creating professional and clean-looking assemblies.

Our machining services are designed to take the hassle out of preparing T-slot profiles for assembly. Whether you need a single custom-cut profile or large batches with complex machining, we have the capabilities to deliver high-quality results efficiently. Combined with our wide range of accessories, we ensure a seamless and professional solution from start to finish.

We maintain a wide inventory of T-slot aluminum profiles and accessories as listed on our website HTS-ALU. Our stock primarily features silver anodized profiles, which are the most popular choice, alongside a smaller selection of black anodized profiles.

One of our key advantages is flexibility—there is no minimum order quantity (MOQs). Whether you need just a few profiles for a small project or a large batch for industrial use, we are here to meet your demands.

Our inventory is located in China, and we can ship globally. For small orders, shipping costs may be higher relative to order size, so we recommend that customers confirm their transportation preferences. As long as you’re willing to cover the freight costs, we are happy to fulfill orders of any size and deliver them efficiently.

By providing ready stock and flexible ordering options, we ensure you can get the materials you need when you need them.

For custom aluminum extrusion projects, we accept a variety of drawing formats, including CAD files, STEP files, and PDF files. However, for extrusions that require additional machining processes, it’s recommended to provide STEP files, as they ensure precise 3D modeling for machining accuracy.

While PDF files are acceptable, converting them into CAD drawings may result in the loss of certain details, requiring us to manually redraw the design, which could increase lead time. For the fastest and most accurate quotation, we recommend providing CAD files (e.g., DWG/DXF) and STEP files to ensure efficient design evaluation and pricing.

Mold fees are an essential part of the custom aluminum extrusion process. Since every order requires a uniquely designed mold tailored to specific requirements, these molds cannot be used for other products. Therefore, the mold fee is necessary and non-negotiable.

We require 100% upfront payment of the mold fee before mold development begins to ensure timely production. However, as a token of appreciation for your support, we offer a refund of the mold fee or equivalent discounts once the order reaches a certain production volume. Specific policies can be discussed based on your order volume and collaboration details.

Packaging can be customized according to your needs. Options include using protective film or paper to separate and protect the surface, or foam film for additional surface protection. Products can be palletized or packed into cartons, and the quantity per pallet or carton can be specified by the customer.

The standard packaging involves bundling several pieces together with plastic wrap and then securing them onto pallets. Any packaging requirements beyond the standard will be accommodated, and the associated costs will be clearly provided to the customer.

Aluminum profiles are naturally corrosion-resistant due to the formation of a thin, protective oxide layer when exposed to air or water. This oxide layer is stable and self-repairing, meaning that even if the surface is scratched or cut (such as at exposed ends or during processing), the aluminum will not rust or corrode like iron or steel. Instead, the exposed areas will quickly form a new oxide layer, providing continuous protection against further oxidation.

With proper design, installation, and maintenance, aluminum profiles can last for decades, even in challenging environments. For example, untreated aluminum can easily withstand 20-30 years in outdoor applications, while profiles with surface treatments like anodizing or powder coating can last even longer, often exceeding 50 years. This makes aluminum an excellent choice for applications where durability and long-term performance are essential.

The price of aluminum profiles consists of several components: raw material costs, extrusion processing fees, surface treatment fees, machining costs, and additional packaging fees. Among these, the cost of aluminum as a raw material tends to fluctuate frequently, while other fees remain relatively stable. Due to these fluctuations, our quotations are typically valid for 7 days.

Pricing can be structured in different ways depending on the product and requirements. It can be calculated by weight (e.g., cost per ton), by length (e.g., cost per meter), or by piece (e.g., cost per unit). For products involving extensive machining, such as heat sinks, pricing is generally calculated on a per-piece basis to accurately reflect the additional processing costs. This flexible pricing approach ensures the quote is tailored to the specific needs of the customer.

We can manufacture aluminum profiles in compliance with technical requirements that meet European standards (EN), American standards (ASTM/AA), or other standards as specified by the customer. Custom production is tailored to ensure that the profiles meet the specific standard requirements requested.

Our production equipment is designed for the metric system. If the drawings provided are in the imperial system, we will convert them into metric units for production to ensure accuracy.

It is important to note that while we can machine imperial-threaded holes for fasteners, if you require us to supply matching imperial fasteners, they may not always be available in stock. Custom orders for imperial fasteners typically require a large volume for production. Please consider this when planning your project.