Custom Precision Extruded Aluminum Telescoping Tubing | Pole Profile

Extruded aluminum telescoping tubing, available in round, square, and oval shapes, meets diverse structural needs with customizable sizes for smooth nesting. Its versatility includes surface treatments like woodgrain finishes, offering aesthetic appeal while retaining aluminum’s strength and corrosion resistance. This adaptability makes it ideal for applications like telescopic poles, camera tripods, lighting stands, and decorative architectural elements, where adjustable, lightweight, and visually pleasing solutions are essential.

We at HTS-ALU, a custom aluminum profile extrusion factory based in China, offer a wide range of aluminum profiles with various surface treatments and machining services.

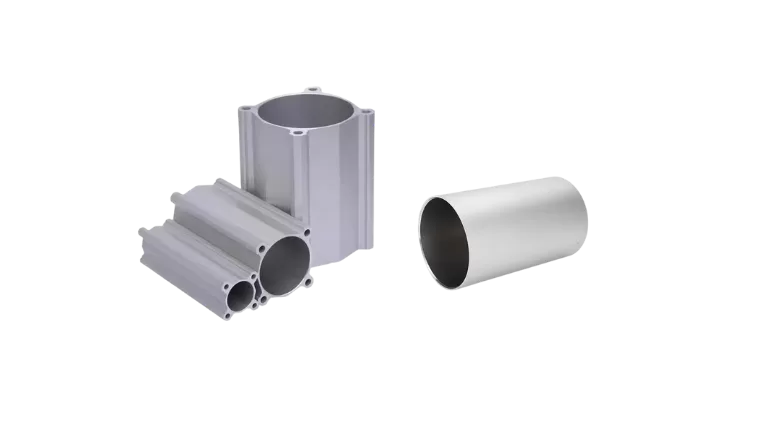

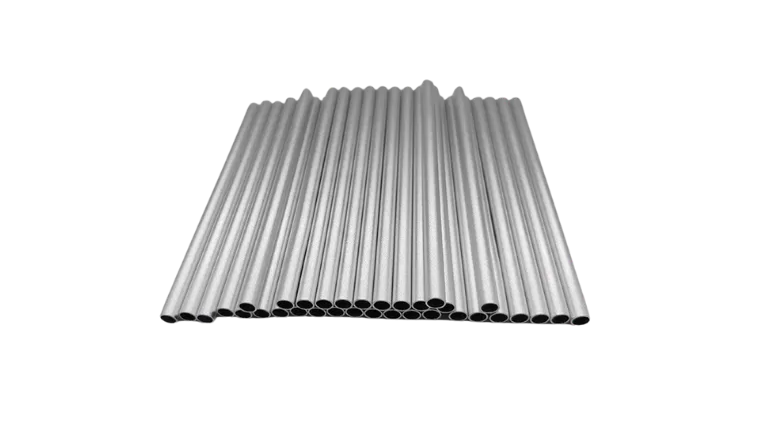

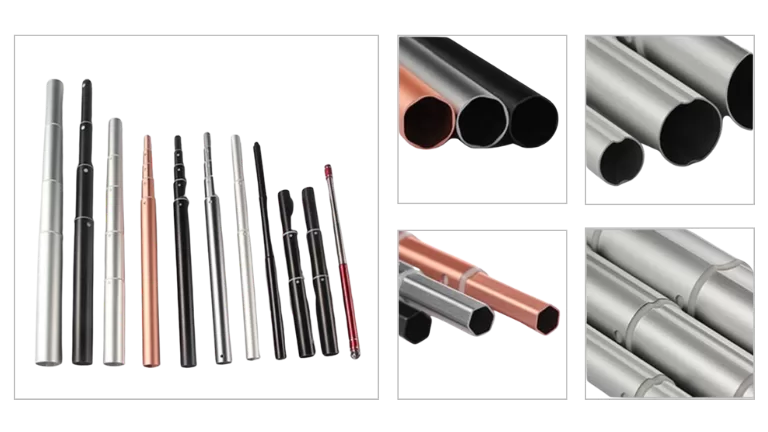

Round Extruded Aluminum Telescoping Pole

The round aluminum  telescoping pole is a hollow cylindrical aluminum profile designed so that multiple tubes of varying diameters can slide into or out of each other smoothly. This feature allows for easy adjustment of the tube’s overall length and convenient storage. The use of aluminum provides the tube with a lightweight structure, high strength, and excellent resistance to corrosion. Telescoping aluminum round tubes are widely used in adjustable poles, supports, stands, and other applications that require flexible length, portability, and reliable structural

telescoping pole is a hollow cylindrical aluminum profile designed so that multiple tubes of varying diameters can slide into or out of each other smoothly. This feature allows for easy adjustment of the tube’s overall length and convenient storage. The use of aluminum provides the tube with a lightweight structure, high strength, and excellent resistance to corrosion. Telescoping aluminum round tubes are widely used in adjustable poles, supports, stands, and other applications that require flexible length, portability, and reliable structural

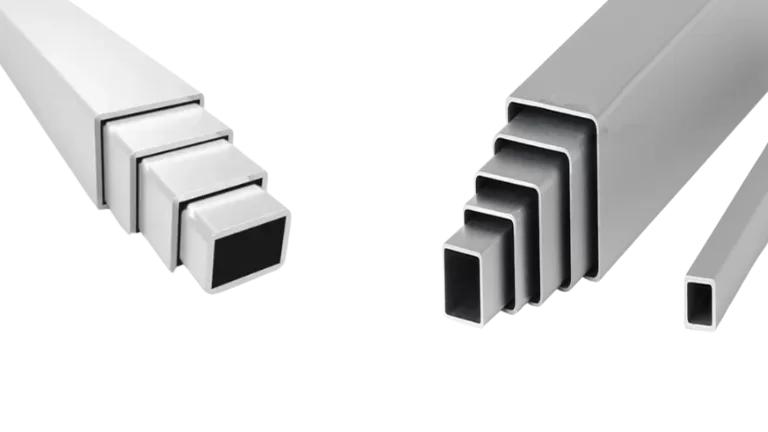

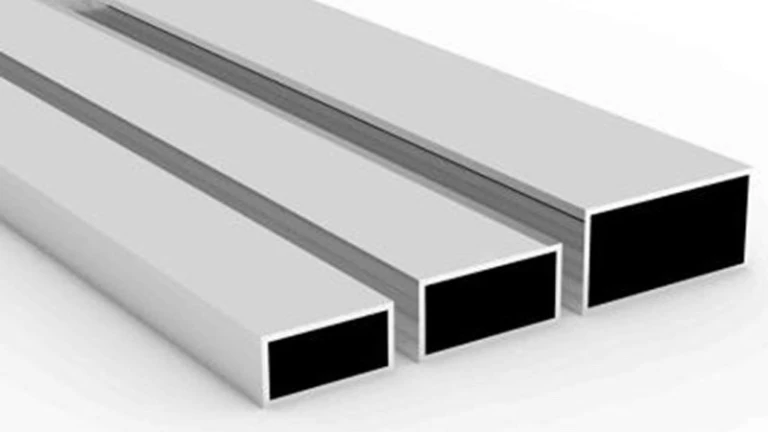

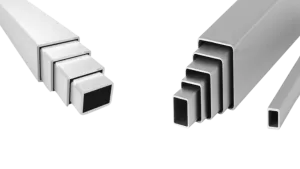

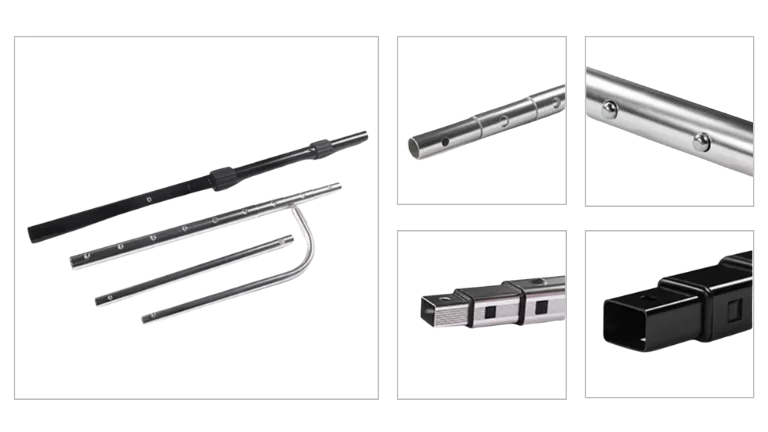

Telescoping Aluminum Square | Rectangular Tubing

The telescoping aluminum square tubing is a type of hollow aluminum profile with a square cross-section, designed so that multiple sections can slide smoothly inside one another. This allows for adjustable length and compact storage. Made from lightweight yet strong aluminum, these tubes offer excellent corrosion resistance and are commonly used in applications where flexible length, easy assembly, and structural stability are required, such as adjustable frameworks, supports, and portable structures.

square tubing is a type of hollow aluminum profile with a square cross-section, designed so that multiple sections can slide smoothly inside one another. This allows for adjustable length and compact storage. Made from lightweight yet strong aluminum, these tubes offer excellent corrosion resistance and are commonly used in applications where flexible length, easy assembly, and structural stability are required, such as adjustable frameworks, supports, and portable structures.

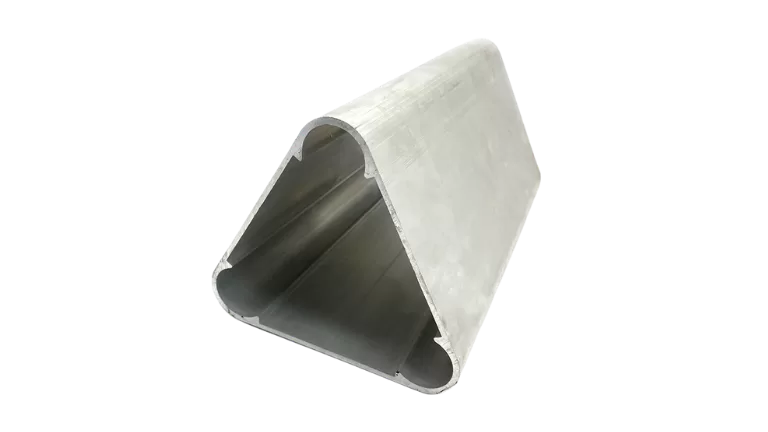

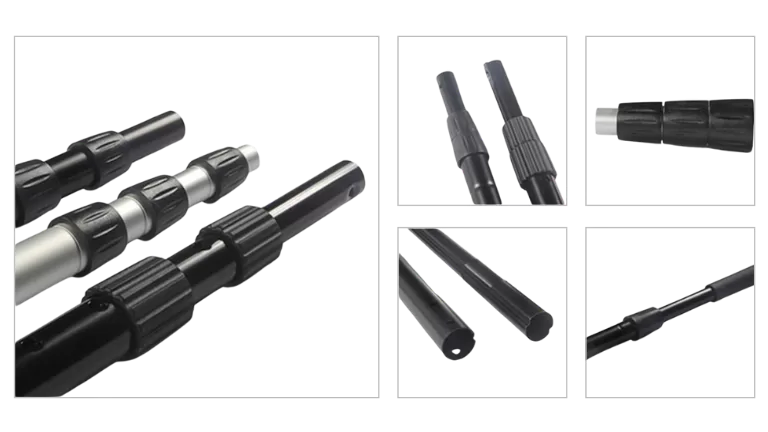

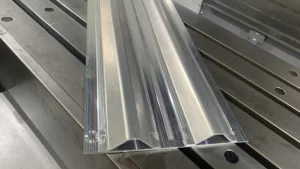

Custom-Shaped Extruded Aluminum Telescoping Tube

Custom-shaped extruded  aluminum telescoping tubes are specially designed aluminum profiles with non-standard cross-sections tailored to unique application needs. These tubes can smoothly slide within one another to allow for adjustable length, while their custom shapes—such as oval, hexagonal, or T-slot—offer enhanced functionality or aesthetics. Lightweight, strong, and corrosion-resistant, they are ideal for industries like automation, robotics, and furniture that require specialized, adjustable structural solutions.

aluminum telescoping tubes are specially designed aluminum profiles with non-standard cross-sections tailored to unique application needs. These tubes can smoothly slide within one another to allow for adjustable length, while their custom shapes—such as oval, hexagonal, or T-slot—offer enhanced functionality or aesthetics. Lightweight, strong, and corrosion-resistant, they are ideal for industries like automation, robotics, and furniture that require specialized, adjustable structural solutions.

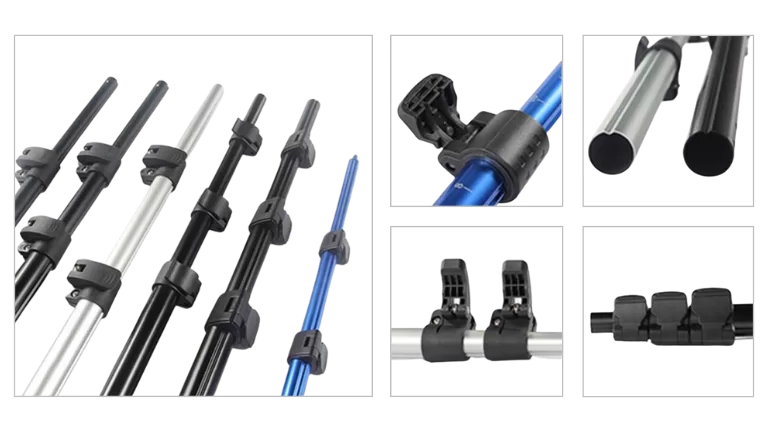

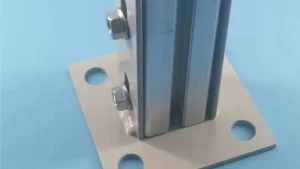

Machining of Extruded Aluminum Locking Telescoping Tubes

We use aluminum alloy extrusion techniques to  produce telescoping tubes with integrated locking mechanisms, customizing the dimensions and shapes according to customer requirements. Each tube segment is designed to slide smoothly within another and can be securely fixed at the desired length using a specialized locking device. Throughout the production process, we emphasize dimensional precision and high-quality surface finishing to ensure that the telescoping tubes are not only reliable and stable in use but also feature an excellent appearance and superior corrosion resistance. These products are suitable for a wide range of applications that demand flexible extension and secure locking.

produce telescoping tubes with integrated locking mechanisms, customizing the dimensions and shapes according to customer requirements. Each tube segment is designed to slide smoothly within another and can be securely fixed at the desired length using a specialized locking device. Throughout the production process, we emphasize dimensional precision and high-quality surface finishing to ensure that the telescoping tubes are not only reliable and stable in use but also feature an excellent appearance and superior corrosion resistance. These products are suitable for a wide range of applications that demand flexible extension and secure locking.

Aluminum Telescoping Tubing Specifications

| Item | Specification |

|---|---|

| Material | Aluminum alloy (6061/6063) |

| Size | Outer Diameter: 3-250mm; Thickness: 0.3-50mm |

| Shape | Circular or Rectangular/Customized |

| Surface Treatment | Anodizing, Powder Coating, Sand Blasting, Polishing, Wooden Finish, etc. |

| Length | 10mm - 6000mm / Customized Length |

| Machining | Drilling, Tapping, Cutting, Milling, Bending, Custom Machining |

| Packaging | Standard Export Packaging or Customized Solutions |

Telescoping Tubing Self-locking Mechanism

Aluminum telescoping tubing can be secured at the desired length using a variety of locking mechanisms, including spring-loaded buttons, twist-lock systems, clamps, push pins, or external collars. These options provide dependable adjustment and maintain stability during operation, catering to different needs for ease of use and dependable performance.

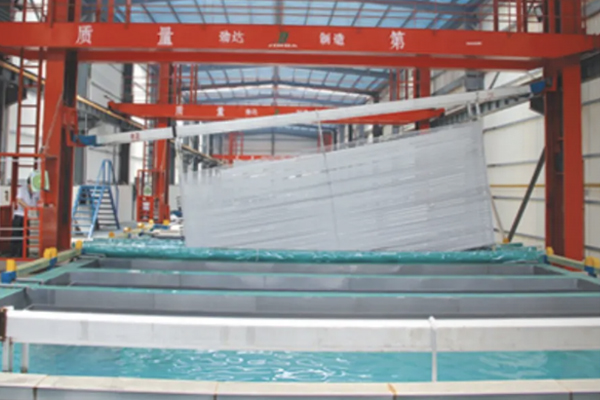

Precision Aluminum Extrusion Process

With state-of-the-art equipment for forming and precision cutting, we are able to manufacture aluminum telescoping tubing—even with complex shapes—with outstanding accuracy. Our skilled technical team carefully manages every stage of production to ensure that each telescoping tube meets strict quality requirements and precise dimensional standards.

Design and Manufacture of Moulds

When creating custom molds for aluminum telescoping tubing, we design each mold according to the client’s specific requirements. We ensure that the dimensions and fit are extremely precise, maintaining a tight tolerance of ±0.03mm and high standards for both dimensional accuracy and surface smoothness.

Once the mold is made, we conduct test runs and provide samples of the telescoping tubing for client approval. We maintain close communication throughout the process and make any required adjustments to the mold, ensuring the final tubing meets the client’s expectations and functional needs.

Material for Extruded Aluminum

Quality for aluminum telescoping tubing begins with premium raw materials. At HTS Aluminum, we select only top-grade aluminum alloys to ensure our telescoping tubes deliver reliable strength, durability, and corrosion resistance for a wide range of uses.

1. The 6061-T6 alloy provides excellent strength (tensile strength ≥ 260 MPa) and supports loads exceeding 50 kg, making it well-suited for heavy-duty telescoping applications in industrial machinery or high-altitude equipment.

2. The 6063-T5 alloy is valued for its precise tolerances (±0.03mm) and superior surface finish (anodized thickness ≥ 15μm). This makes it an excellent choice for telescoping tubes in construction props, camera tripods, and similar precision-required applications.

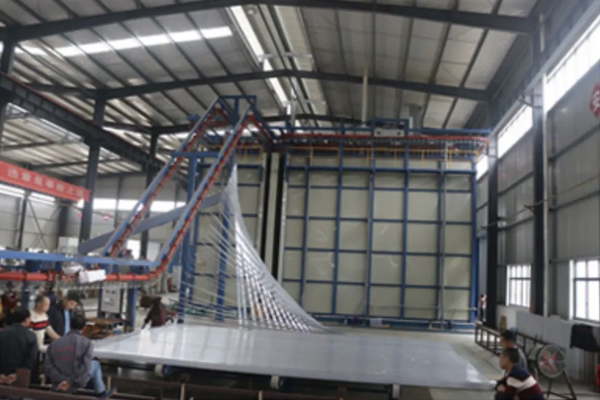

Surface Finishing for Extruded Aluminum Telescoping Tubes

Extruded aluminum telescoping tubes can undergo various surface treatments to improve durability and aesthetics. Non-exposed surfaces benefit from anodizing for corrosion resistance. Exposed areas can feature colorful anodizing for vibrant looks, electrophoretic coatings for smooth finishes, or wood grain effects to mimic natural wood, combining durability with visual appeal. These options make the tubes versatile for various applications.

Applications of Telescopic Aluminum Profiles

Telescopic aluminum profiles are a marvel of engineering, offering both strength and flexibility across various industries. Their ability to extend and retract makes them invaluable in situations where adjustable length and compact storage are crucial. Below, we delve into the multifaceted applications of these profiles, highlighting specific products that benefit from their unique properties.

For Photography and Videography Equipment

In the world of media production, telescopic aluminum profiles are integral to the design of camera tripods and boom poles. They allow photographers and videographers to achieve the perfect height and angle, ensuring that their equipment remains stable and secure while capturing high-quality images and footage.

For Adjustable Furniture

The furniture industry has embraced the utility of telescopic profiles to create innovative and space-saving designs. Items such as adjustable table legs and TV stands utilize these profiles, providing consumers with the flexibility to modify furniture height and position with ease.

For Medical Devices

Telescopic aluminum profiles play a critical role in the healthcare sector. They are employed in the construction of IV stands, mobile medical carts, and other adjustable equipment that needs to be moved and adapted to the varying needs of patients and healthcare professionals.

For Automotive and Transportation

Within the automotive industry, telescopic profiles are used in the manufacturing of roof racks, cargo management systems, and adjustable seat structures. Their durability and ease of use make them perfect for applications that require frequent adjustments to accommodate different load sizes and shapes.

For Sporting Goods

Telescopic aluminum profiles have found their way into the sporting goods market, particularly in the construction of hiking poles, tent frames, and portable sports nets. Their lightweight and collapsible features make them a favorite among outdoor enthusiasts and athletes.

For Emergency Services

For emergency and rescue operations, telescopic profiles are used in the design of collapsible ladders, stretcher poles, and lighting equipment. These applications require quick deployment and retraction, which is effortlessly provided by the aluminum profiles.

For Architectural and Construction Tools

In construction, telescopic aluminum profiles are used to create extendable levels, measuring sticks, and scaffolding components. Their ability to adjust to different lengths makes them indispensable tools on any construction site.

Telescoping Aluminum Poles vs. Steel and Plastic

| Comparison Dimension | Telescoping Aluminum Pole | Telescoping Steel Pole | Telescoping Plastic Pole |

|---|---|---|---|

| Weight & Portability | Light at 2.7g/cm³ (1/3 of steel), easy one-handed operation for outdoor use | Heavy at 7.85g/cm³, tiring to move | Lighter, but may lack rigidity and deform under load |

| Corrosion Resistance | Rusts easily, needs regular painting, high maintenance costs | Oxide film requires no maintenance, stable lifespan | Water-resistant but sensitive to solvents, ages over time |

| Scene Adaptability | -20℃ to 300℃ range, suitable for various applications, can be anodized | Good low-temperature but high heat conduction; may need coatings | Up to 120℃, softens at high temps, brittle in cold |

| Overall Cost | Higher than plastic, lower than specialty steel, lasts 5-10 years with good recycling value | Low initial cost but high maintenance, disposal causes pollution | Lowest initial cost, replace every 3-5 years; low-quality may leach harmful substances |

Advantages of Telescopic Aluminium Profile

Compared to other materials such as steel or plastic, aluminum extrusions offer a lightweight yet robust solution. Aluminum’s inherent properties, such as its high strength-to-weight ratio and natural corrosion resistance, make it an ideal choice for telescopic applications. Additionally, aluminum is easy to machine and can be customized with a variety of surface treatments to enhance its appearance and durability.

leading manufacturer from China

Custom Extruded Aluminum Telescoping Tubes

Our aluminum extrusion factory, located in Nanchang, Jiangxi Province, covers an extensive area of 30,000 square meters and is home to a dedicated workforce of over 120 skilled individuals. We place a strong emphasis on environmental responsibility, ensuring that our production processes adhere to strict environmental standards. Additionally, we prioritize the well-being of our employees, providing a safe and nurturing work environment. Our commitment to sustainability and employee welfare sets us apart as a responsible and ethical manufacturer in the industry.

Advanced Extrusion Lines

Boasting over 30 high-precision extrusion production lines from Japan and Germany, we ensure unmatched quality and efficiency.

Custom Mold Design and Processing

We tailor-make molds based on client designs or samples, providing prototypes for confirmation to meet precise specifications.

Comprehensive Surface Treatment Techniques

Our surface treatment capabilities include anodizing, electroplating, sandblasting, powder coating, fluorocarbon painting, and wood grain transfer printing to enhance product durability and aesthetics.

Over Two Decades of Expertise

Since 2013, we have been manufacturing aluminum profiles, accumulating vast experience in producing a wide array of profiles for windows, doors, and various industrial applications.

Our Factory

HTS NEW MATERIALS stands as a premier aluminum extrusion profile manufacturer in China. Boasting more than 40 production lines and housing the largest 6000-ton extrusion press, we excel in delivering high-quality solutions. Our capabilities extend to mold design and processing, along with comprehensive surface treatment and advanced machining services.

RFQ of Extruded Aluminum Tlescoping Tubing

At our factory, we offer a wide range of machining services to enhance the functionality of our aluminum profiles. Our capabilities include precision cutting for exact lengths, punching and threading for modifications, and slotting for component compatibility. We also specialize in bending and welding for complex assemblies and robust structures. Additionally, our assembly services ensure complete, ready-to-use components.

Punching

Punching, involves applying high force to create holes, indentations, or other shapes in aluminum profiles. This process is essential for creating ventilation openings, mounting slots, or lightweight structures with uniform patterns.

Drilling

Drilling creates necessary holes in aluminum profiles, allowing for the attachment of components with bolts or other fasteners, crucial for modular constructions.

Cutting

Precision cutting is crucial to ensure that each aluminum profile is trimmed to exact length specifications, facilitating a perfect fit in final assembly.

Milling

Milling involves the removal of aluminum material using rotary cutters to achieve desired shapes and surfaces. This process is perfect for creating slots, grooves, and complex contours, enhancing the functionality and precision of aluminum profiles.

Tapping

Tapping adds threads to the drilled holes in aluminum profiles, enabling the secure fastening of bolts and screws, which is vital for assembly and maintenance.

This technique shapes aluminum profiles into desired curves or angles, maintaining material integrity and is essential for both architectural and functional structures.

1. Routine Maintenance: Clean the surface using a soft, damp cloth to preserve the anodized coating; do not use abrasive materials like steel wool.

2. After Harsh Environmental Exposure: Should the telescoping tube be used in coastal or dusty conditions, rinse thoroughly with a mild detergent, dry it completely, and lightly apply a silicone-based lubricant to maintain smooth operation.

3. Extended Storage: Retract the tube to its minimum length during storage to reduce stress from weight, helping to prevent metal fatigue over time.

The heat treatment of aluminum extrusions determines their mechanical properties, strength, and suitability for specific applications. Among the various heat treatment methods, T5, T6, and T66 are the most commonly used. Here’s an in-depth look:

| Heat Treatment State | Cooling Method | Strength | Key Features and Benefits | Applications |

|---|---|---|---|---|

| T5 | Air cooling (fan) | Moderate | Adequate strength, good dimensional stability, used for architectural purposes. | Windows, doors, curtain walls, building structures. |

| T6 | Water quenching (fast) | High | Higher strength and hardness, ideal for industrial and structural uses. | Automotive, aerospace, machinery, transport parts. |

| T66 | Water quenching (fast) | Very high | Optimized mechanical properties for higher strength and performance demands. | Automotive, rail transportation, high-end machinery. |

Other Heat Treatment States

- T4: Solution heat-treated and naturally aged. Used in applications requiring intermediate strength and enhanced formability.

- T7: Overaged for better stress-corrosion resistance, often used for aerospace and marine purposes.

- O (Annealed): Very soft condition suitable for extensive forming or bending requirements.

- F (As-Fabricated): No heat treatment applied, used in non-critical applications with low strength requirements.

. Anodizing (Oxidation)

- Common Colors:

Natural silver

Black

Champagne

Light bronze

Dark bronze

Gold

2. Electrophoresis Coating (E-Coating)

- Common Colors:

Black

Champagne

Light bronze

Dark bronze

Custom metallic colors

3. Powder Coating

- Colors:

Can match any color based on the RAL color chart.

Offers textures like matte, gloss, satin, and custom finishes.

4. PVDF Coating (Polyvinylidene Fluoride)

- Colors:

Also customizable using the RAL color chart.

High-end finishes with matte or glossy effects.

5. Wood Grain Transfer Printing

- Colors and Patterns:

Mimics various wood types (e.g., oak, walnut, teak, mahogany).

Custom patterns available based on provided samples.

6. Film Lamination

- Colors and Patterns:

Includes textures like marble, leather, and solid colors.

Custom finishes and patterns based on provided samples.

Pre-Treatment Options (Impact on Final Color)

- Brushing/Polishing: Produces smooth or reflective metallic surfaces.

- Sandblasting: Adds a rough, matte texture before the final surface treatment.

Mold fees are an essential part of the custom aluminum extrusion process. Since every order requires a uniquely designed mold tailored to specific requirements, these molds cannot be used for other products. Therefore, the mold fee is necessary and non-negotiable.

We require 100% upfront payment of the mold fee before mold development begins to ensure timely production. However, as a token of appreciation for your support, we offer a refund of the mold fee or equivalent discounts once the order reaches a certain production volume. Specific policies can be discussed based on your order volume and collaboration details.

Mold production typically takes 7 days. After the sample is confirmed, producing a full container load of 26 tons generally requires 14 days for extrusion alone. If surface treatment is required, an additional 3 days will be needed. For machining, extra time will be required depending on the complexity and volume of the machining work. The exact additional time for machining will be determined based on the specific processing requirements.

Aluminum profiles are naturally corrosion-resistant due to the formation of a thin, protective oxide layer when exposed to air or water. This oxide layer is stable and self-repairing, meaning that even if the surface is scratched or cut (such as at exposed ends or during processing), the aluminum will not rust or corrode like iron or steel. Instead, the exposed areas will quickly form a new oxide layer, providing continuous protection against further oxidation.

With proper design, installation, and maintenance, aluminum profiles can last for decades, even in challenging environments. For example, untreated aluminum can easily withstand 20-30 years in outdoor applications, while profiles with surface treatments like anodizing or powder coating can last even longer, often exceeding 50 years. This makes aluminum an excellent choice for applications where durability and long-term performance are essential.

The price of aluminum profiles consists of several components: raw material costs, extrusion processing fees, surface treatment fees, machining costs, and additional packaging fees. Among these, the cost of aluminum as a raw material tends to fluctuate frequently, while other fees remain relatively stable. Due to these fluctuations, our quotations are typically valid for 7 days.

Pricing can be structured in different ways depending on the product and requirements. It can be calculated by weight (e.g., cost per ton), by length (e.g., cost per meter), or by piece (e.g., cost per unit). For products involving extensive machining, such as heat sinks, pricing is generally calculated on a per-piece basis to accurately reflect the additional processing costs. This flexible pricing approach ensures the quote is tailored to the specific needs of the customer.

We can manufacture aluminum profiles in compliance with technical requirements that meet European standards (EN), American standards (ASTM/AA), or other standards as specified by the customer. Custom production is tailored to ensure that the profiles meet the specific standard requirements requested.

Our production equipment is designed for the metric system. If the drawings provided are in the imperial system, we will convert them into metric units for production to ensure accuracy.

It is important to note that while we can machine imperial-threaded holes for fasteners, if you require us to supply matching imperial fasteners, they may not always be available in stock. Custom orders for imperial fasteners typically require a large volume for production. Please consider this when planning your project.