Aluminium Heat Dissipation | Thermal Conductivity

1. Thermal Conductivity of Aluminum

Aluminium is the material of choice for heat dissipation in modern thermal management systems, thanks to its unique balance of thermal conductivity, lightweight properties, and cost efficiency. With a thermal conductivity ranging from 160–220 W/(m·K)(depending on alloy composition), aluminium efficiently transfers heat while being 3x lighter than copper and far more affordable.

Aluminium is the material of choice for heat dissipation in modern thermal management systems, thanks to its unique balance of thermal conductivity, lightweight properties, and cost efficiency. With a thermal conductivity ranging from 160–220 W/(m·K)(depending on alloy composition), aluminium efficiently transfers heat while being 3x lighter than copper and far more affordable.

Thermal Performance Comparison: Aluminum vs. Copper Heat Sinks

| Metric | مشتت حراري من الألومنيوم | Copper Heat Sink | Steel Heat Sink |

|---|---|---|---|

| التوصيل الحراري | 160–220 W/(m·K) <br>(Pure Al: ~237) | ~398 W/(m·K) | ~50–80 W/(m·K) |

| Specific Heat Capacity | 0.9 J/g·K (fast thermal response) | 0.385 J/g·K (slower response) | ~0.45 J/g·K (moderate response) |

| Surface Emissivity | 0.1 (polished) → 0.8–0.9 (black anodized) | 0.03–0.1 (natural) | ~0.1–0.3 (depends on surface finish) |

| Contact Thermal Resistance | 0.1–0.5 K·cm²/W (with TIMs) | <0.1 K·cm²/W (lower resistance) | ~0.5–1.0 K·cm²/W (higher resistance) |

| الكثافة | 2.7 g/cm³ (lightweight) | 8.96 g/cm³ (heavy) | 7.87 g/cm³ (moderate weight) |

| يكلف | Low (cost-effective for mass production) | High (3–5× more expensive than Al) | Very Low (cheapest option) |

2. Aluminum Alloy Grades Impact Heat Dissipation

When designing an aluminum heat sink, selecting the right alloy is critical for balancing thermal performance, mechanical strength, and manufacturability. While pure aluminum offers the highest thermal conductivity, most industrial applications use alloyed aluminum to improve durability and ease of production.

2.1 Pure Aluminum (1xxx Series) – Best Conductivity, Weak Strength

Key Alloys: 1050, 1060, 1100

| ملكية | القيمة | Impact on Heat Dissipation |

|---|---|---|

| التوصيل الحراري | ~200–237 W/(m·K) | Highest possible for Al, ideal for thermal transfer. |

| قوة الشد | 70–110 MPa | Too weak for structural applications. |

| Typical Use | Thin-fin heat sinks, LED cooling. |

Pros:

Pros:

✔ Best thermal performance among aluminum alloys.

✔ Easy to extrude into complex fin shapes.

Cons:

✖ Low mechanical strength – prone to bending under stress.

✖ Rarely used in high-vibration environments (e.g., automotive).

2.2 6xxx Series (6061, 6063) – The Industry Standard

Most Common Alloys: 6061-T6, 6063-T5

| ملكية | 6063-T5 | 6061-T6 | Impact on Heat Sinks |

|---|---|---|---|

| التوصيل الحراري | ~200 W/(m·K) | ~170 W/(m·K) | Slightly lower than pure Al but still efficient. |

| قوة الشد | 186 MPa | 310 MPa | Strong enough for most applications. |

| Extrudability | ممتاز | جيد | 6063 is easier to shape into thin fins. |

Why 6xxx Series Dominates?

Why 6xxx Series Dominates?

✔ Balanced thermal & mechanical properties – ideal for electronics, automotive, and industrial heat sinks.

✔ 6063-T5 is the go-to alloy for extruded heat sinks (common in CPU coolers).

✔ 6061-T6 is stronger, used in high-stress environments (e.g., power converters).

Trade-off:

✖ ~10–20% lower conductivity than pure aluminum.

2.3 5xxx Series (5052, 5083) – Corrosion-Resistant but Poor Conductivity

Key Alloys: 5052, 5083

| ملكية | القيمة | Impact on Heat Dissipation |

|---|---|---|

| التوصيل الحراري | ~120–140 W/(m·K) | Significantly worse than 6xxx series. |

| قوة الشد | 210–290 MPa | Stronger than 6063 but harder to extrude. |

| مقاومة التآكل | ممتاز | Good for marine/high-humidity environments. |

When to Use?

When to Use?

✔ Outdoor or corrosive environments (e.g., marine electronics).

✔ Structural components needing moderate cooling.

Avoid If:

✖ Thermal performance is critical (conductivity is ~40% lower than 6063).

2.4 2xxx & 7xxx Series (2024, 7075) – High Strength, Worst Conductivity

Key Alloys: 2024-T6, 7075-T6

| ملكية | القيمة | Impact on Heat Sinks |

|---|---|---|

| التوصيل الحراري | ~120–150 W/(m·K) | Poor heat dissipation. |

| قوة الشد | 400–570 MPa | Used in aerospace/defense. |

| قابلية التصنيع | ممتاز | Hard to extrude; often CNC-machined. |

Why Avoid for Heat Sinks?

✖ Very low thermal conductivity (~50% of 6063).

✖ Expensive and overkill unless extreme strength is needed.

Exception:

✔ Aerospace heat sinks where weight and strength matter more than cooling efficiency.

2.5 Specialized Alloys (Al-SiC, Al-Graphite) – High Performance, High Cost

Example: Al-SiC (Silicon Carbide Reinforced)

| ملكية | القيمة | Impact on Heat Dissipation |

|---|---|---|

| التوصيل الحراري | 250–300 W/(m·K) | Better than pure aluminum. |

| CTE (Coeff. of Thermal Expansion) | Matches semiconductors (e.g., Si, GaAs). | Reduces thermal stress in high-power electronics. |

| يكلف | 5–10× standard Al alloys. | Only justified in niche applications. |

Best For:

Best For:

✔ High-power laser diodes, RF amplifiers, aerospace electronics.

✔ Where CTE matching is critical (e.g., power modules).

Drawback:

✖ Extremely expensive – not viable for consumer products.

Summary: Choosing the Right Alloy for Your Heat Sink

| Alloy Series | Best For | التوصيل الحراري | قوة | يكلف |

|---|---|---|---|---|

| 1xxx (Pure Al) | Thin-fin heat sinks, LEDs | ★★★★★ (~237 W/(m·K)) | ★★☆☆☆ | $ |

| 6xxx (6063, 6061) | Electronics, automotive | ★★★★☆ (~200 W/(m·K)) | ★★★★☆ | $$ |

| 5xxx (5052, 5083) | Marine/outdoor use | ★★☆☆☆ (~130 W/(m·K)) | ★★★☆☆ | $$ |

| 2xxx/7xxx (2024, 7075) | Aerospace/defense | ★★☆☆☆ (~140 W/(m·K)) | ★★★★★ | $$$$ |

| Al-SiC Composites | High-power RF, lasers | ★★★★★ (~300 W/(m·K)) | ★★★★☆ | $$$$$ |

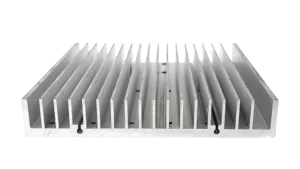

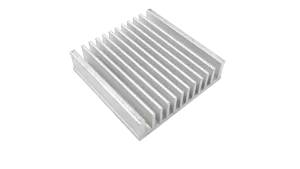

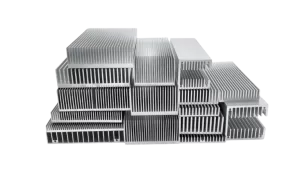

3. Impact of Structure on Aluminum Cooling

While material selection is critical, the structural design of a heat sink plays an equally important role in heat dissipation efficiency. Even the best aluminum alloy will underperform if the geometry and airflow dynamics are poorly optimized.

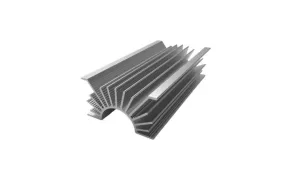

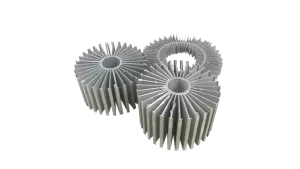

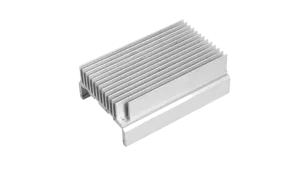

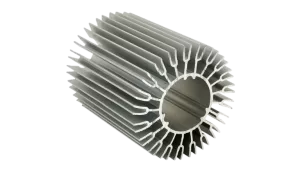

3.1 Fin Geometry: The Heart of Heat Dissipation

The fins are responsible for maximizing surface area to transfer heat to the surrounding air. Key parameters include:

(1) Fin Height (H) & Spacing (P)

| المعلمة | Optimal Range | Too Low | Too High |

|---|---|---|---|

| Height (H) | 5–50 mm (natural convection)<br>10–100 mm (forced air) | Reduced surface area | Airflow blockage (natural convection) |

| Spacing (P) | 3–15 mm (depends on airflow) | Airflow resistance | Reduced heat transfer area |

Design Tip:

Design Tip:

- ل natural convection, use taller fins (20–50 mm) with wider spacing (5–15 mm)to allow hot air to rise.

- ل forced air cooling, shorter fins (10–30 mm) with tighter spacing (3–8 mm)improve turbulence.

(2) Fin Shape & Surface Texture

| Fin Type | Advantage | Best Use Case |

|---|---|---|

| Straight Fins | Easy to manufacture | Low-cost electronics |

| Pin Fins | 20–30% more surface area | Compact spaces (e.g., GPU coolers) |

| Wave/Offset Fins | Disrupts laminar flow → better turbulence | High-speed forced air (servers, telecom) |

| Textured/Sandblasted | +10–15% convection efficiency | Passive cooling (no fan) |

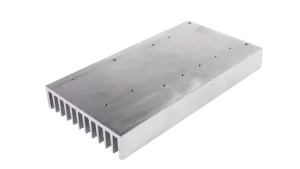

3.2 Base Plate Design: The Thermal Bridge

The base plate transfers heat from the source (e.g., CPU) to the fins. Key considerations:

| المعلمة | Optimal Value | التأثير على الأداء |

|---|---|---|

| سماكة | 3–10 mm | Too thin → heat congestion<br>Too thick → unnecessary weight |

| Flatness | ≤0.05 mm/m | Poor flatness increases thermal resistance |

| مادة | Copper base + Al fins (hybrid) | Better for high-power chips (e.g., CPUs) |

Critical Note:

Critical Note:

- أ 6 mm-thick aluminum base is standard for most electronics.

- ل >100W heat loads, a copper core or vapor chamber is recommended.

3.3 Heat Pipes & Vapor Chambers: Boosting Efficiency

When aluminum’s lateral conductivity is insufficient, phase-change technologies help spread heat evenly.

| Technology | How It Works | Best For |

|---|---|---|

| Heat Pipes | Evaporates/condenses fluid to transfer heat | Laptops, CPU coolers |

| Vapor Chambers | Flat, two-dimensional heat spreader | High-power GPUs, LEDs |

Performance Gain:

Performance Gain:

- Heat pipes can reduce thermal resistance by 40–60% vs. pure aluminum.

- Vapor chambers are ideal for >150W/cm² hotspots.

4. Surface Treatment Effects on Aluminum Cooling

While material selection and structural design are critical for heat sink performance, surface treatments play a vital role in enhancing heat dissipation efficiency, corrosion resistance, and long-term reliability. Different treatments can improve thermal radiation, convection, and even interfacial heat transfer.

4.1 Anodizing: The Gold Standard for Aluminum Heat Sinks

الأكسدة creates a controlled oxide layer on aluminum, improving durability and thermal emissivity.

Types of Anodizing & Their Impact

| Type | سماكة | Emissivity (ε) | Thermal Conductivity Impact | Best Use Case |

|---|---|---|---|---|

| Clear Anodizing | 5–25 µm | 0.1–0.2 (low) | Slight reduction (~5–10%) | General-purpose heat sinks |

| Black Anodizing | 10–25 µm | 0.8–0.9 (high) | Moderate reduction (~10–15%) | Passive cooling, radiative heat transfer |

| الأكسدة الصلبة | 25–100 µm | 0.3–0.5 | Significant reduction (~20–30%) | High-wear industrial applications |

Key Benefits:

Key Benefits:

✔ Corrosion resistance – Protects against oxidation and chemical exposure.

✔ Improved emissivity (black anodizing) – Boosts radiative cooling by 8–10× vs. bare aluminum.

✔ Electrical insulation – Prevents short circuits in electronics.

Trade-offs:

✖ Reduced thermal conductivity – The oxide layer is less conductive than pure aluminum.

✖ Thicker coatings increase thermal resistance – Keep anodizing <15 µm for optimal heat transfer.

4.2 Chemical Conversion Coatings (Chromate/Phosphate)

These thin coatings enhance corrosion resistance without significantly affecting thermal performance.

| Coating Type | سماكة | Effect on Heat Transfer | Best Use Case |

|---|---|---|---|

| Chromate Conversion | 0.5–2 µm | Negligible impact | Military, aerospace (where toxicity is acceptable) |

| Phosphate Coating | 1–5 µm | Slight reduction (~3–5%) | Automotive, industrial heat sinks |

المميزات:

✔ Very thin – Minimal impact on thermal resistance.

✔ Improves paint/adhesive bonding – Useful for coated heat sinks.

Disadvantages:

✖ Limited emissivity improvement – Not as effective as anodizing for radiative cooling.

4.3 Powder Coating & Paint: Aesthetic but Thermally Restrictive

طلاء مسحوق provides color and protection but can hinder heat dissipation.

| المعلمة | Typical Impact | Recommendation |

|---|---|---|

| سماكة | 30–100 µm | Avoid on high-power heat sinks |

| Emissivity | 0.4–0.8 (depends on color) | Black paint helps slightly |

| Thermal Resistance | High (20–50% reduction in cooling) | Use only on low-power or decorative heat sinks |

When to Use?

When to Use?

- Consumer electronics where appearance matters.

- Low-power applications (e.g., LED housings).

Avoid If:

- High thermal performance is needed – The coating acts as an insulator.

4.4 Mechanical Texturing (Sandblasting, Brushing)

Altering surface roughness can improve convection efficiency.

| Treatment | Surface Roughness (Ra) | Effect on Cooling |

|---|---|---|

| النفخ الرملي | 3–10 µm | +10–15% convection efficiency |

| تنظيف الأسنان بالفرشاة | 1–5 µm | +5–10% convection efficiency |

Pros:

✔ No added thermal resistance – Only modifies surface texture.

✔ Cost-effective – No chemical processes required.

Cons:

✖ No improvement in radiative cooling – Only aids convection.

Best For:

- Forced-air cooling systems (e.g., server heat sinks).

- Industrial heat exchangers.

4.5 Plating (Nickel, Silver, Gold) – Niche but Effective

Electroplating can enhance conductivity or corrosion resistance.

| Plating Type | التوصيل الحراري | Best Use Case | Drawback |

|---|---|---|---|

| Nickel Plating | ~90 W/(m·K) | Corrosion protection | Adds ~0.2 K·cm²/W thermal resistance |

| Silver Plating | ~429 W/(m·K) | Ultra-high-performance cooling | Expensive, tarnishes over time |

| Gold Plating | ~318 W/(m·K) | RF/space applications (oxidation-proof) | Extremely costly |

When to Consider?

- Silver plating for extreme thermal performance (e.g., superconductors).

- Nickel plating for humid/marine environments.

Summary: Choosing the Right Surface Treatment

| Treatment | Best For | Thermal Impact | يكلف |

|---|---|---|---|

| Black Anodizing | Passive cooling, high emissivity | ★★★★☆ (optimal radiation) | $$ |

| Clear Anodizing | General corrosion protection | ★★★☆☆ (minimal impact) | $ |

| النفخ الرملي | Forced convection improvement | ★★★★☆ (better airflow) | $ |

| Nickel Plating | Marine/outdoor use | ★★☆☆☆ (adds resistance) | $$$ |

| طلاء المسحوق | Aesthetic applications | ★☆☆☆☆ (insulating) | $$ |