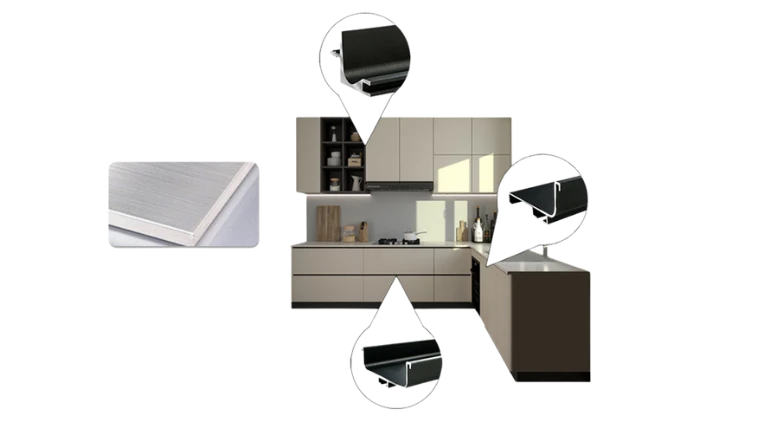

Aluminum Lean Pipe Connectors for Assembly Projects

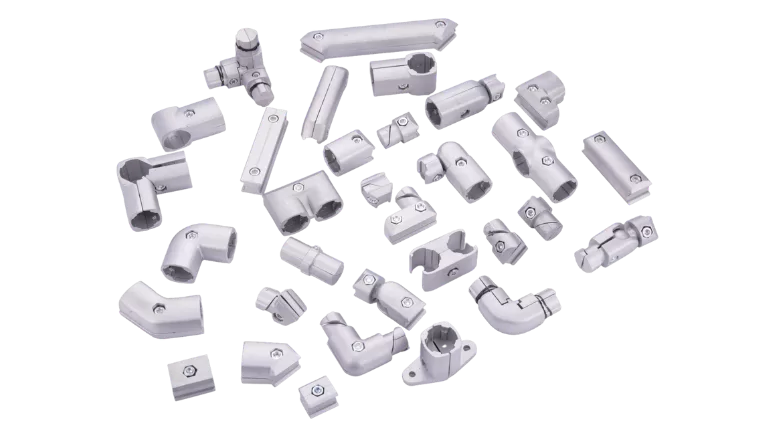

HTS-ALU is a leading manufacturer of aluminum lean pipe and assembly accessories in China. We offer a diverse range of aluminum lean pipe connectors, including right-angle connectors, parallel connectors, and various specialized types to cater to different connection requirements.

- A full selection of connectors is available for all lean pipe needs.

- Anodized surfaces ensure no color discrepancy with lean pipes.

- Finely machined connectors guarantee an ideal fit with lean pipes.

- Sufficient inventory is maintained to meet supply demands quickly.

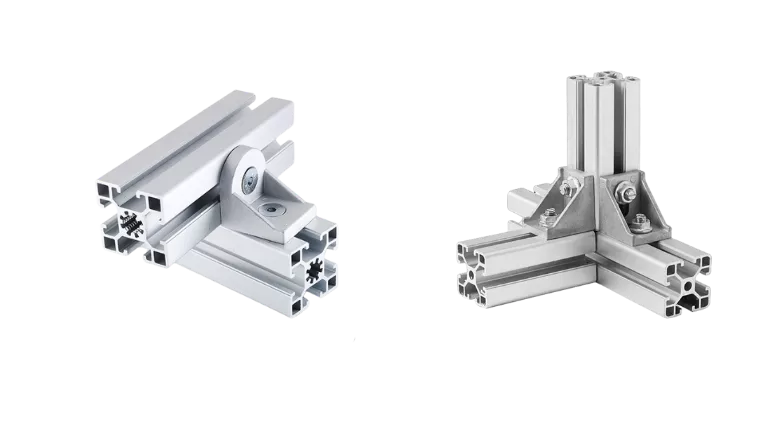

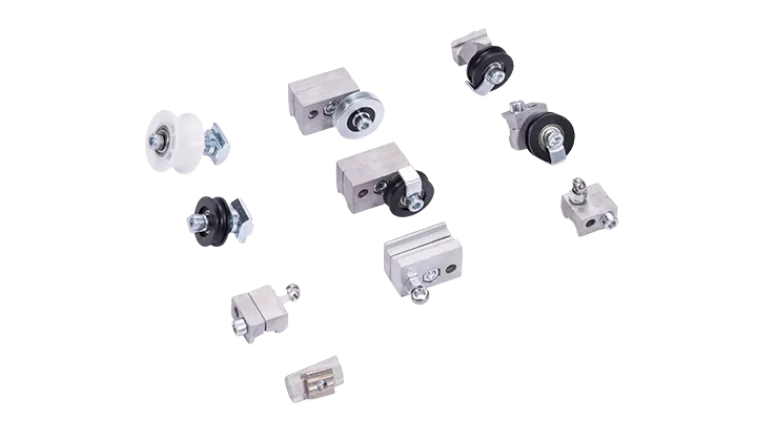

Amuminum Lean Pipe Connectors

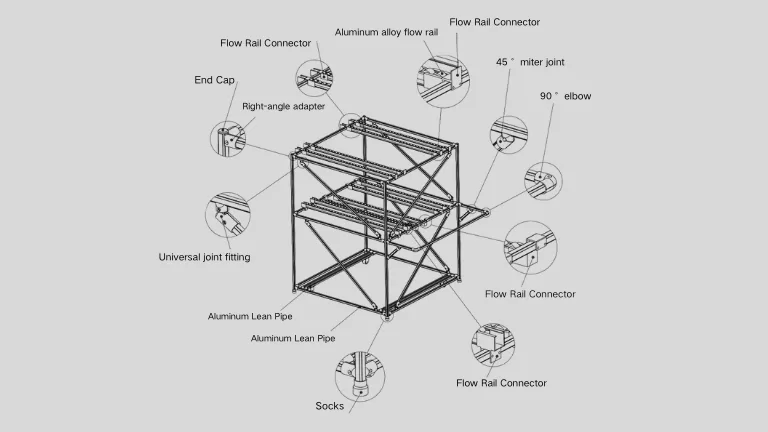

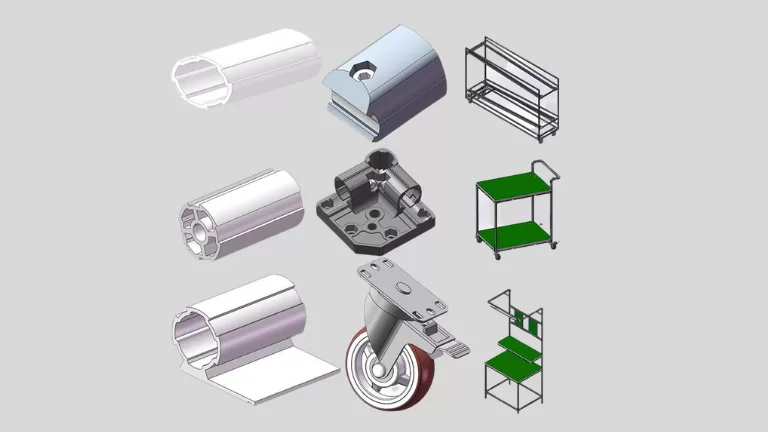

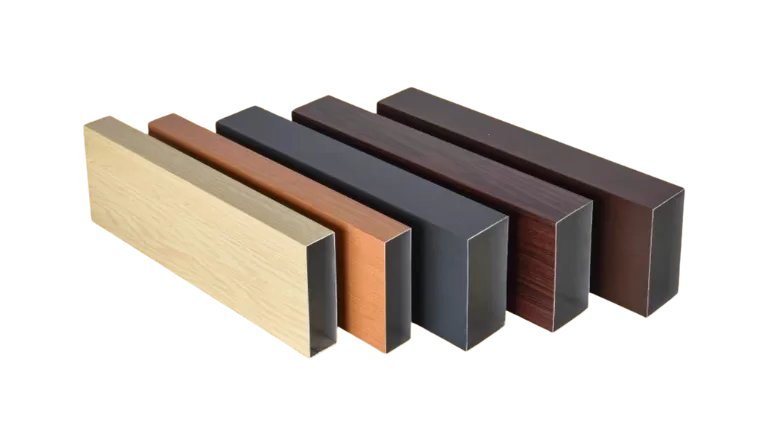

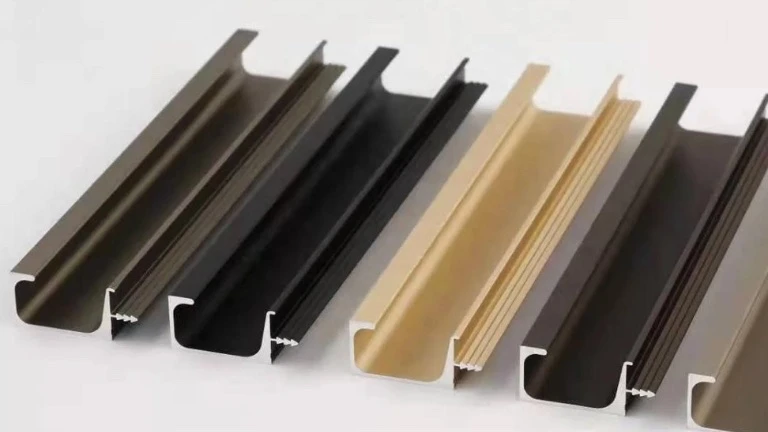

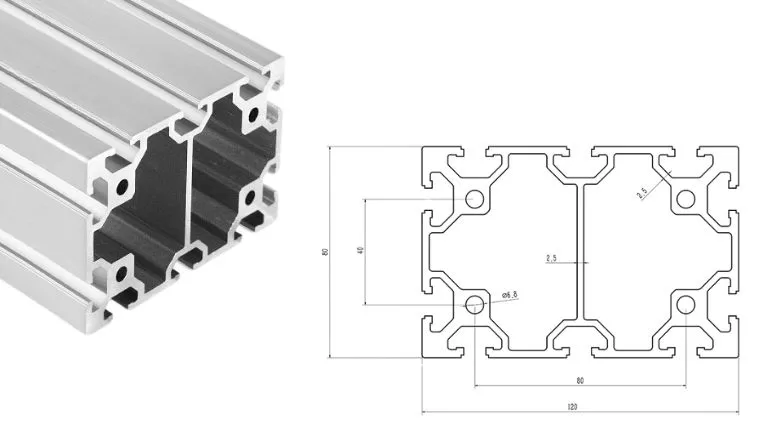

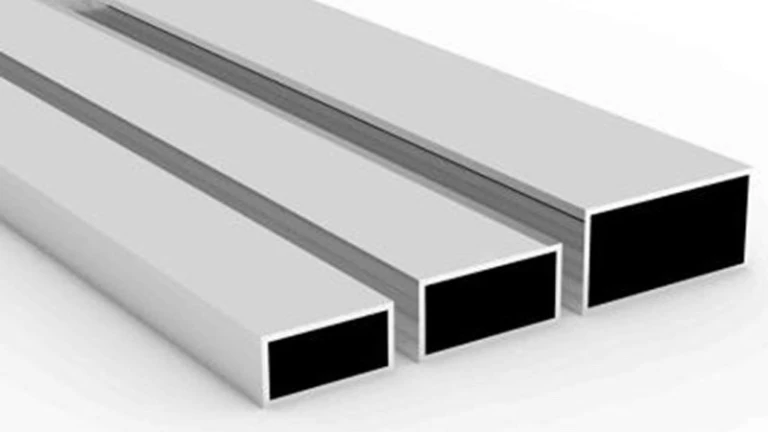

Aluminum Lean Pipe Connectors are lightweight and durable components designed for flexible lean pipe systems. Compatible with 19mm, 28mm, and 43mm lean pipes, these connectors provide various connection angles, including straight, parallel, 90 degrees, 45 degrees, 135 degrees, and three-way connections. The anodized surface treatment enhances corrosion resistance while ensuring a uniform appearance. These connectors enable easy assembly and disassembly, making them ideal for modular setups.

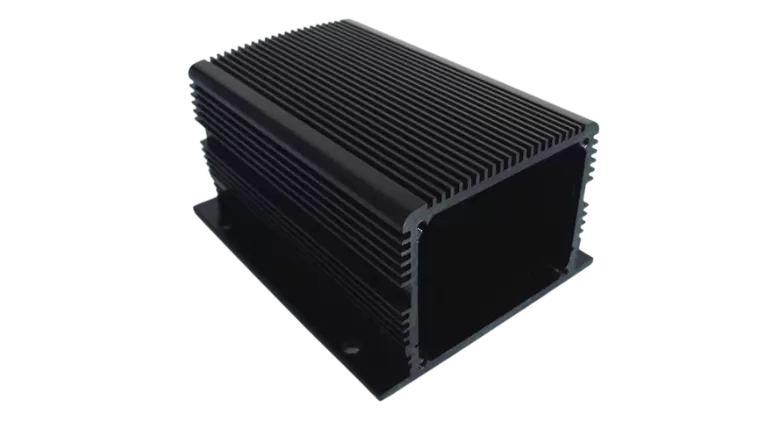

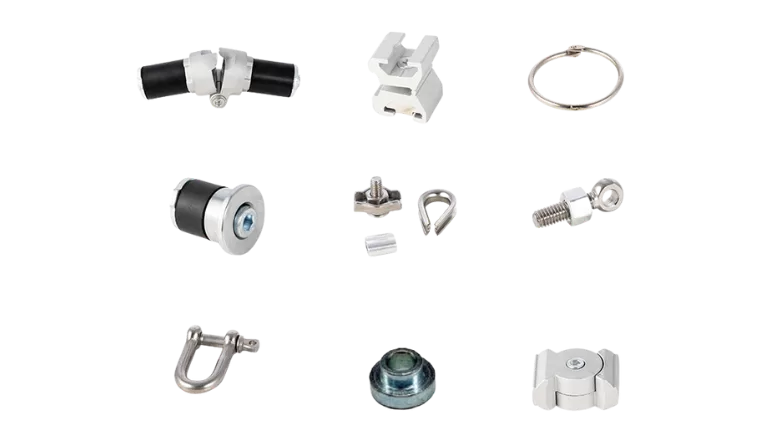

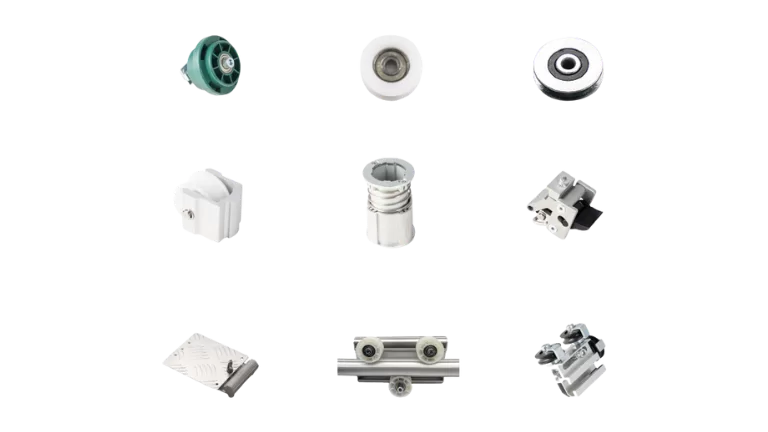

Aluminum Lean Pipe Metal Function Accessories

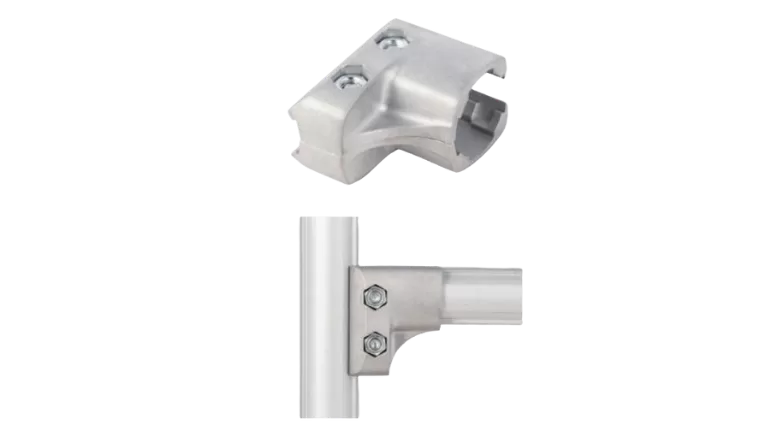

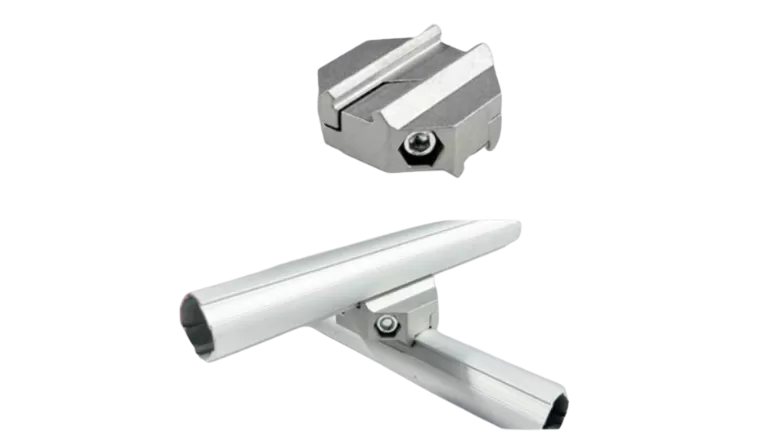

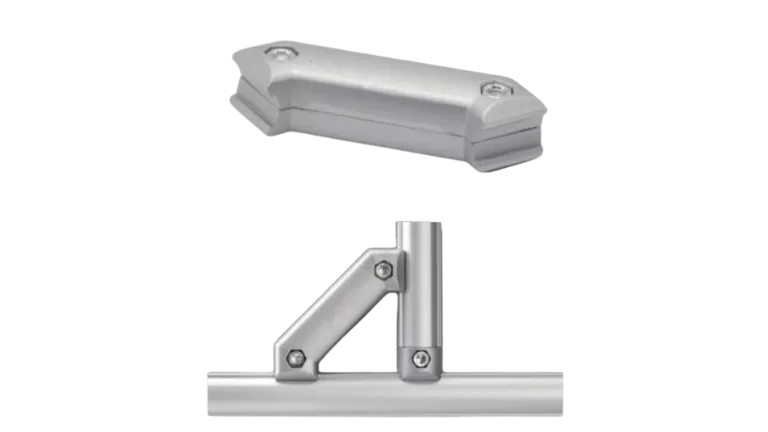

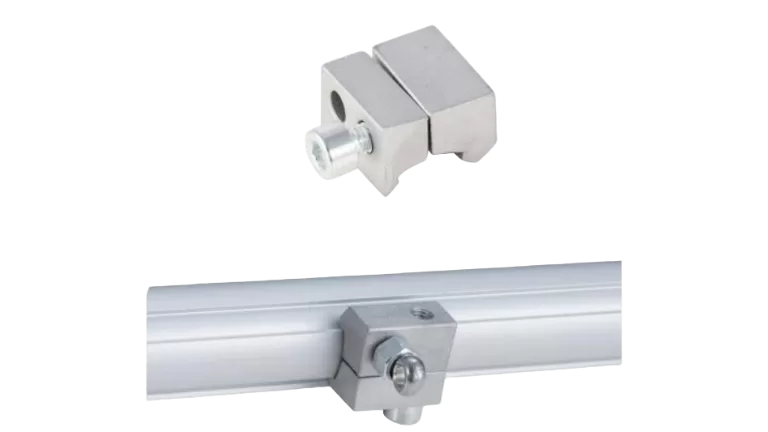

Aluminum Lean Pipe Metal Function Accessories enhance the versatility of lean pipe systems. In addition to aluminum connectors, these components include T-joints for three-way connections, cross joints for four-way intersections, angle brackets for securing pipes at various angles, and elbows for direction changes. Pipe supports provide stability, clamps ensure tight connections, cap covers offer a clean finish, and foot plates stabilize the structure.

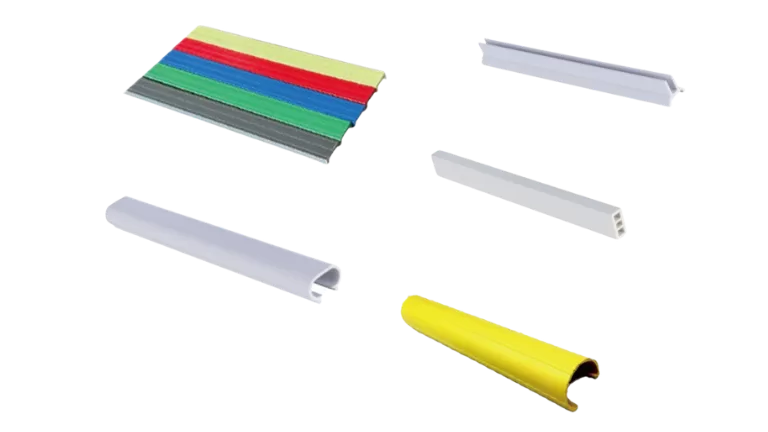

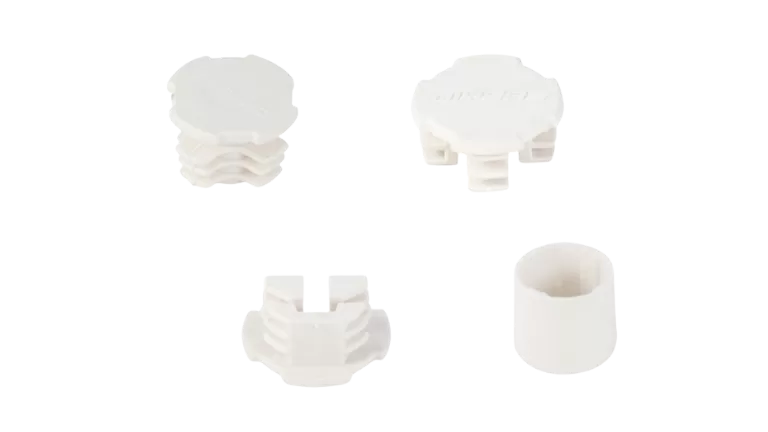

Lean Pipe Non-metallic Functional Accessories

Lean Pipe Plastic Accessories are essential for building flexible lean pipe systems. This category includes plastic corner connectors for secure angles, end caps that protect pipe ends, and connector joints for easy assembly and disassembly. Additional items like junctions and pipe clamps ensure a stable and adjustable framework. These accessories are ideal for effective workspace organization in various industrial applications.

Assembly and Practical Application

Lean pipes with connectors provide versatile applications in various industries. They can be used to create customized workstations for better workflow, modular storage racks for efficient inventory management, and conveyor systems for moving goods. In retail, lean pipes can form adjustable display stands, and they can also serve as safety barriers in manufacturing settings. Additionally, lean pipes support material handling solutions like carts and bins and can be arranged into flexible assembly lines.

Aluminum Lean Pipe Connector Solution

HTS-ALU offers extensive experience in aluminum lean pipe solutions, providing a comprehensive range of connectors and accessories for various applications. Our product lineup includes nearly all the components you might need, ensuring versatility and adaptability in your projects. With superior processing techniques, we deliver high-quality products that enhance the efficiency and effectiveness of lean pipe systems, making them ideal for diverse industrial needs.

Contact us today to discover how our aluminum lean pipe connector solutions can optimize your workspace!

Benefits of Using Aluminum Lean Pipe Connectors

1. Flexible Combinations: The aluminum lean pipe connectors can be assembled in various ways to meet different shapes, sizes, and weight requirements.

2. Easy Assembly: You can quickly put the entire frame together using simple tools like wrenches and screwdrivers.

3. Cost-Effective: Using these connectors helps minimize material waste during assembly, reducing costs and increasing efficiency.

4. Reusable: The connectors can be easily disassembled and reused, which helps cut down on waste.

5. Safe and Reliable: The aluminum lean pipe connectors ensure stability and reliability at the joints, guaranteeing safe use even under heavy loads.

Installation Instructions for Lean Pipe Connectors

Basic Connection Methods

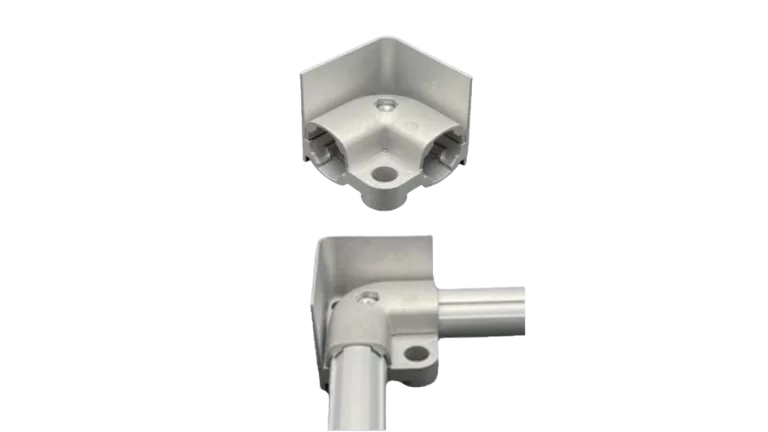

1. Right Angle Connection

– External Connector Installation: Place the two pipes into the two openings of the 90-degree external connector and tighten the screws with a wrench to secure them.

– Internal Expansion Connector Installation: Insert the right angle internal expansion connector inside the pipe, then tighten the screws from the bottom to complete the vertical connection.

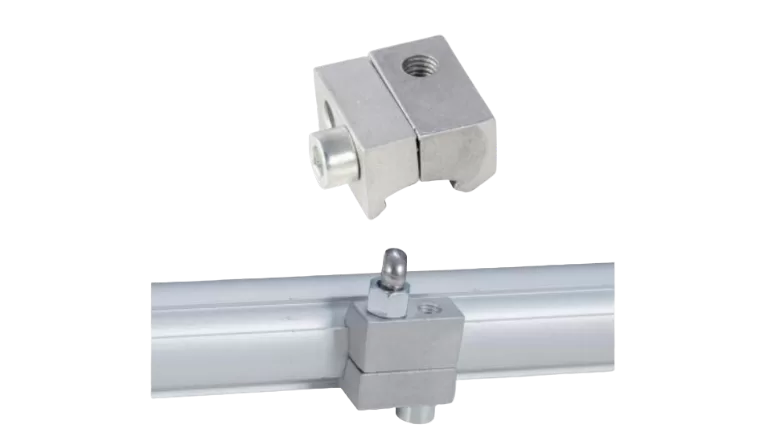

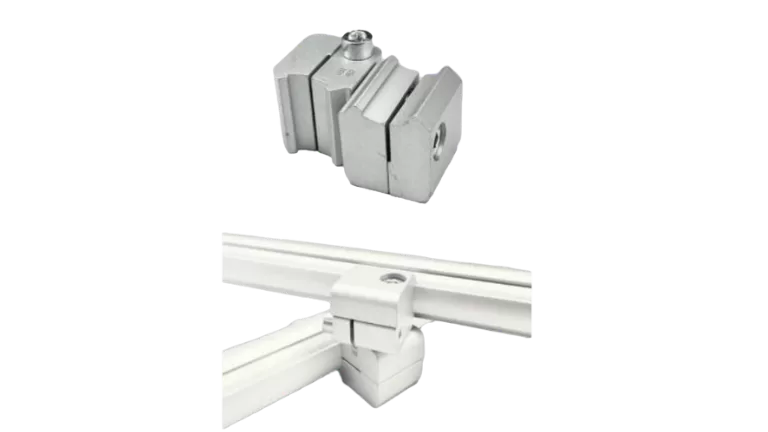

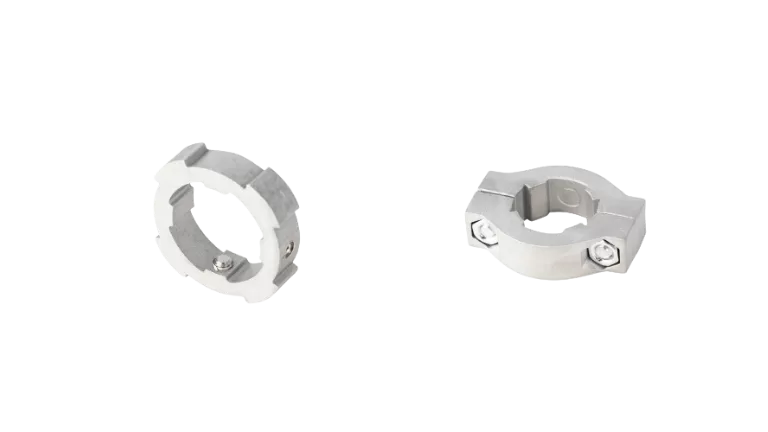

2. Parallel Connection

– Parallel Clamp: Choose the appropriately sized clamp based on load requirements, and use screws to secure the two parallel pipes.

– Panel Clamp: Simply clip the clamp onto both sides of the parallel pipes for quick installation without any tools.

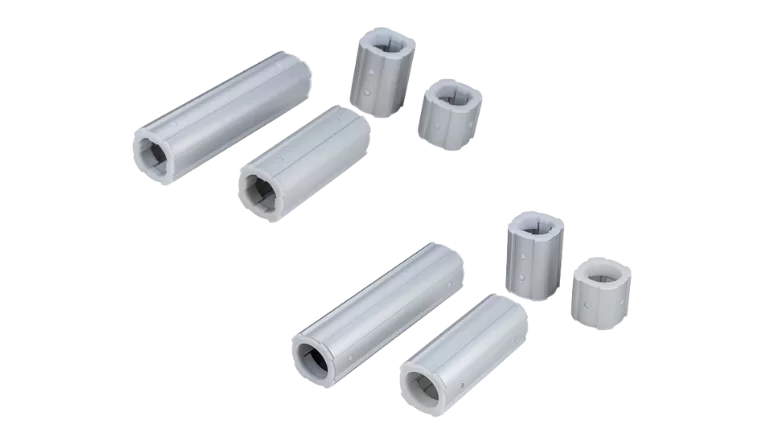

3. Extension Connection

– Straight Internal Expansion Connector: Insert it inside the pipe and secure it with screws to extend the length of the pipe.

Special Angle Connections

1. 45-Degree Connection

– Diagonal Brace Clamp: Install the clamp on the outside of the two vertical pipes to form an equilateral triangle structure for added stability.

– Internal Expansion Connector: Use an internal 45-degree connector to create a triangular support structure with a short pipe.

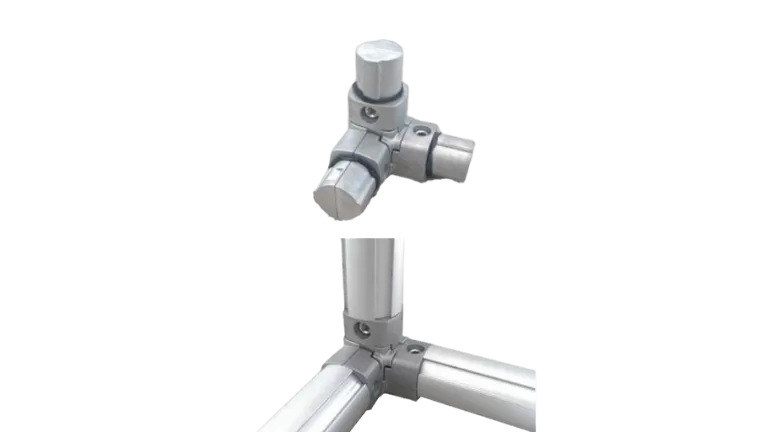

2. Universal Joint Connection

– External Connector: Install the universal joint connector externally, allowing the pipes to be adjusted to any angle.

– Internal Expansion Joint: Install the universal joint connector internally, supporting hidden multi-angle connections.

3. Cross Connection

– Cross Connector: Used for two vertical pipes that are not on the same plane. After securing the external connector, the pipes will form a cross shape.

Tips for Using Aluminum Lean Pipe Connectors

1. Make sure to use the correct size and type of connectors to ensure stability and a good seal at the joints.

2. Be careful with the amount of force you apply during assembly to avoid damaging the connectors or the joints.

3. Keep the joints clean, flat, and free of rust to ensure a good connection.

4. Choose the right material and design for the frame to ensure it can handle the expected weight.

5. Avoid putting the joints under vibration or heavy loads, as this can affect the connection’s effectiveness.

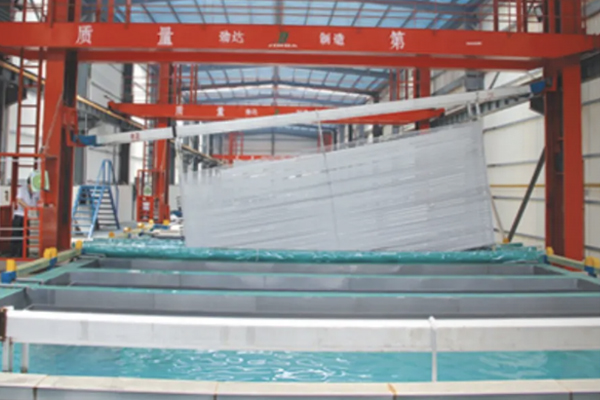

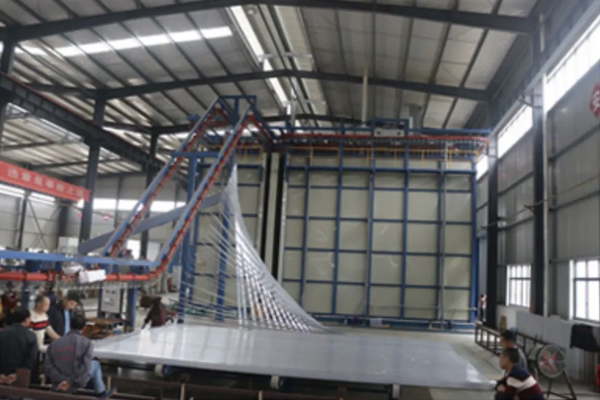

Our Factory