Diverse Assembly Methods of Aluminum Lean Pipe Connectors

Fixed Connection of Lean Pipe Connectors

A fixed connection is a basic method for assembling aluminum lean pipe connectors. It involves securely attaching the connectors to the pipes to ensure stability and safety. This type of connection typically uses screws, welding, or push-fit methods, making it suitable for situations where a fixed position is required for a long time. The advantages of fixed connections include high strength and durability, providing solid support for various industrial applications and reducing the risk of loosening due to vibrations or external forces.

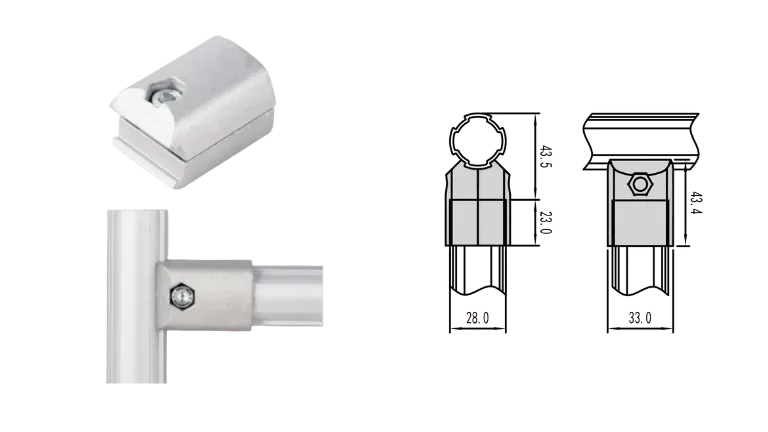

Outer Straight Connector

Outer straight connector of the 90 ° aluminum lean pipe structure can be connected to the wire rod in four directions and is the main connecting component of the frame structure.

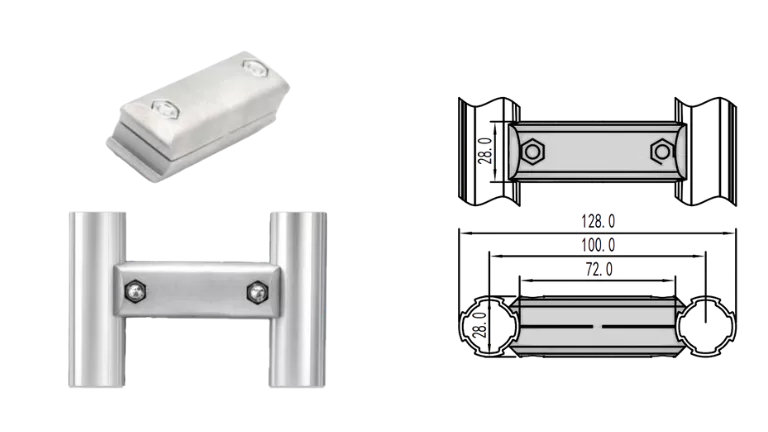

Parallel Extension Connector

The elongated joint of the aluminum lean pipe in a parallel structure is used for extending the main structure and for connections that require local reinforcement, among other applications.

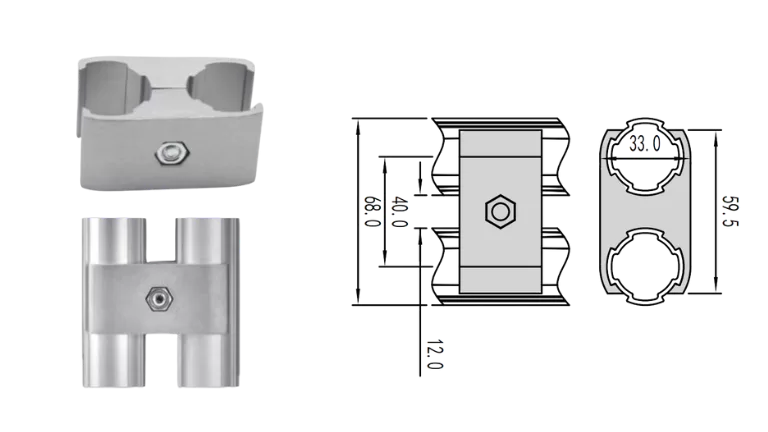

Parallel Fixed Connector A

The basic joint of the aluminum lean pipe in a parallel structure is designed for extending the main structure and for connections that require local reinforcement, among other applications.

Parallel Outsourcing Connector

The outsourcing connector for aluminum lean pipe parallel structures is used for expansion and local reinforcement of the main structure.

Parallel Fixed Connector B1

The connecting joint of the aluminum lean pipe in a parallel structure has a smaller spacing compared to the parallel fixed joint A, allowing it to be used in conjunction with the 90° cross joint.

Parallel Fixed Connector B2

The connecting joint of the aluminum lean pipe in a parallel structure features an elongated design, enhancing the strength and stability of the connections.

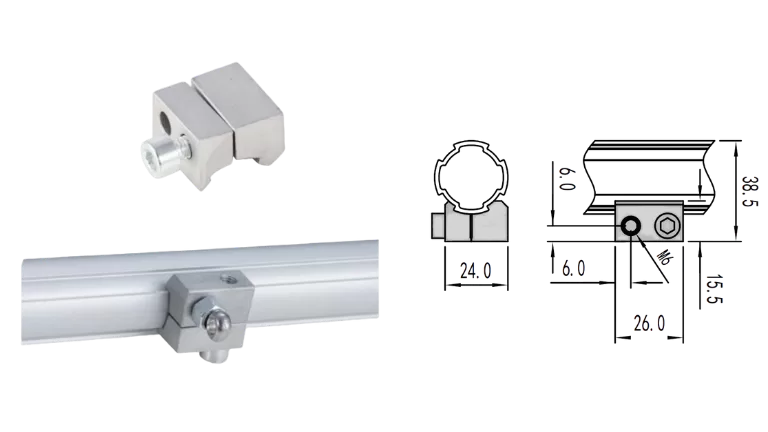

Double Hole Functional Accessories

Aluminum lean pipe is used to assist in the installation of connectors for other accessories and comes with two M6 mounting holes.

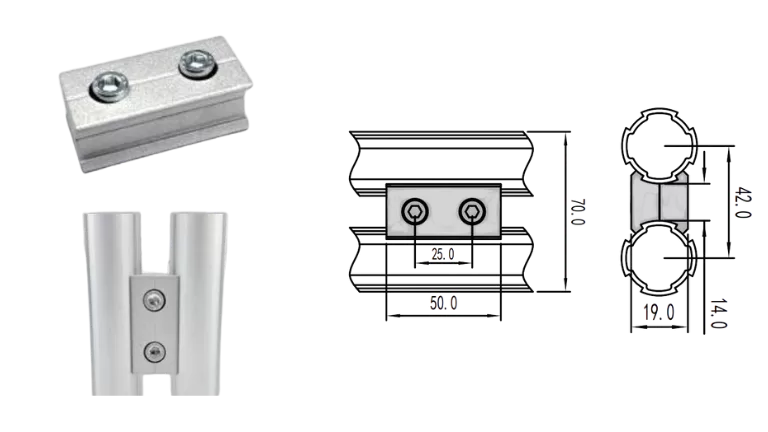

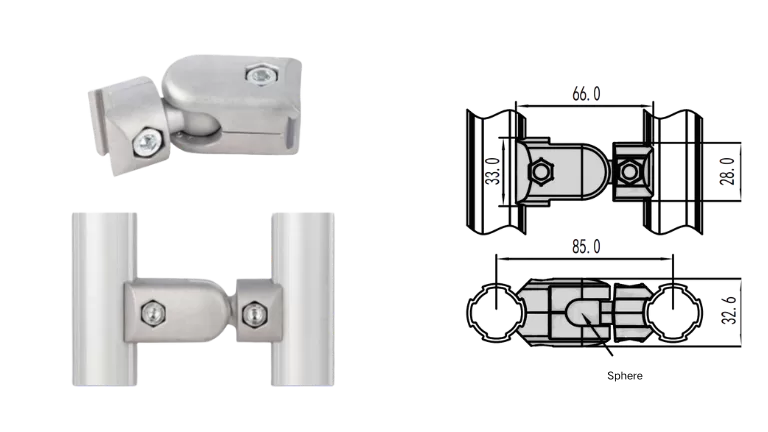

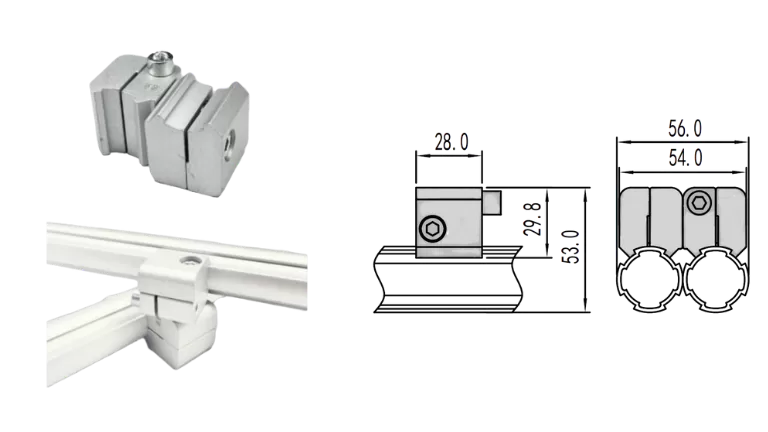

Double Pipe Outer Straight Connector

The basic external joint of the aluminum double-linked lean pipe with a 90° structure can also connect to double-support lean pipes, providing versatile connectivity options.

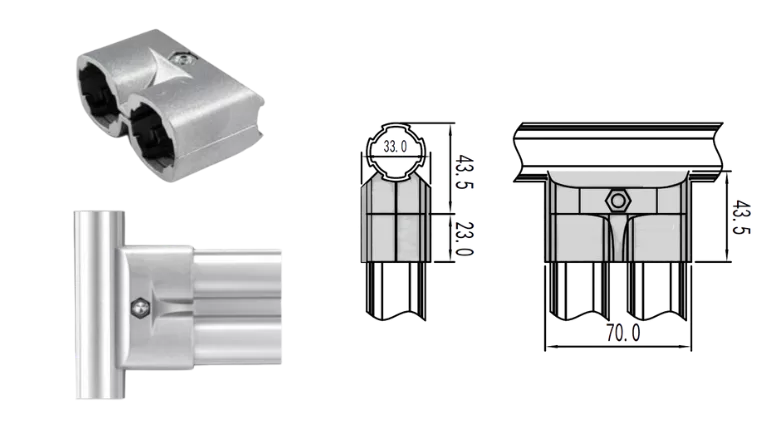

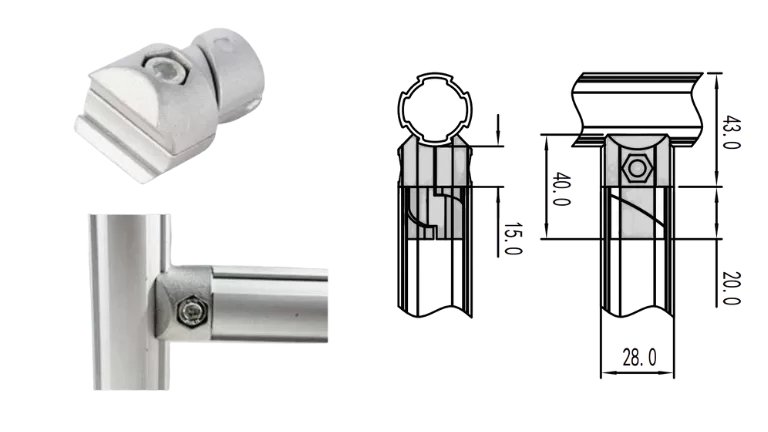

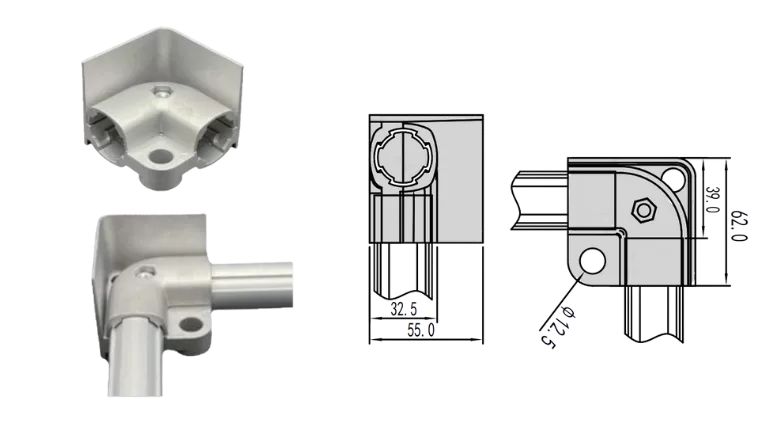

Handrail Dedicated Connectors

The specialized joint for the handrail structure of the aluminum lean pipe is designed to provide secure and stable connections specifically for handrail applications.

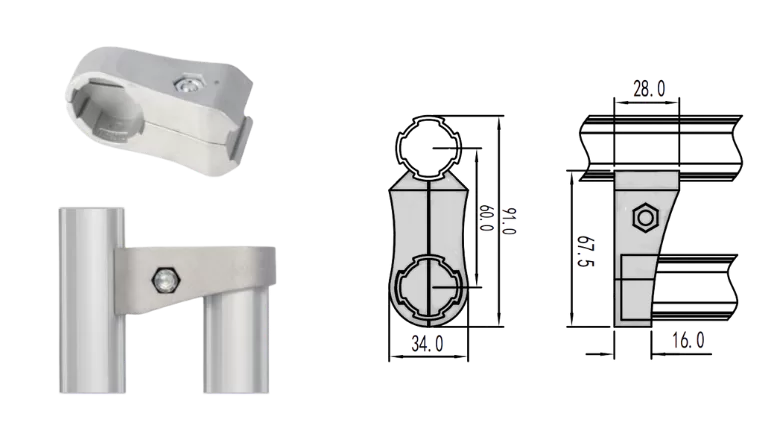

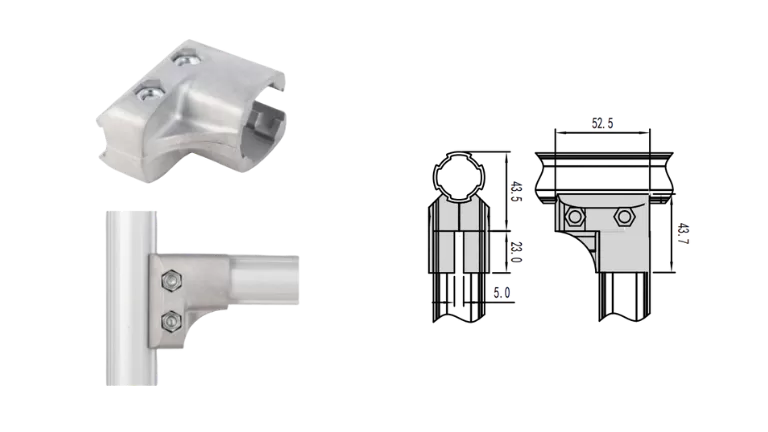

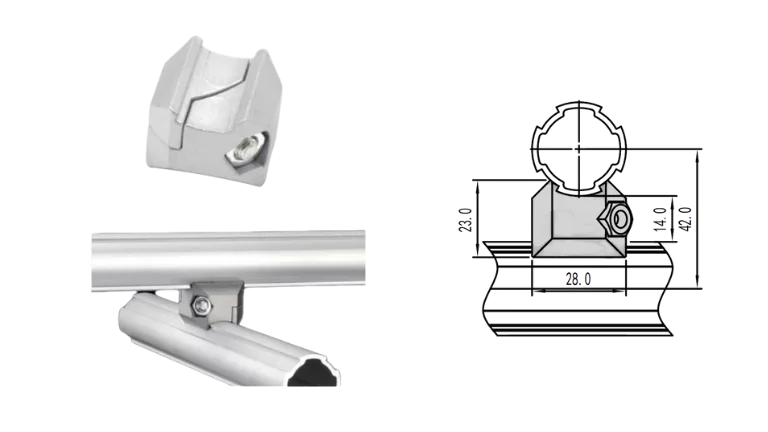

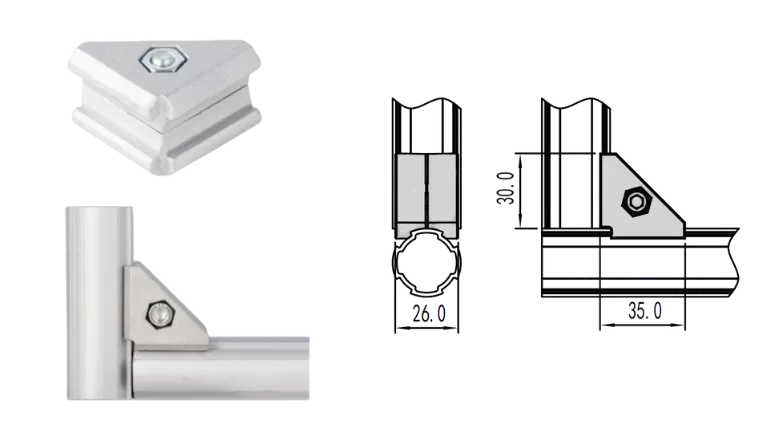

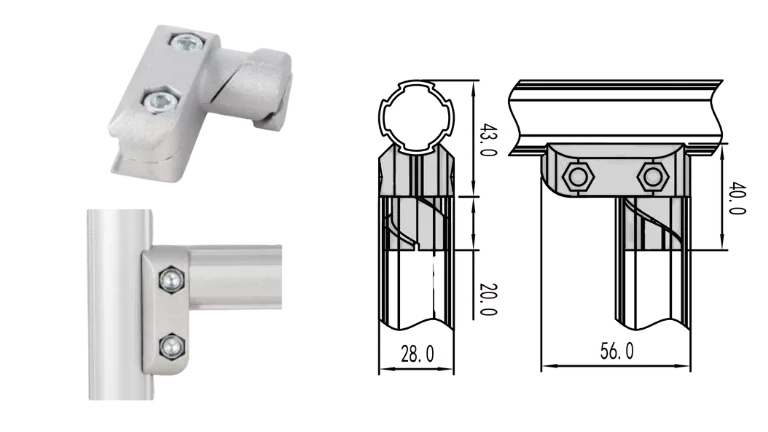

Outer Embrace Base

The joint for connecting aluminum lean pipes with other industrial aluminum profiles can also be used for connections to ground and wall surfaces.

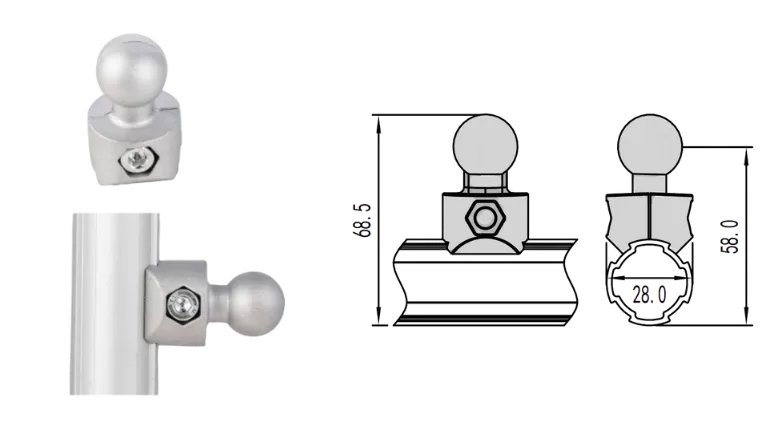

Round Head Hook

The aluminum lean pipe comes with easy and quick installation hooks that can be used to hang tools with rope loops and other similar items.

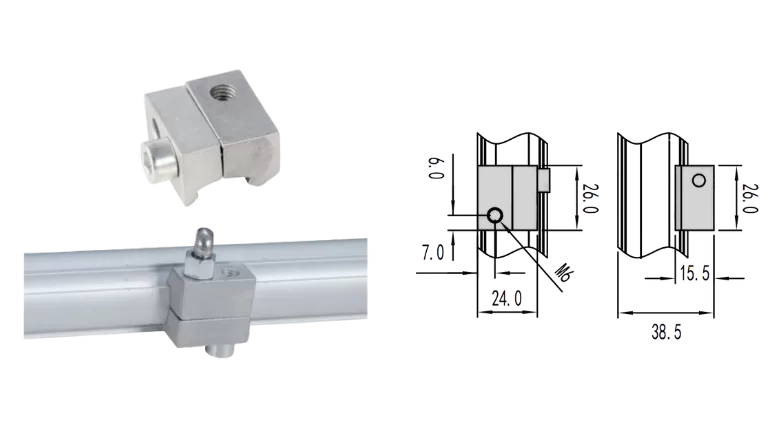

Functional Accessory A

The main structure of the aluminum lean pipe needs to install pulleys or other accessories with M6 threads, and it can also accommodate panels and other components.

Functional Accessory B

The main structure of the aluminum lean pipe requires the installation of pulleys or other accessories with M6 threads.

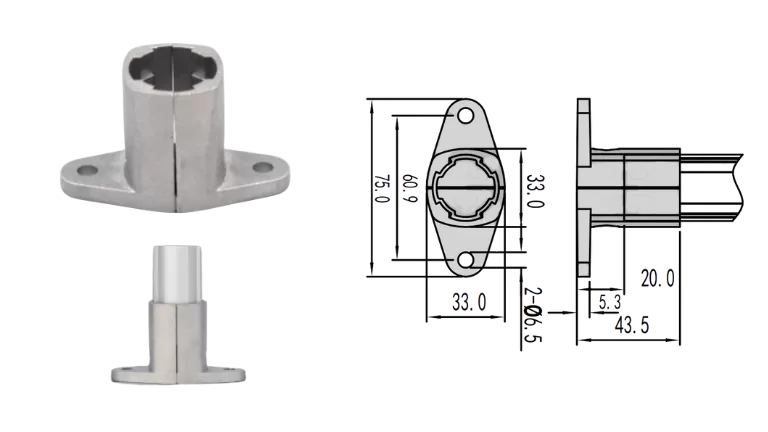

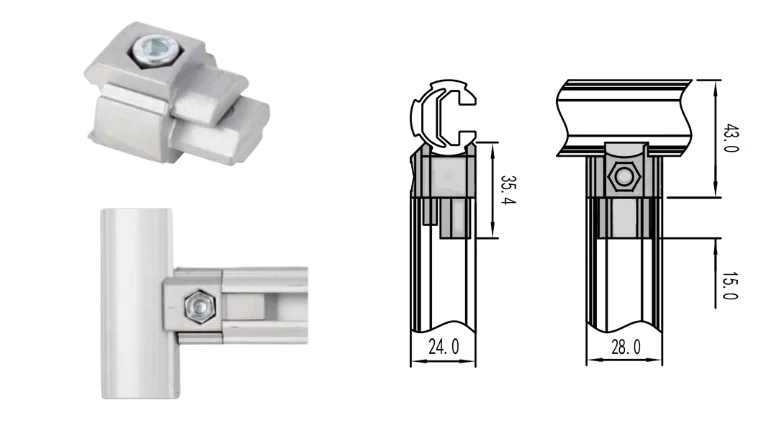

EU Profile Connector Seat

The connection joints for aluminum lean pipes with the 40 European standard profile series are more secure compared to fixed connections.

Inner Straight Connector

The basic internal joint of the aluminum lean pipe at a 90° angle is suitable for situations where appearance is important, although its load-bearing capacity is lower compared to external joints.

1.2 Inner Straight Connector

The specialized internal joint for the 90° structure of the 1.2 basic line pipe cannot be used with other generations of lean pipes.

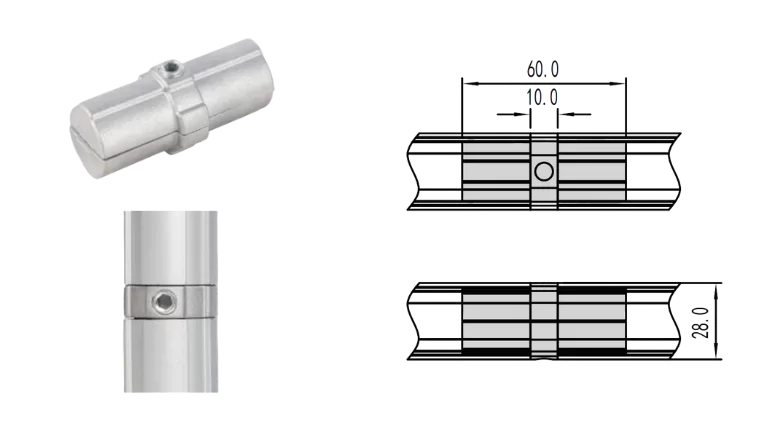

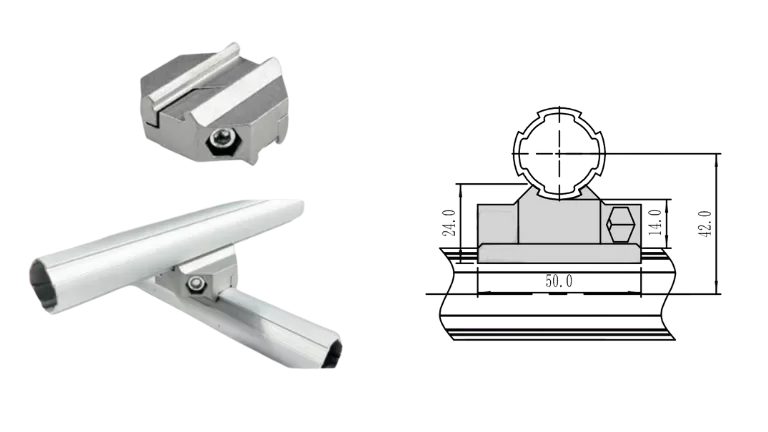

Aluminum Pipe Extension Connectors

The joint for extending the hollow aluminum pipe connects by inserting the joint into the end of the pipe and securing it with screws or clamps to ensure a stable connection and extend the pipe.

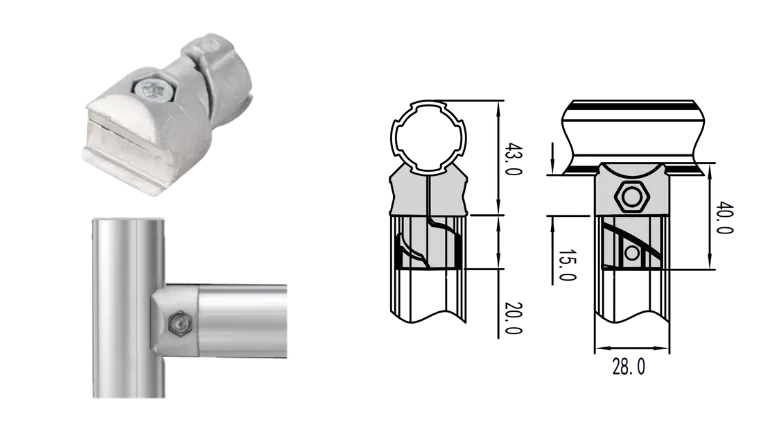

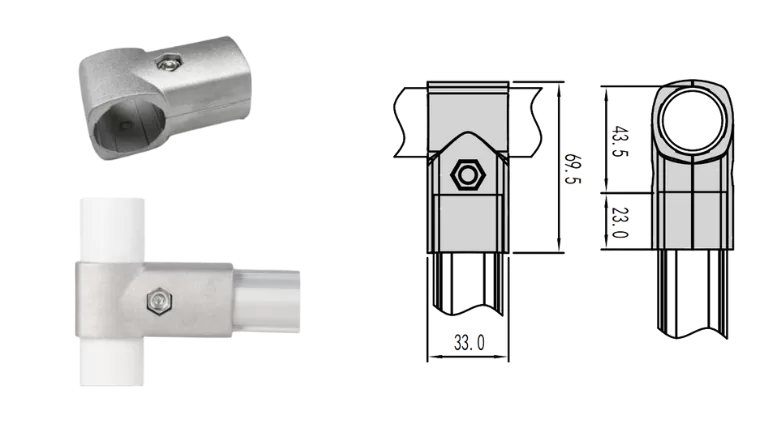

T-shaped Pipe Inner Straight

The basic internal joint for the 90° T-slot rail connects by inserting the joint into the end of the rail and securing it with screws. This method ensures a strong connection for assembling T-slot rails.

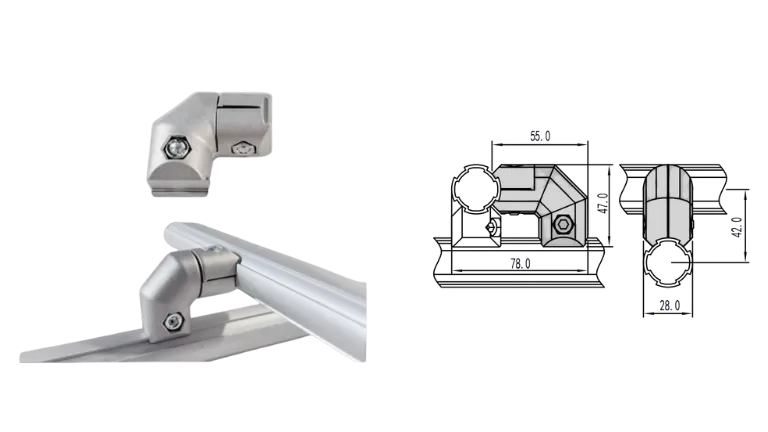

Outer Embrace Straight A

Connecting aluminum lean pipes to first and second-generation lean pipes with a 90° connector is easy. Just insert the ends of both pipes into the connector and tighten the screws to secure them.

Outer Embrace Straight B

The basic internal joint for the 90° T-slot rail connects by inserting the joint into the end of the rail and securing it with screws.

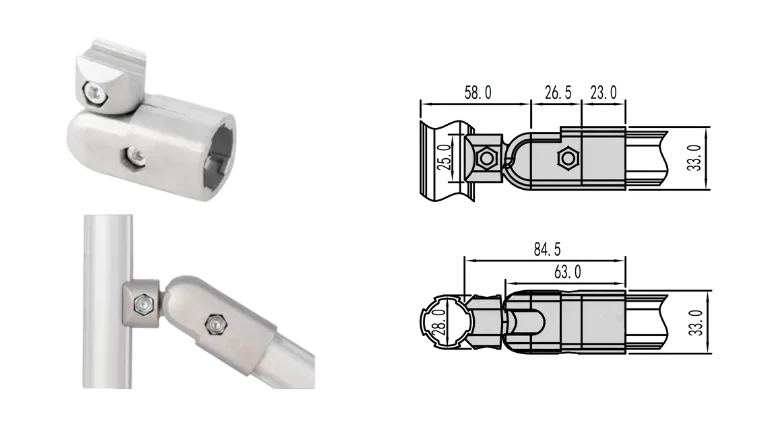

Rotating Connection of Lean Pipe Connectors

A rotating connection offers flexibility by allowing connected parts to rotate freely around the connection point. This method usually uses special aluminum lean pipe connectors, enabling parts to be adjusted or moved without compromising the overall stability of the structure. Rotating connections can support various angles, including 45 degrees, 90 degrees, 135 degrees, and 180 degrees, making them suitable for different applications.

Strengthen Outer Straight Connector

The basic external joint of the aluminum lean pipe has a 90° structure and can connect with the line rod in four different directions.

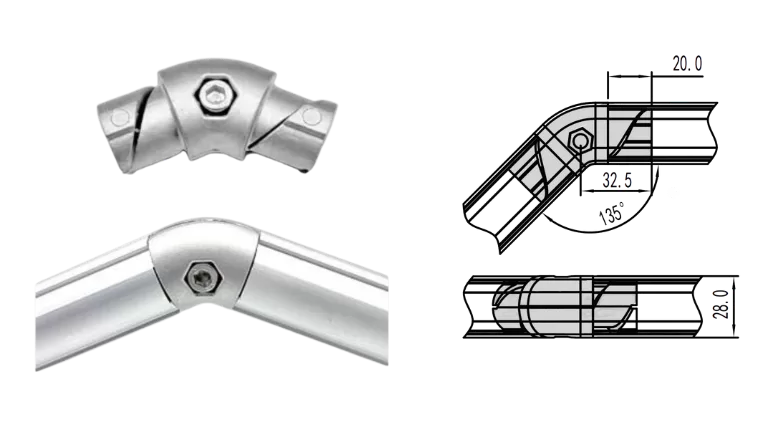

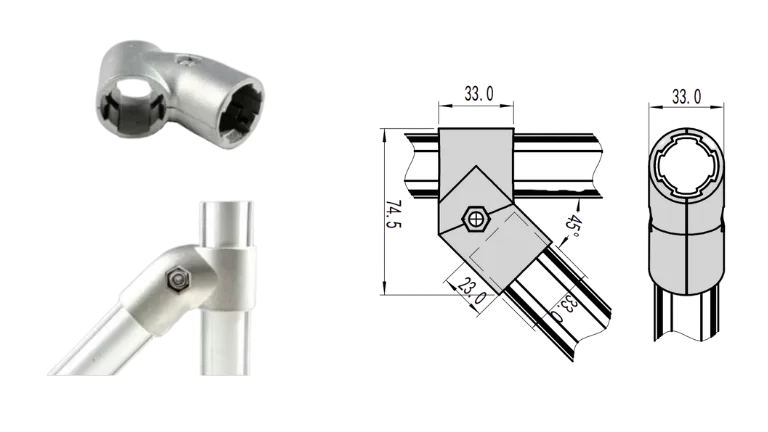

135 ° Outer Straight

The 135° external joint of the aluminum lean pipe is used for connecting two pipes at a specific angle.

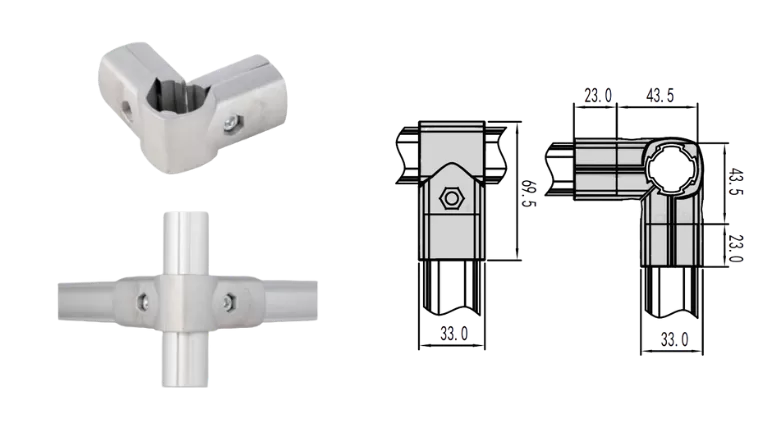

90 ° Cross Connector

The cross connection of aluminum lean pipes uses special fittings to connect multiple pipes at one point.

90° Cross Reinforcing Connector A

After connecting aluminum lean pipes in a cross shape, reinforced joints can be used to increase stability. This helps prevent the pipes from shifting and improves the overall safety of the structure.

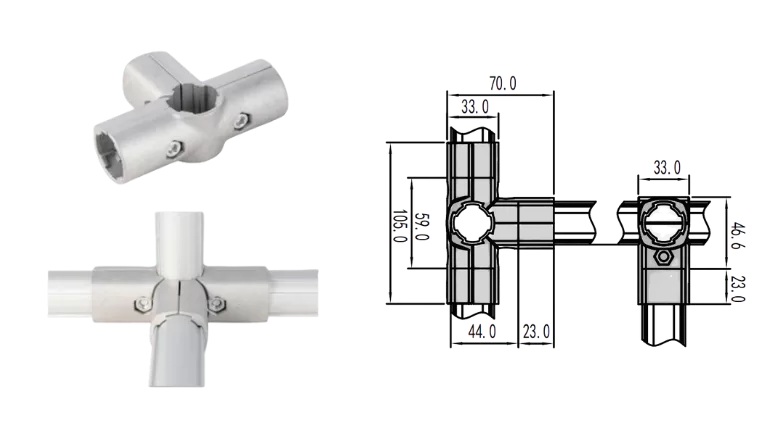

90° Cross Reinforcing Connector B

On the basis of the 90° cross connector, the strength has been increased, while both have the same pipe center installation dimensions.

180 ° Fixed Outer Connector

The reinforced joint of the aluminum lean pipe features a 180° adjustable angle structure, suitable for structural designs at any angle in another direction. Once tightened with screws, the angle is fixed in place.

180 ° Fixed Outer

The connection joint of the aluminum lean pipe with a 180° adjustable angle structure secures the angle in place once the screws are tightened.

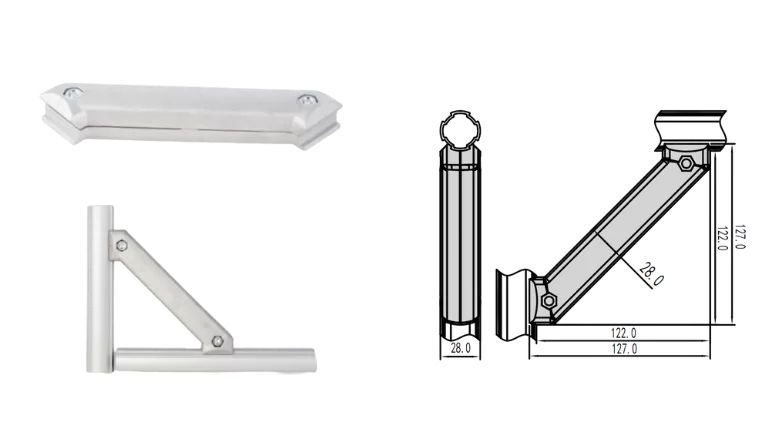

45 ° Strengthen Outer Connector

The reinforced joint of the aluminum lean pipe with a 90° L-angle structure is used for strengthening connections at right angles or vertical surfaces.

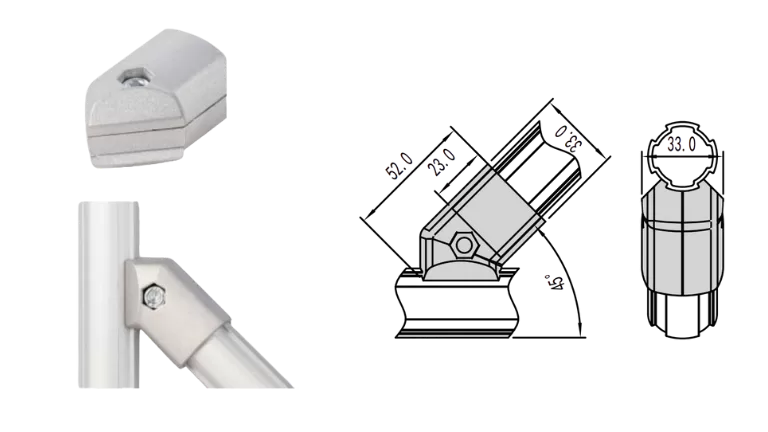

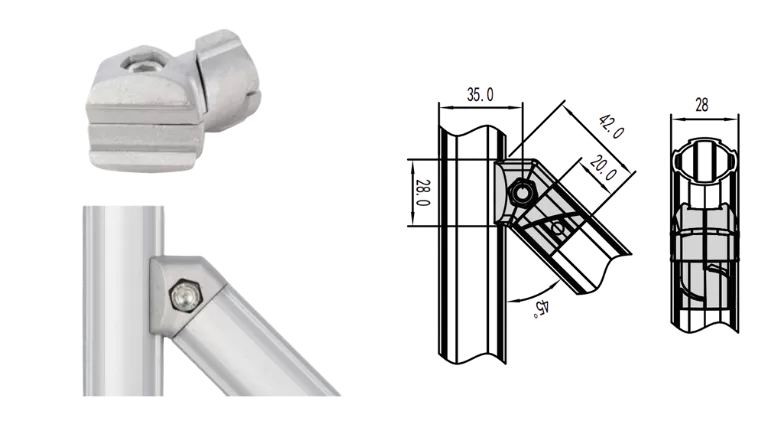

45 ° Outer Connector

The basic external joint of the aluminum lean pipe with a 45° structure is used for reinforcing connections at right angles or vertical surfaces.

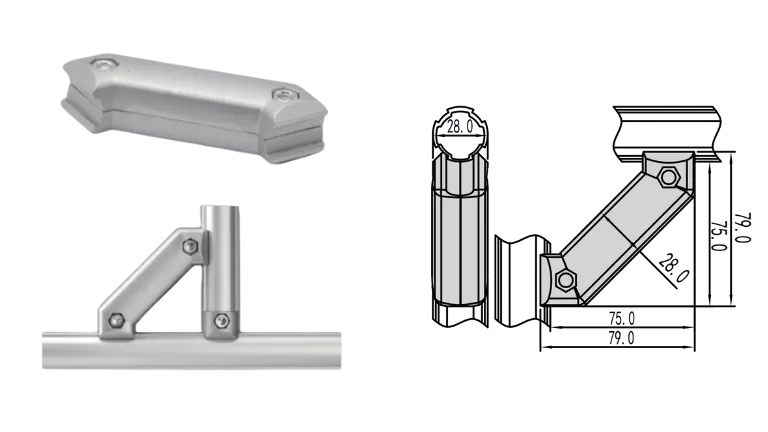

45 ° Strengthen Long Outer Connector

The elongated reinforced joint of the aluminum lean pipe with a 90° L-angle structure is used for strengthening connections at right angles or vertical surfaces and is also compatible with the 43 series.

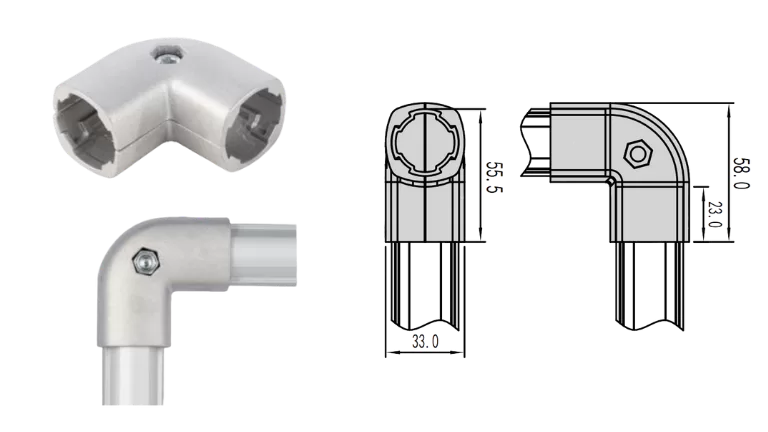

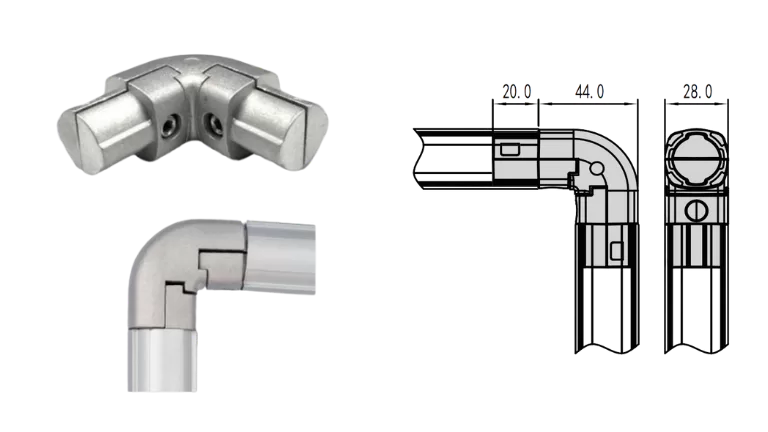

90 °Outer Connector

The external connecting joint of the aluminum lean pipe features an L-shaped 90° structure, designed to facilitate connections at right angles while ensuring structural integrity and stability.

90 ° Right Angle Fixed Connector

To install the 90° corner joint for aluminum lean pipes, insert the ends of the pipes into the openings of the joint at the desired angle. Then, secure the joint to ensure that the connection is strong and stable.

Parallel Movable Connector

The main structure of the aluminum lean pipe needs to be equipped with pulleys or other M6 threaded accessories.

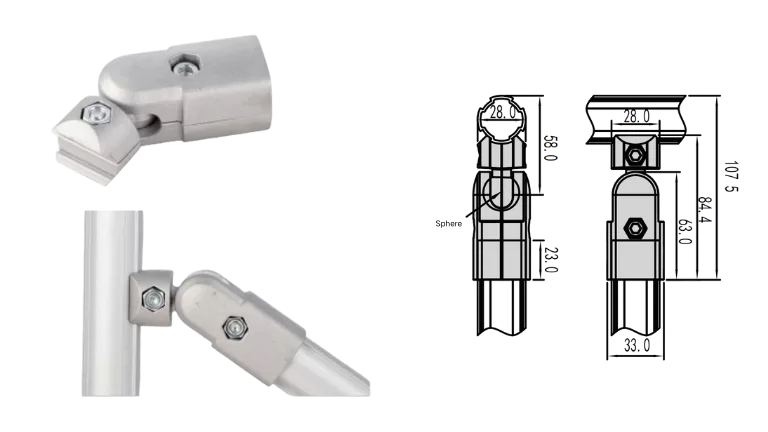

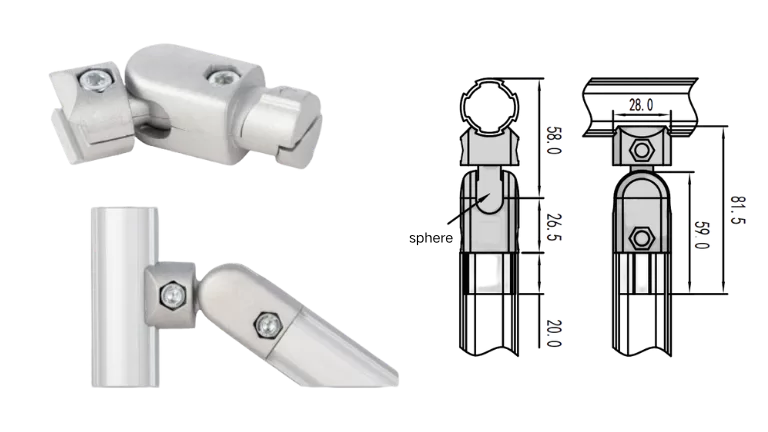

Internal Straight Rotating Connector

The aluminum lean pipe connector has a rotating design that allows it to reach the necessary angle for connecting horizontal lean pipes. Once tightened, it maintains a fixed position.

Strengthening The Inner Straight

The reinforced inner connector of the 90 ° aluminum lean pipe structure enhances its load-bearing capacity.

135 ° Inner Connector

The connection method for the aluminum pipe 135° internal joint is to insert the joint into one end of the pipe and secure it with screws. Make sure it's tight, then adjust the angle of the pipe as needed.

180 ° Fixed Inner Connector

The built-in connector of the 180° adjustable structure for lean pipes allows for design flexibility at any angle in another direction. Once tightened with screws, it securely holds the angle in place.

45 ° Inner Connector

The built-in connector of aluminum lean pipe 45 °structure is used for strengthening connections at right angles or elevations.

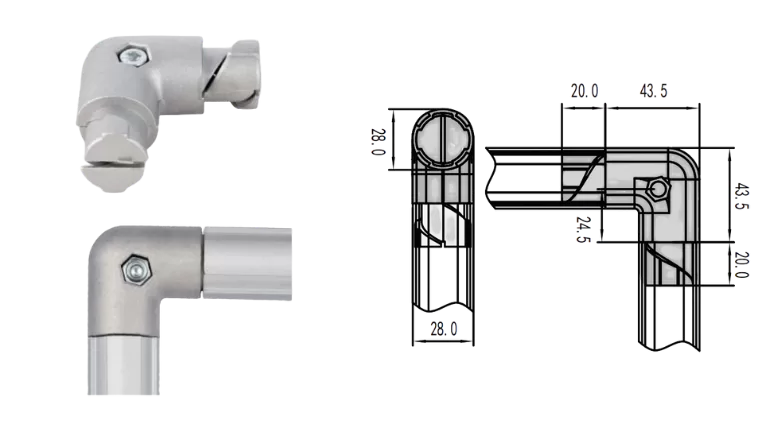

90 ° Inner Connector A

The L-shaped 90° internal connector for aluminum lean pipes allows right-angle connections. Insert two pipe sections and tighten them to create a strong L-shaped structure.

90 ° Inner Connector B

The L-shaped 90° internal connector for aluminum lean pipes only requires tightening one screw, making it more convenient compared to the standard 90° connector.

Outer Embrace Straight Connector

It is used to strengthen connections at a variable angle of 180°. The design includes a shaft sleeve in the middle to increase the locking surface.

External 45° Connector

45° reinforced connections for right angles or facades increase vertical strength by about 1.5 times compared to 45° external connections.

90° External Connector With A Flange

Aluminum lean pipe construction for a special connector for turtle cars. Connect the aluminum lean pipe to the special connector, then fasten it with screws or clamps to ensure a stable connection.

90 ° Movable Outer Connector

The basic outer connector of the aluminum lean pipe with a 90° structure can still rotate 90° even after the screw is locked.

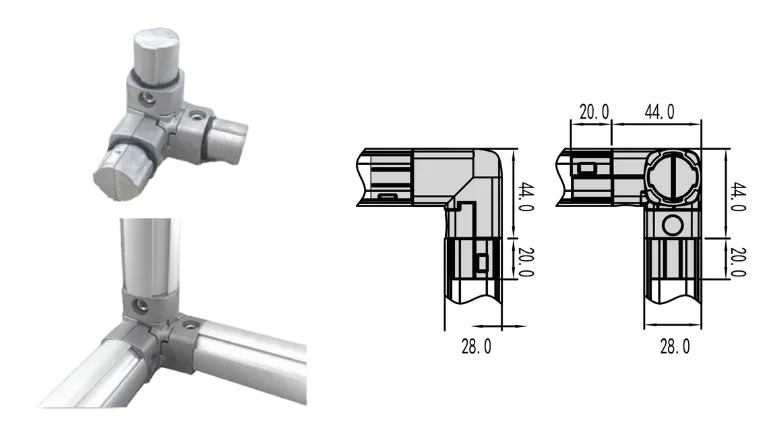

Tee Connection of Lean Pipe Connectors

A tee connection involves connecting three aluminum lean pipes together to form a “Y” shape, commonly used for distributing fluids or forces. This connection method is achieved using specialized tee aluminum lean pipe connectors, allowing three pipes to connect at one point and ensuring effective distribution of fluids or forces. The design of tee connections makes the system more flexible in layout, meeting various functional needs and making them an essential part of many complex systems.

Tee Corner Inner Connector

The aluminum lean pipe's angle tee connector uses an insertion method for connection. First, insert one end of the pipe into the opening of the tee, making sure it fits snugly. Once it's in place, tighten it to secure the connection, enhancing the appearance of the corner and ensuring the overall stability of the structure.

Outer Embrace L-shaped Connector

The L-shaped reinforced external connector for aluminum lean pipes is used for building heavy products. To connect, insert the ends of the pipes into the sides of the connector, then tighten the screws to secure them.

Outer Embrace T-shaped Connector

The T-shaped external reinforced connector for aluminum lean pipes is used for building heavy products. To connect, insert the ends of the straight pipes into the sides of the connector, then insert the crossing pipe into the middle part, and finally tighten the screws to secure everything.

Outer Embrace Straight Connector

The straight reinforced external connector for aluminum lean pipes is used for building heavy products. To connect, insert the ends of the pipes into the sides of the connector, and then tighten the screws to secure them.