Aluminum Hung Window

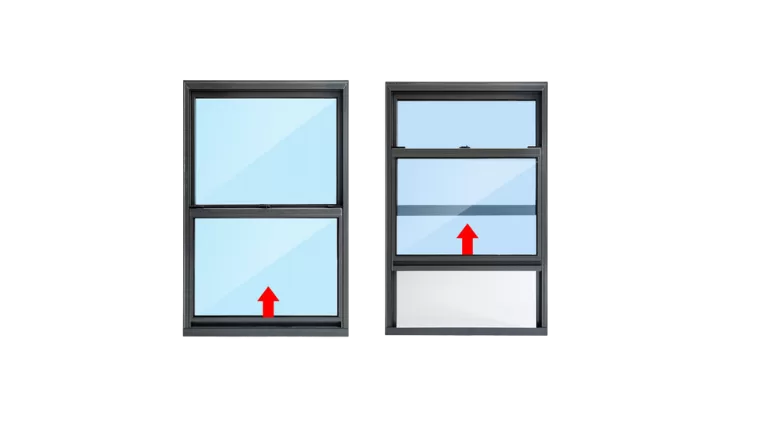

Aluminum Hung Windows are a type of window with a vertical sliding mechanism, made with aluminum frames and glass panels. They come in two styles: Single-Hung Windows, where only the bottom sash slides, and Double-Hung Windows, where both sashes can move. Known for their ease of use, durability, and simple design, they are widely used in homes, commercial buildings, and public spaces, especially in modern architectural styles.

A key advantage of aluminum hung windows is their efficient use of space. The vertical sliding design means no outward space is needed, unlike casement windows, making them ideal for areas where space in front of the window is limited.

Features

Efficient Space Use: The vertical sliding design doesn’t need extra space for opening, making it perfect for areas with limited front clearance.

Good Ventilation: Double-hung windows provide excellent airflow by allowing both sashes to move, while single-hung windows offer basic ventilation with the lower sash.

Durable and Long-Lasting: Built with aluminum frames, they resist rust and corrosion, making them great for humid or coastal areas.

Easy to Maintain: The smooth aluminum surface is easy to clean and doesn’t easily deform or age, ensuring long-term use.

Lightweight and Strong: Aluminum is light yet strong, ideal for larger windows while maintaining durability.

Modern Look: The clean and simple design fits well with modern architecture and enhances a building’s appearance.

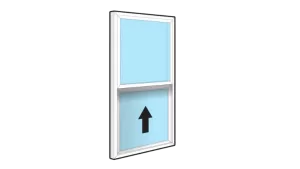

Single-Hung Windows

Single-hung windows feature a design where only the bottom sash is operational, while the top sash remains fixed in place. This structure makes them simpler in functionality, and they are often more affordable compared to double-hung windows. Single-hung windows are frequently used in homes, apartments, and commercial spaces where basic ventilation is sufficient. Additionally, because fewer moving parts are involved, single-hung windows tend to have lower maintenance requirements and a longer lifespan.

Single-hung windows feature a design where only the bottom sash is operational, while the top sash remains fixed in place. This structure makes them simpler in functionality, and they are often more affordable compared to double-hung windows. Single-hung windows are frequently used in homes, apartments, and commercial spaces where basic ventilation is sufficient. Additionally, because fewer moving parts are involved, single-hung windows tend to have lower maintenance requirements and a longer lifespan.

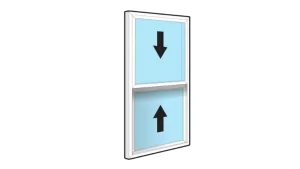

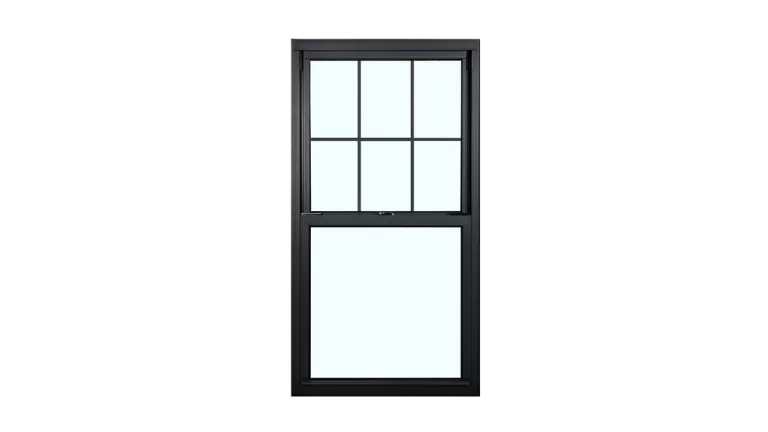

Double-Hung Windows

Double-hung windows are more versatile, allowing both the top and bottom sashes to slide vertically. This dual-sash functionality promotes better ventilation, providing options for air circulation from either the top, bottom, or both simultaneously. This makes them a preferred choice in areas where enhanced airflow control is needed. These windows are also easier to clean, as both sashes can typically tilt inward, making the exterior accessible from inside the building. Their flexibility, combined with modern design, makes them suitable for residential homes, commercial properties, and public spaces.

Double-hung windows are more versatile, allowing both the top and bottom sashes to slide vertically. This dual-sash functionality promotes better ventilation, providing options for air circulation from either the top, bottom, or both simultaneously. This makes them a preferred choice in areas where enhanced airflow control is needed. These windows are also easier to clean, as both sashes can typically tilt inward, making the exterior accessible from inside the building. Their flexibility, combined with modern design, makes them suitable for residential homes, commercial properties, and public spaces.

Residential Aluminum Hung Windows

Bedrooms and Living Rooms:

Single-hung windows are commonly used in bedrooms where moderate ventilation is sufficient. Double-hung windows are often chosen for living rooms to ensure better airflow and a supply of fresh air for communal spaces.

Basements:

Aluminum hung windows are ideal for basements as they effectively block surface water while providing basic lighting and ventilation. Their compact design also fits well in limited spaces typically found in basement settings.

Commercial Hung Windows

Offices, Shopping Malls, and Restrooms:

In commercial spaces, double-hung windows are frequently used for side windows or restroom ventilation. They provide excellent airflow, are easy to clean, and save space on building facades. Their durable design and sleek appearance make them a practical and aesthetic choice for professional environments.

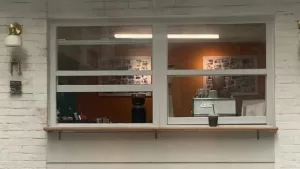

Food Trucks and Mobile Vendor Stalls:

Aluminum hung windows are also used as service windows in food trucks and mobile vending vehicles. Their sliding operation is space-efficient, allowing the windows to open easily for serving customers without interfering with the vehicle or surrounding areas.

Structural of Aluminum Hung Windows

Aluminum hung windows are designed for durability, functionality, and aesthetic appeal. The main structural components of these windows include:

1. Window Frame and Window Sash

- Constructed from high-strength aluminum alloy material for enhanced durability and stability.

- The aluminum frame section is treated with anodizing, electrophoretic coating, or powder coating to increase corrosion resistance and extend lifespan.

2. Sliding Track

- The window operation relies on a vertically installed sliding track system.

- The window sash moves freely up and down along the track, ensuring a smooth and controlled motion.

3. Balance Mechanism

- Equipped with a spring or pulley balancing system to ensure the sash moves smoothly and remains stable during operation.

- Provides safety and ease of use by preventing sudden movements.

4. Glass Panel

- Available glass options include:

- Ordinary Glass: Standard performance.

- Insulated Glass (Double Glazed): Enhances thermal and acoustic insulation.

- Laminated Glass: Provides added safety and soundproofing.

- These options allow customization to meet specific requirements for thermal insulation, soundproofing, and safety.

5. Sealing System

- Features high-quality sealing strips and waterproof designs to provide excellent protection against wind and rain when closed.

- Ensures enhanced air tightness and water tightness for interior comfort.

Specifications of Aluminum Hung Windows

Aluminum hung windows combine practicality, durability, and versatility, making them a popular choice for both residential and commercial buildings. Their customizable sizes and varied glass options allow them to adapt to different architectural designs and functional requirements. Below are the key specifications commonly used:

Window Dimensions:

- Width: 600mm ~ 1800mm

- Height: 1000mm ~ 2400mm

Glass Types:

- Single Glass: 5mm ~ 6mm, suitable for basic applications.

- Insulated Glass: 5+12A+5 mm or 6+15A+6 mm, offering better thermal and sound insulation.

- Laminated Glass: 5+0.76PVB+5 mm, providing enhanced safety and noise reduction.

Material Selection for Aluminum Hung Windows

The choice of materials and surface treatment significantly impacts the performance, durability, and aesthetics of aluminum hung windows. Below are the details of the materials and finishing options commonly used:

Aluminum Alloy Grades

- 6063 Aluminum Alloy:

Known for its excellent corrosion resistance, lightweight nature, and good mechanical properties, this grade is widely used in constructing aluminum window frames, offering durability and ease of fabrication. - 6061 Aluminum Alloy:

A stronger and more robust option, this alloy is highly resistant to wear and tear, making it suitable for applications requiring higher strength and durability.

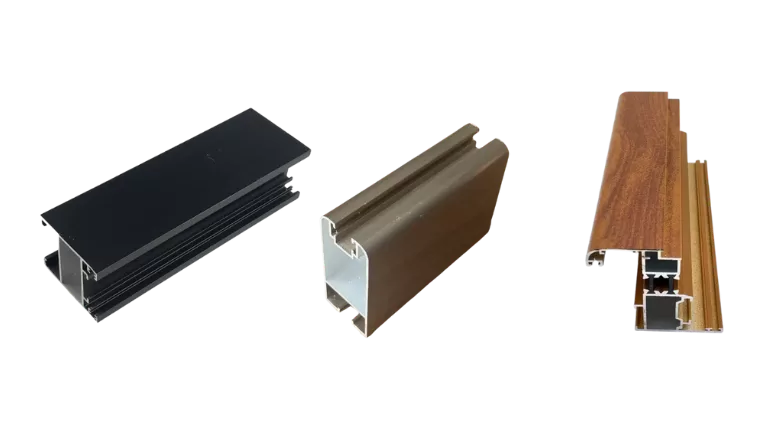

Surface Treatment

Advanced surface treatment techniques are applied to enhance the appearance and corrosion resistance of aluminum hung windows. These include:

Anodizing

Creates a corrosion-resistant and long-lasting protective layer with a smooth metallic finish. Ideal for modern aesthetics.Electrophoresis Coating (E-Coating)

Enhances durability while delivering bright, smooth surfaces with uniform color. Commonly used for premium-grade windows.Powder Coating

Offers a wide range of color options with a durable, weather-resistant finish that is both decorative and protective.Wood Grain Transfer Printing

Provides a natural wood-like appearance (e.g., maple, walnut) with the strength and durability of aluminum, achieving a warm and sophisticated look ideal for residential and commercial applications.

Color Choices

- Natural Shades: Silver-gray, white

- Modern Shades: Black, deep gray

- Wood Textures: Maple, walnut

Performance Indicators of Aluminum Hung Windows

Aluminum hung windows are designed to meet high standards of functionality and durability, with excellent physical and thermal performance. The following are the key performance indicators:

Air Tightness:

Conforms to national Level 6 standards, effectively preventing air infiltration and ensuring energy efficiency.

Water Tightness:

Can withstand water pressures of approximately 300Pa ~ 700Pa, preventing rainwater from entering indoor spaces.

Wind Pressure Resistance:

Rated at ≥2000Pa, making these windows ideal for high-rise buildings and areas prone to strong winds.

Soundproofing:

Provides noise reduction of 30 dB ~ 45 dB, depending on the glass type, ensuring a quieter indoor environment.

Thermal Insulation:

Utilizing thermal break aluminum frames combined with insulated glass, the U-value (thermal transmittance) can be reduced to below 2.5 W/(m²·K), significantly improving energy efficiency.

Custom Window Manufacturing Services

Our Window & Door Division specializes in global customization of high-quality windows, including glass integration. We support a wide range of window types to meet diverse architectural needs:

Available Window Styles

- Sliding Windows

- Casement (Awning/Crank-out) Windows

- Top-Hung & Bottom-Hung Windows

- Tilt & Turn Windows

- Double-Hung & Single-Hung Windows

- Lift & Slide Windows

- Folding Window

- Fixed Windows

Customization Process

Provide Design Details:

- Submit technical drawings or specify frame dimensions (width/height/depth).

- Indicate operational type (e.g., sliding, casement).

Surface Treatment Options:

- Anodizing (silver, bronze, black)

- Powder Coating (RAL/color-matching)

- Wood Grain Transfer

- PVDF Fluorocarbon Coating

Glass Integration:

- Double/triple glazing, tempered, Low-E, laminated, or decorative glass.

Our Factory

Our factory is equipped with 40 extrusion production lines to efficiently manufacture aluminum profile. We have one anodizing and electrophoresis line, along with two vertical spraying machines and two horizontal spraying machines for surface treatment. Additionally, we operate two sandblasting machines and six wood grain transfer printing lines, enabling us to provide various aesthetic finishes. To support our production, we also have furnaces for casting aluminum bars, aging furnaces, annealing furnaces, water cooling treatment equipment, and machining equipment, ensuring comprehensive capabilities for high-quality output.

Vinyl (uPVC) vs. Aluminum Windows Comparison

PVC is a polymer material, while aluminum is a metal. PVC is lighter, with only half the density of aluminum. It also performs better in soundproofing and thermal insulation compared to standard aluminum, though aluminum can be improved with thermal break technology. Both materials are corrosion-resistant, but like other plastics, PVC is prone to aging over time. In terms of cost, PVC is more affordable than aluminum, making it a budget-friendly choice for many projects.

| Feature | Vinyl (uPVC) Windows | Aluminum Windows |

|---|---|---|

| Energy Efficiency | Excellent thermal insulation due to low conductivity and multi-chamber design. | Requires thermal break technology to match vinyl’s insulation, otherwise conducts heat easily. |

| Durability | Lifespan of 15–20 years; prone to degradation under prolonged sun or extreme cold. | Long-lasting (40–50 years); resistant to UV, corrosion, and harsh weather. |

| Aesthetics | Available in various colors and wood grain finishes, but lacks the refined, modern appeal of metal. | Sleek, narrow profiles with diverse finishes like brushed, matte, or textured; highly customizable. |

| Soundproofing | Naturally soundproof due to sealed, multi-chamber construction. | Slightly less soundproof; advanced sealing and upgraded glazing improve performance. |

| Cost | Budget-friendly with low initial cost and better energy saving. | Higher material and manufacturing costs, especially with thermal break technology. |

| Maintenance | Low maintenance, but may yellow or fade over time. | Resistant to aging; can be repainted after fading for a refreshed look. |

| Best Applications | Ideal for residential homes, energy efficiency, and quiet environments. | Perfect for modern designs, durability in extreme climates, and large, open spaces. |