Custom Precision Extruded Aluminum Extendable Tube

As a specialized Chinese manufacturer, we offer complete solutions for custom aluminum extendable tubes, from mold development to finishing and machining, ensuring high quality and reliability for your needs.

- Custom Mold Development: We design and develop molds to produce aluminum extendable tubes in any shape you need.

- Advanced Extrusion: Our modern extrusion process ensures precise, strong, and smooth tubes for complex applications.

- Multiple Surface Finishes: Options include anodizing, electrophoresis, or powder coating for superior protection and appearance.

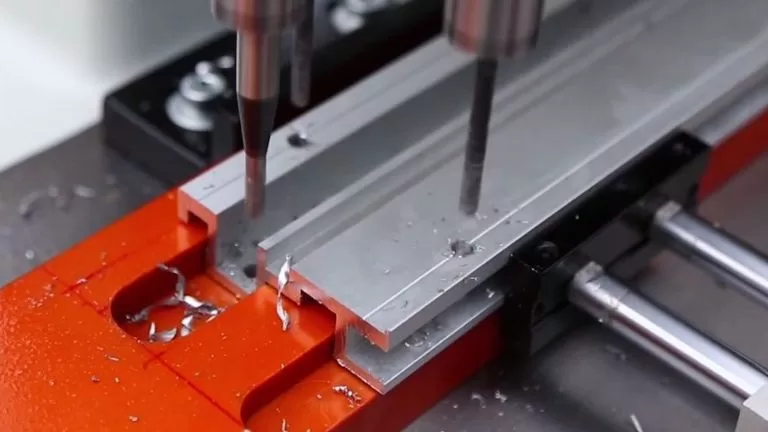

- Precision Machining: With advanced CNC equipment, we deliver accurate cutting, drilling, and threading to meet your requirements.

Aluminum Extendable Tube

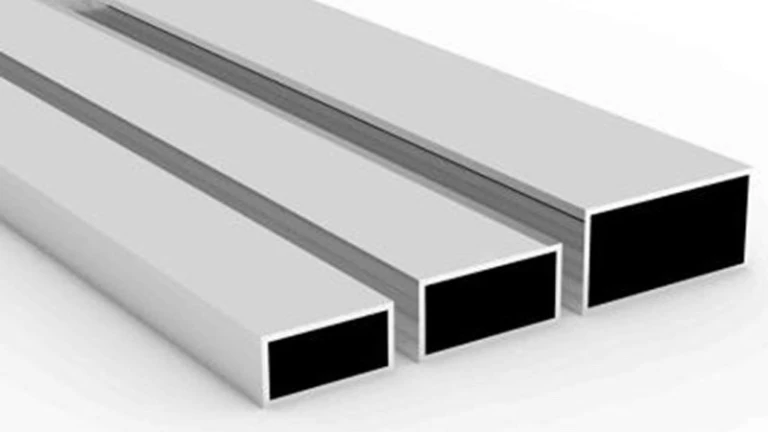

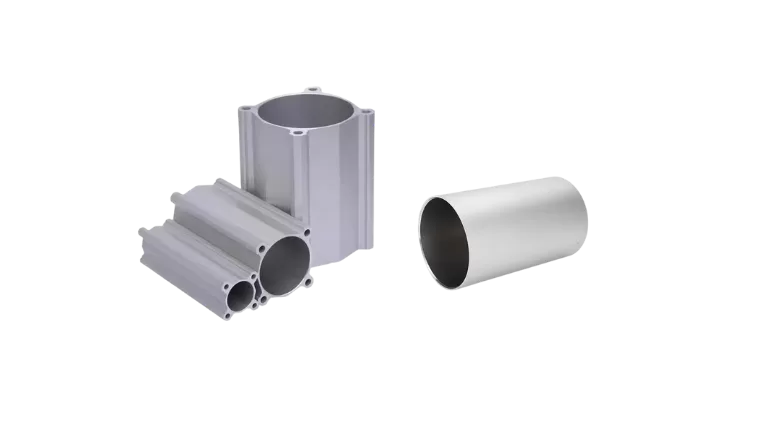

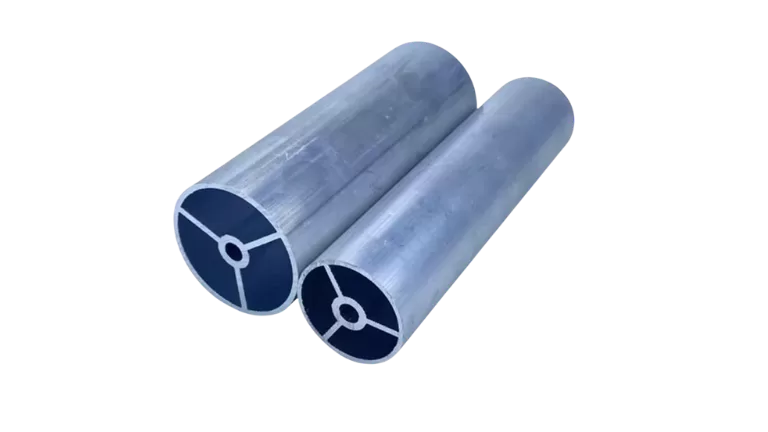

We specialize in making custom aluminum extendable tubes for a wide range of uses, including construction, electronics, and outdoor gear. Our product range includes extendable square tubes, extendable round tubes, custom-shaped tubes, and lockable extendable tubes to meet various functional needs. Made from high-quality 6061 and 6063 aluminum alloys, our tubes offer strength and durability. With advanced extrusion technology, every tube is produced with precise dimensions. We provide surface finishes like anodizing and powder coating to match different styles and requirements. Dedicated to quality and reliable service, we strive to be your trusted partner for all your aluminum extendable tube needs.

Extendable Tube Specifications

| Item | Specification |

|---|---|

| Material | Aluminum alloy (6061/6063) |

| Size | Outer Diameter: 3-250mm; Thickness: 0.3-50mm |

| Shape | Circular or Rectangular/Customized |

| Surface Treatment | Anodizing, Powder Coating, Sand Blasting, Polishing, Wooden Finish, etc. |

| Length | 10mm - 6000mm / Customized Length |

| Machining | Drilling, Tapping, Cutting, Milling, Bending, Custom Machining |

| Packaging | Standard Export Packaging or Customized Solutions |

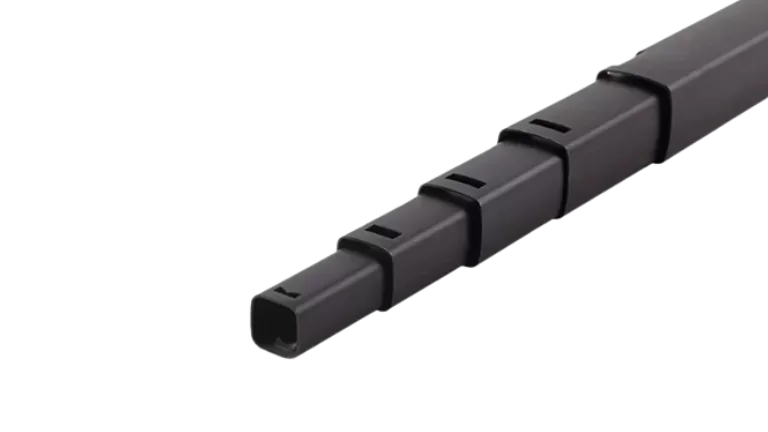

Extendable Tube Scaling Type

Straight Telescopic

Our straight extension tubes have a smooth, electroplated surface that resists rust and corrosion. They’re available in many sizes to suit your specific needs.

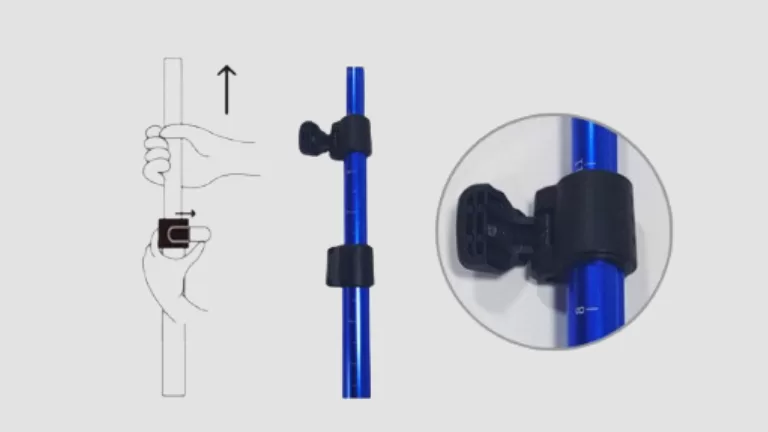

Flip Lock Telescopic

With a flip-lock system, these tubes are lightweight, easy to carry, and quick to adjust. Made with strong materials and top-quality manufacturing for reliable use.

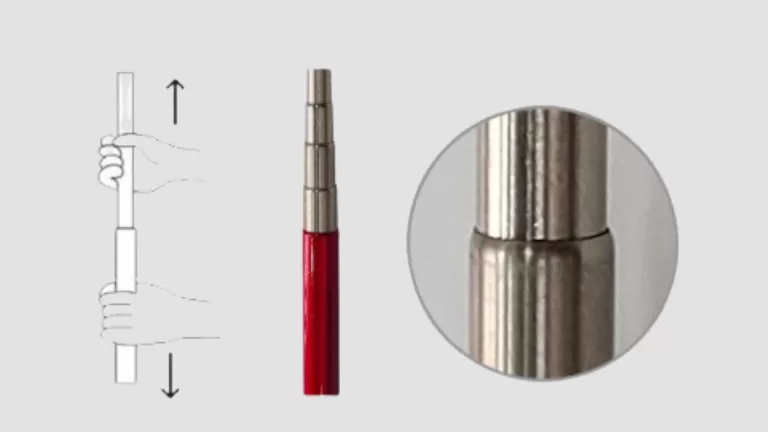

Spring-Loaded Telescopic

These feature a built-in compression spring and an easy-release mechanism, making them simple to adjust and ideal for any pole that needs to extend and retract smoothly.

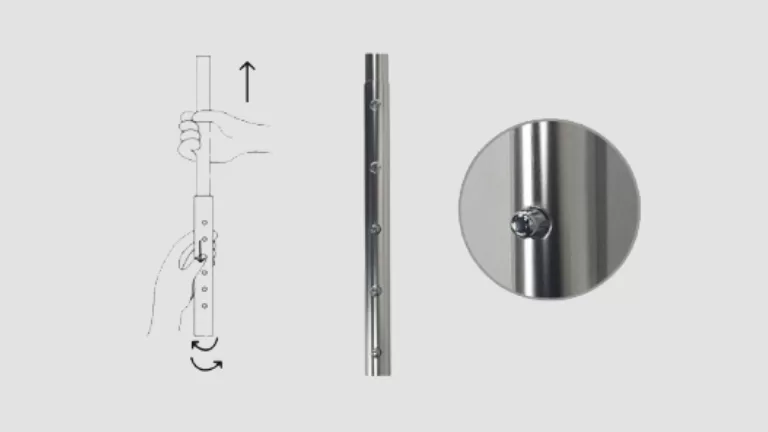

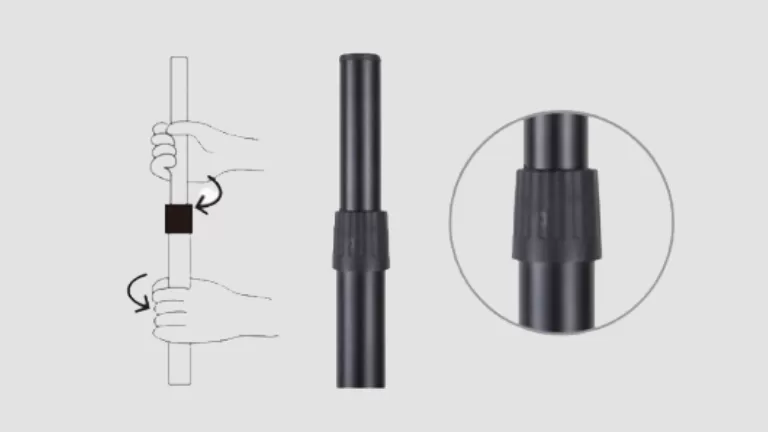

Twist-Lock Telescopic

The twist-lock design saves space and is easy to adjust, perfect for tour flags, selfie sticks, and tent poles.

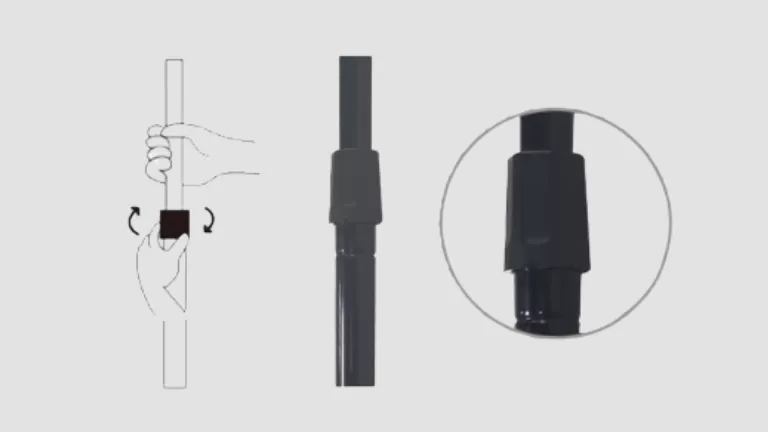

Clutch-Lock Telescopic

Ideal for industrial uses, these tubes allow for precise length adjustments. We offer a wide range at affordable prices with full support.

Custom Solutions

You can customize the length, size, color, and locking mechanism. Our professional engineers provide free design help to deliver exactly what you need.

Aluminum Extrusion for Extendable Tubing

Aluminum extendable poles are commonly made using the aluminum extrusion process. In this method, aluminum billets are heated and then forced through a customized die to create long, seamless tubes with precise dimensions. Extrusion allows for consistent wall thickness and smooth surfaces, which are essential for the telescoping function—ensuring the tubes slide smoothly and fit tightly within each other. After extrusion, the tubes can be cut to length, anodized for extra protection and appearance, and further processed as needed. We use advanced extrusion technology to produce high-quality telescopic tubes that meet your specific requirements for strength, finish, and accuracy.

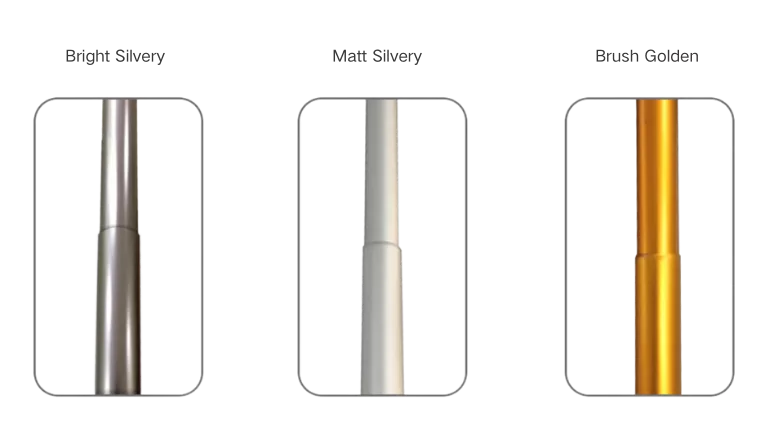

Surface Treatment for Extendable Poles

To enhance both the appearance and durability of aluminum extendable poles, we offer a variety of surface treatment options. Anodizing is the most popular method, providing a protective oxide layer that increases corrosion resistance and abrasion resistance. In addition to standard silver and natural finishes, we can provide tubes in a wide range of colors, including black, gold, blue, red, and more. Custom colors are also available upon request, allowing you to match your specific branding or design requirements. Our high-quality surface treatments ensure that the telescopic tubes not only look attractive but also maintain their performance in different environments.

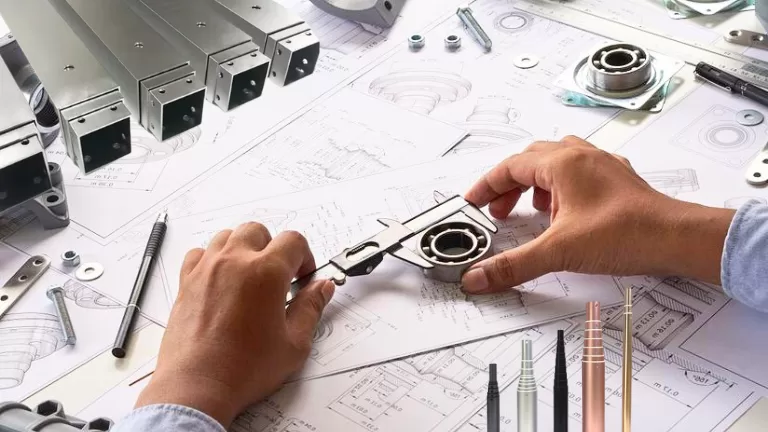

Precision Finishing for Extendable Tubing

We offer advanced precision finishing services for aluminum extendable poles using state-of-the-art CNC machining equipment. Our CNC technology ensures each tube is accurately cut, drilled, and shaped according to your specifications, resulting in tight tolerances and excellent consistency. Precision machining allows us to create custom features such as holes, slots, threads, and complex end forms, enabling seamless integration into your final products. With our expertise and high-end equipment, we guarantee high-quality finishing that meets your most demanding application requirements.

Applications of Extendable Tubing

From cutting-edge architecture to everyday home solutions, telescoping aluminum pipes are essential in many areas. In construction, they’re used for scaffolding, support systems, and temporary structures. In machinery, they act as connectors or adjustable components, boosting equipment versatility and performance. For home improvement and DIY projects, these pipes are perfect for creating adjustable storage, racks, and other custom solutions. At HTS-ALU, we offer a wide range of telescoping aluminum pipes and custom options to meet your needs. Our products are lightweight yet strong, designed to withstand tough indoor and outdoor conditions, and provide the durability and flexibility required for any project.

Features and Advantages of Extendable Poles

1. Adjustable Length: The telescoping design allows for easy extension and retraction, making it versatile for different applications and space requirements.

2. Lightweight yet Strong: Made from high-quality aluminum, these pipes provide excellent strength while remaining easy to handle and transport.

3. Corrosion Resistant: Aluminum offers natural protection against corrosion, making the pipes suitable for both indoor and outdoor environments.

4. Easy Installation: The simple structure enables quick assembly and disassembly, saving time and effort during installation or adjustments.

5. Customizable Options: Various diameters, wall thicknesses, and surface treatments are available to fit your specific needs.

6. Cost-effective: Durable and reusable, telescoping aluminum pipes provide long-term value for a wide range of uses.

RFQ of Extruded Extendable Tube

1. Aluminum Alloy 6061

- Characteristics:

- Excellent mechanical properties

- Good corrosion resistance

- Medium to high strength

- Weldable

- Benefits: Versatile and widely used in structural applications, offering good fatigue resistance and ease of fabrication.

2. Aluminum Alloy 6063

- Characteristics:

- Good corrosion resistance

- Excellent extrudability and finishing

- Lower strength compared to 6061

- Benefits: Ideal for architectural applications and situations requiring aesthetic appeal, such as window frames and custom shapes.

3. Aluminum Alloy 6082

- Characteristics:

- High strength and good corrosion resistance

- Good weldability

- Excellent machinability

- Benefits: Suitable for heavy-duty applications, including structural components in buildings and bridges.

4. Aluminum Alloy 5052

- Characteristics:

- Good corrosion resistance, especially in marine environments

- Excellent workability and weldability

- Moderate strength

- Benefits: Commonly used in applications where the material may be exposed to harsh conditions, such as fuel tanks and pressure vessels.

5. Aluminum Alloy 5005

- Characteristics:

- Good corrosion resistance

- Excellent anodizing properties

- Moderate strength

- Benefits: Often used for decorative applications and architectural features due to its surface finishing capabilities.

6. Aluminum Alloy 2024

- Characteristics:

- High strength-to-weight ratio

- Good fatigue resistance

- Less corrosion resistant compared to other alloys

- Benefits: Frequently used in aerospace applications and other high-stress environments, where strength is critical.

7. Aluminum Alloy 7075

- Characteristics:

- Very high strength

- Lower corrosion resistance

- Heat-treatable

- Benefits: Ideal for aerospace and military applications, where maximum strength is required.

1. Daily Cleaning: Wipe with a damp cloth; avoid using steel wool (to protect the anodized layer).

2. After Exposure to Extreme Environments: Rinse with a neutral cleaner after exposure to coastal or dusty environments, then dry and apply a thin layer of lubricant (silicone oil preferred).

3. Long-Term Storage: Collapse to the shortest state to avoid prolonged pressure from gravity, which can lead to metal fatigue.

The heat treatment of aluminum extrusions determines their mechanical properties, strength, and suitability for specific applications. Among the various heat treatment methods, T5, T6, and T66 are the most commonly used. Here’s an in-depth look:

| Heat Treatment State | Cooling Method | Strength | Key Features and Benefits | Applications |

|---|---|---|---|---|

| T5 | Air cooling (fan) | Moderate | Adequate strength, good dimensional stability, used for architectural purposes. | Windows, doors, curtain walls, building structures. |

| T6 | Water quenching (fast) | High | Higher strength and hardness, ideal for industrial and structural uses. | Automotive, aerospace, machinery, transport parts. |

| T66 | Water quenching (fast) | Very high | Optimized mechanical properties for higher strength and performance demands. | Automotive, rail transportation, high-end machinery. |

Other Heat Treatment States

- T4: Solution heat-treated and naturally aged. Used in applications requiring intermediate strength and enhanced formability.

- T7: Overaged for better stress-corrosion resistance, often used for aerospace and marine purposes.

- O (Annealed): Very soft condition suitable for extensive forming or bending requirements.

- F (As-Fabricated): No heat treatment applied, used in non-critical applications with low strength requirements.

. Anodizing (Oxidation)

- Common Colors:

Natural silver

Black

Champagne

Light bronze

Dark bronze

Gold

2. Electrophoresis Coating (E-Coating)

- Common Colors:

Black

Champagne

Light bronze

Dark bronze

Custom metallic colors

3. Powder Coating

- Colors:

Can match any color based on the RAL color chart.

Offers textures like matte, gloss, satin, and custom finishes.

4. PVDF Coating (Polyvinylidene Fluoride)

- Colors:

Also customizable using the RAL color chart.

High-end finishes with matte or glossy effects.

5. Wood Grain Transfer Printing

- Colors and Patterns:

Mimics various wood types (e.g., oak, walnut, teak, mahogany).

Custom patterns available based on provided samples.

6. Film Lamination

- Colors and Patterns:

Includes textures like marble, leather, and solid colors.

Custom finishes and patterns based on provided samples.

Pre-Treatment Options (Impact on Final Color)

- Brushing/Polishing: Produces smooth or reflective metallic surfaces.

- Sandblasting: Adds a rough, matte texture before the final surface treatment.

Mold fees are an essential part of the custom aluminum extrusion process. Since every order requires a uniquely designed mold tailored to specific requirements, these molds cannot be used for other products. Therefore, the mold fee is necessary and non-negotiable.

We require 100% upfront payment of the mold fee before mold development begins to ensure timely production. However, as a token of appreciation for your support, we offer a refund of the mold fee or equivalent discounts once the order reaches a certain production volume. Specific policies can be discussed based on your order volume and collaboration details.

Mold production typically takes 7 days. After the sample is confirmed, producing a full container load of 26 tons generally requires 14 days for extrusion alone. If surface treatment is required, an additional 3 days will be needed. For machining, extra time will be required depending on the complexity and volume of the machining work. The exact additional time for machining will be determined based on the specific processing requirements.

Aluminum profiles are naturally corrosion-resistant due to the formation of a thin, protective oxide layer when exposed to air or water. This oxide layer is stable and self-repairing, meaning that even if the surface is scratched or cut (such as at exposed ends or during processing), the aluminum will not rust or corrode like iron or steel. Instead, the exposed areas will quickly form a new oxide layer, providing continuous protection against further oxidation.

With proper design, installation, and maintenance, aluminum profiles can last for decades, even in challenging environments. For example, untreated aluminum can easily withstand 20-30 years in outdoor applications, while profiles with surface treatments like anodizing or powder coating can last even longer, often exceeding 50 years. This makes aluminum an excellent choice for applications where durability and long-term performance are essential.

The price of aluminum profiles consists of several components: raw material costs, extrusion processing fees, surface treatment fees, machining costs, and additional packaging fees. Among these, the cost of aluminum as a raw material tends to fluctuate frequently, while other fees remain relatively stable. Due to these fluctuations, our quotations are typically valid for 7 days.

Pricing can be structured in different ways depending on the product and requirements. It can be calculated by weight (e.g., cost per ton), by length (e.g., cost per meter), or by piece (e.g., cost per unit). For products involving extensive machining, such as heat sinks, pricing is generally calculated on a per-piece basis to accurately reflect the additional processing costs. This flexible pricing approach ensures the quote is tailored to the specific needs of the customer.

We can manufacture aluminum profiles in compliance with technical requirements that meet European standards (EN), American standards (ASTM/AA), or other standards as specified by the customer. Custom production is tailored to ensure that the profiles meet the specific standard requirements requested.

Our production equipment is designed for the metric system. If the drawings provided are in the imperial system, we will convert them into metric units for production to ensure accuracy.

It is important to note that while we can machine imperial-threaded holes for fasteners, if you require us to supply matching imperial fasteners, they may not always be available in stock. Custom orders for imperial fasteners typically require a large volume for production. Please consider this when planning your project.

Factory Show

Our factory features 40 extrusion lines for efficient aluminum profile production. We offer a full range of surface treatments—including anodizing, electrophoresis, powder coating, sandblasting, and wood grain transfer printing—with advanced equipment. In-house casting, aging, annealing, water cooling, and machining ensure complete control and high-quality results for all products.