Premium Aluminum Balcony Railing Profile

Aluminum balcony railing is a modern guardrail system made from high-quality aluminum alloy profiles, often combined with infill materials such as tempered glass, stainless steel cables, or perforated metal panels. Its lightweight and corrosion-resistant properties make it particularly suitable for outdoor use on balconies and terraces, providing both safety and long-lasting durability.

Besides their protective function, aluminum balcony railings are valued for their design flexibility and visual appeal. They can be customized to suit various architectural styles and allow for clear or partially open views, offering a safe yet stylish solution for residential, commercial, and public spaces.

Mainstream Types of Balcony Railing

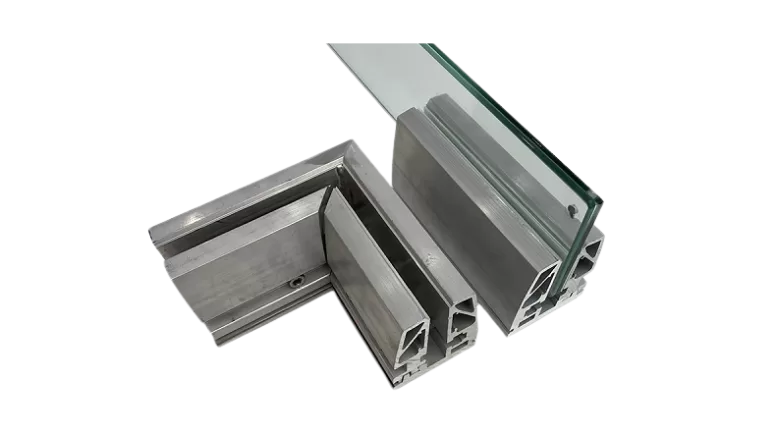

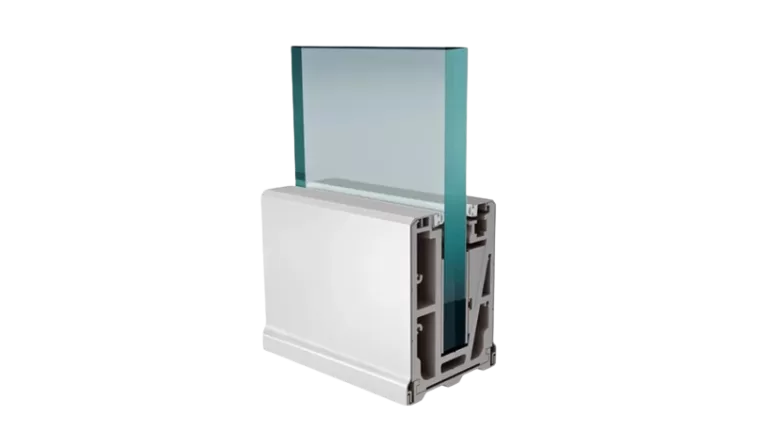

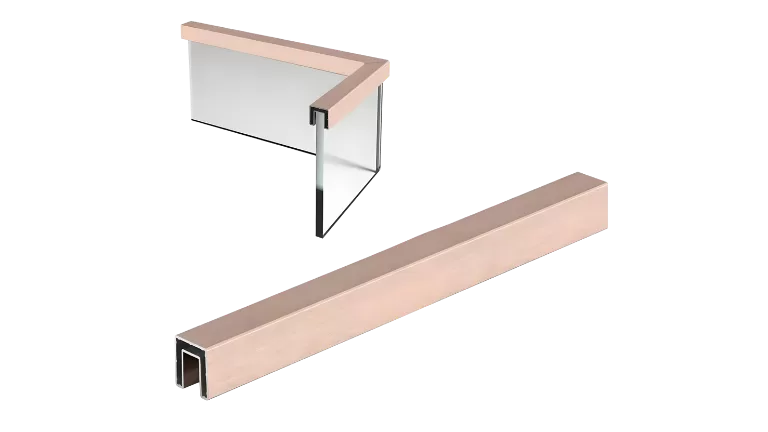

Aluminum Glass Railing

This type features tempered glass panels set within an aluminum frame, offering a sleek, contemporary appearance. Glass panel railings provide excellent visibility and an open, airy feel, making them ideal for spaces that prioritize unobstructed views and modern design.

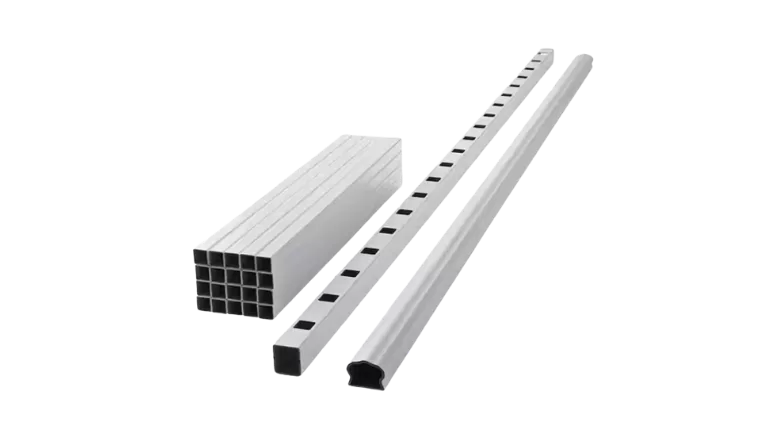

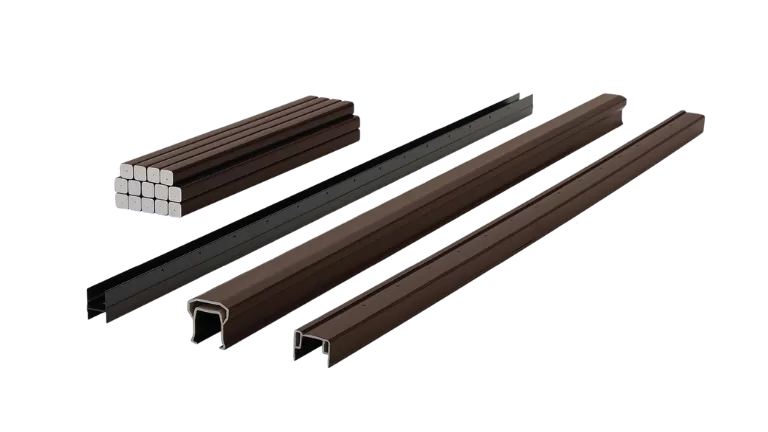

Aluminum Picket Railing

Picket railings are composed of evenly spaced vertical aluminum bars attached to top and bottom horizontal rails. This classic and secure style is widely used in residential applications, providing effective safety with a clean, timeless look.

Aluminum Cable Railing

Cable railings incorporate stainless steel cables tensioned between aluminum posts and rails. This design delivers a minimalist, modern aesthetic and allows for maximum transparency, making it perfect for settings that require safety without sacrificing the view.

Features of Aluminum Balcony Railing

Lightweight and Durable

Corrosion Resistant

Low Maintenance

Versatile Design Options

Safety and Security

Easy Installation

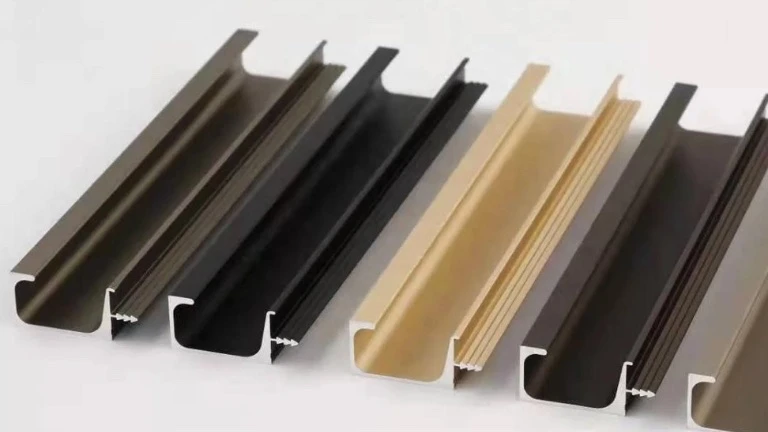

Surface Treatment of Balcony Railing

As a leading aluminum extrusion manufacturer based in China, we are dedicated to delivering high-quality balcony aluminum railings with premium surface finishes. Our expertise extends from precise extrusion to a comprehensive range of advanced surface treatment processes, including anodizing, powder coating, and wood grain transfer. These finishing options not only enhance the appearance of our railings but also provide outstanding corrosion resistance, durability, and weather protection. With full control over the finishing process, we ensure that every railing meets strict quality standards and the specific aesthetic and functional requirements of each project.

Process:

Creates a thin, durable oxide (Al₂O₃) layer on the aluminum surface via electrolysis (thickness: 5–25 microns). Can be dyed for color variety.

Features:

- Excellent corrosion resistance, ideal for humid or coastal areas

- Fade-resistant, uniform coloring (e.g., champagne, dark gray)

- High hardness and strong wear resistance

Applications:

Popular for outdoor railings needing a sleek look and long-lasting durability.

Process:

Process:

Applies dry powder with electrostatic spray, then cures at high temperatures to form a coating (60–120 microns thick).

Features:

- Wide choice of colors and finishes (matte, gloss, wood grain)

- Sealed surface resists UV, chemicals, and pollution

- Easy to repair and maintain

Applications:

Ideal for modern balconies, especially where vibrant colors or decorative finishes are needed.

Process:

Process:

Heat-transfer technique applies wood grain patterns on anodized or powder-coated aluminum.

Features:

- Realistic wood look (e.g., walnut, oak) with metal strength

- Low maintenance, pest-resistant, and won’t crack

- Blends with modern and traditional styles

Applications:

Great for homes aiming for a natural, cozy feel or harmony with garden/woodland surroundings.

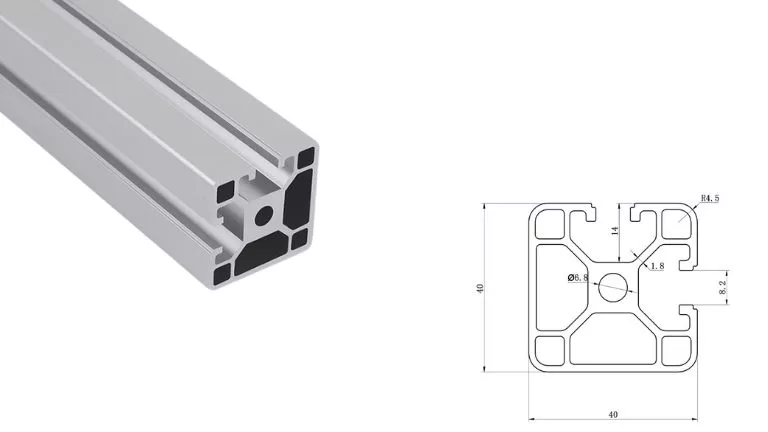

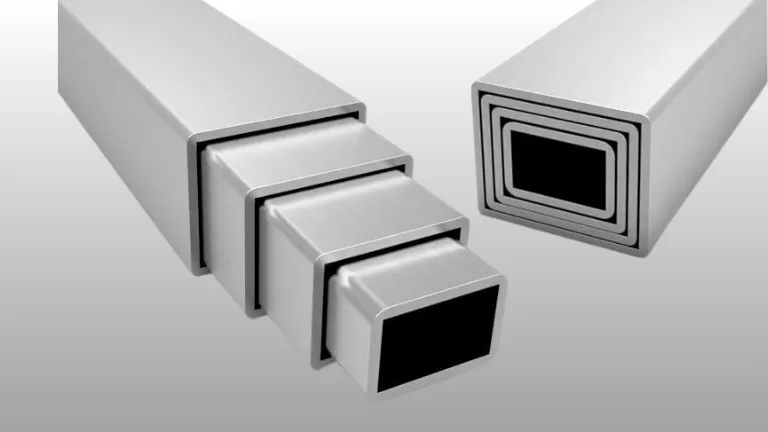

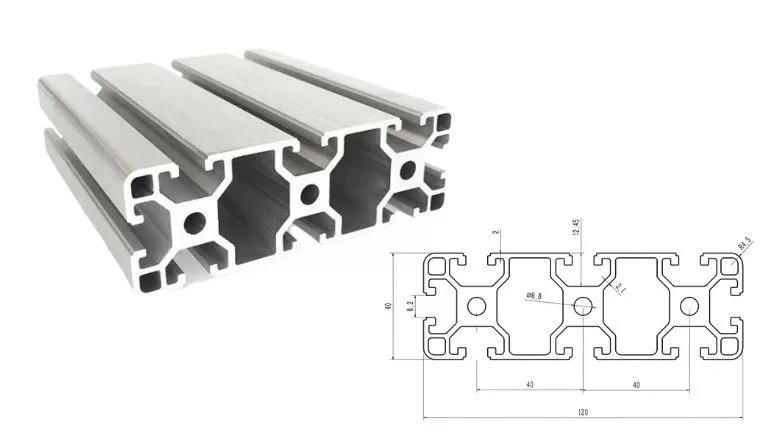

Raw Materials for Aluminum Balcony Railing

For aluminum balcony railings, the most commonly used materials are 6063-T5 and 6061-T6, each offering distinct advantages to meet different structural and design requirements.

1. 6063-T5

6063-T5 is one of the most commonly used materials for aluminum balcony railings, offering excellent extrusion properties, a smooth surface finish, and good corrosion resistance—ideal for architectural applications. In the T5 temper, the alloy is cooled from the extrusion process and then artificially aged, which improves both its strength and durability while maintaining attractive surface quality. This makes 6063-T5 a preferred choice for designs that require both aesthetics and functionality.

2. 6061-T6

6061-T6 is favored for balcony railing components that demand higher strength and superior mechanical properties. In the T6 temper, the material undergoes solution heat treatment followed by artificial aging, maximizing its mechanical strength and overall durability. 6061-T6 is widely used for structural parts or in outdoor settings where additional load-bearing capacity and long-term weather resistance are required.

Common Applications of Aluminum Balcony Railing

1. Residential Balconies:

Used in apartment buildings, condominiums, and private homes to provide safety and enhance exterior aesthetics.

2. Commercial Buildings:

Installed on office building terraces, hotel balconies, and restaurants to create secure and visually appealing outdoor spaces.

3. Public Facilities:

Applied in schools, hospitals, and public housing projects where safety and low maintenance are essential.

4. Rooftop Terraces:

Ideal for rooftop gardens or lounge areas, offering secure barriers without blocking the view.

5. Staircases and Walkways:

Often used along exterior stairs and elevated walkways for additional safety and architectural continuity.

Installation & Maintenance Guide

Installation Process:

- Precise Measurement: Use a laser distance meter to locate post positions, ensuring a level error of ≤1/8 inch per 10 feet.

- Post Fixing: For concrete bases, use expansion bolts (diameter ≥10mm). For wooden bases, embed galvanized steel plates in advance.

- Panel Installation: For glass railings, seal with silicone structural adhesive. For cable railings, gradually tighten using tensioners.

- Detail Finishing: Install caps to cover hardware and apply protective strips to glass edges.

Maintenance Recommendations:

- Routine Cleaning: Wipe frames and panels quarterly with a soft cloth and neutral detergent. Avoid strong acids or alkalis.

- Regular Inspection: Annually check the sealant on glass, cable tension (within ±10% of standard), and the tightness of post fasteners.

- After Extreme Weather: Inspect for frame deformation and glass cracks after typhoons or heavy rain. For coastal areas, a comprehensive inspection is recommended once a year.

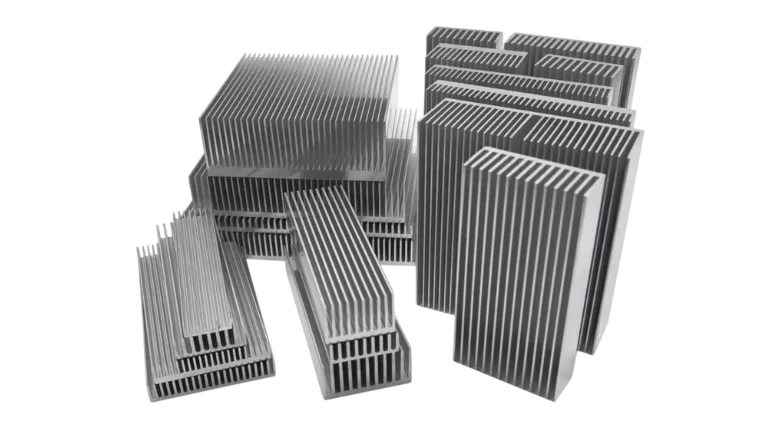

Our Factory

Our factory is equipped with 40 extrusion production lines to efficiently manufacture aluminum profile. We have one anodizing and electrophoresis line, along with two vertical spraying machines and two horizontal spraying machines for surface treatment. Additionally, we operate two sandblasting machines and six wood grain transfer printing lines, enabling us to provide various aesthetic finishes. To support our production, we also have furnaces for casting aluminum bars, aging furnaces, annealing furnaces, water cooling treatment equipment, and machining equipment, ensuring comprehensive capabilities for high-quality output.