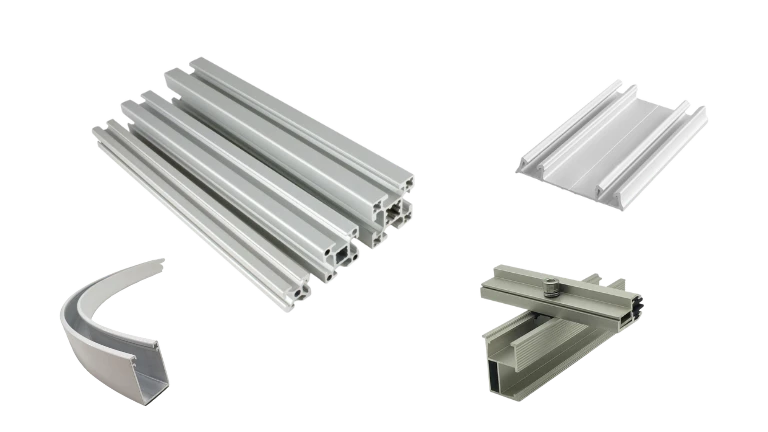

Custom Aluminium Extrusion Caravan Profile Solutions

Aluminium Extrusions in Caravan Manufacturing

Aluminium extrusion profiles are a pivotal component in the manufacturing and assembly of caravans, offering a unique blend of strength, flexibility, and lightweight properties. Unlike traditional materials, aluminium profiles provide a superior alternative due to their durability and resistance to corrosion, making them ideal for the caravan industry. Our custom aluminium extrusion profiles stand out from other alternatives with their precision manufacturing, adherence to stringent quality standards, and customizable options tailored to meet the specific needs of our clients.

Interior Applications

Overhead Cabinet Trim Profiles

Aluminium extrusions are used to create the trim profiles for overhead cabinets, providing a sleek finish and protecting the edges from wear and tear. These profiles also contribute to the lightweight construction of the cabinetry.

Bathroom Profiles

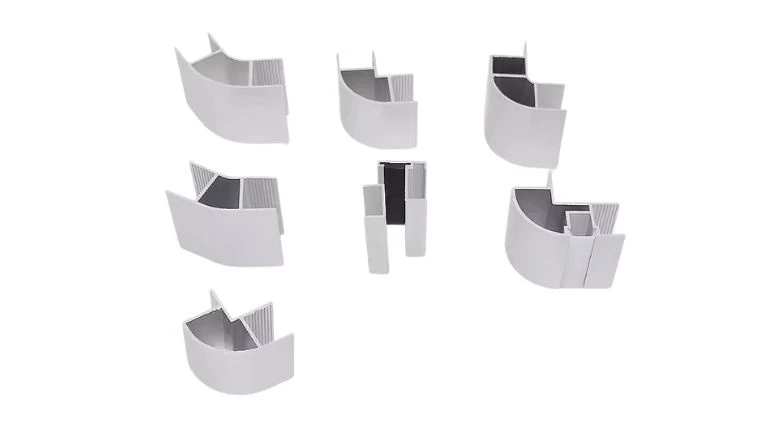

Specific aluminium profiles are designed for use in caravan bathrooms, offering water resistance and durability in humid conditions. These include shower frames, door tracks, and other structural components.

Curtain Rail Profiles

Window curtain rail profiles made from aluminium extrusions offer smooth operation and durability. Their lightweight nature ensures minimal strain on the caravan’s structure.

Exterior Applications

Caravan Body Trim Strips

Trim strips made from aluminium extrusions are used to finish the edges of the caravan body, providing a clean look and protecting the edges from environmental damage.

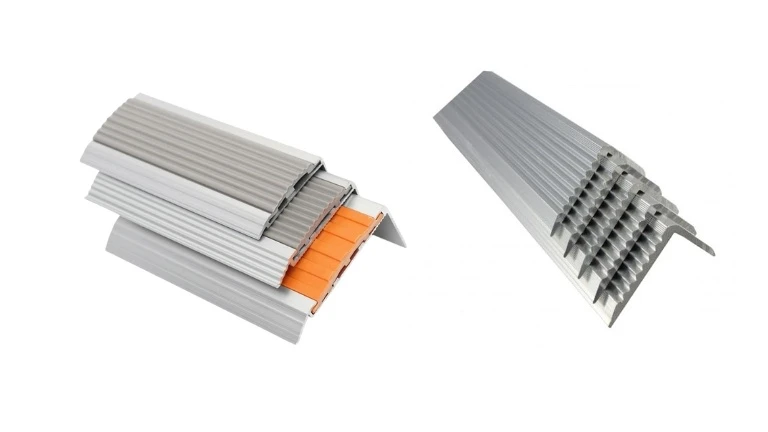

Step Profiles

Steps leading into the caravan are often constructed from aluminium extrusions for their strength and anti-slip properties, ensuring safe entry and exit.

Awning Rail Profiles

Aluminium extrusions are used to create the rail profiles for awnings, providing a strong and reliable support system for retractable awnings.

Push-out Window Support Bars

For caravans featuring push-out windows, aluminium extrusions are used to manufacture the support bars, offering both strength and flexibility.

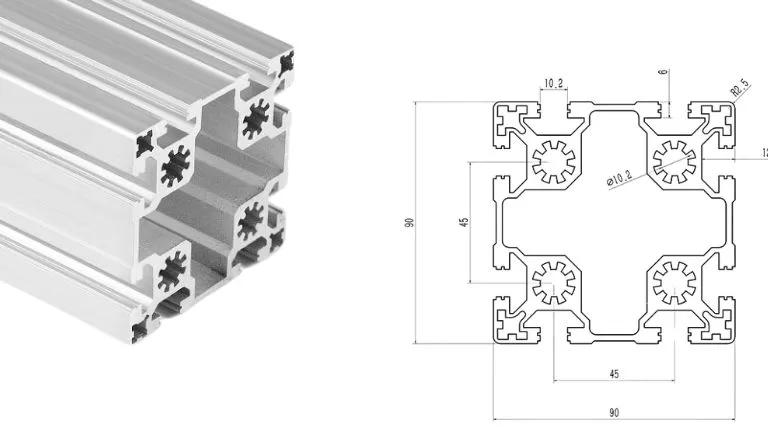

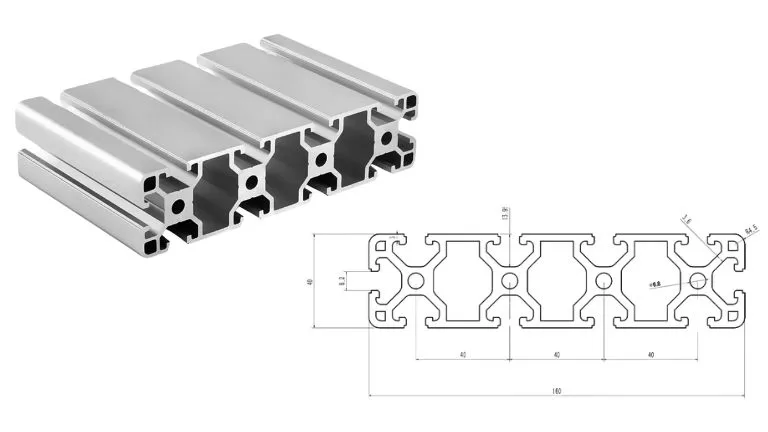

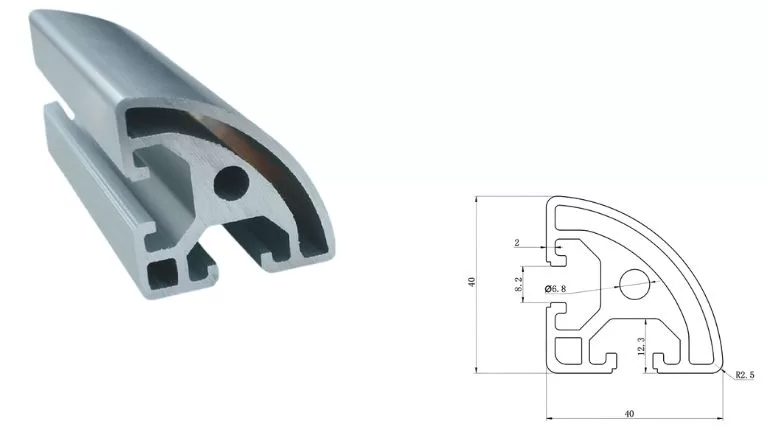

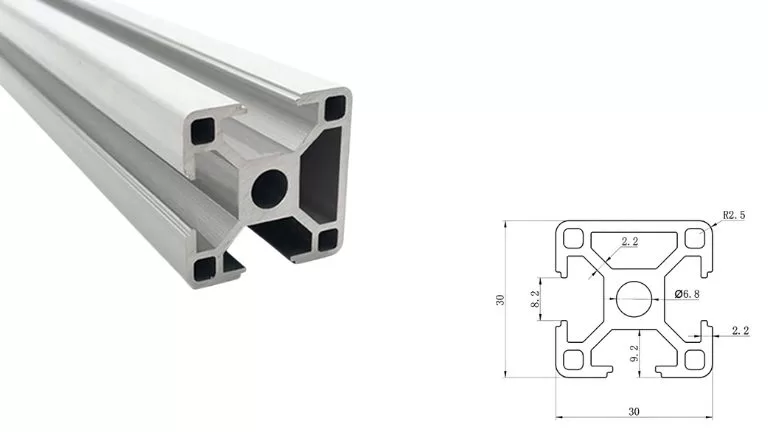

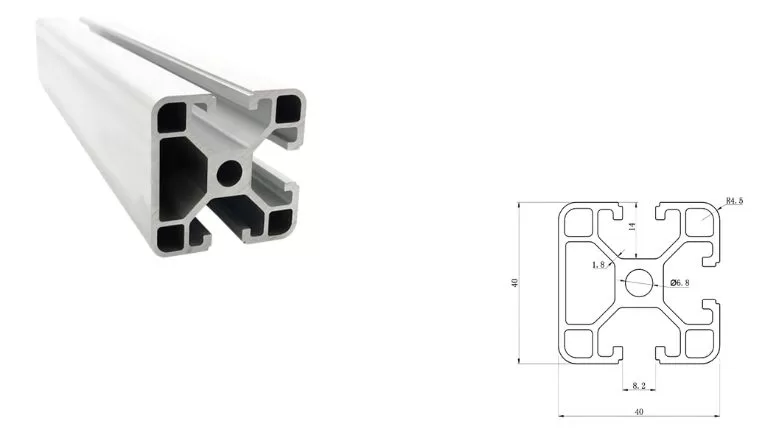

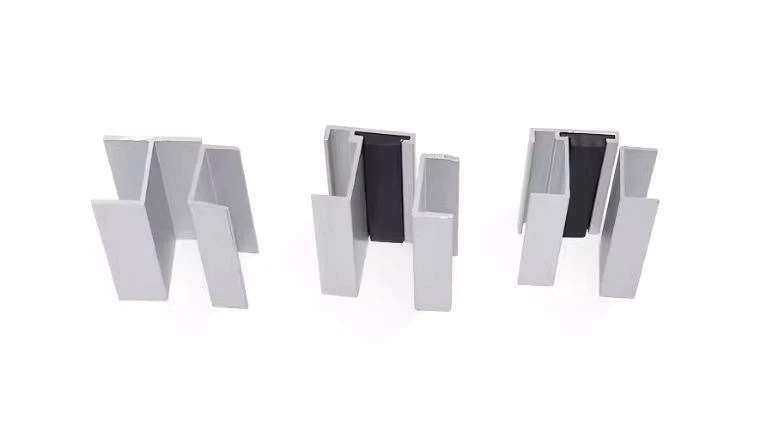

T-slot Structural Components

T-slot aluminium extrusions are widely used for structural purposes within the caravan, allowing for easy assembly and flexibility in attaching various components and accessories.

Accessory and Utility Applications

Caravan Ladders and Folding Steps

Aluminium extrusions are ideal for manufacturing both fixed and folding ladders or steps, providing lightweight yet sturdy access to the caravan or its roof.

Gutters and Drainage Channels

To manage water runoff, aluminium extrusions are used to create gutters and drainage channels that are both effective and aesthetically pleasing.

Luggage Racks

For additional storage, luggage racks made from aluminium extrusions offer a robust solution without significantly adding to the caravan’s weight.

Bicycle Racks

Aluminium extrusions are also utilized in the construction of bicycle racks, ensuring a secure and stable means of transporting bicycles.

Custom Extrusion Aluminum Profile

At our facility, we specialize in providing custom extrusion aluminum profile services tailored to meet the unique needs of our clients. Whether you have a detailed drawing or just an idea, our team is equipped to bring your vision to life. With our expertise in aluminum extrusion and a commitment to precision, we ensure that each profile is manufactured to the highest standards.

Mold Development

The first step in our custom extrusion process involves the creation of a mold based on your specifications. This crucial phase takes approximately 7 days and is where your ideas begin to take physical shape. Our team works closely with you to ensure the mold accurately reflects the desired profile, ensuring a seamless transition to production.

Aluminum Alloys and Heat Treatment

Aluminum profiles are predominantly made from various aluminum alloys, each offering distinct characteristics suited to different applications.

- 6061 Aluminum Alloy: Known for its strength, corrosion resistance, and weldability, 6061 is ideal for structural components. It contains magnesium and silicon as its major alloying elements.

- 6063 Aluminum Alloy: This alloy is famous for its excellent extrudability, high corrosion resistance, and superb surface finish quality. It’s often used in architectural applications.

- 7075 Aluminum Alloy: With zinc as the primary alloying element, 7075 stands out for its high strength, making it suitable for aerospace and military applications.

Heat treatment further enhances the properties of aluminum profiles, improving their strength, ductility, and stress resistance, making them suitable for more demanding applications.

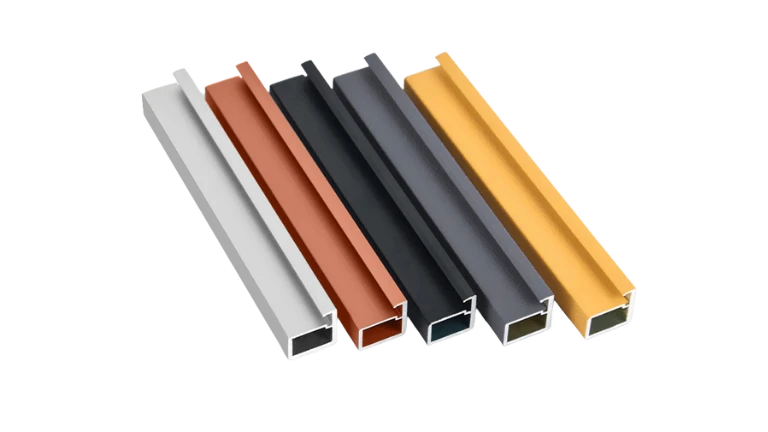

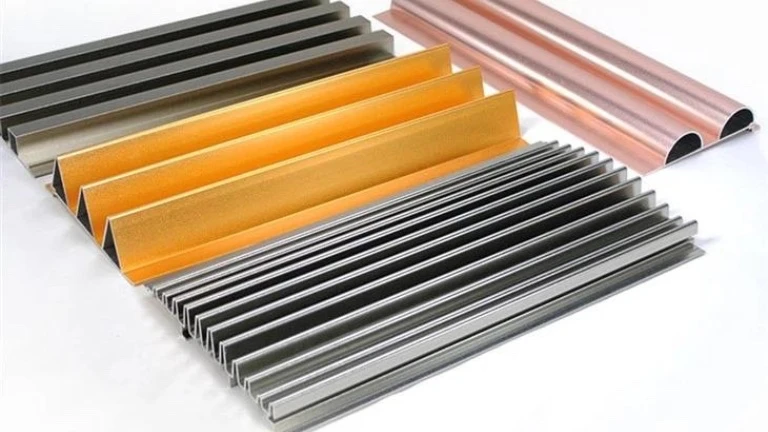

Surface Treatments

Surface treatments not only enhance the aesthetic appeal of aluminum profiles but also extend their lifespan by improving corrosion resistance.

- Anodizing: This electrochemical process forms a durable, corrosion-resistant oxide layer on the surface. It’s ideal for adding color or improving surface hardness.

- Powder Coating: A dry finishing process that provides a thick, wear-resistant layer available in a wide range of colors. It’s environmentally friendly and offers excellent durability.

- Electroplating: This process deposits a metal coating on the extruded profiles, improving their appearance and corrosion resistance.

- Fluorocarbon Painting: Known for its outstanding resistance to fading, chalking, and corrosion, making it suitable for exterior applications.

- Wood Grain Transfer: A decorative process that imitates the appearance of wood, offering the aesthetic appeal of wood with the durability of aluminum.

Machining Services

To further accommodate the specific needs of our clients, we offer a range of machining services:

- CNC Machining: For precision cutting, drilling, and shaping that meets tight tolerances.

- Bending: To create angles and curves in profiles without compromising their strength.

- Welding: For joining sections of aluminum profiles in the construction of complex structures.

- Laser Engraving: Ideal for adding detailed markings, logos, or designs to the surface of the aluminum profiles.

- Cutting & Drilling: Custom sizes and shapes are easily achieved with our cutting and drilling services, ensuring each piece fits perfectly in its intended application.

Delivery Times

Our production timeline is highly efficient, with a turnaround time ranging from 10 to 20 days for a typical order of 26 tons. This ensures that your custom aluminum profiles are delivered promptly, keeping your project on schedule.

Partner with Us for Custom Caravan Alu Profiles

Choosing our aluminium extrusion caravan profiles means opting for precision, reliability, and customization. We are committed to providing solutions that not only meet but exceed your expectations. Our state-of-the-art manufacturing facilities, combined with our expertise in aluminium extrusion, make us the ideal partner for your caravan manufacturing needs.

Custom Your Aluminum Profile

Our aluminum extrusion factory, located in Nanchang, Jiangxi Province, covers an extensive area of 30,000 square meters and is home to a dedicated workforce of over 120 skilled individuals.

Advanced Extrusion Lines

Boasting over 30 high-precision extrusion production lines from Japan and Germany, we ensure unmatched quality and efficiency.

Custom Mold Design and Processing

We tailor-make molds based on client designs or samples, providing prototypes for confirmation to meet precise specifications.

Comprehensive Surface Treatment Techniques

Our surface treatment capabilities include anodizing, electroplating, sandblasting, powder coating, fluorocarbon painting, and wood grain transfer printing to enhance product durability and aesthetics.

Over Two Decades of Expertise

Since 2013, we have been manufacturing aluminum profiles, accumulating vast experience in producing a wide array of profiles for windows, doors, and various industrial applications.

The Advantages of Aluminium Extrusions in Caravan Manufacturing

In the realm of caravan manufacturing, the choice of materials plays a pivotal role in determining the quality, durability, and performance of the final product. Among the various materials available, aluminium extrusions have emerged as a preferred choice for many manufacturers due to their unique set of advantages. This article explores the multitude of benefits that aluminium extrusions offer in the context of caravan manufacturing.

Lightweight Construction

One of the most significant advantages of using aluminium extrusions in caravan manufacturing is the reduction in overall vehicle weight. Aluminium is renowned for its lightweight properties, which is particularly beneficial for caravans that need to be towed. A lighter caravan means easier towing, better fuel efficiency, and the ability to be towed by a wider range of vehicles. This not only makes caravans more accessible to a broader audience but also contributes to a more sustainable and cost-effective travel experience.

Structural Integrity

Despite its lightweight nature, aluminium possesses an excellent strength-to-weight ratio, ensuring that caravans manufactured with aluminium extrusions maintain high levels of structural integrity. This strength is crucial for withstanding the rigors of travel and providing a safe, stable, and durable home away from home. Aluminium’s inherent resistance to corrosion further enhances the longevity of caravans, allowing them to retain their structural integrity and appearance over time.

Design Versatility

The process of creating aluminium extrusions involves forcing aluminium alloy through a die to create profiles with specific shapes and sizes. This method offers unparalleled design flexibility, enabling manufacturers to produce complex cross-sectional profiles tailored to specific requirements. As a result, caravan designers can innovate without constraints, incorporating sleek, modern designs that optimize space, improve aerodynamics, and enhance overall aesthetics. This versatility also extends to the interior, where aluminium extrusions can be used for lightweight, durable fittings and fixtures.

Thermal Efficiency

Aluminium’s excellent thermal conductivity can be leveraged in caravan manufacturing to improve insulation and climate control within the vehicle. By incorporating thermal breaks within the aluminium profiles, manufacturers can reduce heat transfer, maintaining a comfortable interior temperature regardless of external weather conditions. This thermal efficiency is particularly beneficial for caravans, which often face varying climates during travel.

Ease of Maintenance

Caravans manufactured with aluminium extrusions require minimal maintenance, thanks to aluminium’s resistance to corrosion and its durability. Unlike other materials that may rust or degrade over time, aluminium maintains its appearance and structural integrity with basic care. This ease of maintenance ensures that caravan owners can spend more time enjoying their travels and less time on upkeep.

Environmental Sustainability

Aluminium is highly recyclable, with the recycling process requiring only a fraction of the energy needed to produce primary aluminium. This characteristic makes aluminium extrusions an environmentally friendly choice for caravan manufacturing. By utilizing recycled aluminium or ensuring that the caravan’s aluminium components are recyclable at the end of their life, manufacturers can significantly reduce the environmental impact of their products.

Custom Aluminum Extrusion Steps

At HTS Aluminum Profiles, we specialize in delivering custom aluminum extrusion solutions tailored to your specific needs. Here’s a step-by-step guide to our customization process:

Step 1: Initial Consultation

Your journey begins with an initial consultation where we discuss your project requirements. We encourage you to share your design concepts, application needs, and any critical parameters that the aluminum profile must meet. This collaborative approach ensures that we fully understand your vision and objectives.

Step 2: Design and Engineering

Leveraging our extensive experience in aluminum extrusion, our skilled engineers work closely with you to refine your design. We consider factors such as the aluminum alloy grade, temper, and mechanical properties required for your application. Our team uses advanced CAD software to create precise technical drawings and 3D models of the proposed profile.

Step 3: Die Fabrication

Once the design is finalized, we proceed to manufacture the custom extrusion dies. Our precision die-making process ensures that the final profile will match your specifications with high accuracy. We employ state-of-the-art CNC machines to craft dies that can withstand the rigors of extrusion while maintaining tight tolerances.

Step 4: Aluminum Extrusion

With the dies ready, the actual extrusion process begins. We select the appropriate aluminum alloy and heat it to the precise extrusion temperature. The heated billet is then pressed through the die to create the custom profile. Our extrusion presses, ranging from 600 to 3600 tons, are capable of producing a wide range of profile sizes and shapes.

Step 5: Surface Treatment and Finishing

Following extrusion, the profiles undergo various surface treatments as per your requirements. Options include anodizing, electroplating, sandblasting, powder coating, fluorocarbon painting, and wood grain transfer printing. These processes enhance the profiles’ durability, corrosion resistance, and aesthetic appeal.

Step 6: Quality Assurance

Quality is at the heart of everything we do. Each custom aluminum profile is subjected to rigorous quality checks to ensure it meets ISO standards and our European quality certifications. We perform dimensional inspections, mechanical testing, and surface finish evaluations to guarantee that your profiles are delivered without defects.

Step 7: Packing and Delivery

After passing all quality inspections, the aluminum profiles are carefully packed to prevent any damage during transit. We use robust packaging materials and methods tailored to the profiles’ dimensions and your delivery preferences. Our logistics team then manages the safe and timely delivery of your custom aluminum profiles to your specified location.

Step 8: After-Sales Support

Our commitment to your satisfaction extends beyond delivery. We offer comprehensive after-sales support to address any concerns or additional requirements you may have. Our customer service team is always ready to assist you with any questions or feedback.

Partner with Us

We are committed to delivering precision-engineered aluminum profiles that meet the highest standards of quality. From initial design to final delivery, we provide a seamless and personalized experience, ensuring that your custom aluminum solutions are produced efficiently and to your satisfaction.

Take the next step in your project and contact us for a consultation on your custom aluminum extrusion needs.