Versatile Applications of T-Slot Aluminum Extrusions

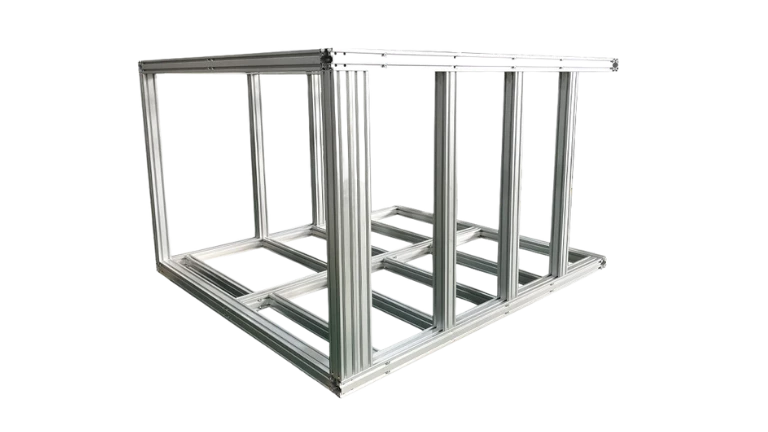

T-slot aluminum extrusions are versatile profiles created by pushing aluminum through a die, forming long pieces with T-shaped slots. They are popular in industries like manufacturing, automation, and DIY projects due to their easy assembly and reconfiguration. The T-slots allow components to be attached with specialized connectors and accessories, making it simple to build or modify structures like frames and workstations.

A major advantage of T-slot extrusions is their flexibility, allowing quick adjustments without welding or special tools. By using a variety of compatible accessories, users can easily customize and expand their projects. This feature saves time and reduces costs in both prototyping and production. Their modular nature also supports the rapid creation of customized solutions, making them ideal for both permanent and temporary structures like exhibition stands.

Aluminum T-slot for Industrial Automation

T-Slot aluminum extrusions play a crucial role in industrial automation by providing a modular framework that can easily be adjusted and expanded. This versatility is essential for building machine frames, conveyor systems, and robotic devices. The ease of assembly and disassembly allows manufacturers to alter production lines swiftly, integrating new technologies or reconfiguring layouts to optimize processes without incurring high costs or delays.

Customizable Workstations and Benches with T-Slot

In workshop and factory environments, T-Slot aluminum extrusions are used to create highly customizable workstations and benches. These structures can be fine-tuned to fit various ergonomic and operational requirements. With the use of T-Slot profiles, facilities can easily adjust the height, add attachments like monitors or storage bins, and even integrate lighting or power strips to enhance productivity and comfort for users.

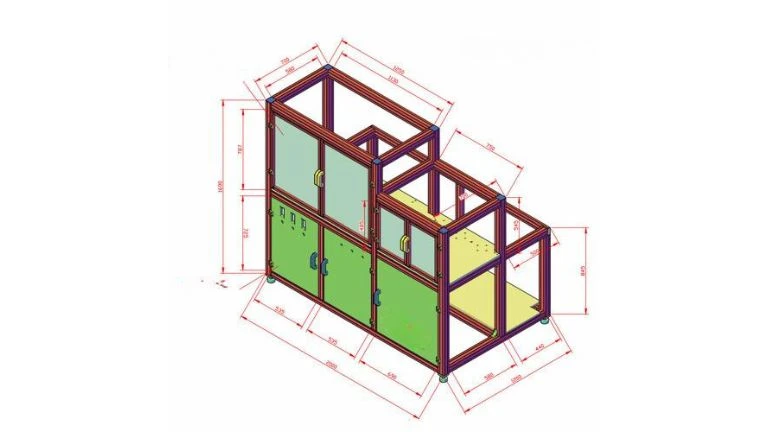

Enclosures and Cabinets Built with T-Slot Extrusions

T-Slot aluminum extrusions allow for the construction of protective enclosures and cabinets ideal for sensitive equipment and electronics. These structures can be sealed for dust and particle resistance, improve workspace aesthetics, and increase the level of organization in tech-heavy environments. Their modular nature makes it easy to expand, modify, or redeploy assemblies as needs change.

T-Slot for Shelving and Storage Solutions

Utilizing T-Slot extrusions for shelving and storage systems offers facilities the flexibility to adapt as their inventory or work requirements change. These extrusions allow users to build dynamic storage units that can be easily reconfigured by adding or removing shelves and rearranging sections to accommodate different items, thereby promoting efficient space utilization.

Safety Guards and Machinery Fencing Using T-slot

Safety is paramount in industrial settings, and T-Slot aluminum extrusions facilitate the creation of protective guards and fencing around machinery. These setups help prevent workplace injuries by clearly delineating hazardous areas while allowing for the easy modification or relocation of guard systems as equipment and safety standards evolve.

Crafting Displays and Exhibits with T-Slot Aluminum

The sleek and professional look of T-Slot aluminum extrusions makes them perfect for building displays, trade show exhibits, and point-of-purchase stands. Their modularity allows for innovative designs that can easily be assembled on-site and tailored to the specific needs of a presentation or marketing event, ensuring a standout presence.

Elevating Ladders, Industrial Steps, and Mobile Platform

T-Slot aluminum extrusions are ideal for building elevating ladders, industrial steps, and mobile platforms due to their strength and lightweight properties. These structures can be easily customized with features like handrails and non-slip surfaces to ensure safety. Their modular design allows for quick adjustments to adapt to different industrial needs, and they can be fitted with wheels for easy mobility, making them versatile for various work environments.

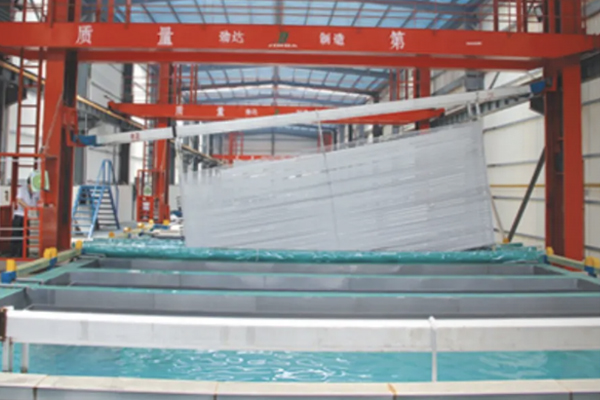

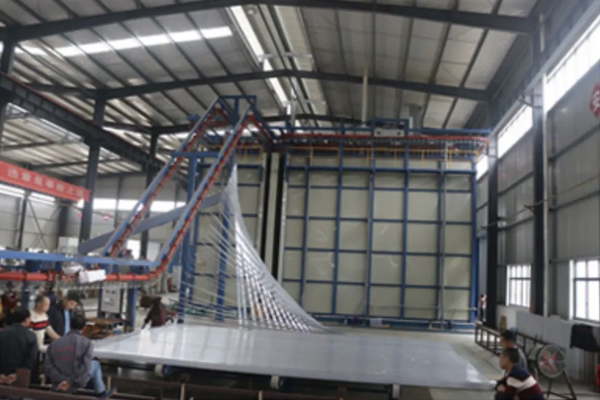

Our Factory

HTS NEW MATERIALS stands as a premier aluminum extrusion profile manufacturer in China. Boasting more than 40 production lines and housing the largest 6000-ton extrusion press, we excel in delivering high-quality solutions. Our capabilities extend to mold design and processing, along with comprehensive surface treatment and advanced machining services.