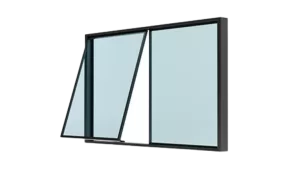

Aluminum Awning Window

An aluminum awning window is a type of window fixed with top hinges, allowing the sash to open outward from the bottom. This design enhances indoor ventilation while effectively blocking rainwater, dust, and other debris. In the closed position, it offers excellent wind and water resistance. Even when open, it can provide protection against light rain thanks to its outward-tilting design.

Due to the aluminum material, these windows offer excellent durability, lightweight construction, and a sleek, modern appearance. Aluminum awning windows are commonly used in residential, commercial, and industrial buildings, making them ideal for areas requiring high ventilation, such as kitchens, bathrooms, and basements.

Features

Top-Hinge Design: The sash tilts outward from the bottom, allowing rainwater to flow along the outer edge. This ensures ventilation even during rain.

Lightweight Construction: Aluminum frames are lightweight, making installation easier and suitable for various window sizes and designs.

Excellent Durability: Aluminum is resistant to rust and corrosion, making it ideal for long-term use in humid environments like bathrooms and kitchens.

Superior Sealing Performance: Equipped with sealing strips and closing mechanisms, the window effectively blocks wind, rain, and dust when closed.

High-Strength Design: Built to withstand high wind pressure, aluminum awning windows are ideal for high-rise buildings and areas with strong winds, maintaining shape and structural integrity.

Manual Awning Windows

Manual Awning Windows

Operated using a crank handle or lever for manual adjustment.

Simple and cost-effective, making them a popular choice for residential applications.

Easy to use, offering precise control of ventilation.

Chain Awning Windows

Chain Awning Windows

Utilize a chain mechanism, either manual or motorized, for opening and closing.

Provide a smooth operation and are versatile for various sizes.

Particularly suitable for areas requiring higher placement, like kitchens or bathrooms.

Modern Awning Windows

Modern Awning Windows

Feature slim aluminum frames or frameless designs for a contemporary aesthetic.

Ideal for creating a minimalist look and maximizing natural light.

Combine style with functionality, while maintaining durability and excellent sealing performance.

House Aluminum Awning Windows

Kitchen: Awning windows in kitchens optimize ventilation, helping to reduce cooking odors and oil residue. The aluminum material ensures resistance to humidity and prevents corrosion, even in high-moisture environments.

Bathroom: In bathrooms, awning windows are ideal for preventing moisture buildup, maintaining a dry and fresh environment. Their excellent sealing properties also ensure privacy and block external dust or rain.

Basement: For basements, awning windows enhance natural lighting, making typically darker areas more inviting. They also improve ventilation, contributing to a more comfortable living space.

Commercial Buildings Awning Windows

Office Buildings: Awning windows are used in office restrooms and shared areas for natural ventilation and fresh air. They are energy-efficient, durable, and complement modern office designs.

Hotels: In hotels, awning windows are found in guest bathrooms and communal spaces. They provide ventilation, reduce exterior noise, and blend seamlessly with sleek, modern architecture.

Restaurants: Awning windows in restaurants allow natural light and fresh air into the space, creating an inviting atmosphere. Their weather-resistant design ensures durability in busy dining environments.

Structural of Aluminum Awning Windows

Aluminum awning windows are designed for functionality, durability, and weather resistance. They consist of the following main structural components:

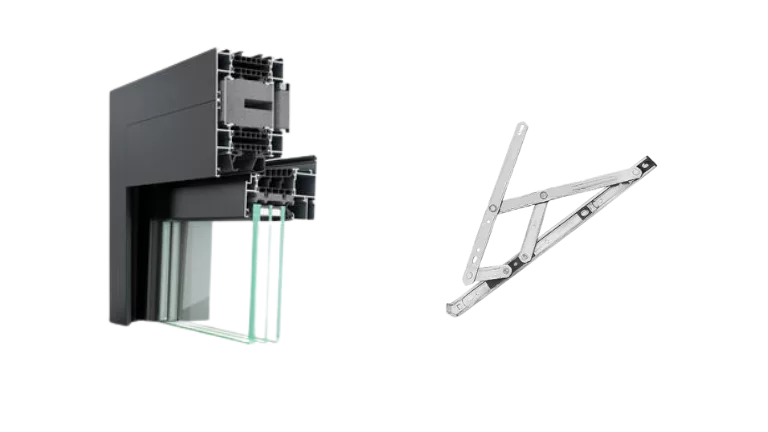

1. Aluminum Alloy Frame and Sash

- Constructed with high-strength aluminum alloy profiles as the primary material, ensuring durability and structural stability.

- The surface undergoes treatments such as anodizing or electrophoretic coating for enhanced corrosion resistance and longevity.

2. Window Sash Hinges

- Hinges are typically mounted at the top of the window frame, allowing the sash to open outward from the bottom.

- This design ensures efficient ventilation while providing protection from rain.

3. Operation Mechanism

- The window functionality is controlled by:

- Manual Controllers: Allows the sash to be opened and adjusted by hand.

- Electric Window Openers: Motorized systems for convenient and automated operation.

4. Sealing Strips

- EPDM (Ethylene-Propylene-Diene Monomer) rubber sealing strips are installed around the frame to provide excellent waterproof, windproof, and thermal performance when the window is closed.

5. Glass Options

- Typically equipped with double or triple-glazed insulated glass to achieve:

- Enhanced thermal insulation.

- Improved soundproofing.

- Anti-fog and condensation resistance.

Common Models of Aluminum Awning Window

1. Window Dimensions:

- Standard Width Range: 400mm ~ 1500mm

- Standard Height Range: 400mm ~ 2000mm

- Custom Sizes: Special dimensions are available to accommodate different architectural needs, ensuring adaptability to unique building designs.

2. Material Specifications:

Aluminum Profile Thickness:

1.2mm ~ 2.0mm, determined based on load-bearing and wind pressure requirements.Thermal Insulation Options:

Insulated aluminum profiles can be selected for enhanced thermal performance, helping regulate indoor temperatures effectively.Glass Thickness:

- Single Glass: 5mm ~ 6mm

- Insulated Glass: Options include 5+12+5 mm or 6+16+6 mm configurations.

- Laminated Glass: Typically 5+0.76PVB+5 mm, offering added safety and durability.

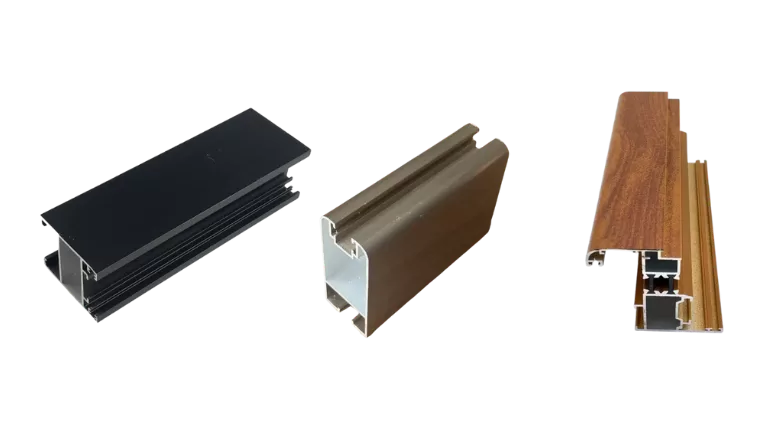

3. Surface Treatments:

Anodizing:

Offers corrosion and wear resistance with natural colors or metallic brushed effects.Powder Coating:

Provides a wide range of color options, including white, gray, black, and more, to suit various aesthetic requirements.Electrophoretic Coating:

Delivers a high-gloss finish, enhancing oxidation resistance and extending the window’s lifespan.Wood Grain Finish:

Mimics natural wood patterns, creating a warm and cozy appearance, especially suitable for residential settings.

Awning Window Frame Material Selection

Different aluminum alloys have varying properties such as strength, corrosion resistance, and processability. Additionally, thermal treatments (e.g., T5, T6) can further enhance their performance, making window aluminum frame suitable for specific applications. Below are common options for bi-fold windows:

- Most commonly used for folding windows due to its balance of strength, corrosion resistance, and excellent surface finish.

- Easy to process and compatible with treatments like anodizing and powder coating.

- Stronger and more durable, ideal for heavy-duty or commercial applications requiring higher load capacity.

- Offers superior strength and wear resistance, suitable for high-traffic or outdoor areas.

- Less common due to slightly lower processability compared to 6063.

Performance of Aluminum Awning Windows

1. Wind Resistance: Withstand pressure levels of ≥2000 Pa, making it suitable for high-rise buildings and areas with strong winds.

2. Water Tightness: Achieves a water resistance range of 500 Pa ~ 700 Pa, effectively preventing rainwater intrusion.

3. Sound Insulation: Reduces noise levels by 30 dB ~ 50 dB, ensuring a quieter and more comfortable indoor environment.

4. Thermal Insulation: Features insulated glass and thermal break aluminum profiles, reducing heat transfer to a U-value as low as K=2.0 W/m²·K, enhancing energy efficiency.

Other Types Window

Custom Window Manufacturing Services

Our Window & Door Division specializes in global customization of high-quality windows, including glass integration. We support a wide range of window types to meet diverse architectural needs:

Available Window Styles

- Sliding Windows

- Casement (Awning/Crank-out) Windows

- Top-Hung & Bottom-Hung Windows

- Tilt & Turn Windows

- Double-Hung & Single-Hung Windows

- Lift & Slide Windows

- Folding Window

- Fixed Windows

Customization Process

Provide Design Details:

- Submit technical drawings or specify frame dimensions (width/height/depth).

- Indicate operational type (e.g., sliding, casement).

Surface Treatment Options:

- Anodizing (silver, bronze, black)

- Powder Coating (RAL/color-matching)

- Wood Grain Transfer

- PVDF Fluorocarbon Coating

Glass Integration:

- Double/triple glazing, tempered, Low-E, laminated, or decorative glass.

Our Factory

Our factory is equipped with 40 extrusion production lines to efficiently manufacture aluminum profile. We have one anodizing and electrophoresis line, along with two vertical spraying machines and two horizontal spraying machines for surface treatment. Additionally, we operate two sandblasting machines and six wood grain transfer printing lines, enabling us to provide various aesthetic finishes. To support our production, we also have furnaces for casting aluminum bars, aging furnaces, annealing furnaces, water cooling treatment equipment, and machining equipment, ensuring comprehensive capabilities for high-quality output.