Özel Ekstrüde Alüminyum Muhafaza

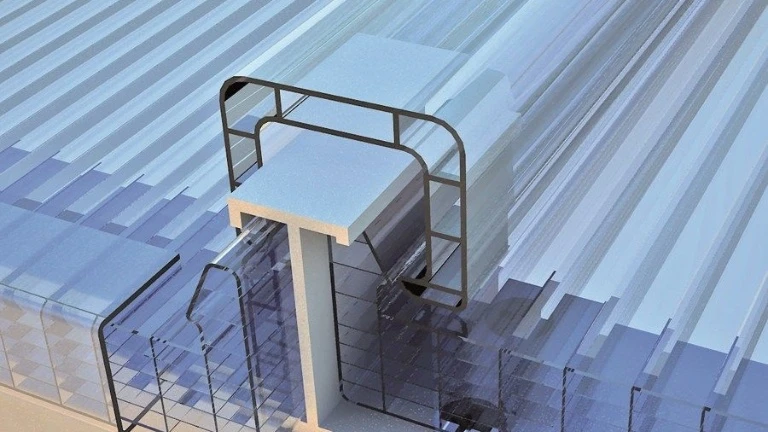

Ekstrüde alüminyum muhafazalar, elektronik bileşenleri, sensörleri, güç modüllerini ve diğer cihazları korumak için tasarlanmış dayanıklı, hafif ve çok yönlü yapılardır. Hassas kullanılarak üretilmiştir ekstrüzyon süreçleriBu muhafazalar mukavemet, korozyon direnci ve mükemmel ısı dağılımıBu da onları elektronik, telekomünikasyon, otomotiv ve endüstriyel otomasyon gibi endüstriler için ideal hale getirir.

Son derece özelleştirilebilir muhafazalarekstrüzyon alüminyum muhafazalar, plastik veya sac metal alternatiflerine kıyasla mekanik hasara, çevresel faktörlere ve elektromanyetik girişime (EMI) karşı üstün koruma sağlar. Profesyonel görünümleri ve uyarlanabilirlikleri, onları hem tüketici hem de endüstriyel uygulamalar için uygun hale getirir.

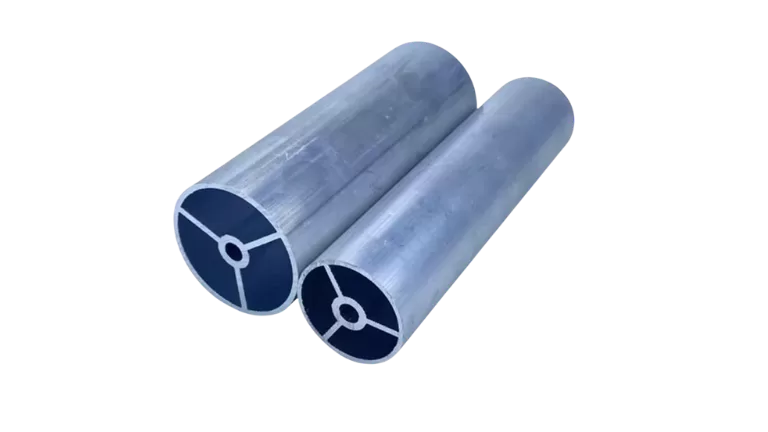

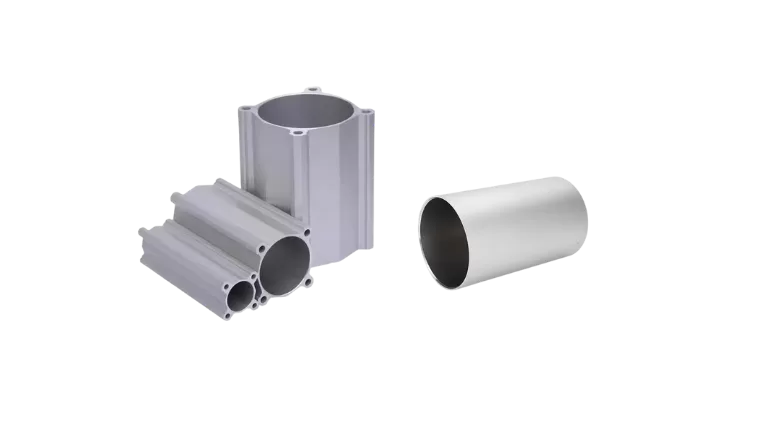

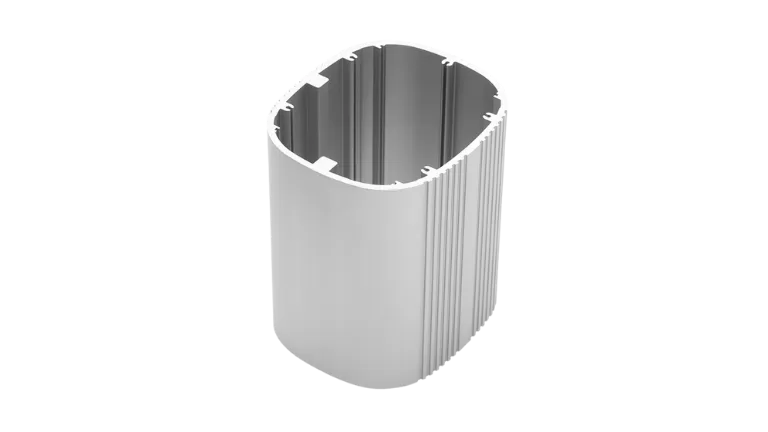

Yuvarlak Gövdeler

Yuvarlak ekstrüzyon alüminyum muhafazalar, şık, kompakt tasarımları ve mükemmel yapısal bütünlükleri nedeniyle elektromekanik ürünlerde yaygın olarak kullanılmaktadır. Bu muhafazalar motorlar, sensörler ve diğer silindirik bileşenler için kusursuz koruma sağlar, üstün dayanıklılık ve hafiflik sunar. Yuvarlak şekilleri de verimli montaj sağlar ve rotasyonel veya mekanik sistemlere daha kolay entegrasyonu kolaylaştırır.

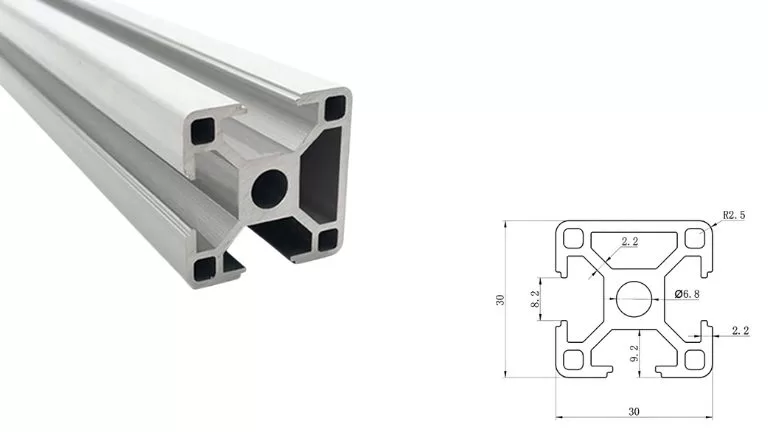

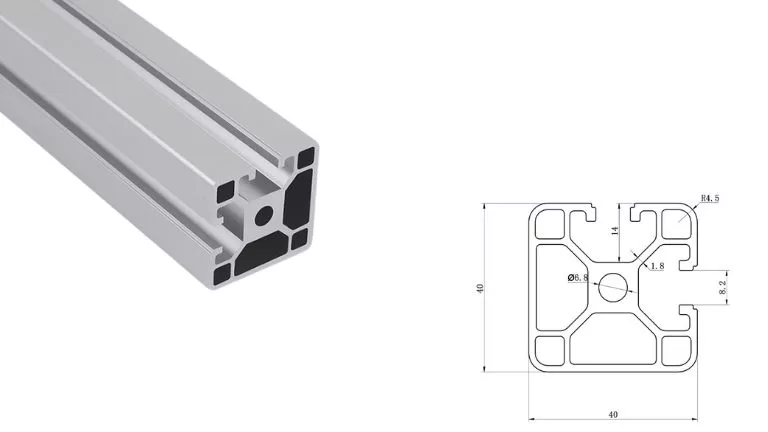

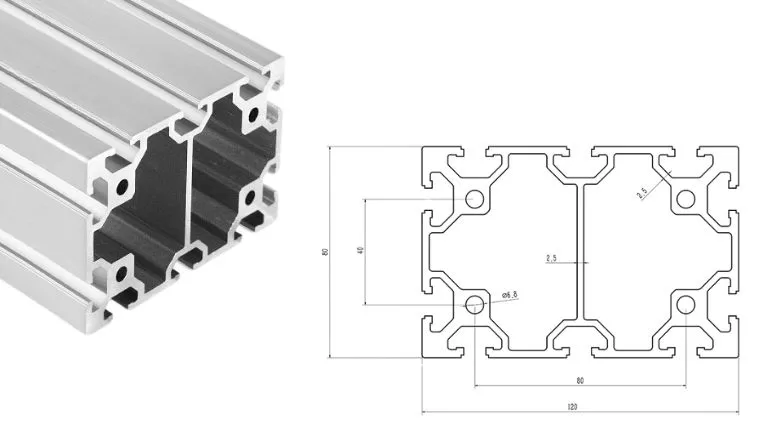

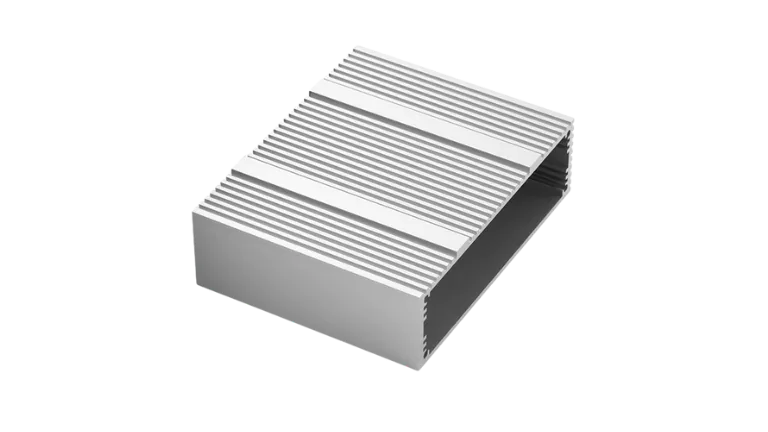

Dikdörtgen veya kutu şeklindeki ekstrüzyon alüminyum muhafazalar, iletişim cihazları, modüller ve kontrol sistemleri gibi elektronik ürünler için idealdir. Hassas boyutları ve özelleştirilebilir bölmeleriyle bu muhafazalar çevresel faktörlere ve elektromanyetik girişime (EMI) karşı mükemmel koruma sağlar. Çok yönlü tasarımları devre kartlarının ve bileşenlerin kolayca monte edilmesine olanak tanıyarak tüketici elektroniği ve endüstriyel kontrol cihazlarında popüler bir seçim olmalarını sağlar.

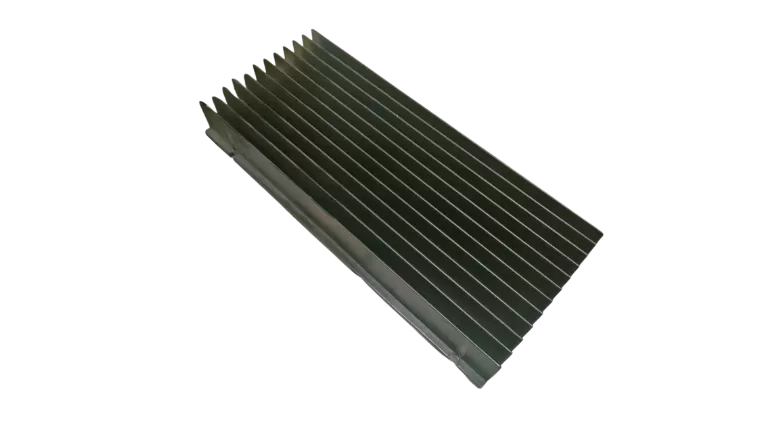

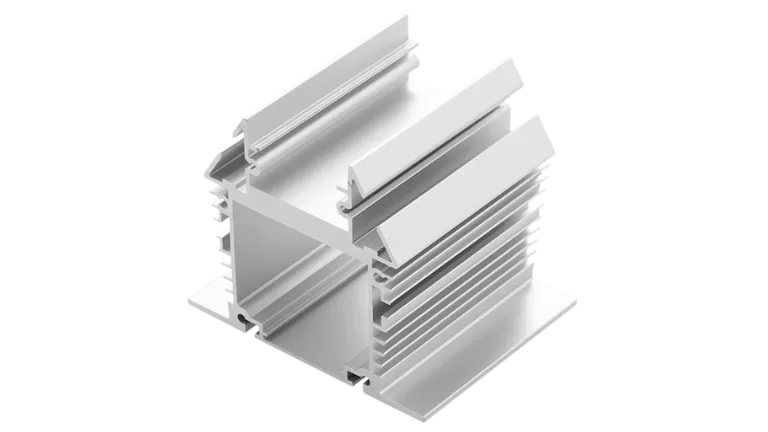

Entegre soğutma kanatlarına sahip ekstrüde alüminyum muhafazalar, mükemmel ısı dağılımı gerektiren uygulamalar için tasarlanmıştır. Bu muhafazalar güç modülleri, LED sürücüler ve termal yönetimin kritik olduğu yüksek ısı elektronikleri için mükemmeldir. Genişletilmiş kanatlar, verimli ısı transferi için yüzey alanını önemli ölçüde artırarak yüksek sıcaklıklı ortamlarda bile güvenilir performans sağlar.

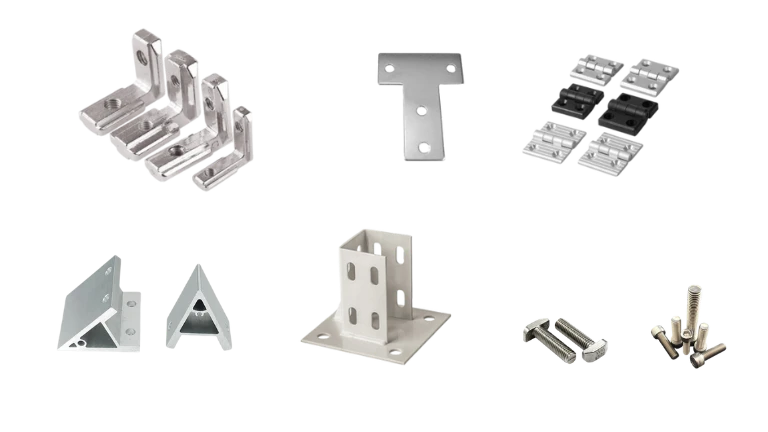

Ekstrüde Alüminyum Gövde İşleme Yetenekleri

Çin merkezli lider bir alüminyum ekstrüzyon üreticisi olarak, çok çeşitli uygulamalar için yüksek kaliteli ekstrüzyon alüminyum muhafazalar üretme konusunda uzmanız. Yeteneklerimiz, özel kalıp tasarımı ve geliştirmesiyle başlar ve her projenin benzersiz gereksinimlerini karşılayan hassas şekiller sağlar. Ham ekstrüzyondan yüzey işlemeye ve gelişmiş işlemeye kadar, tam entegre üretim süreçlerimiz, olağanüstü performans ve dayanıklılığa sahip alüminyum muhafazalar sunmamızı sağlar.

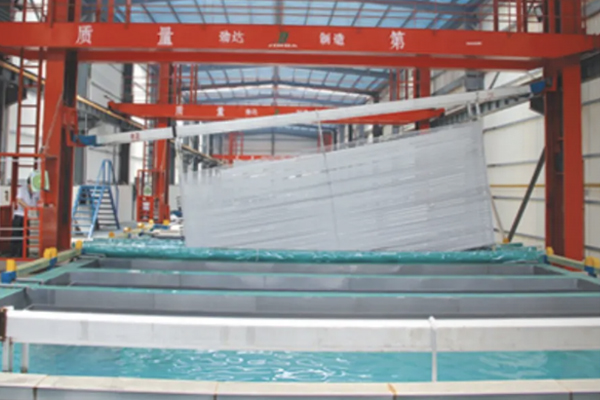

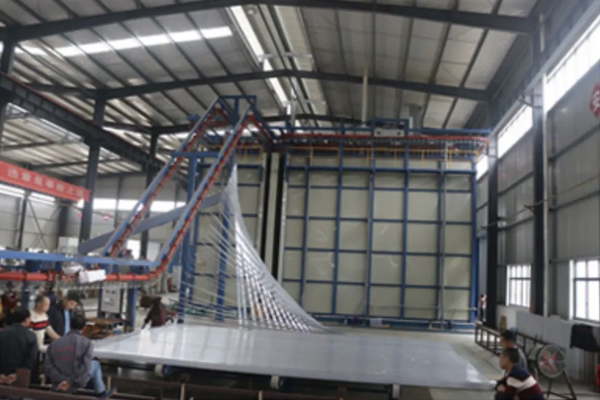

Üretim tesislerimiz, güçlü 6000 tonluk ekstrüzyon presleri de dahil olmak üzere 40'tan fazla gelişmiş ekstrüzyon hattıyla donatılmıştır. Bu sayede silindirik gövdeler, dikdörtgen muhafazalar ve kanatlı ısı dağıtma tasarımları gibi çeşitli şekil ve boyutlarda ekstrüzyon alüminyum muhafazalar üretebiliyoruz. İster elektronik, ister güç modülleri veya endüstriyel sistemler için muhafazalara ihtiyacınız olsun, tam spesifikasyonlarınıza uygun özel çözümler sunuyoruz.

Alüminyum profil üretiminde hassasiyet ve verimlilik sağlamak için ekstrüzyon kalıplarını şirket içinde tasarlama ve üretme uzmanlığına sahibiz. Deneyimli ekibimiz, çizimlere veya numunelere dayalı özel kalıplar geliştirmek için müşterilerle yakın bir şekilde çalışarak özel gereksinimleri için optimum performans sağlar. Tipik olarak, kalıp üretim süreci yaklaşık 7 gün sürer ve ardından tam ölçekli üretime başlamadan önce müşteri onayı için numuneler sağlarız.

Alüminyum profil üretiminde hassasiyet ve verimlilik sağlamak için ekstrüzyon kalıplarını şirket içinde tasarlama ve üretme uzmanlığına sahibiz. Deneyimli ekibimiz, çizimlere veya numunelere dayalı özel kalıplar geliştirmek için müşterilerle yakın bir şekilde çalışarak özel gereksinimleri için optimum performans sağlar. Tipik olarak, kalıp üretim süreci yaklaşık 7 gün sürer ve ardından tam ölçekli üretime başlamadan önce müşteri onayı için numuneler sağlarız.

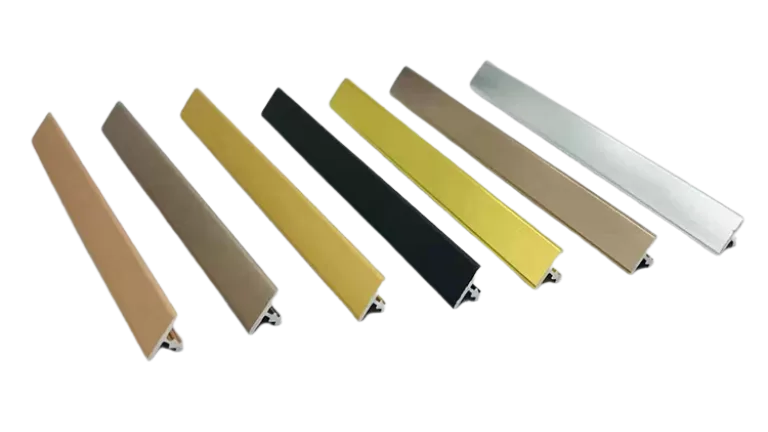

Ekstrüde alüminyum muhafazalarımızın görünümünü, dayanıklılığını ve korozyon direncini artırmak için eloksal, toz boya ve kumlama dahil olmak üzere bir dizi yüzey işleme seçeneği sunuyoruz. Bu işlemler, şık ve profesyonel bir görünüm sağlarken zorlu ortamlarda mükemmel performans sağlar. Ayrıca, özel tasarım gereksinimlerini karşılamak için özel renkler ve dokular uygulayabilir, muhafazaların hem işlevsel hem de estetik ihtiyaçları karşılamasını sağlayabiliriz. Yüzey işlemlerimiz, çeşitli uygulamalarda uzun süreli koruma ve kalite sağlamak için titizlikle test edilir.

Titiz standartları karşılamak için, gelişmiş işleme ve üretim süreçlerimiz diş açma ve delmeden CNC işlemeye kadar her ayrıntıda doğruluk sağlar. Ayrıca, cihazlarınıza ve sistemlerinize sorunsuz entegrasyon için hazırlanmış muhafazalar sunarak montaja hazır çözümler de sunuyoruz. Gelişmiş hassasiyet yeteneklerimiz sayesinde karmaşık tasarımlara ve dar toleranslara uyum sağlayarak hassas elektronik ve endüstriyel bileşenler için güvenilir performans sağlıyoruz. Ayrıca, şirket içi denetim süreçlerimiz, her muhafazanın teslimattan önce katı kalite standartlarını karşılamasını garanti eder.

Özelleştirme Seçenekleri

Benzersiz gereksinimlerinizi karşılamak üzere ekstrüzyon alüminyum muhafazalar için kapsamlı bir özelleştirme seçenekleri yelpazesi sunuyoruz. Malzemelerden son rötuşlara kadar her ayrıntı, projeniz için mükemmel çözümü sunmak üzere uyarlanabilir.

Malzeme Seçenekleri

Uygulamanızın özel performans taleplerini karşılamak için 6063, 6061 veya 6005 gibi yüksek kaliteli alüminyum alaşımları arasından seçim yapın. Her alaşım mükemmel mukavemet, korozyon direnci ve termal iletkenlik sunarak elektronik, endüstriyel veya otomotiv uygulamaları için idealdir. Ayrıca, malzemenin mekanik özelliklerini, sertliğini ve dayanıklılığını daha da geliştirmek için T5 ve T6 temperleme gibi ısıl işlem seçenekleri sunarak projenizin zorlu gereksinimlerini karşılamasını sağlıyoruz.

Özel Kalıp Geliştirme

Herhangi bir şekil veya konfigürasyonda ekstrüde alüminyum gövde profilleri oluşturmak için özel kalıp tasarımı ve geliştirme hizmetleri sunuyoruz. İster silindirik, ister dikdörtgen veya karmaşık özel tasarımlara ihtiyacınız olsun, sağladığınız çizimlere veya fiziksel numunelere dayanarak kalıplar geliştirebiliriz. Kolaylaştırılmış bir süreç ve gelişmiş ekipmanla, kalıp üretimini genellikle yaklaşık 7 gün içinde tamamlayarak proje zaman çizelgenizi karşılamak için hızlı ve hassas üretim sağlıyoruz.

Yüzey İşlem Seçenekleri

Çok çeşitli yüzey işlemleriyle ekstrüzyon alüminyum muhafazalarınızın dayanıklılığını, görünümünü ve korozyon direncini artırın. Bu işlemler yalnızca zorlu ortamlarda performansı artırmakla kalmaz, aynı zamanda estetik veya işlevsel ihtiyaçlara uyacak şekilde özelleştirmeye de olanak tanır. Seçeneklerimiz şunları içerir:

Eloksal (şeffaf, siyah, renkli, vb.)

Dekoratif ve koruyucu bir oksit tabakası oluştururken üstün korozyon direnci sağlar. Eloksal, markanıza veya tasarım gereksinimlerinize uyacak şekilde çeşitli renklerde özelleştirilebilir ve çizilmelere ve aşınmaya karşı dayanıklı uzun ömürlü bir yüzey sağlar.

Toz Boya

Hem çevre dostu hem de ufalanmaya, solmaya ve aşınmaya karşı dayanıklı ve dekoratif bir yüzey sunar. Çeşitli renk ve dokularda mevcut olan toz kaplama, görsel çekiciliği artırırken muhafazanın zorlu çevre koşullarına dayanabilmesini sağlar.

Kumlama

Yüzeyde düzgün, mat bir doku oluşturarak estetik çekiciliği artırır ve muhafazayı eloksal veya boyama gibi daha ileri işlemler için hazırlar. İşlem, yüzey kusurlarını ortadan kaldırarak tasarımın sofistikeliğine katkıda bulunan temiz ve pürüzsüz bir yüzey elde edilmesini sağlar.

Fırçalama ve Parlatma

Yüzeyde ince bir doku veya ayna benzeri bir yüzey oluşturarak şık ve profesyonel bir görünüm sağlar. Fırçalama modern, endüstriyel bir görünümü vurgularken, cilalama üst düzey uygulamalar için uygun, son derece yansıtıcı, birinci sınıf bir görünümle sonuçlanır.

Kimyasal Aşındırma

Markalaşma veya özelleştirilmiş yüzeyler için mükemmel olan daha derin yüzey desenlerine, benzersiz dokulara veya karmaşık tasarımlara izin verir. Bu yöntem, mükemmel işlevsellik ve dayanıklılığı korurken muhafazanın estetik çekiciliğini artırır.

Yüzey İşleme Hizmetleri Seçenekleri

Karmaşık geometrilere ve dar toleranslara sahip gövde tasarımları oluşturmak için hassas işleme sunuyoruz. Bu, aşağıdaki gibi hizmetleri içerir:

Diş açma ve delme

CNC işleme

Kanal açma, kılavuz çekme ve oyma

Bu süreçler, muhafazaların montaja hazır olmasını ve belirli bileşen gereksinimlerini karşılamasını sağlar.

Logo Özelleştirme

Ekstrüde alüminyum muhafazalarınızı özel logolar veya markalarla kişiselleştirin. Seçenekler arasında lazer kazıma, serigrafi baskı veya kabartmalı/oymalı profiller yer alır ve ürününüzün kimliğini geliştirmenize olanak tanır.

Paketleme Seçenekleri

Özelleştirilmiş kutular, köpük ekler, shrink ambalajlar veya koruyucu filmler gibi seçeneklerle ambalajınızı ihtiyaçlarınıza göre uyarlayın. Ayrıca, güvenli nakliye sağlarken sürdürülebilir girişimleri desteklemek için çevre dostu ambalaj çözümleri de sunuyoruz.

Fabrikamız

Bizden Özel Ekstrüzyon

At HTS YENİ MALZEMELERbenzersiz gereksinimlerinizi karşılamak için tasarlanmış özel alüminyum ekstrüzyonlar sağlama konusunda uzmanız. Gelişmiş üretim tesisleri ve 40'tan fazla ekstrüzyon hattıyla, havacılık, otomotiv, inşaat ve daha fazlası dahil olmak üzere çok çeşitli endüstriler için birinci sınıf, hassas mühendislik profilleri sunuyoruz.

Özel ekstrüzyon hizmetlerimiz şunları içerir:

- Özel Kesitler: Özel proje ihtiyaçlarınıza uyacak şekilde özelleştirilmiş uzman kalıp yapım yeteneklerimizle benzersiz alüminyum profiller oluşturun.

- Çeşitli Yüzey İşlemleri: Eloksal, toz boya, cilalama ve daha fazlası gibi seçeneklerle profillerinizin hem görünümünü hem de dayanıklılığını geliştirin.

- Hassas İşleme: Kesme, delme, frezeleme ve gelişmiş işleme hizmetleri ile tam boyutsal doğruluk sağlayın.

- Esnek Sıcaklıklar: Uygulamanız için ideal mekanik özellikleri elde etmek üzere T5, T6 ve diğerleri dahil olmak üzere çeşitli ısıl işlemler arasından seçim yapın.

İle ortak olun HTS YENİ MALZEMELER Projenizin başarısını artıran yenilikçi, uygun maliyetli ve güvenilir özel alüminyum ekstrüzyon çözümleri için.

Ekstrüde Alüminyum Profil RFQ

Ekstrüzyon ve döküm alüminyum muhafazalar arasında seçim yaparken, malzeme özellikleri, üretim yöntemleri, tasarım esnekliği ve uygulamalar açısından nasıl farklılık gösterdiklerini anlamak önemlidir. Aşağıda temel farklılıkların bir dökümü yer almaktadır:

1. Üretim Süreci

- Ekstrüde Alüminyum Gövde:

Ekstrüzyon işlemi, tutarlı bir enine kesite sahip uzun profiller oluşturmak için ısıtılmış alüminyum kütüklerin özel bir kalıptan geçirilmesini içerir. Bu profiller daha sonra kesilir, işlenir veya çeşitli muhafaza tasarımlarına göre şekillendirilir. - Alüminyum Döküm Gövde:

Basınçlı döküm, belirli bir şekil oluşturmak için erimiş alüminyumun yüksek basınç altında çelik bir kalıba (kalıp) enjekte edilmesini içerir. Süreç, tek bir adımda tamamen şekillendirilmiş parçalar üretir ve genellikle daha az ikincil işleme gerektirir.

2. Malzeme Kullanımı ve Özellikleri

- Ekstrüde Alüminyum:

Mükemmel korozyon direnci, yüksek mukavemet/ağırlık oranı ve üstün termal iletkenliği ile bilinen 6063, 6061 ve 6005 gibi alüminyum alaşımları kullanır. LED muhafazaları ve elektronik muhafazalar gibi hafif ve yüksek termal performans gerektiren muhafazalar için idealdir. - Alüminyum Döküm:

ADC12 ve A380 gibi daha yüksek yoğunluğa ve biraz daha düşük korozyon direncine sahip olma eğiliminde olan ancak mükemmel döküm özellikleri sağlayan alaşımları kullanır. Bunlar, iyi boyutsal kararlılığa sahip karmaşık, entegre şekiller oluşturmak için idealdir.

3. Tasarım Karmaşıklığı

- Ekstrüde Alüminyum:

Silindirik veya dikdörtgen muhafazalar gibi tutarlı bir enine kesite sahip basit, doğrusal tasarımlar için en uygunudur. Ek işleme karmaşıklık katabilirken, tasarımlar çoğunlukla ekstrüzyon profili ile sınırlıdır. - Alüminyum Döküm:

Önemli ölçüde daha fazla tasarım özgürlüğü sunarak eğriler, ince duvarlar ve karmaşık desenler gibi son derece ayrıntılı ve karmaşık geometrilere izin verir. Montaj delikleri veya ince duvarlar gibi entegre özellikler gerektiren parçalar için mükemmeldir.

4. Boyutsal Doğruluk ve Yüzey İşlemi

- Ekstrüde Alüminyum:

Sıkı boyut toleransları ve özel tasarımlar elde etmek için CNC işleme gibi sonradan işleme gerektirir. Genellikle yüzey kaplaması tek tiptir, ancak ek son işlem (eloksal veya toz kaplama gibi) nihai görünümünü iyileştirir. - Alüminyum Döküm:

Doğrudan kalıptan sıkı toleranslar ve ayrıntılı şekiller elde eder. Kalıptan çıktığında daha pürüzsüz bir yüzeye sahiptir, ancak estetik için kaplama veya cilalama gibi son işlem seçenekleri eklenebilir.

5. Maliyet ve Üretim Hacmi

- Ekstrüde Alüminyum:

Uzun ve tutarlı profillerin gerekli olduğu orta ila yüksek üretim hacimleri için uygundur. Kalıplar için ön maliyet basınçlı dökümden daha düşüktür, bu da belirli tasarımlar için daha ekonomik olmasını sağlar. - Alüminyum Döküm:

Daha yüksek kalıp maliyetleri içerir ve yüksek hacimli üretim için en uygunudur. Parça başına maliyet, tek adımlı sürecin verimliliği nedeniyle daha büyük parti boyutlarında önemli ölçüde azalır.

6. Uygulamalar

- Ekstrüde Alüminyum:

LED soğutucuları, elektronik muhafazalar ve endüstriyel muhafazalar gibi mükemmel ısı dağılımı gerektiren muhafazalar için yaygın olarak kullanılır. - Alüminyum Döküm:

Otomotiv parçaları, motor gövdeleri ve makine veya cihazlar için karmaşık muhafazalar gibi karmaşık şekillere veya son derece entegre tasarımlara sahip muhafazalarda kullanılır.

Sonuç

- Ekstrüde Alüminyum Gövde basitlik, hafiflik ve mükemmel termal iletkenliğin gerekli olduğu uygulamalar için idealdir.

- Alüminyum Döküm Gövde yüksek boyutlu doğruluk ve entegre özellikler gerektiren karmaşık ve ayrıntılı tasarımlar için daha uygundur.

İkisi arasındaki seçim, tasarım, performans, üretim hacmi ve bütçe dahil olmak üzere özel gereksinimlerinize bağlıdır.

Muhafaza uygulamaları için bir malzeme seçerken ağırlık, mukavemet, ısı dağılımı, görünüm ve işleme esnekliği gibi faktörleri göz önünde bulundurmak çok önemlidir. Aşağıda ayrıntılı bir karşılaştırma yer almaktadır ekstrüde alümi̇nyum gövdeler, plasti̇k muhafazalarve çelik muhafazalar.

| Karakteristik | Ekstrüde Alüminyum Gövde | Plastik Gövde | Çelik Gövde |

|---|---|---|---|

| Ağırlık | Hafiftir, kullanımı ve kurulumu kolaydır. | En hafif, ancak daha düşük mukavemetli. | Ağırdır, bu da nakliye ve kurulumun daha zor olmasına neden olur. |

| Güç ve Dayanıklılık | Yüksek mukavemet ve deformasyona karşı mükemmel direnç, uzun süreli dayanıklılık sunar. | Düşük mukavemetli, stres altında çatlamaya veya kırılmaya eğilimli. | Mükemmel mukavemet, dış kuvvetlere karşı yüksek direnç. |

| Isı Dağılımı | Üstün termal iletkenlik, verimli ısı dağıtımı gerektiren uygulamalar için idealdir. | Özellikle kapalı ortamlarda zayıf ısı dağılımı. | Orta düzeyde ısı dağılımı, daha yavaş termal iletkenlik. |

| Korozyon Direnci | Eloksal işlemleriyle daha da geliştirilmiş üstün korozyon direnci. | Zayıf korozyon direnci, zaman içinde bozulmaya meyilli. | Korozyona direnmek için kaplama veya galvanizleme gerektirir. |

| Premium Görünüm | Şık, üst düzey bir görünüme sahip modern ve özelleştirilebilir tasarım. | Sade bir görünüme sahip, daha az premium. | Endüstriyel tarzdaki tasarımlar için uygundur, ancak modern estetikten yoksundur. |

| İşleme Esnekliği | Son derece özelleştirilebilir, gelişmiş işleme ve ekstrüzyon teknikleri sayesinde karmaşık şekillere ve hassas tasarımlara izin verir. | Belirli özelliklerin veya geometrilerin işlenmesinde bazı sınırlamalarla birlikte orta düzeyde özelleştirilebilirlik. | Özel tasarımlar için daha yüksek işlem maliyetleri ile düşük esneklik. |

| Elektromanyetik Ekranlama | Parazitlere karşı mükemmel koruma, elektronik bileşenler için uygundur. | Elektromanyetik kalkan özelliklerinden yoksundur. | Bazı uygulamalarda alüminyum gövdeleri bile aşan üstün ekranlama performansı. |

| Uygulamalar | İç ve dış mekanlarda kullanım için çok yönlüdür, elektronik, endüstriyel ortamlar ve daha fazlasında uygulanabilir. | Sınırlı dayanıklılık ve mukavemet nedeniyle genellikle iç mekan uygulamalarında kullanılır. | Ağır hizmet tipi endüstriyel ekipman muhafazaları ve yüksek mekanik dayanım gerektiren ortamlar için idealdir. |

1. Endüstriyel Ürünler

- Endüstriyel Kontrol Kutuları: PLC kontrolörleri, röleler veya endüstriyel sensörler için kullanılır ve zorlu ortamlarda sağlam koruma sağlar.

- Elektrikli Ekipman Gövdeleri: Paneller, ekranlar ve giriş terminalleri için güvenilir koruma sağlar.

- Endüstriyel Otomasyon Ürünleri: Otomasyon kontrol cihazları ve modüler sistemler için koruyucu muhafazalar olarak hizmet vererek operasyonel güvenlik ve dayanıklılık sağlar.

2. İletişim Ekipmanları

- Kablosuz ve Kablolu Ağ Cihazları: Sinyal amplifikatörleri, yönlendiriciler ve diğer ağ ekipmanları için muhafazalar.

- Telekom Baz İstasyonu Modülleri: Dahili iletişim modüllerini korurken zorlu dış ortam koşullarına dayanacak şekilde tasarlanmıştır.

- Fiber Alıcı-Vericiler ve Radyo Cihazları: Optik modüller ve küçük kablosuz iletişim cihazları gibi ekipmanlar için dayanıklı muhafazalar.

3. Tüketici Elektroniği

- Ses Amplifikatörleri: Hem ısı dağılımını hem de koruyucu performansı artıran sızdırmaz muhafazalar.

- Taşınabilir Güç Cihazları: Güç bankaları, el cihazları ve adaptörler için koruyucu kılıflar.

- Akıllı Ev Cihazları: Akıllı hub'lar, kablosuz ürünler ve kontrol modülleri gibi sistemler için muhafazalar.

4. Otomotiv ve Taşımacılık

- Otomotiv Elektroniği: Batarya Yönetim Sistemleri (BMS) veya elektrikli motor kontrolörleri gibi elektronik modüller için muhafazalar.

- Motor Kontrolörü ve Ekran Koruma Muhafazaları: Yerleşik sistemler için sağlam ekranlama sağlar.

- Demiryolu Transit Ekipmanları: İletişim cihazları, sinyal amplifikatörleri veya diğer kritik demiryolu bileşenleri için muhafazalar.

5. Tıbbi Cihazlar

- Teşhis ve Test Ekipmanları: Taşınabilir tanı araçları gibi tıbbi cihazlar için kompakt muhafazalar.

- İnfüzyon Pompaları ve İzleme Cihazları: EKG makineleri de dahil olmak üzere tıbbi izleme ekipmanları için koruyucu kılıflar.

- Tıbbi Alet Modülleri: Hassas tıbbi aletler için modüler alüminyum braketler.

6. Güç ve Yenilenebilir Enerji

- Enerji Depolama Sistemi Gövdeleri: Akü paketleri ve invertör sistemleri için koruyucu muhafazalar.

- LED Sürücü Muhafazaları: LED sürücüler için termal düzenleme ve dayanıklılık sağlayan güvenilir muhafazalar.

- Güneş Enerjisi Kontrol Ekipmanları: Güneş invertörleri, batarya yönetim sistemleri ve şarj yığınları için muhafazalar.

7. Dış Mekan Cihazları ve Aletleri

- Gözetim ve Güvenlik Kameraları: Dış mekan izleme ekipmanları için sağlam, hava koşullarına dayanıklı muhafazalar.

- Yağmur ve Toz Geçirmez Sensör Muhafazaları: Zorlu hava koşullarında veya endüstriyel sahalarda kullanılan dış mekan sensörleri için koruma.

- Meteorolojik ve Çevresel İzleme Cihazları: İklim veya kirliliği izlemek için kullanılan cihazların muhafazaları.

Özel alüminyum ekstrüzyon projeleri için, aşağıdakiler de dahil olmak üzere çeşitli çizim formatlarını kabul ediyoruz CAD dosyaları, STEP dosyalarıve PDF dosyaları. Bununla birlikte, ek işleme süreçleri gerektiren ekstrüzyonlar için aşağıdakilerin sağlanması önerilir STEP dosyalarıİşleme hassasiyeti için hassas 3D modelleme sağladıkları için.

Bir yandan PDF dosyaları kabul edilebilir olsa da, bunları CAD çizimlerine dönüştürmek belirli ayrıntıların kaybolmasına neden olabilir, tasarımı manuel olarak yeniden çizmemizi gerektirebilir ve bu da teslim süresini uzatabilir. En hızlı ve en doğru fiyat teklifi için şunları sağlamanızı öneririz CAD dosyaları (örn. DWG/DXF) ve STEP dosyaları verimli tasarım değerlendirmesi ve fiyatlandırma sağlamak için.

Kalıp ücretleri, özel alüminyum ekstrüzyon sürecinin önemli bir parçasıdır. Her sipariş özel gereksinimlere göre tasarlanmış benzersiz bir kalıp gerektirdiğinden, bu kalıplar başka ürünler için kullanılamaz. Bu nedenle, kalıp ücreti gereklidir ve pazarlığa tabi değildir.

İhtiyacımız olan 100% kalıp ücretinin peşin ödenmesi zamanında üretim sağlamak için kalıp geliştirme başlamadan önce. Bununla birlikte, desteğiniz için bir takdir göstergesi olarak, sipariş belirli bir üretim hacmine ulaştığında kalıp ücretinin iadesini veya eşdeğer indirimleri sunuyoruz. Belirli politikalar, sipariş hacminize ve işbirliği ayrıntılarınıza göre tartışılabilir.

Minimum sipariş miktarımız (MOQ) ürünün boyutuna bağlı olarak değişir. Daha küçük boyutlu ürünler için MOQ tipik olarak 500kgdaha büyük boyutlu ürünler için ise 2 ton.

Teklif süreci sırasında tam MOQ gereksinimlerini belirteceğiz. Sipariş miktarınız MOQ'u karşılamıyorsa, yine de üretim ayarlayabiliriz, ancak kalıp ön ısıtma ve üretim kurulum süresini karşılamak için ek bir ücret uygulanacaktır. İçiniz rahat olsun, bu ekstra ücret makul olacaktır ve sorunsuz bir işbirliği sağlamak için mümkün olduğunca minimum düzeyde tutmayı hedefliyoruz.

Kalıp üretimi tipik olarak 7 gün. Numune onaylandıktan sonra, tam bir konteyner yükü 26 ton genellikle şunları gerektirir 14 gün tek başına ekstrüzyon için. Yüzey işlemi gerekiyorsa, ek bir 3 gün gerekli olacaktır. İşleme için, işleme işinin karmaşıklığına ve hacmine bağlı olarak ekstra zaman gerekecektir. İşleme için tam ek süre, özel işleme gereksinimlerine göre belirlenecektir.

Alüminyum profiller, havaya veya suya maruz kaldıklarında ince, koruyucu bir oksit tabakası oluşması nedeniyle doğal olarak korozyona dayanıklıdır. Bu oksit tabakası sabittir ve kendi kendini onarır, yani yüzey çizilse veya kesilse bile (açıkta kalan uçlarda veya işleme sırasında olduğu gibi) alüminyum demir veya çelik gibi paslanmayacak veya korozyona uğramayacaktır. Bunun yerine, maruz kalan alanlar hızla yeni bir oksit tabakası oluşturacak ve daha fazla oksidasyona karşı sürekli koruma sağlayacaktır.

Doğru tasarım, kurulum ve bakım ile alüminyum profiller uzun süre dayanabilir onlarca yılzorlu ortamlarda bile. Örneğin, işlenmemiş alüminyum dış mekan uygulamalarında kolayca 20-30 yıl dayanabilirken, eloksal veya toz kaplama gibi yüzey işlemlerine sahip profiller daha da uzun süre dayanabilir, genellikle bu süreyi aşar 50 yıl. Bu, alüminyumu dayanıklılık ve uzun vadeli performansın gerekli olduğu uygulamalar için mükemmel bir seçim haline getirir.

Alüminyum profillerin fiyatı çeşitli bileşenlerden oluşur: hammadde maliyetleri, ekstrüzyon işleme ücretleri, yüzey işleme ücretleri, işleme maliyetleri ve ek paketleme ücretleri. Bunlar arasında, hammadde olarak alüminyumun maliyeti sık sık dalgalanma eğilimi gösterirken, diğer ücretler nispeten sabit kalmaktadır. Bu dalgalanmalar nedeniyle, fiyat tekliflerimiz genellikle aşağıdakiler için geçerlidir 7 gün.

Fiyatlandırma, ürüne ve gereksinimlere bağlı olarak farklı şekillerde yapılandırılabilir. Hesaplanabilir ağırlığa göre (örneğin, ton başına maliyet), uzunluğa göre (örneğin, metre başına maliyet) veya parça tarafından (örneğin, birim başına maliyet). Aşağıdakiler gibi kapsamlı işleme içeren ürünler için ısı alıcılarıfiyatlandırma, ek işleme maliyetlerini doğru bir şekilde yansıtmak için genellikle parça başına hesaplanır. Bu esnek fiyatlandırma yaklaşımı, fiyat teklifinin müşterinin özel ihtiyaçlarına göre uyarlanmasını sağlar.

Alüminyum profilleri teknik gereksinimlere uygun olarak üretebiliyoruz. Avrupa standartları (EN), Amerikan standartları (ASTM/AA)veya müşteri tarafından belirtilen diğer standartlar. Özel üretim, profillerin talep edilen belirli standart gereksinimleri karşılamasını sağlamak için uyarlanmıştır.

Üretim ekipmanlarımız aşağıdakiler için tasarlanmıştır metrik sistem. Eğer sağlanan çizimler emperyal sistemDoğruluğu sağlamak için bunları üretim için metrik birimlere dönüştüreceğiz.

Bağlantı elemanları için emperyal dişli delikleri işleyebilmemize rağmen, eşleşen delikleri tedarik etmemizi istiyorsanız emperyal bağlantı elemanlarıher zaman stokta bulunmayabilir. Emperyal bağlantı elemanları için özel siparişler genellikle bir büyük hacimli üretim için. Lütfen projenizi planlarken bunu göz önünde bulundurun.