Aluminium Conductivity in the Electrical Industry

According to the International Aluminium Institute (IAI), global demand for aluminum in the electronics industry is expected to rise from 8 million tons to 12 million tons in the coming years. At the same time, demand for copper is also projected to reach a similar level—around 13 million tons. This raises an important question: how does aluminum actually perform as a conductive material? For designers, product developers, and businesses looking to take advantage of aluminum’s cost-effectiveness and lightweight properties, understanding its electrical conductivity is essential. In this article, we will explore aluminum conductors, the electrical characteristics of aluminum, and its potential as an alternative to copper and other conductive metals.

Metallic Properties of Aluminum

Did you know that aluminum is the most abundant metal on Earth and sits at number 13 on the periodic table? Even though it’s everywhere, you won’t find pure aluminum in nature—it has to be extracted from bauxite ore through industrial processes.

When it comes to conducting electricity, aluminum ranks fourth after silver, copper, and gold. Not all aluminum alloys conduct electricity equally, but the metal’s natural properties make it an excellent choice for electrical applications. Aluminum is lightweight, easy to work with, and highly resistant to corrosion. That means it’s simple to form into wires and easy to weld, making installation and maintenance a breeze.

Fun fact: that number 13 isn’t just for show—it represents the number of electrons orbiting the aluminum atom. It’s the way these electrons are arranged that gives aluminum its impressive electrical conductivity.

Aluminium Electrical Conductivity vs Other Metals

Testing the electrical conductivity of aluminum not only helps identify its alloy grade but also determines if it has been heat-treated—since heat treatment changes conductivity levels. Each alloy and treatment method has its own IACS (International Annealed Copper Standard) rating.

There are differences in electrical conductivity both among aluminum alloys and between aluminum and other metals. This table from ResearchGate compares the conductivity of aluminum to that of several well-known metals.

| Rank | Metal | Electrical Conductivity (S * m-1) |

|---|---|---|

| 1 | Silver | 66.7 * 106 |

| 2 | Bakır | 64.1 * 106 |

| 3 | Altın | 49.0 * 106 |

| 4 | Alüminyum | 40.8 * 106 |

| 5 | Rhodium | 23.3 * 106 |

| 6 | Zinc | 18.2 * 106 |

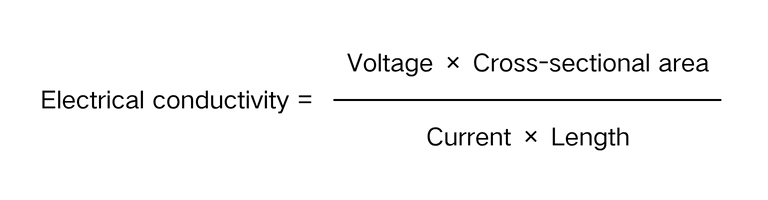

How to Measure Electrical Conductivity

Electrical conductivity tells us how well a metal can conduct electricity, and it’s measured in Siemens per meter (S/m). To test the conductivity of aluminum, here’s what you do: First, you pass a known amount of current through your aluminum sample. Then, using probes, you measure the voltage drop between two points on the sample. With these values, you can easily calculate the electrical conductivity using the standard formula. It’s a straightforward process and gives you a clear idea of how efficiently aluminum carries electric current.

Aluminum’s Electrical Conductivity

Aluminum is known as one of the best metals for conducting electricity—second only to pure copper. Pure aluminum conductors have an electrical conductivity of 33.3×10⁷ S/m. To make things easier to compare, we usually look at aluminum’s conductivity relative to pure copper, which is used as an industry standard called the International Annealed Copper Standard (IACS). Aluminum’s conductivity is about 61% IACS—that means aluminum conducts electricity at 61% the effectiveness of copper.

Thanks to its cost-effectiveness and low electrical resistance, aluminum is widely used in electrical equipment. It’s also worth noting that aluminum is lightweight—about 30% the density of copper—making it an ideal choice for overhead power cables. In fact, most power transmission lines use aluminum conductors, and even household electricity is commonly delivered through aluminum wiring.

How Does Aluminum Conduct Electricity

Aluminum’s ability to conduct electricity comes down to its atomic structure and the way its atoms bond. Basically, electricity is the flow of charge—often electrons—through a material. In an aluminum atom, the center (the nucleus) is packed with protons and neutrons, but the outer electrons are only loosely held. These outer electrons can move around freely.

When an aluminum atom loses one of its outer electrons, it becomes a positively charged aluminum ion. In a chunk of aluminum, the atoms are packed closely together, and their outer electrons form what’s called a “sea of free electrons.” When there’s a voltage across a piece of aluminum, these free electrons flow toward the positive end. This movement of electrons is what creates an electric current—that’s the basic reason why aluminum conducts electricity so well.

Why Is Copper a Better Conductor Than Aluminum?

Even though aluminum is a great electrical conductor, copper is still the top choice for most wiring. There are a few reasons for this: copper is more ductile, has a distinctive appearance, and is both stronger and harder than aluminum. But most importantly, from an electrical point of view, copper has a lower electrical resistivity—so, for the same length and size, a copper wire simply carries electricity better than an aluminum one.

This all comes down to how electrons move through each metal. In copper, free electrons have fewer “phonon collisions”—these are tiny interruptions caused by vibrations in the atoms that can scatter electrons and slow down the current. Even though aluminum actually has more free electrons, its electrons are more likely to be scattered by these vibrations, which increases resistance. That’s why copper remains the go-to option when the highest conductivity is needed.

Aluminum Alloy Grades and Electrical Conductivity

While pure aluminum is an excellent conductor, most real-world applications use aluminum that’s been processed, alloyed, or has added impurities. Aluminum alloys are sorted by grades that range from the 1000 series all the way up to the 8000 series. The 1000 series has the highest purity—and therefore the best conductivity. For example, EC grade aluminum (like 1350 Al), part of the 1000 series, offers great electrical and thermal conductivity, with a conductivity of about 61% IACS. Other grades, like AA-8006 and AA-8011, are also good conductors and commonly used in aluminum wire and building applications. The 2000 series mainly includes copper alloys, while the 6000 series combines magnesium and silicon with aluminum.

How Surface Treatments Affect Aluminum Conductivity

The way aluminum is treated on the surface can change its electrical behavior. Naturally, aluminum forms a very thin oxide layer that’s non-conductive. To boost durability, aluminum is often anodized, which thickens this oxide layer and increases corrosion resistance—but it also creates an insulating layer that doesn’t conduct electricity. Other treatments like powder coating, heat treatment, painting, or plastic coatings can also impact conductivity. Sometimes, analyzing the ratio of a conductor’s measured conductivity to its IACS value helps identify what type of heat treatment it has gone through.

Where Aluminum Is Used in Electrical & Electronic Products

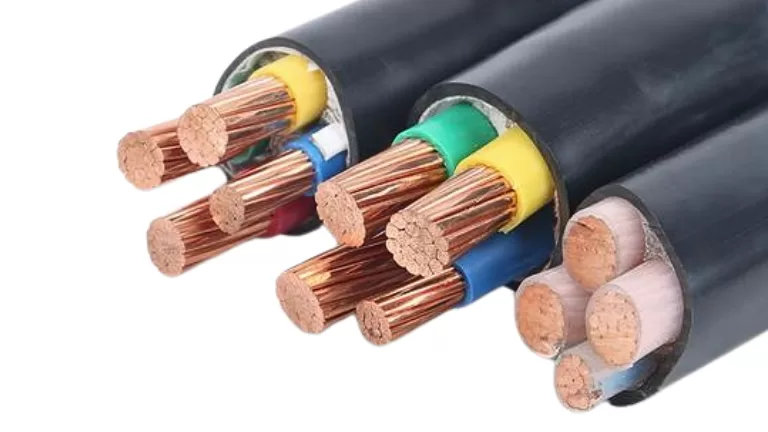

Wires and Cables

Aluminum wire is popular for overhead power lines because it’s much lighter than copper—about one-third the weight—which helps minimize cable sag. While copper is still preferred in homes and construction sites, aluminum is widely used in industrial settings and power plants. High-performing 8000 series aluminum wires are even being used for home wiring in some cases.

Electrical Components

From small connectors to large electronic devices, aluminum’s good conductivity and light weight make it a favorite for many electrical components. It’s also widely used in electric vehicles, where aluminum motor housings and other parts help offset the heavy weight of batteries.

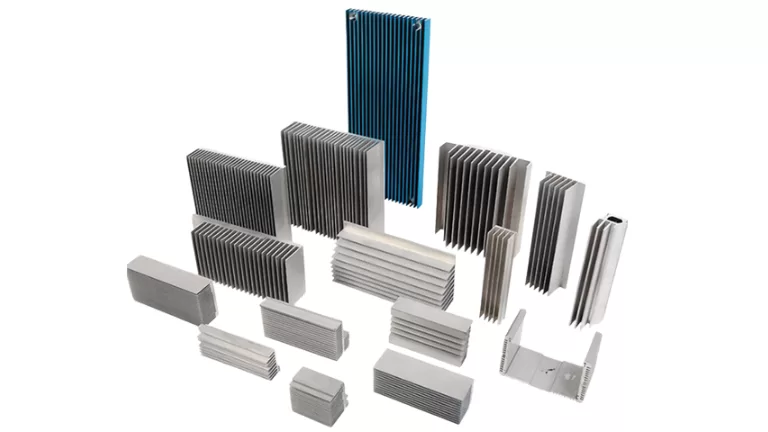

Isı Emiciler

Aluminum’s excellent thermal conductivity makes it ideal for heat sinks, which help cool electronics like computers, processors, lighting fixtures, and amplifiers. By maximizing heat dissipation, aluminum heat sinks keep devices running smoothly and efficiently.

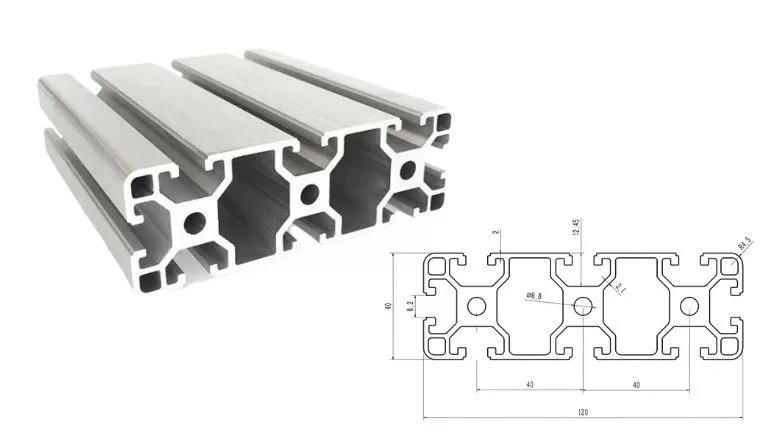

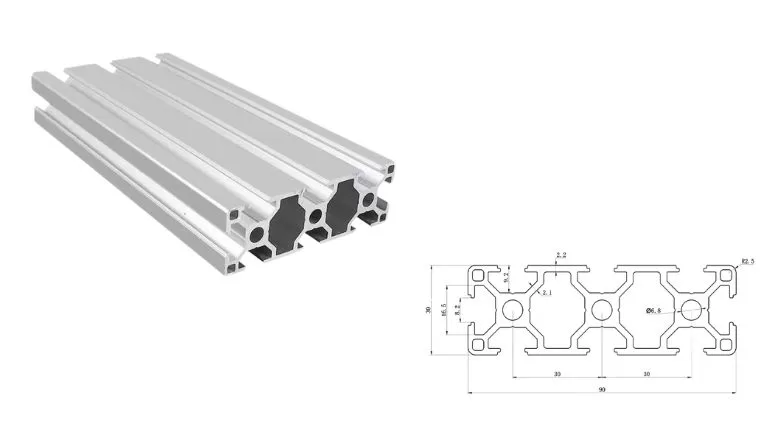

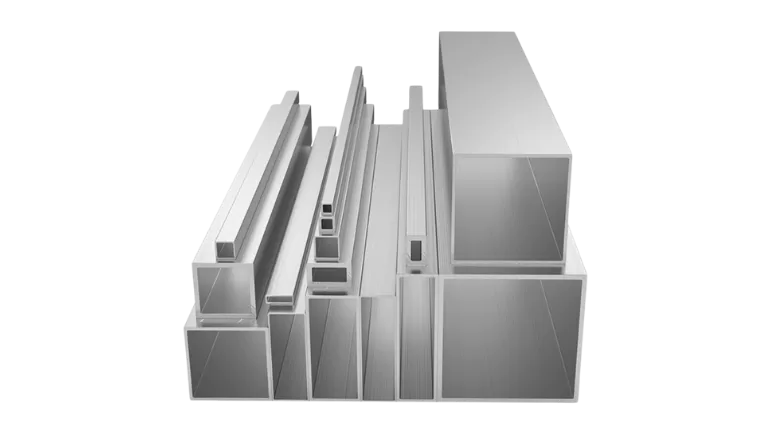

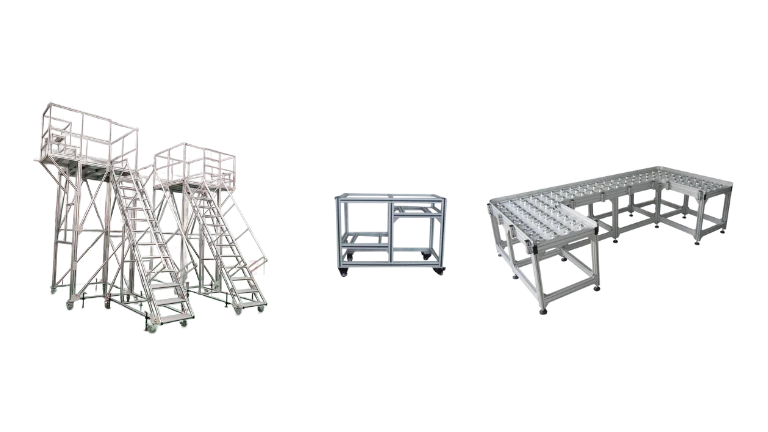

Alüminyum Profil İşleme Yetenekleri

Lider bir şirket olarak alüminyum ekstrüzyon üreticisi Çin merkezli olarak, çok çeşitli endüstriler için yüksek kaliteli alüminyum profiller sağlamayı taahhüt ediyoruz. Yeteneklerimiz, müşterilerimizin özel ihtiyaçlarını karşılayan hassas ekstrüzyon şekilleri sağlayan özel kalıp tasarımı ve üretimi ile başlar. Ham ekstrüzyondan yüzey işlemeye ve gelişmiş işlemeye kadar, tam entegre üretim süreçlerimiz, titiz standartları karşılayan ve her projenin benzersiz gereksinimlerini karşılayan alüminyum profiller sunmamızı sağlar.

Üretim tesisimiz, 6000 tonluk güçlü bir ekstrüzyon presi gibi son teknoloji ekipmanlara sahip 40'tan fazla gelişmiş ekstrüzyon hattına ev sahipliği yapmaktadır. Bu, standart endüstriyel uygulamalardan üst düzey kapı ve pencereler için termal kırılma profilleri gibi özel ürünlere kadar çeşitli boyut ve formlarda alüminyum profillerin oluşturulmasını sağlar. Ekstrüzyon kabiliyetimizin esnekliği, inşaat ve hassas mühendislik dahil olmak üzere geniş bir endüstri yelpazesine hitap edebilmemizi sağlar.

Üretim tesisimiz, 6000 tonluk güçlü bir ekstrüzyon presi gibi son teknoloji ekipmanlara sahip 40'tan fazla gelişmiş ekstrüzyon hattına ev sahipliği yapmaktadır. Bu, standart endüstriyel uygulamalardan üst düzey kapı ve pencereler için termal kırılma profilleri gibi özel ürünlere kadar çeşitli boyut ve formlarda alüminyum profillerin oluşturulmasını sağlar. Ekstrüzyon kabiliyetimizin esnekliği, inşaat ve hassas mühendislik dahil olmak üzere geniş bir endüstri yelpazesine hitap edebilmemizi sağlar.

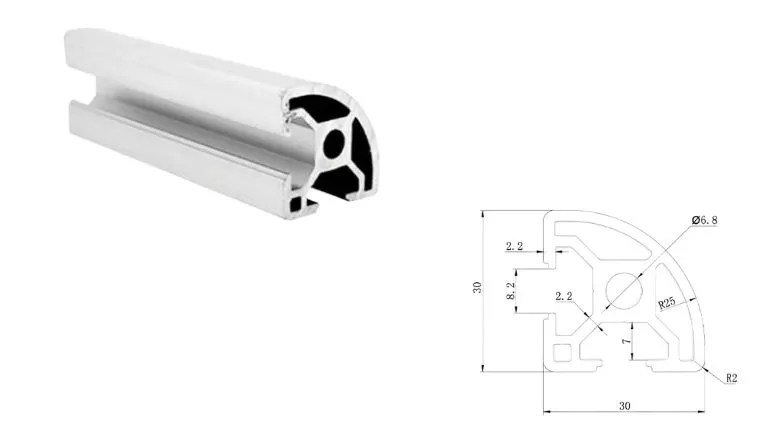

Alüminyum profil üretiminde hassasiyet ve verimlilik sağlamak için ekstrüzyon kalıplarını şirket içinde tasarlama ve üretme uzmanlığına sahibiz. Deneyimli ekibimiz, çizimlere veya numunelere dayalı özel kalıplar geliştirmek için müşterilerle yakın bir şekilde çalışarak özel gereksinimleri için optimum performans sağlar. Tipik olarak, kalıp üretim süreci yaklaşık 7 gün sürer ve ardından tam ölçekli üretime başlamadan önce müşteri onayı için numuneler sağlarız.

Alüminyum profil üretiminde hassasiyet ve verimlilik sağlamak için ekstrüzyon kalıplarını şirket içinde tasarlama ve üretme uzmanlığına sahibiz. Deneyimli ekibimiz, çizimlere veya numunelere dayalı özel kalıplar geliştirmek için müşterilerle yakın bir şekilde çalışarak özel gereksinimleri için optimum performans sağlar. Tipik olarak, kalıp üretim süreci yaklaşık 7 gün sürer ve ardından tam ölçekli üretime başlamadan önce müşteri onayı için numuneler sağlarız.

Üstün dayanıklılık ve görsel çekicilik için çeşitli yüzey işleme çözümleri sunuyoruz. Bunlar arasında daha fazla korozyon direnci için eloksal, canlı yüzeyler için toz kaplama, gelişmiş hava direnci için florokarbon kaplama ve zarif, doğal görünümlü tasarımlar için ahşap damarı transfer teknolojisi bulunmaktadır. Bu işlemler, belirli estetik ve işlevsel ihtiyaçlara uyacak şekilde özelleştirilebilir ve profillerin yalnızca iyi performans göstermesini değil, aynı zamanda olağanüstü görünmesini de sağlar.

Eksiksiz alüminyum profil çözümleri sağlamak için kapsamlı ileri işleme yetenekleri sunuyoruz. Hizmetlerimiz arasında CNC işleme, frezeleme, diş açma, delme, hassas kesme, delme, kaynak ve montaj bulunmaktadır. Bu imalat seçenekleri yelpazesi, müşterilerimize benzersiz esneklik ve güvenilirlik sunarak, tam proje özelliklerine göre uyarlanmış kullanıma hazır profiller sunmamızı sağlar.

Bizden Özel Alüminyum Ekstrüzyon

At HTS YENİ MALZEMELERbenzersiz gereksinimlerinizi karşılamak için tasarlanmış özel alüminyum ekstrüzyonlar sağlama konusunda uzmanız. Gelişmiş üretim tesisleri ve 40'tan fazla ekstrüzyon hattıyla, havacılık, otomotiv, inşaat ve daha fazlası dahil olmak üzere çok çeşitli endüstriler için birinci sınıf, hassas mühendislik profilleri sunuyoruz.

Özel ekstrüzyon hizmetlerimiz şunları içerir:

- Özel Kesitler: Özel proje ihtiyaçlarınıza uyacak şekilde özelleştirilmiş uzman kalıp yapım yeteneklerimizle benzersiz alüminyum profiller oluşturun.

- Çeşitli Yüzey İşlemleri: Eloksal, toz boya, cilalama ve daha fazlası gibi seçeneklerle profillerinizin hem görünümünü hem de dayanıklılığını geliştirin.

- Hassas İşleme: Kesme, delme, frezeleme ve gelişmiş işleme hizmetleri ile tam boyutsal doğruluk sağlayın.

- Esnek Sıcaklıklar: Uygulamanız için ideal mekanik özellikleri elde etmek üzere T5, T6 ve diğerleri dahil olmak üzere çeşitli ısıl işlemler arasından seçim yapın.

İle ortak olun HTS YENİ MALZEMELER Projenizin başarısını artıran yenilikçi, uygun maliyetli ve güvenilir özel alüminyum ekstrüzyon çözümleri için.